Powder metallurgy preparation method for nano-particle reinforced ultra-fine grain metal-matrix composite

A nano-particle and composite material technology is applied in the field of powder metallurgy preparation of nano-particle reinforced ultra-fine-grained metal matrix composite materials, which can solve the problems of long ball milling time, high energy consumption, time-consuming and laborious, etc., so as to improve the work hardening ability, The effect of high dispersion uniformity and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Nano silicon carbide / aluminum (SiC / Al) composite material

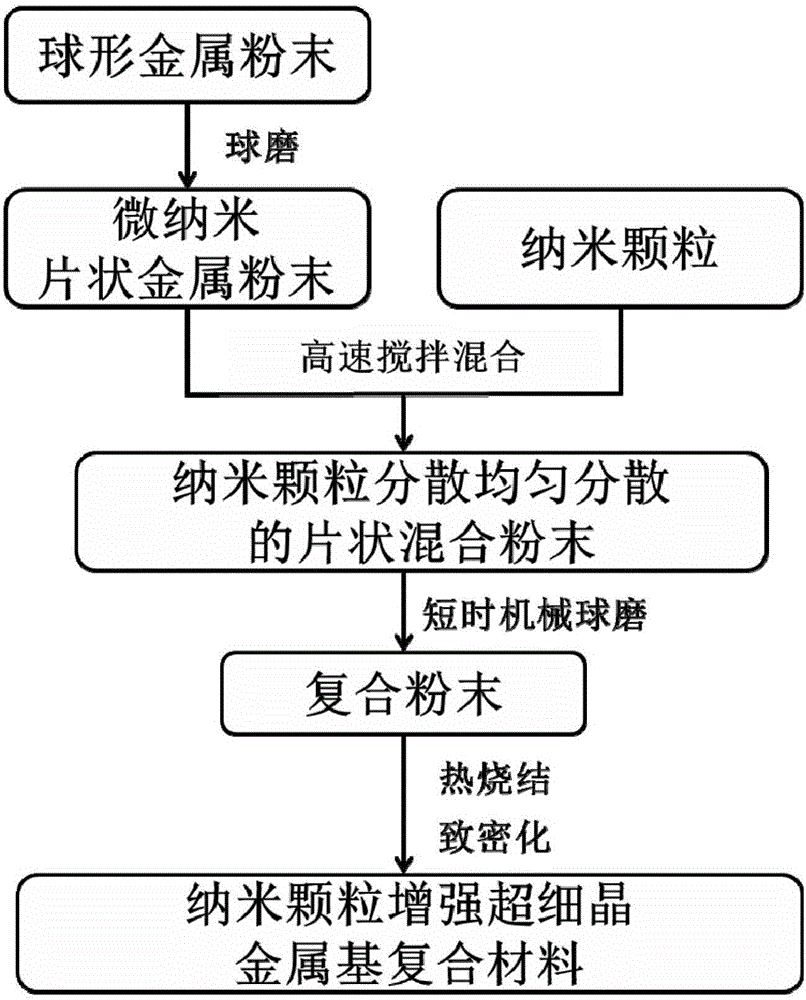

[0048] like figure 1 Shown, a kind of powder metallurgy preparation method of nanoparticle reinforced ultrafine grain metal matrix composite material, described method is used for preparing the process of nano silicon carbide / aluminum (SiC / Al) composite material as follows:

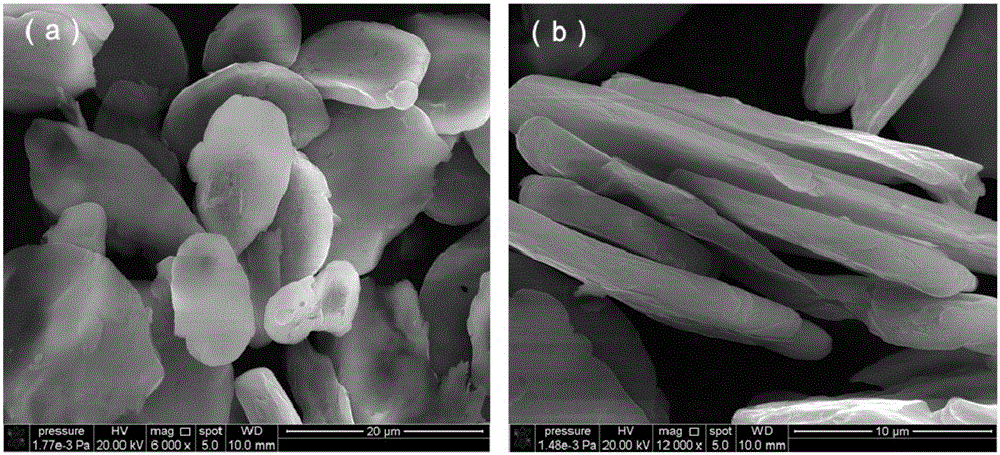

[0049] Take 1000g of 10μm pure aluminum (Al) powder in a stirring ball mill, use absolute ethanol as a solvent, add 40g of titanate as a ball milling process control agent, the ratio of ball to material is 20:1, and ball mill at a speed of 352 rpm After 1h, filter and vacuum dry to obtain flake aluminum powder, the diameter of the flake aluminum powder is 20-40 μm, the thickness is 1-2 μm, and the diameter-thickness ratio is 20-40;

[0050] Take 100g of nano-silicon carbide (SiC) particles with an average particle size of 50nm, add them to absolute ethanol for ultrasonic cleaning, filter, and dry;

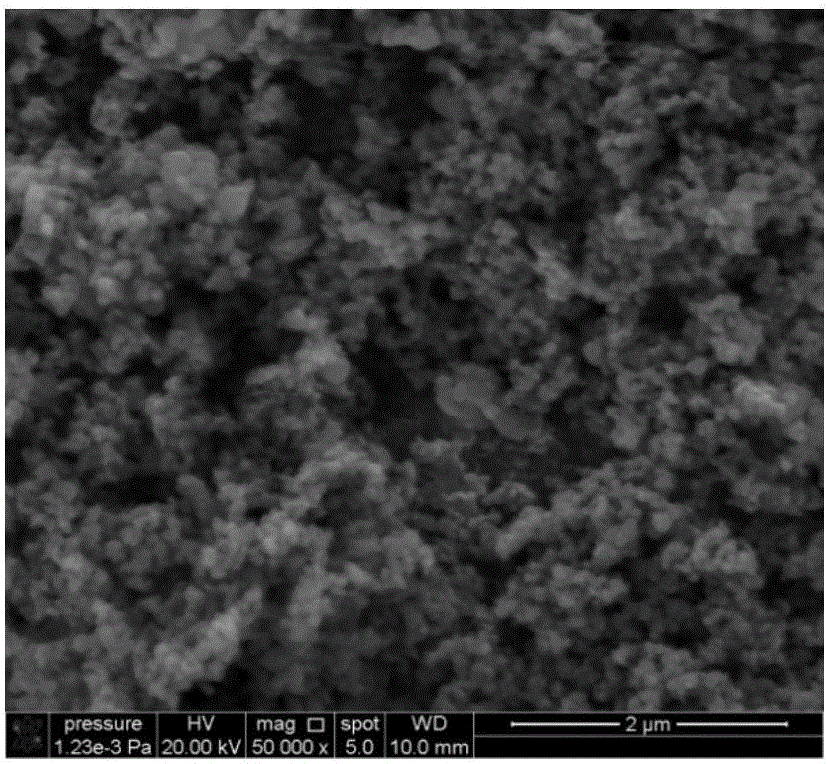

[0051] Add 950g of the a...

Embodiment 2

[0058] Embodiment 2: Nano boron carbide / magnesium composite material

[0059] like figure 1 Shown, a kind of powder metallurgy preparation method of nanoparticle-reinforced ultrafine-grain metal matrix composite material, described method is used for the process of preparing nano-boron carbide / magnesium composite material as follows:

[0060] Take 200g, 30μm spherical magnesium powder and place it in a stirring ball mill, use argon as a protective atmosphere, add 6g of stearic acid as a ball milling process control agent, the ball-to-material ratio is 20:1, and ball mill for 3 hours at a speed of 423 rpm , to obtain flake aluminum powder, the flake aluminum powder has a sheet diameter of 50-70 μm, an average sheet thickness of 200 nm, and a diameter-thickness ratio greater than 200;

[0061] Prepare nano-boron carbide (B) according to the method in Example 1 4 C) powder, the average size of nano boron carbide particles is 40nm;

[0062] Add 186g of the above-mentioned flaky...

Embodiment 3

[0063] Embodiment 3 nanometer titanium carbide / titanium composite material

[0064] like figure 1 Shown, a kind of powder metallurgy preparation method of nanoparticle-reinforced ultra-fine-grained metal-matrix composite material, described method is used for the process of preparing nano-titanium carbide / titanium composite material as follows:

[0065] Take 500g of titanium powder with an average particle size of 45μm and place them in two planetary ball mill jars respectively, use argon as the protective atmosphere, add 2.5g of stearic acid as the ball milling process control agent, the ball-to-material ratio is 20:1, and use 426 rpm Ball milling at a rotating speed of 2 hours per minute to obtain flaky titanium powder with a sheet diameter of 50-70 μm, an average sheet thickness of 300 nm, and a ratio of diameter to thickness greater than 150;

[0066] Add 485g of the above-mentioned flaky titanium powder and 15g of nano-titanium carbide particles with an average diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com