Method for continuously and homogeneously preparing silver tin oxide material

A technology of silver tin oxide and tin oxide, applied in electrical components, electric switches, circuits, etc., can solve the problem of insufficient wettability between tin dioxide and silver matrix materials, uneven distribution of tin dioxide powder, and easy occurrence of macro and micro cracks and other problems, to achieve the effect of easy extrusion, low cost and excellent plastic processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

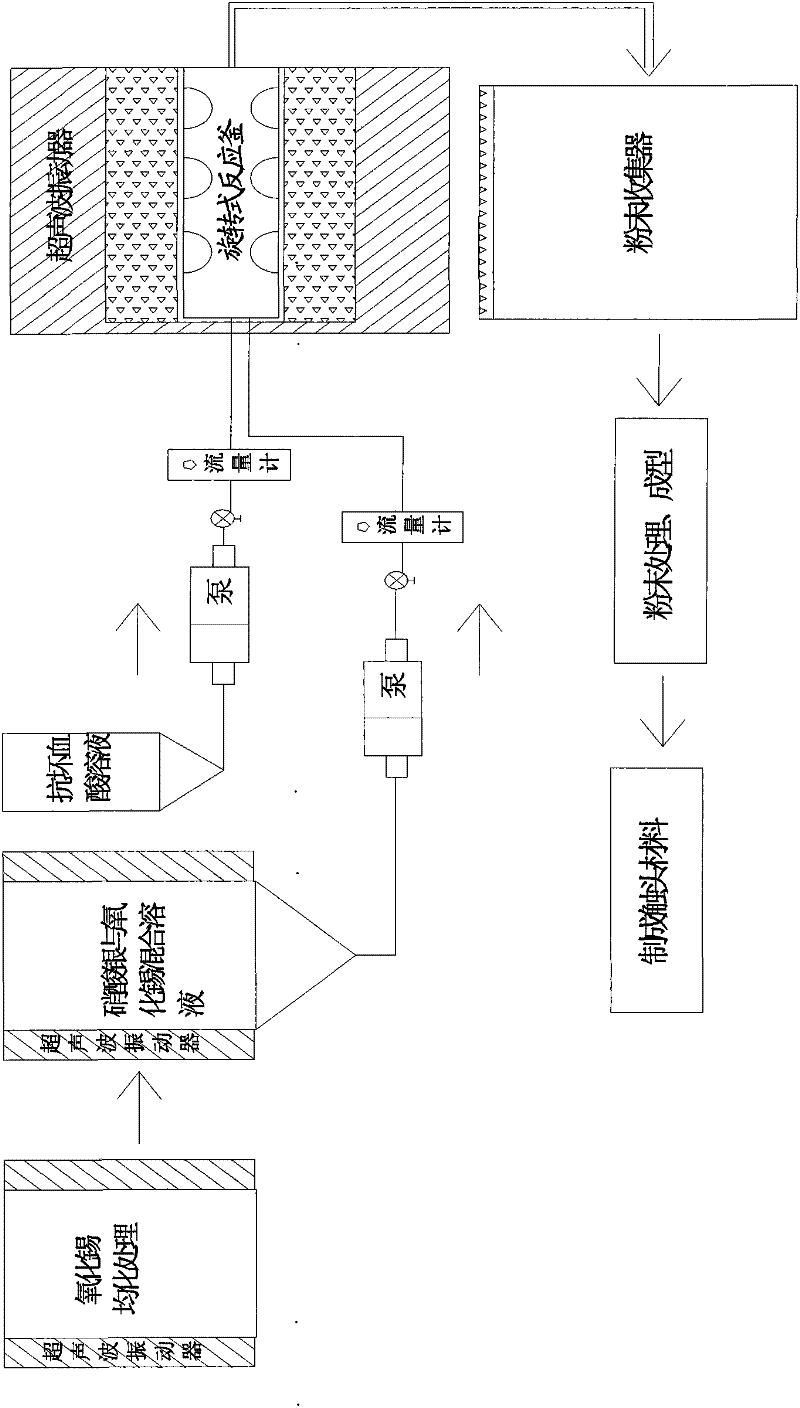

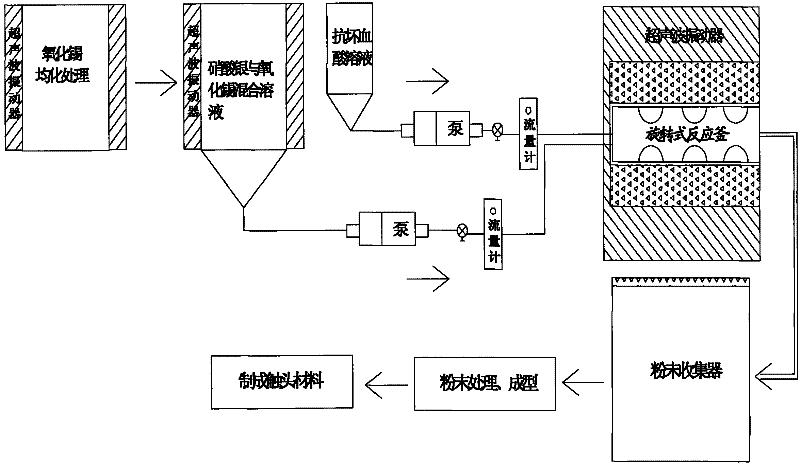

Method used

Image

Examples

Embodiment 1

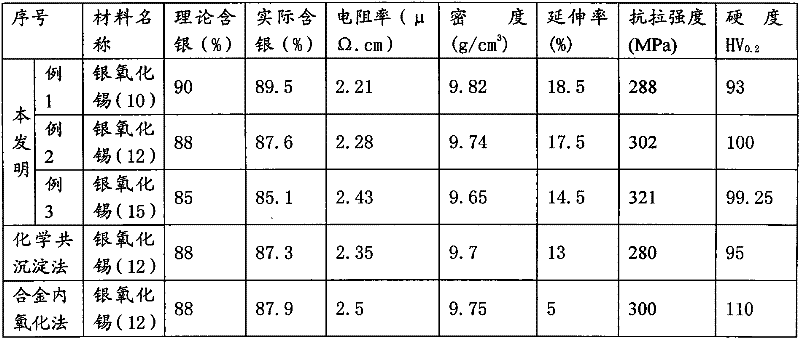

[0007] Embodiment 1: Preparation of silver tin oxide (10) material

[0008] (1) Weigh 0.762 kg of tin oxide powder with a particle size of 1-2 um to prepare a slurry, add an activator, turn on the ultrasonic vibrator, and perform homogenization treatment for 10-20 minutes. Finally, the concentration of the prepared slurry is 30%.

[0009] (2) Weigh 10 kilograms of silver nitrate crystals and prepare a silver nitrate solution with a concentration of 5%. At the same time, the tin oxide slurry is added to the silver nitrate solution and stirred by an ultrasonic vibrator for 30 minutes to form a uniform mixed solution.

[0010] (3) Prepare an appropriate amount of 2% ascorbic acid solution.

[0011] (4) Simultaneously extract the mixed solution of silver nitrate and tin oxide and ascorbic acid solution in the storage tank through two pumps, use a valve to control the flow rate of 300L / h, and transport it to the reactor from the left side of the reactor at the same time, and react...

Embodiment 2

[0018] Embodiment 2: Preparation of silver tin oxide (12) material

[0019] (1) Weigh 1.361 kg of tin oxide powder with a particle size of 3-5 um to prepare a slurry, add an activator, turn on the ultrasonic vibrator, and perform homogenization treatment for 10-20 minutes. Finally, the concentration of the prepared slurry is 25%.

[0020] (2) Take by weighing 15 kilograms of silver nitrate crystals, prepare a silver nitrate solution with a concentration of 4%, add the tin oxide slurry into the silver nitrate solution, and stir for 30 minutes by an ultrasonic vibrator to make a uniform mixed solution.

[0021] (3) Prepare an appropriate amount of 5% ascorbic acid solution.

[0022] (4) remaining process is identical with embodiment 1.

[0023] The chemical composition of the product was tested, and the average silver content was 87.6%. The metallographic examination and processing performance analysis of the wire rod showed that the prepared wire rod product also had good st...

Embodiment 3

[0024] Embodiment 3: Preparation of silver tin oxide (15) material

[0025] (1) Weigh 0.9 kg of tin oxide powder with a particle size of 4-6 um to prepare a slurry, add an activator, turn on the ultrasonic vibrator, and perform homogenization treatment for 10-20 minutes. Finally, the concentration of the prepared slurry is 20%.

[0026] (2) Weigh 8 kg of silver nitrate crystals and prepare it as a silver nitrate solution with a concentration of 4%. At the same time, the tin oxide slurry is added to the silver nitrate solution and stirred by an ultrasonic vibrator for 30 minutes to form a uniform mixed solution.

[0027] (3) Prepare an appropriate amount of 5% ascorbic acid solution.

[0028] (4) remaining process is identical with embodiment 1.

[0029] The chemical composition of the product was tested, and the average silver content was 85.1%. The metallographic examination of the wire rod shows that compared with Example 1 and Example 2, the proportion of oxides containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com