Method utilizing thermal spraying technique for preparing polyimide coating and product of method

A polyimide coating, polyimide technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of low production efficiency, length limitation, etc., achieve low cost, low equipment cost, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

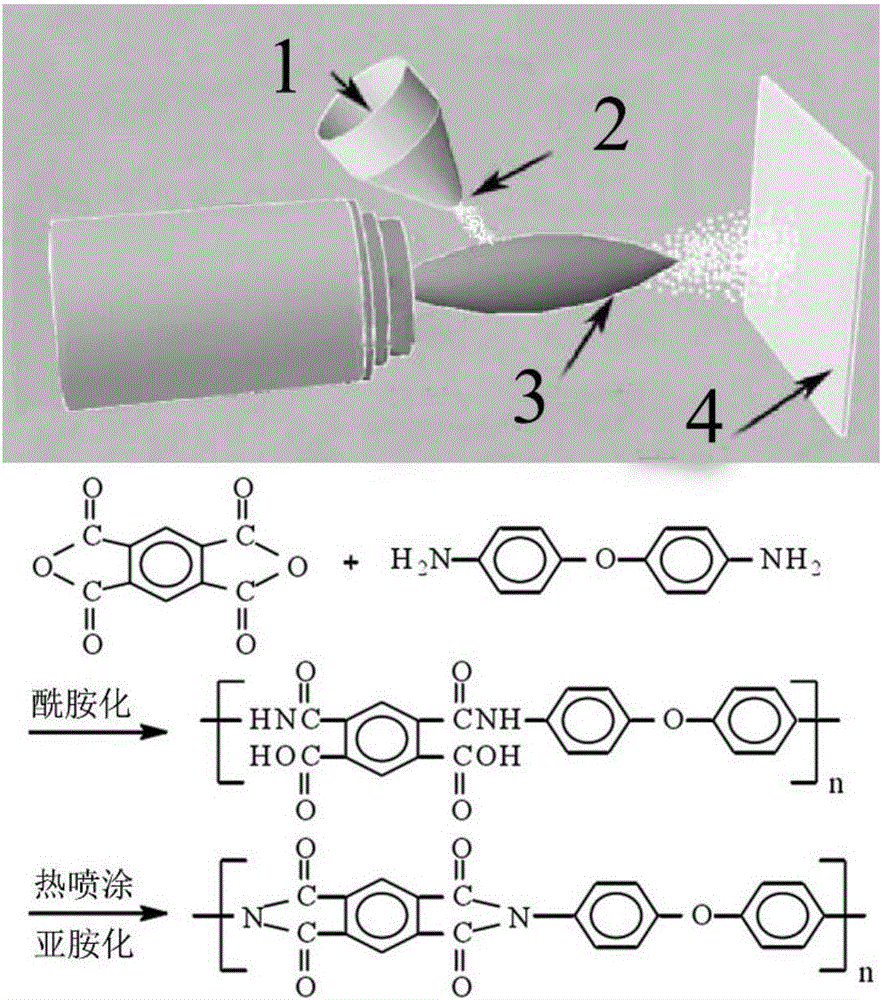

Method used

Image

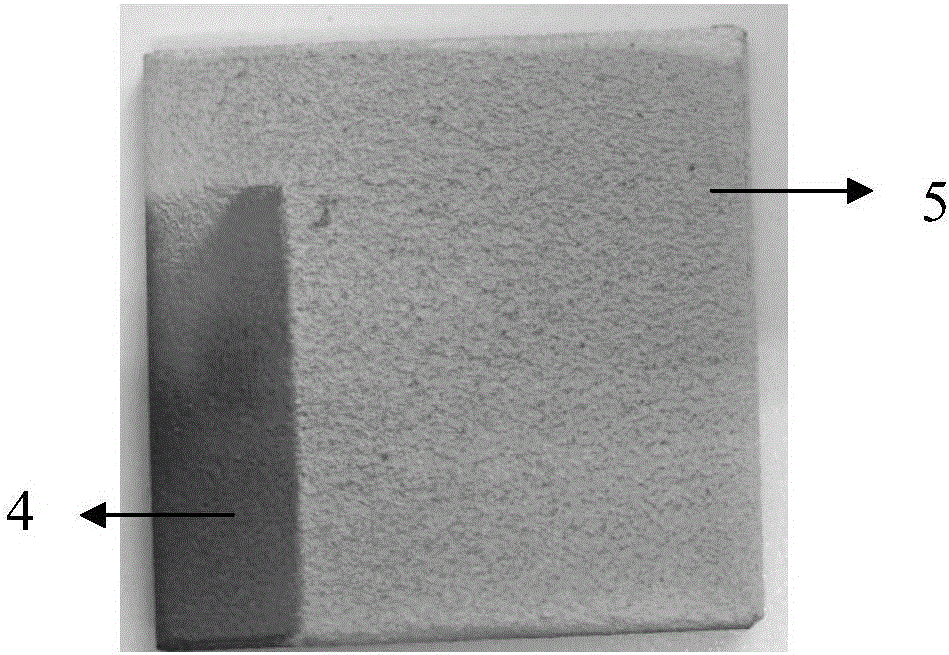

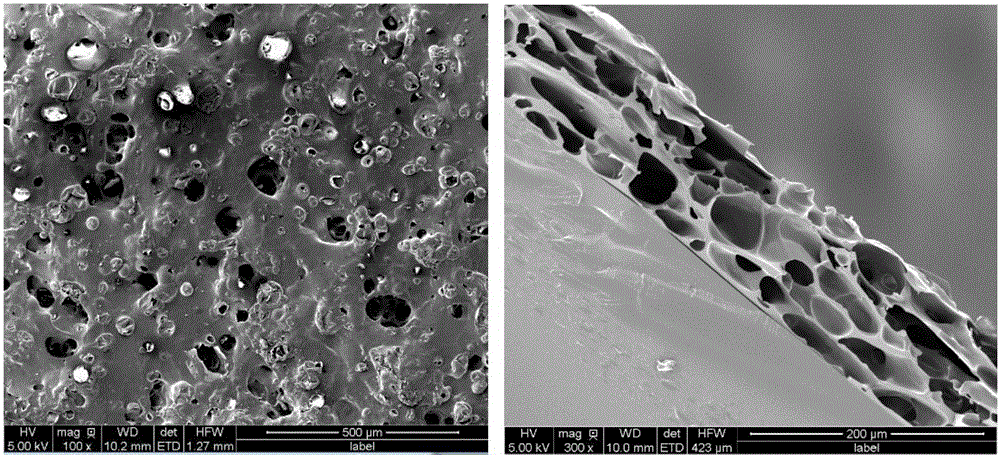

Examples

Embodiment 1

[0058] 1. Use a mortar to grind 4,4'-diaminodiphenyl ether (ODA) and pyromellitic dianhydride (PMDA) respectively, and sieve the pyromellitic dianhydride with a 100-mesh sieve. Put 4,4'-diaminodiphenyl ether in a common oven and bake at 110°C for 4-5 hours before use; put pyromellitic dianhydride in a common oven and bake at 170°C for 4-5 hours before use .

[0059] 2. Weigh 10.002g of 4,4'-diaminodiphenyl ether (ODA) after the above pretreatment, dissolve it in 200ml of N,N-dimethylformamide (DMF), stir to make it completely dissolve ( 5min); then weigh 10.906g of pyromellitic dianhydride (PMDA) after the above-mentioned pretreatment, and add and stir in a small amount to the above-mentioned solution several times; continue stirring for 8-10h after adding completely to obtain 10wt.% Thermosetting polyimide precursor slurry of polyamic acid (PAA);

[0060] 3. Wash and dry the glass substrate with acetone, ethanol, and deionized water in sequence;

[0061] 4. In the flame pr...

Embodiment 2

[0066] 1. Use a mortar to grind 4,4'-diaminodiphenyl ether (ODA) and pyromellitic dianhydride (PMDA) respectively, and sieve the pyromellitic dianhydride with a 100-mesh sieve. Put 4,4'-diaminodiphenyl ether in a common oven and bake at 110°C for 4 to 5 hours; place pyromellitic dianhydride in a common oven and bake at 170°C for 4 to 5 hours.

[0067] 2. Weigh 10.002g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 200ml of N,N-dimethylformamide (DMF), stir to dissolve it completely (5min); then weigh Get 10.906g of pyromellitic dianhydride (PMDA), add a small amount of multiple times to the above solution and stir; continue stirring for 8 to 10 hours after adding completely to obtain a thermosetting polyamic acid containing 10wt.% polyamic acid (PAA). Imide precursor slurry;

[0068] 3. Clean the substrate with acetone, ethanol, and deionized water in sequence, and use 60 mesh brown corundum sand to roughen the surface of the Q345 steel sheet. The air pressure used for s...

Embodiment 3

[0074] 1. Use a mortar to grind 4,4'-diaminodiphenyl ether (ODA) and pyromellitic dianhydride (PMDA) respectively, and sieve the pyromellitic dianhydride with a 100-mesh sieve. Put 4,4'-diaminodiphenyl ether in a common oven and bake at 110°C for 4 to 5 hours; place pyromellitic dianhydride in a common oven and bake at 170°C for 4 to 5 hours.

[0075] 2. Weigh 10.002g of 4,4'-diaminodiphenyl ether (ODA), dissolve it in 400ml of N,N-dimethylformamide (DMF), stir to dissolve completely (5min); then weigh Get 10.906g pyromellitic dianhydride (PMDA), add and stir in a small amount to the above-mentioned solution several times; continue to stir for 8-10 hours after adding completely to obtain a thermosetting polyamic acid containing 5wt.% polyamic acid (PAA). Imide precursor slurry;

[0076] 3. Wash and dry the glass substrate with acetone, ethanol, and deionized water in sequence;

[0077] 4. In the flame preparation process of polyimide coating, the atomizing nozzle with a diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com