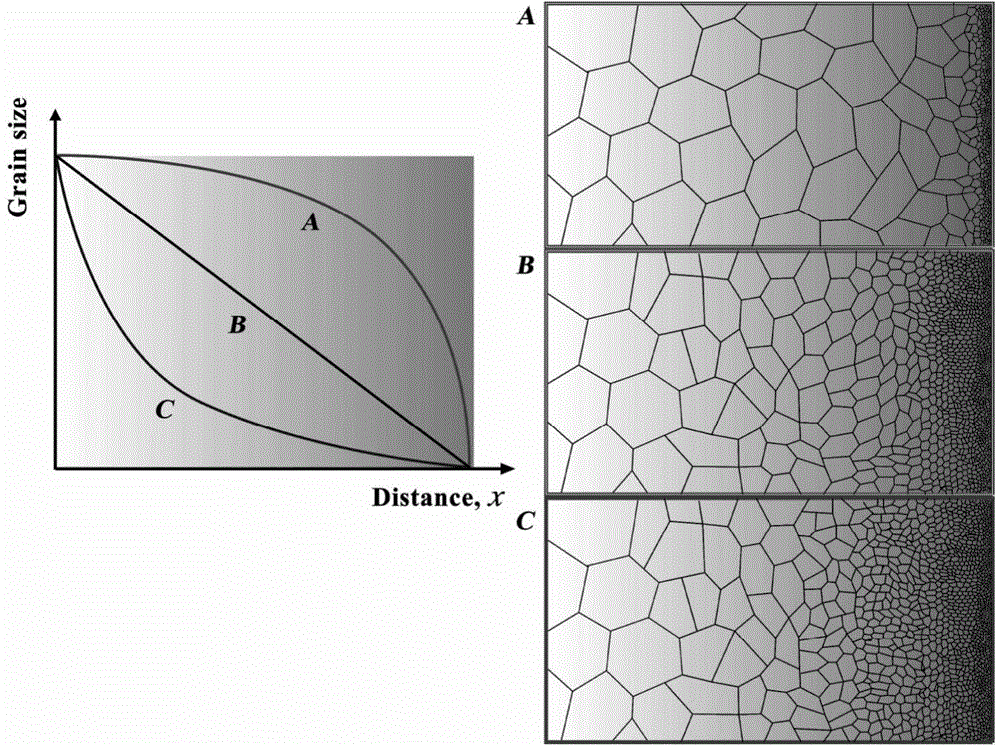

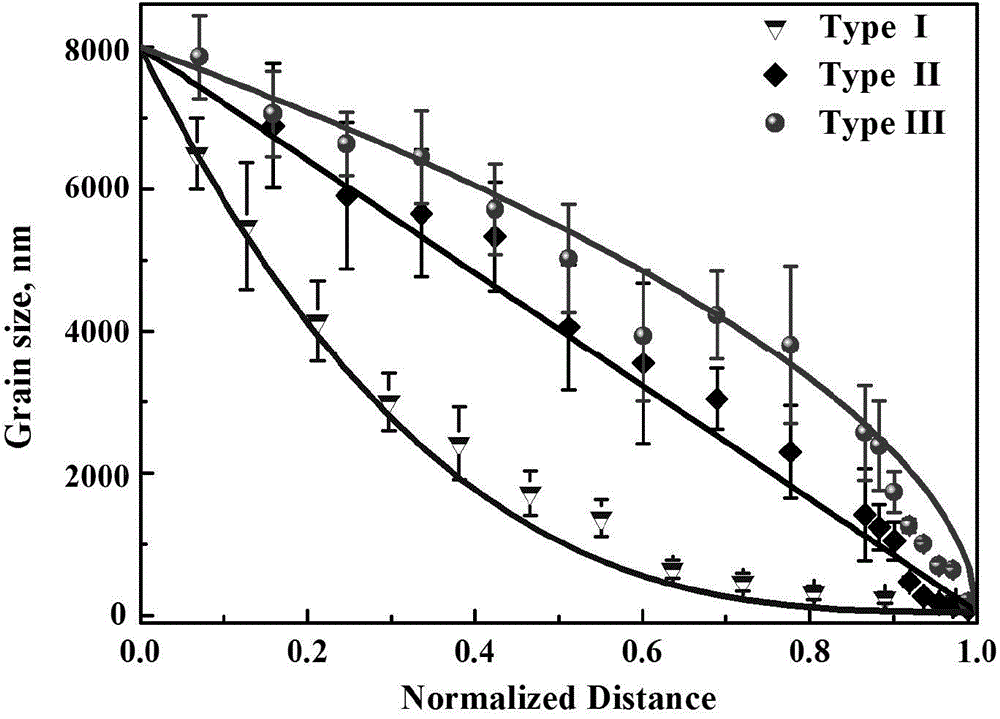

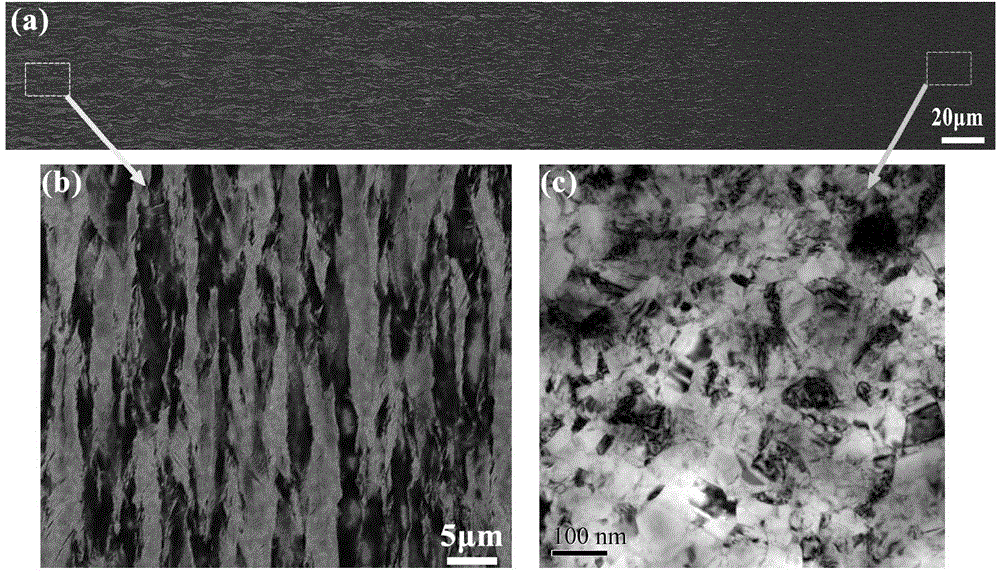

Crystalline grain scale gradient metallic nickel and controllable preparation method thereof

A technology of metal nickel and grain size, applied in the direction of cells, electrolytic process, electrolytic components, etc., can solve the problem of non-interface existence and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Use nickel as the consumable anode and titanium cathode, and configure 800ml of plating solution as required. The composition of the plating solution is:

[0021] NiSO 4 ·7H 2 O:300g / L, NiCl 2 ·6H 2 O: 45g / L, H 3 BO 3 :40g / L, C 12 h 25 OSO 2 Na: 0.05g / L. Weigh the above drugs with a balance and dissolve them in a beaker so that the volume of the solution is no more than three-quarters of the rated volume of the beaker. Stir the prepared plating solution with a magnetic stirrer and adjust the pH value to 4±0.2 with sodium hydroxide solution. The bath temperature is controlled at 55±1°C.

[0022] Computer controlled current density and additive concentration:

[0023] Current density: (1), the current density remains constant at 10mA / cm within the first 47.5h 2 , (2), after 0.75h the current density is changed from 10mA / cm 2 Gradually increase to 20mA / cm 2 , (3), and then within 0.75h the current density gradually increased to 30mA / cm 2 , (4), continue to gr...

Embodiment 2

[0027] Use nickel as the consumable anode and titanium as the cathode, configure 800ml of plating solution as required, and the composition of the plating solution is:

[0028] NiSO 4 ·7H 2 O:300g / L, NiCl 2 ·6H 2 O: 45g / L, H 3 BO 3 :40g / L, C 12 h 25 OSO 2 Na: 0.05g / L. Weigh the above drugs with a balance and dissolve them in a beaker so that the volume of the solution is no more than three-quarters of the rated volume of the beaker. Stir the prepared plating solution with a magnetic stirrer and adjust the pH value to 4±0.2 with sodium hydroxide solution. The bath temperature is controlled at 55±1°C.

[0029] Computer controlled current density and additive concentration:

[0030] The control current density is mainly divided into six stages: (1), the current density is kept constant at 5mA / cm in the first 25h 2 , (2), within 3h after that, the current density changed from 5mA / cm 2 Gradually increase to 20mA / cm 2 , (3), and then gradually increased to 30mA / cm withi...

Embodiment 3

[0034] With nickel as the consumption anode and steel as the cathode, configure 800ml of plating solution as required. The composition of the plating solution is:

[0035] NiSO 4 ·7H 2 O:300g / L, NiCl 2 ·6H 2 O: 45g / L, H 3 BO 3 :40g / L, C 12 h25 OSO 2 Na: 0.06g / L. Weigh the above drugs with a balance and dissolve them in a beaker so that the volume of the solution is no more than three-quarters of the rated volume of the beaker. Stir the prepared plating solution with a magnetic stirrer and adjust the pH value to 4±0.2 with sodium hydroxide solution. The bath temperature is controlled at 55±1°C.

[0036] Computer controlled current density and additive concentration:

[0037] Current density: (1), first keep the current density constant at 7mA / cm for 18h 2 , (2), and then within 3h the current density is changed from 7mA / cm 2 Gradually increase to 20mA / cm 2 , (3), the current density gradually increased to 30mA / cm in the following 3h 2 , (4), continue to gradually i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com