Preparation method of nano-crystalline cellulose-based composite aerogel type organic dye absorption material

A technology of nanocellulose and composite airgel, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve the problems of water-soluble dye adsorption performance and selectivity to be further improved, easy swelling, loss of mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Cationic nanocellulose and chitosan 1:1 (w / w) composite airgel was prepared as follows:

[0020] Disperse 1g of bamboo pulp in 5% NaOH solution, add 2.9g of 2,3-epoxypropyltrimethylammonium chloride and stir at 25°C to make it evenly mixed, then react at 65°C for 6h. After the reaction is completed, adjust the pH to 7 with dilute hydrochloric acid, filter with suction, wash with a large amount of distilled water until neutral, and finally polish the fiber suspension through a high-pressure homogenizer to obtain a positively charged NFC dispersion on the surface;

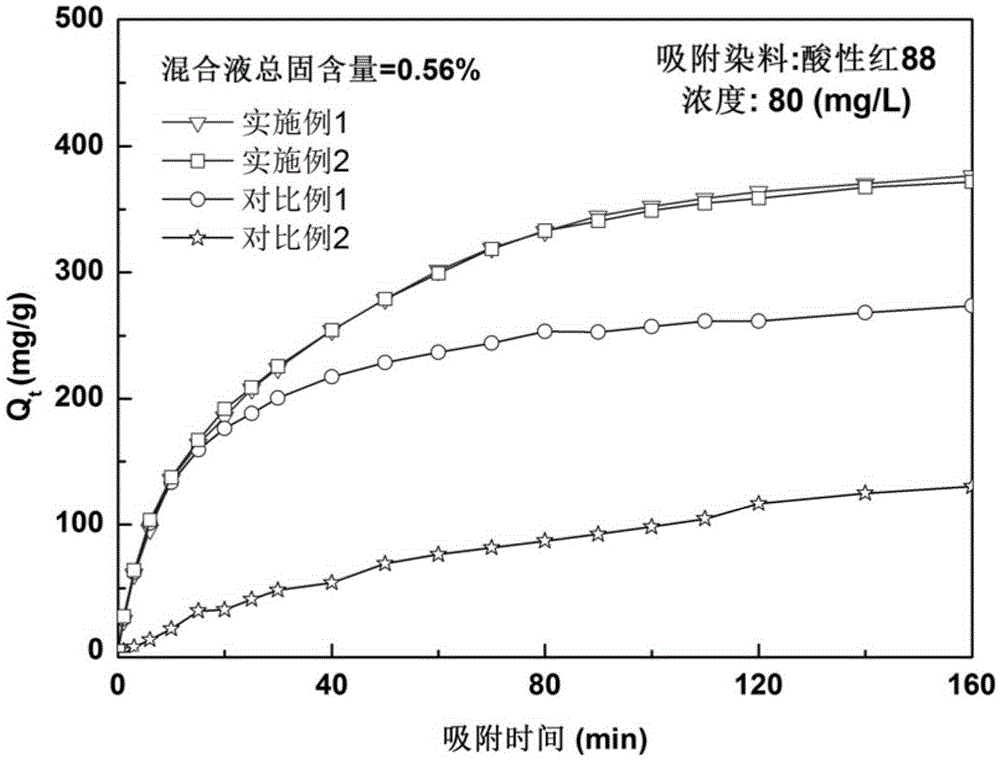

[0021] The mixture of cationic nanocellulose and chitosan (solid mass ratio = 1:1 (w / w)) was placed at -60°C for 4 hours and then freeze-dried, then soaked in 0.5% epichlorohydrin (cross-linked agent) in a 2wt% sodium hydroxide solution at 40° C. for 2 hours, then freeze-dry again. Its performance is shown in Table 1 and figure 1 .

Embodiment 2

[0023] Cationic nanocellulose and chitosan 2:1 (w / w) composite aerogels were prepared as follows:

[0024] Disperse 1g of bamboo pulp in 5% NaOH solution, add 2.9g of 2,3-epoxypropyltrimethylammonium chloride and stir at 25°C to make it evenly mixed, then react at 65°C for 6h. After the reaction is completed, adjust the pH to 7 with dilute hydrochloric acid, filter with suction, wash with a large amount of distilled water until neutral, and finally polish the fiber suspension through a high-pressure homogenizer to obtain a positively charged NFC dispersion on the surface;

[0025] The mixture of cationic nanocellulose and chitosan (solid mass ratio = 2:1 (w / w)) was placed at -60°C for 4 hours and then freeze-dried, then soaked in 0.5% epichlorohydrin (cross-linked agent) in a 2wt% sodium hydroxide solution at 40° C. for 2 hours, then freeze-dry again. Its performance is shown in Table 1 and figure 1 .

Embodiment 3

[0027] Low-charge cationic nanocellulose was prepared as follows:

[0028] Disperse 1g of bamboo pulp in 5% NaOH solution, add 2.9g of 2,3-epoxypropyltrimethylammonium chloride and stir at 25°C to make it evenly mixed, then react at 65°C for 6h. After the reaction, adjust the pH to 7 with dilute hydrochloric acid, filter with suction, wash with a large amount of distilled water until neutral, and finally polish the fiber suspension with a high-pressure homogenizer to obtain a positively charged NFC dispersion on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com