Polymer electrolyte, its preparation method and battery comprising the same

A polymer and electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, secondary batteries, etc., can solve the problems of low mechanical strength and achieve high mechanical strength, enhanced mechanical strength, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a polymer electrolyte, wherein the method includes: adsorbing a solution containing a polymer capable of complexing lithium ions and a lithium salt on the electrospun fiber film, and then removing the solvent to obtain the adsorbed ion The supporting phase for the conductive phase.

[0032] Among them, the method of adsorbing a solution containing a polymer capable of complexing lithium ions and a lithium salt on the electrospun fiber film can adopt various methods known in the art, such as dipping, coating, spraying, etc., preferably, Adsorbing a solution containing a polymer capable of complexing lithium ions and a lithium salt on the electrospun fiber film includes dropping a solution containing a polymer capable of complexing lithium ions and a lithium salt onto the electrospun fiber film, and the method is simple It is easy to operate, and the prepared polymer electrolyte is more uniform and filled better, ...

Embodiment 1

[0044] This example is used to illustrate the polymer electrolyte provided by the present invention and its preparation method.

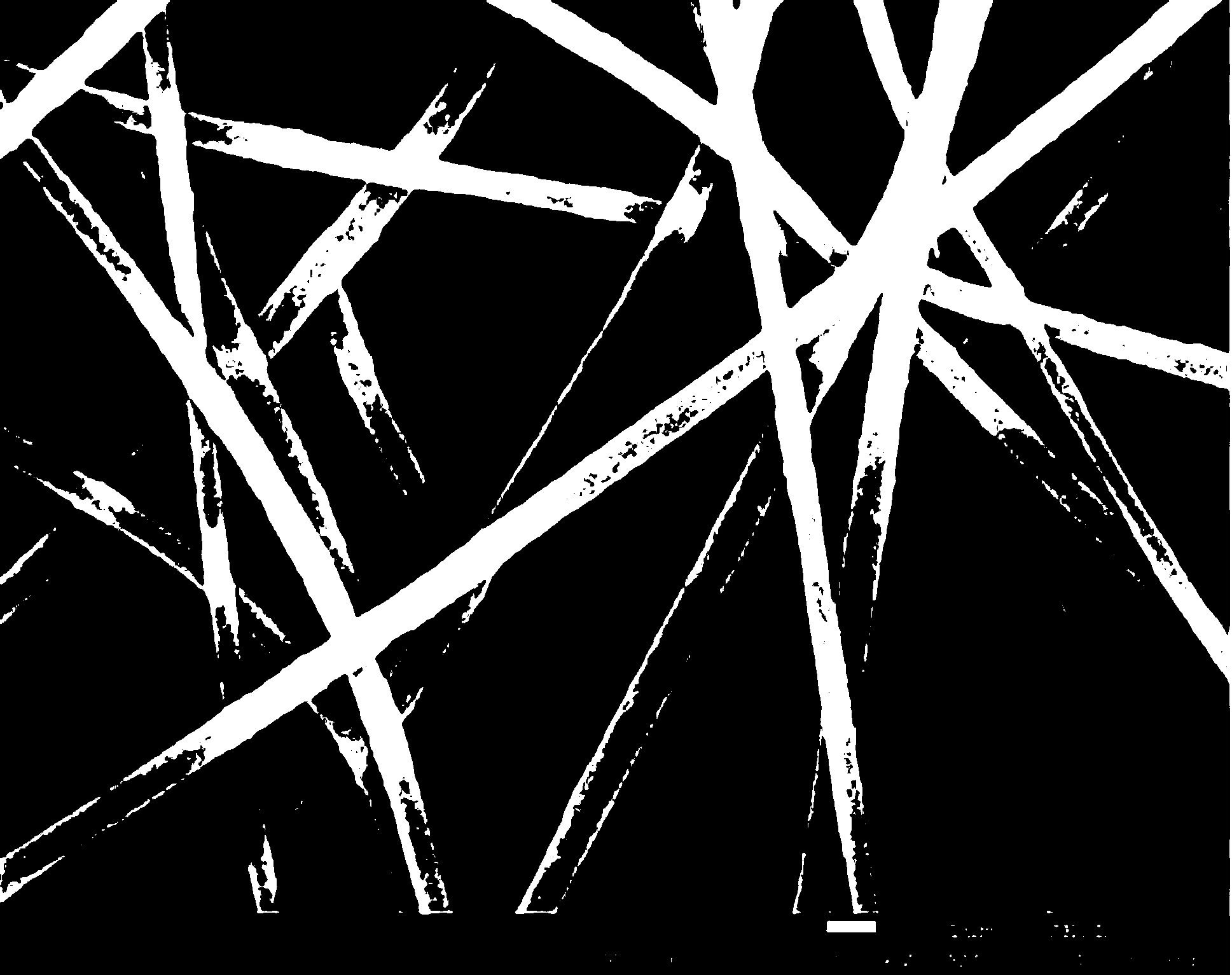

[0045] 1. Preparation of electrospun fiber film

[0046] (1) at V 丙酮 : V N,N-二甲基甲酰胺 =2:8 (6 mL of acetone, 14 mL of N,N-dimethylformamide) was added PVdF ( M w 370 000 g / mol) was stirred and dissolved, and a support phase polymer solution with a mass concentration of 17 wt% was prepared.

[0047] (2) Add the above-mentioned support phase polymer solution into a 10 mL syringe, insert a needle with a diameter of 0.8 mm, and move the needle at a speed of 6 mm / s, and use a syringe pump to propel the polymer solution at an injection rate of 0.8 mL / s h, A DC high-voltage generator is used as a device to generate a high-voltage electrostatic field. A layer of aluminum foil is wrapped on the receiving plate of the cylindrical drum. The voltage is adjusted according to the polymer concentration and viscosity of the support phase. The voltage is 12 kV, a...

Embodiment 2

[0054] This example is used to illustrate the polymer electrolyte provided by the present invention and its preparation method.

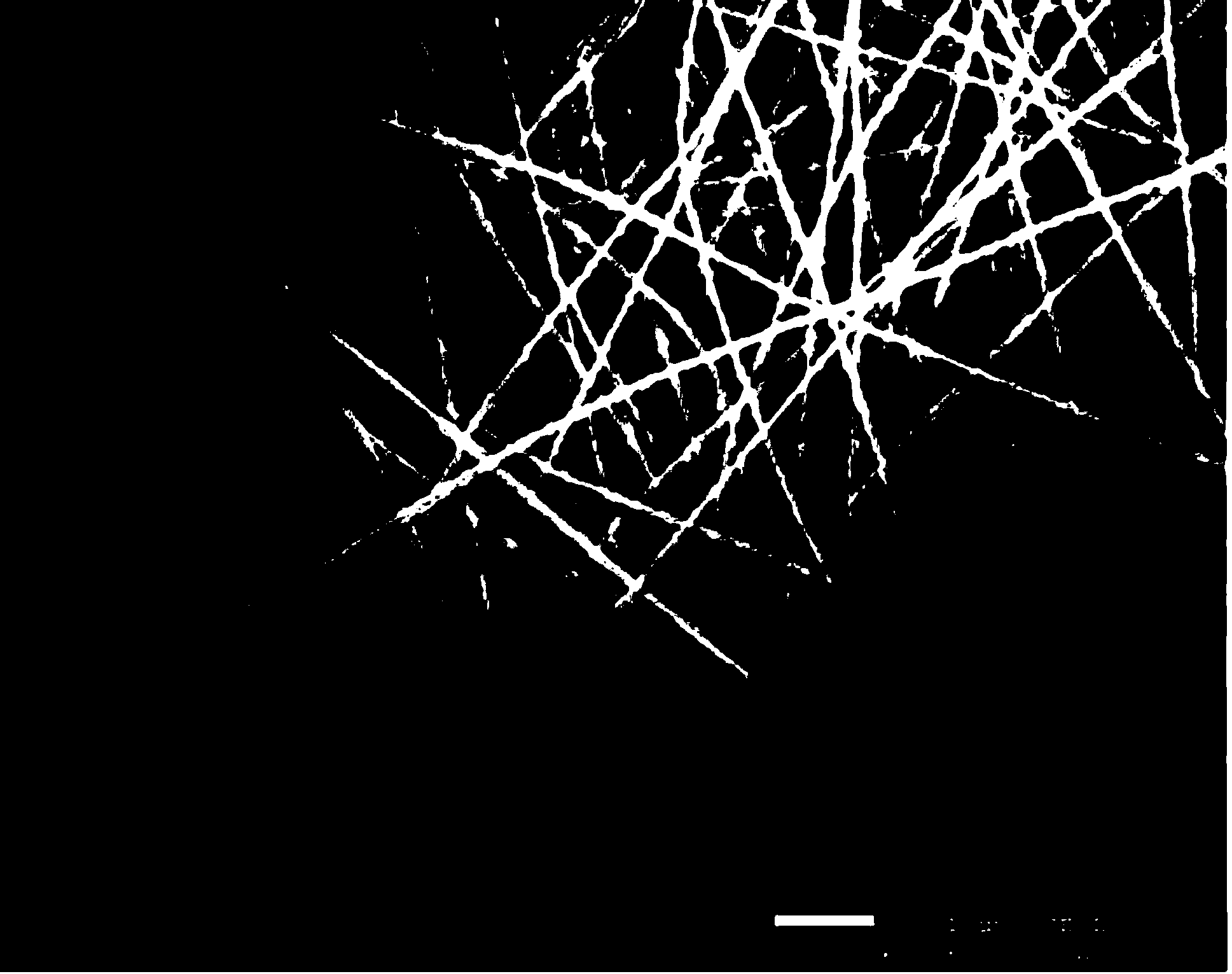

[0055] 1. Preparation of electrospun fiber film

[0056] (1) at V 丙酮 : V N,N-二甲基乙酰胺 =2:8 (6 mL of acetone, 14 mL of N,N-dimethylacetamide) was added PVdF ( M w 625 000 g / mol) was stirred and dissolved, and a support phase polymer solution with a mass concentration of 12 wt% was prepared.

[0057] (2) Add the above-mentioned support phase polymer solution into a 10 mL syringe, insert a needle with a diameter of 0.8 mm, and move the needle at a speed of 6 mm / s, and use a syringe pump to propel the polymer solution at an injection rate of 1.0 mL / s h, A DC high-voltage generator is used as a device to generate a high-voltage electrostatic field. A layer of aluminum foil is wrapped on the receiving plate of the cylindrical drum. The voltage is adjusted according to the polymer concentration and viscosity of the support phase. The voltage is 12 kV, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com