Preparation method and application of nitrogen-doped starch-based activated carbon microsphere material

A technology based on activated carbon microspheres and starch, which is applied in the direction of hybrid capacitor electrodes, etc., can solve problems that have not been seen, and achieve the effects of improved electrochemical performance, good dispersion, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

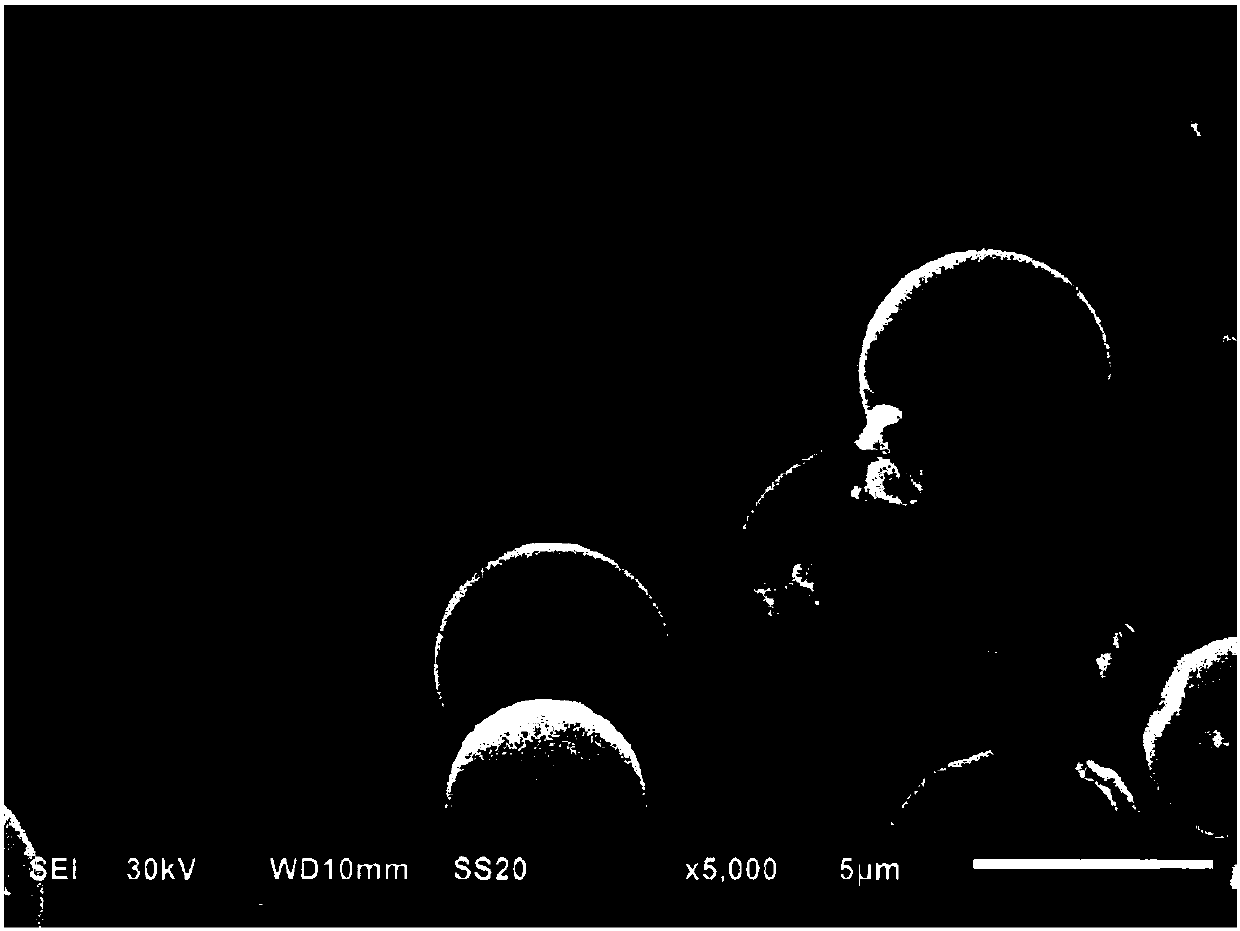

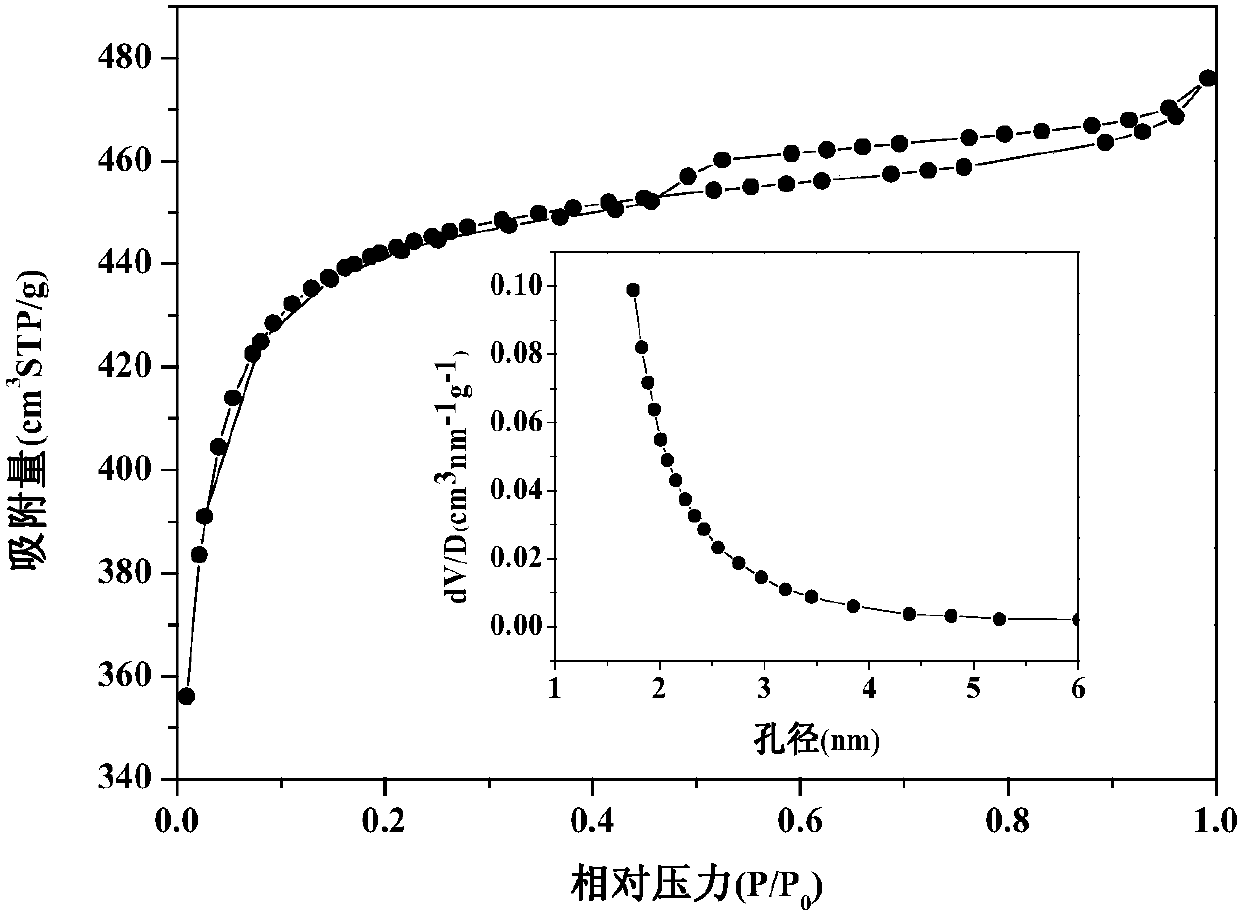

[0036] (1) Take 5g of sweet potato powder, 1g of melamine, and 50ml of water in a reactor, raise the temperature to 100°C, and stir under reflux for 10h to obtain an intermediate product of nitrogen-containing colloid.

[0037] (2) Transfer the nitrogen-containing colloidal intermediate product to a high-pressure hydrothermal reaction kettle with a polytetrafluoroethylene liner with a volume filling rate of 0.5, and perform constant temperature treatment at 200° C. for 12 hours and cool to room temperature with the furnace temperature. The hydrothermal product is washed with distilled water several times and separated from solid and liquid until the washing liquid is neutral, and then the solid is placed in a drying oven at 100°C to dry to constant weight to prepare nitrogen-containing hydrothermal carbon coke.

[0038] (3) According to the mass ratio of nitrogen-containing hydrothermal carbon coke and activator potassium carbonate as 2:1, measure 2 mol / L potassium carbonate so...

Embodiment 2

[0046] (1) Take cassava flour 5g, g-C 3 N 4 Put 1.5g of powder and 50ml of water in a reactor, raise the temperature to 100°C, and stir under reflux for 10 hours to obtain an intermediate product of nitrogen-containing colloid.

[0047] (2) Transfer the nitrogen-containing colloidal intermediate product to a high-pressure hydrothermal reactor with a polytetrafluoroethylene liner of 100 ml, with a volume filling rate of 0.5, and heat it at 180° C. for 12 hours, then cool it naturally with the furnace temperature. The hydrothermal product is washed with distilled water several times and separated from solid and liquid until the washing liquid is neutral, and then the solid is dried at 110°C to constant weight to prepare nitrogen-containing hydrothermal carbon coke.

[0048] (3) Measure according to the mass ratio of nitrogen-containing hydrothermal carbon coke and activator sodium hydroxide as 1:1, measure 2 mol / L sodium hydroxide solution and nitrogen-containing hydrothermal c...

Embodiment 3

[0055] (1) Take 5g of mung bean powder and 50ml of water in a reactor, heat up to 100°C, and stir under reflux for 12h to obtain a colloidal intermediate product.

[0056] (2) Transfer the colloid product obtained in step (1) to a high-pressure hydrothermal reactor with a polytetrafluoroethylene liner of 100ml, and its volume filling rate is 0.7. Allow to cool naturally. The hydrothermal product was washed with distilled water several times and separated from solid and liquid until the washing liquid was neutral, and then the solid was dried in a drying oven at 110°C to constant weight to prepare hydrothermal carbon coke.

[0057] (3) Make the activator sodium phosphate into a solution with a concentration of 1mol / L, add the hydrothermal carbon coke prepared in step (2) according to the mass ratio of 3:1 to the activator, and then add 2.5g of polyaniline Powder with a liquid / solid ratio of 10, then mixed and stirred at room temperature for 12 hours, and then evaporated to dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com