Method for quickly preparing carbon-silicon dioxide composite aerogel

A composite airgel and silica technology, applied in the direction of silica, silica, etc., can solve the problems of long co-gelation and aging time, complicated preparation process, high reaction temperature requirements, etc., to achieve gel and The effects of short aging time, simple preparation process and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix resorcinol and formaldehyde in acetonitrile at a molar ratio of 1:2 at room temperature, then add hydrochloric acid as an acidic catalyst, then add tetraethyl orthosilicate, deionized water and hydrofluoric acid solution in sequence, After stirring evenly, a mixed sol was formed, sealed and left standing at room temperature, and the gel and aging time were 1440 minutes. The molar ratio of added resorcinol, tetraethylorthosilicate, water, hydrogen chloride, hydrogen fluoride and acetonitrile is 1:2:6:0.04:0.5:20.

[0028] (2) Soak the obtained wet gel in acetone for three times of solvent replacement, each time for 8 hours. followed by supercritical fluid CO 2 Dry (40°C, 10MPa) for 4 hours to obtain resorcinol formaldehyde-silica composite airgel.

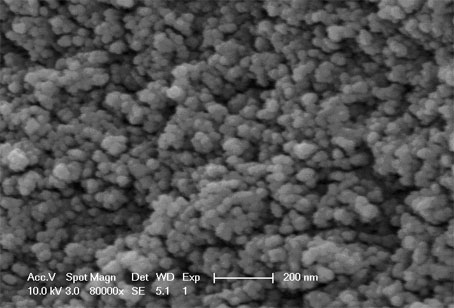

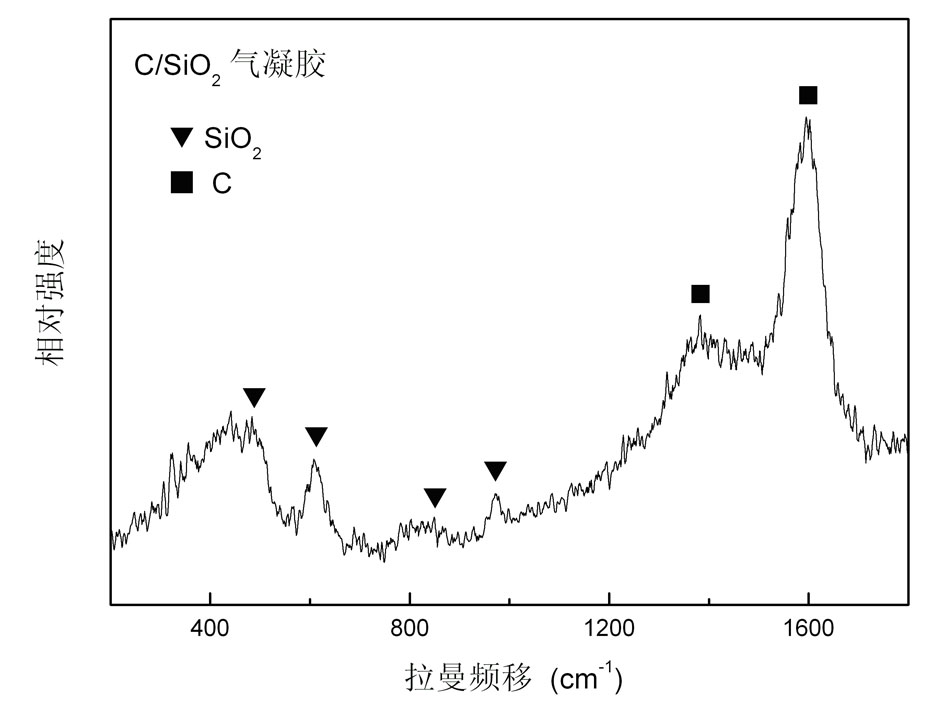

[0029] (3) Carbonize the obtained composite airgel at 700°C for 1 hour under the protection of nitrogen to obtain a carbon-silica composite airgel with a density of 200mg / cm 3 Around 90% porosity and about 30% carb...

Embodiment 2

[0031] (1) Mix resorcinol and formaldehyde in acetonitrile at a molar ratio of 1:2 at room temperature, then add hydrochloric acid as an acidic catalyst, then add tetraethyl orthosilicate, deionized water and hydrofluoric acid solution in sequence, After stirring evenly, a mixed sol was formed, which was sealed and left standing at 80° C., and the gel time was 10 minutes. The molar ratio of added resorcinol, tetraethylorthosilicate, water, hydrogen chloride, hydrogen fluoride and acetonitrile is 1:2:6:0.04:0.5:20.

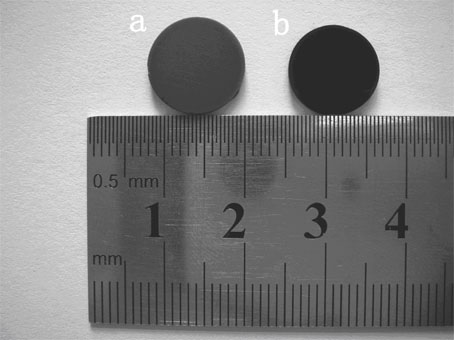

[0032] (2) Soak the obtained wet gel in ethanol for solvent replacement 3 times, 8 hours each time. Then supercritical ethanol drying (255°C, 7MPa) was carried out for 1 hour to obtain resorcinol formaldehyde-silica composite airgel, the physical appearance is as follows figure 1 as shown in a.

[0033] (3) Carbonize the obtained composite airgel at 700°C for 2 hours under the protection of nitrogen to obtain a carbon-silica composite airgel with a density of 200...

Embodiment 3

[0035](1) Mix resorcinol and formaldehyde in acetonitrile at a molar ratio of 1:2 at room temperature, then add hydrochloric acid as an acidic catalyst, then add tetraethyl orthosilicate, deionized water and hydrofluoric acid solution in sequence, After stirring evenly, a mixed sol was formed, sealed and left standing at room temperature, and the gel and aging time were 1440 minutes. The molar ratio of added resorcinol, tetraethylorthosilicate, water, hydrogen chloride, hydrogen fluoride and acetonitrile is 1:1.5:4.5:0.03:0.37:14.

[0036] (2) Soak the obtained wet gel in ethanol for 6 times of solvent replacement, 4 hours each time. Then perform supercritical ethanol drying (245°C, 10MPa) for 1 hour to obtain resorcinol formaldehyde-silica composite airgel.

[0037] (3) Carbonize the obtained composite airgel at 700°C for 2 hours under the protection of nitrogen to obtain a carbon-silica composite airgel with a density of about 300mg / cm 3 , the porosity is above 90%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com