Improved charcoal-based phosphorous removal adsorbent and preparation method thereof

A Technology for Improving Biochar and Phosphorus Adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

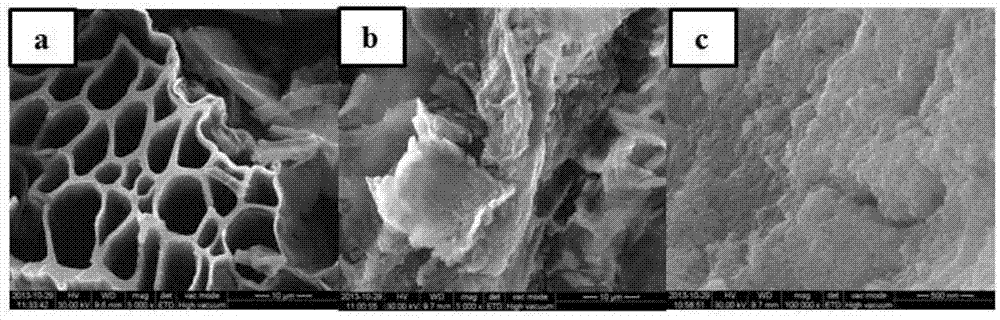

[0031] An improved biochar-based phosphorus removal adsorbent, the preparation method of which comprises the following steps:

[0032] 1) Preparation of biochar raw material A0: Break natural air-dried corn stalks (or other common crop stalks) into pieces with a length of about 0.1-0.5 cm, and wash them repeatedly with deionized water until the washing leachate meets molybdenum. Ammonium acid and ascorbic acid do not appear blue; put the washed straw in an oven at 60-100°C for 6-12 hours, then use a pulverizer to crush it, and pass it through a 60-mesh sieve. The obtained material is the raw material of biochar A0 .

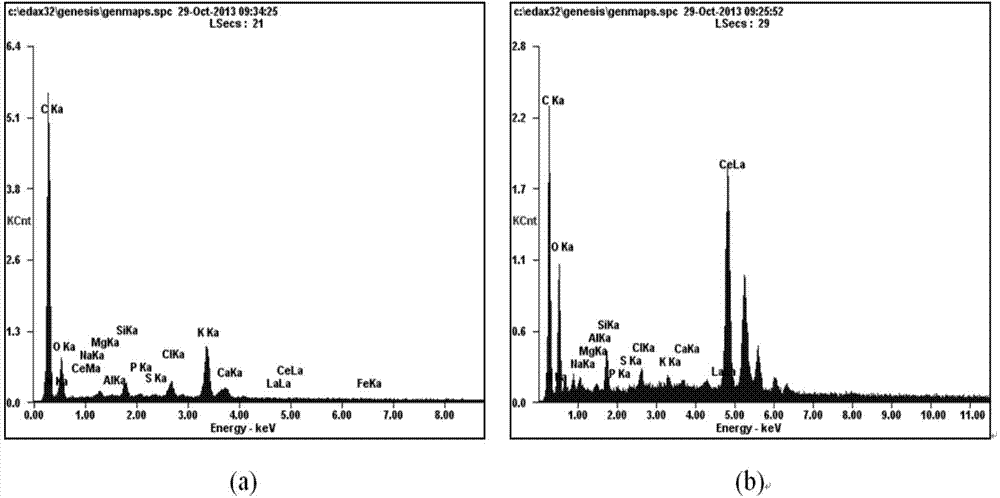

[0033] 2) Preparation of the mixture A1 of biochar raw material A0 and cerium compound: first add cerium chloride (CeCl3 7H2O) into distilled water to fully dissolve, then add the aforementioned A0 material, and the addition ratio (mass volume ratio) is A0 mass (g ): Volume of cerium chloride solution (mL) = 1:10 (g / mL). At the same time, by controlling the con...

Embodiment 1

[0038] In order to obtain the adsorption performance, especially the parameters of the adsorption capacity, of the adsorption material for phosphorus removal prepared in the present invention, an isothermal adsorption test was carried out in this embodiment.

[0039] The preparation method of an improved biochar-based phosphorus removal adsorbent (namely the aforementioned A2) is the same as before.

[0040] The isothermal adsorption test is as follows: Potassium dihydrogen phosphate solution is used to prepare simulated wastewater containing different concentrations of phosphate (between 20-350mg / L), and then mixed with the prepared phosphorus removal adsorbent A2 at 25°C to keep the adsorbent The dosage is 2g / L, shake overnight under the condition of 200rpm, and test the phosphate content in the supernatant after the adsorption equilibrium is reached, and the test method is the molybdenum blue colorimetric method. The phosphate concentration was equilibrated by the supernata...

Embodiment 2

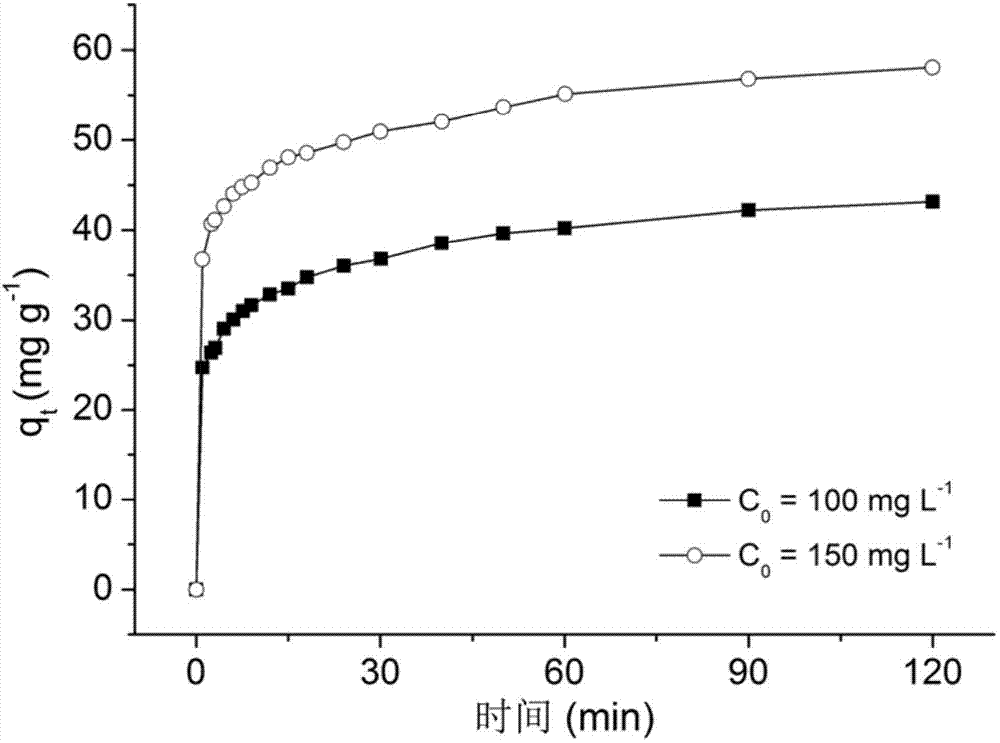

[0045] This example investigates the adsorption process of phosphate radicals by an improved biochar-based phosphorus removal adsorbent produced in the present invention. The preparation method of the phosphorus removal adsorbent in this example is the same as the preparation method of A2 above. The dosage of adsorbent is 2g / L, the shaking speed is 200rpm, and the pH is kept at the original state. The phosphate test method is the molybdenum blue colorimetric method.

[0046] figure 1 The adsorption process curves of the phosphorus removal adsorbent prepared by the present invention under the conditions of different initial concentrations of phosphate are shown. It can be found that under the test conditions, the phosphorus removal adsorbent produced by the present invention can achieve adsorption equilibrium in about 60 minutes, and the adsorption speed is relatively fast, which provides favorable conditions for future applications. Table 2 shows pseudo-first-order and pseu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com