Zirconium diboride/silicon carbide composite material and method for preparing same by means of arc melting in-suit reaction

A technology of zirconium diboride and composite materials, which is applied in the field of ceramic materials, can solve the problems of difficulty in preparing dense zirconium diboride/silicon carbide composite materials, adverse effects on the performance of composite materials, and difficulty in the diffusion process. Controllable microstructure, good industrialization prospects, and the effect of increasing material density and crack growth resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

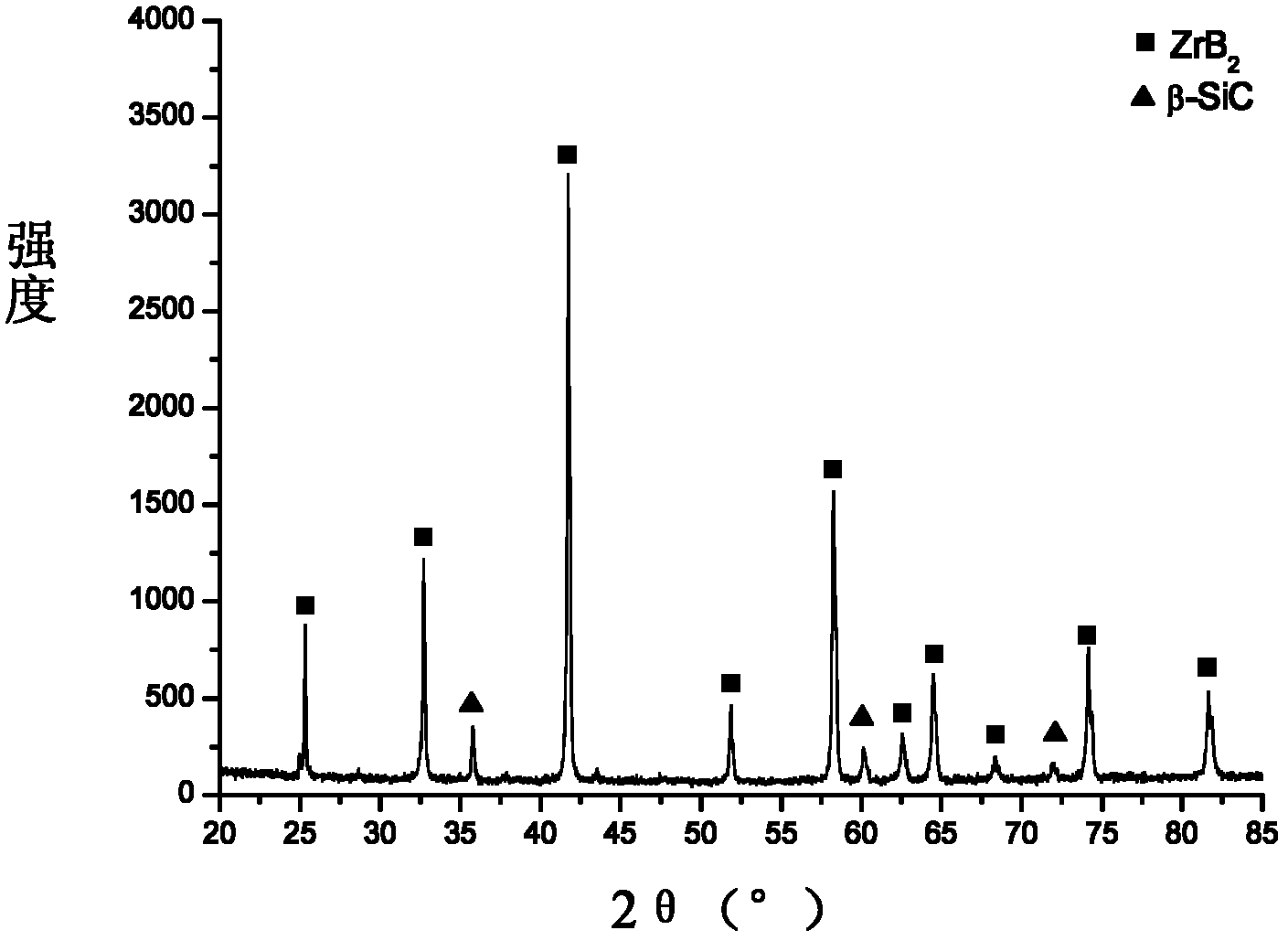

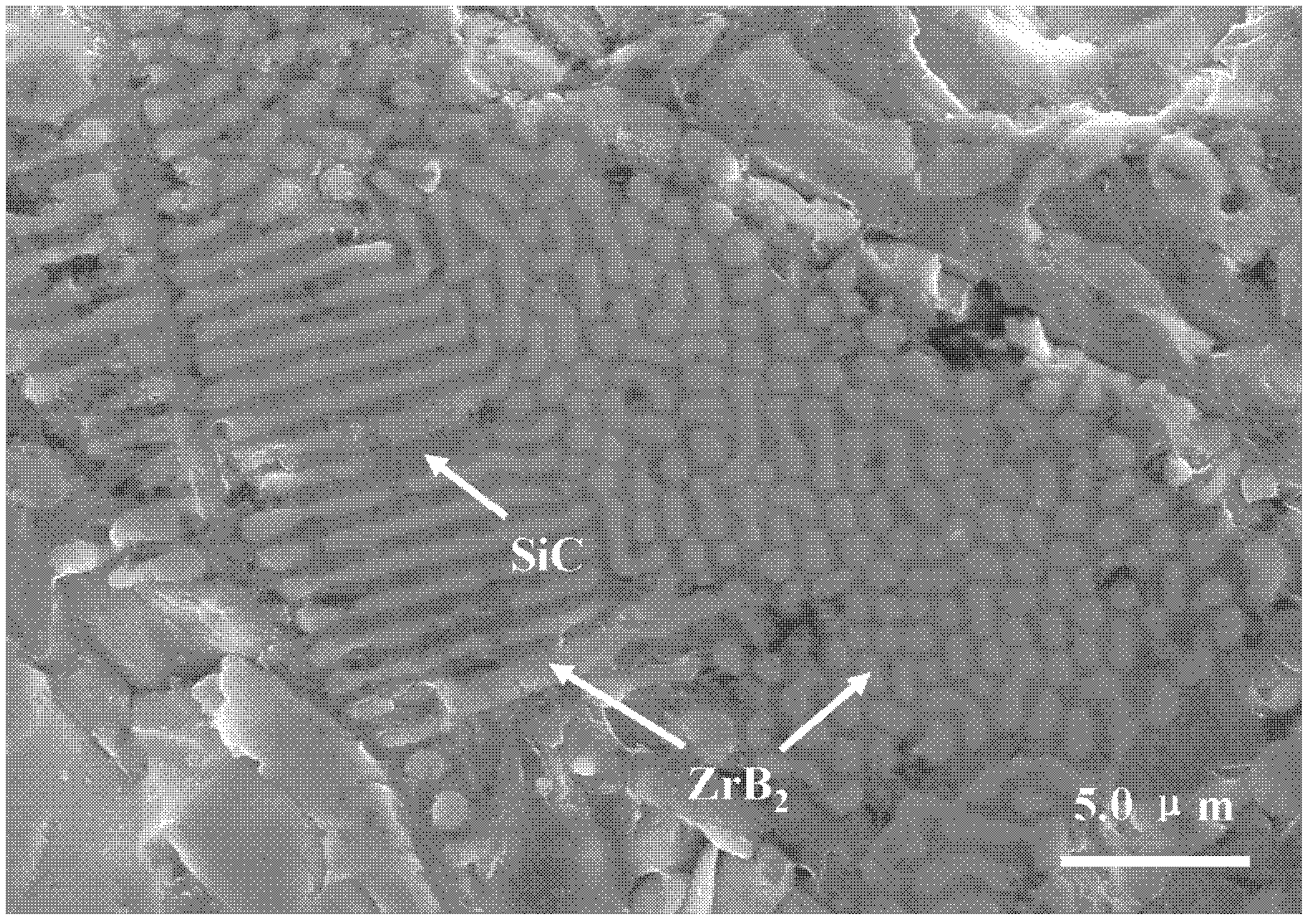

[0022] According to the formula Zr:B 4 The mass ratio of C is 72:28, and the ingredients are weighed, that is, the molar ratio is 1.56:1, and Zr and B are added. 4 The mass fraction of C powder mass is 30% SiC (equivalent to B 4 C:SiC molar ratio is 1:1.5), put in the mortar and grind for 15 minutes, then add 3wt% water glass solution (the volume ratio of water glass and water is 1:1) as binding agent, mix with graphite mold The powder is pressed on the surface of the graphite matrix, and the sample is placed in the room temperature environment to dry in the shade for 24 hours, then heated to 450°C in a drying oven at a heating rate of 2°C / s and stayed for 1 hour, and the dried sample is placed in The cathode is rapidly melted with an electric arc, and the entire arc is under the protection of flowing argon, under the condition of 250A direct current, 35V voltage, 10L / min protective gas flow rate and an arc scanning speed of 1.67mm / s. Finally, a zirconium diboride / silicon ca...

Embodiment 2

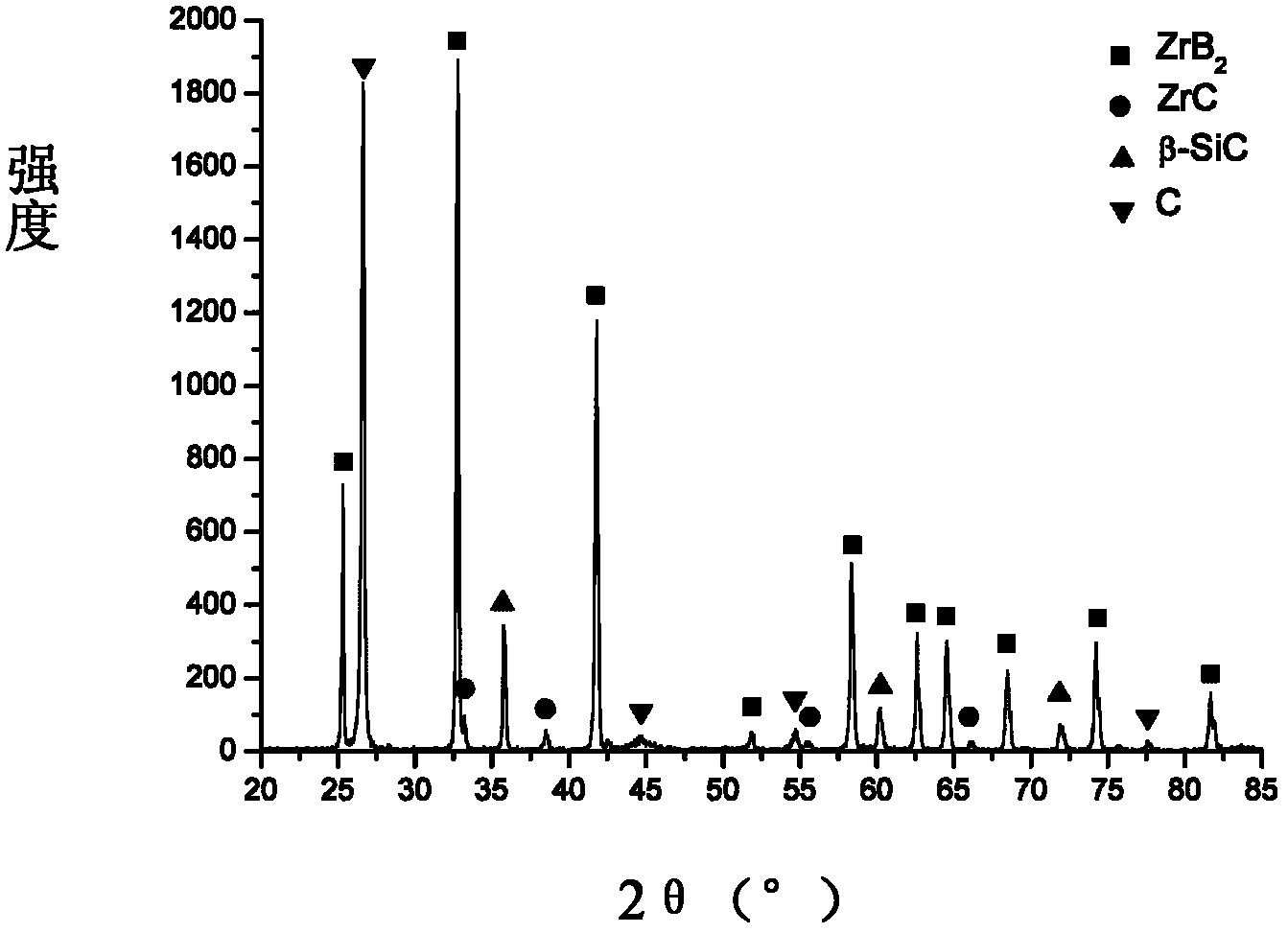

[0024] According to the formula Zr:B 4 The mass ratio of C is 72:28, and the ingredients are weighed, that is, the molar ratio is 1.56:1, and Zr and B are added. 4 The mass fraction of C powder mass is 30% SiC (equivalent to B 4 C:SiC molar ratio is 1:1.5), put in the mortar and grind for 15 minutes, then add 5wt% water glass solution (the volume ratio of water glass and water is 1:1) as binding agent, use graphite mold to mix The powder is pressed and the surface of the graphite substrate is placed, and the sample is placed at room temperature and dried in the shade for 12 hours, then heated to 350°C in a drying oven at a heating rate of 2°C / s and stayed for 0.5 hours, and the dried sample is placed in a The cathode is rapidly melted with an electric arc, and the entire arc is under the protection of flowing argon gas. It is completed under 200A DC, 30V voltage, 10L / min shielding gas flow rate and 1.67mm / s arc scanning speed. Finally, the length, width and thickness are 50mm...

Embodiment 3

[0026] The difference from Example 1 is that it is completed at an arc scanning speed of 2.5mm / s, and a zirconium diboride / silicon carbide composite block material is finally prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com