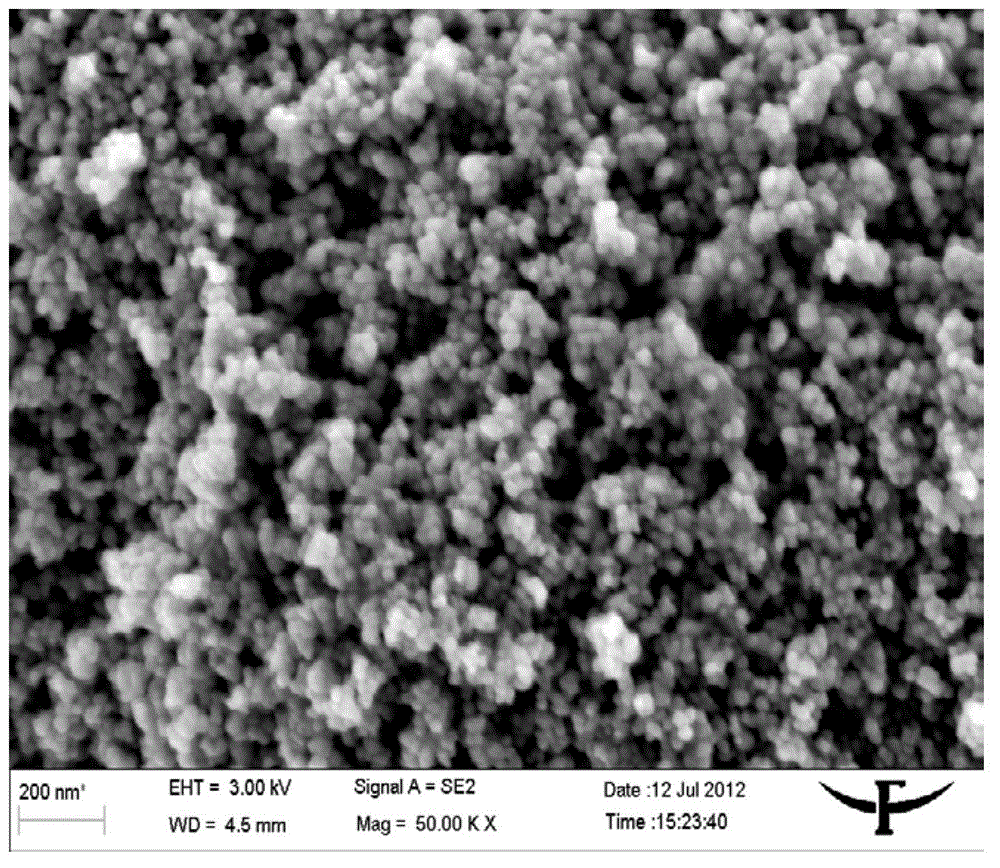

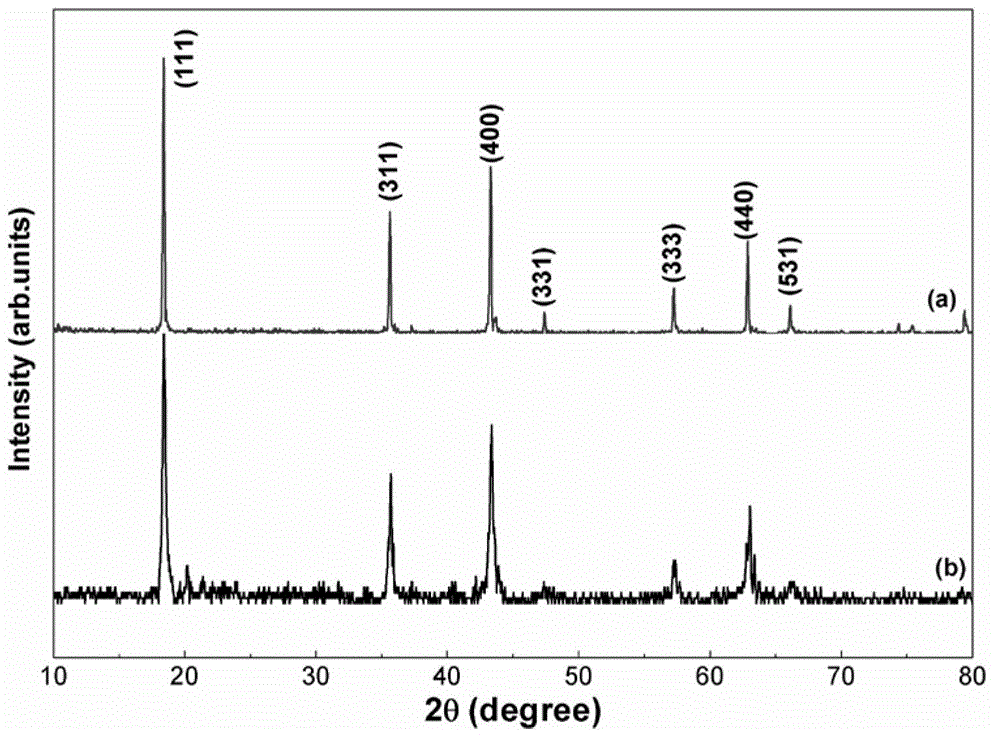

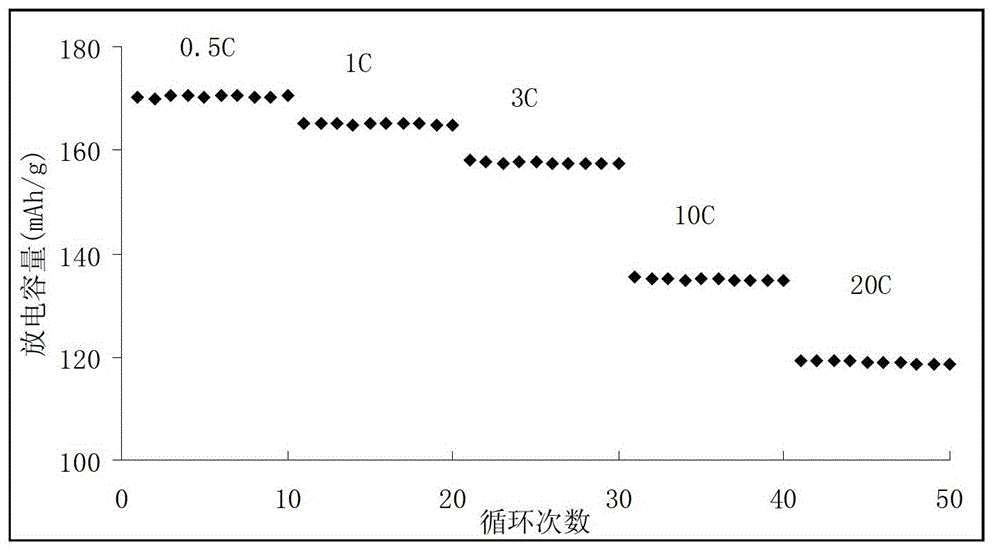

Method for preparing carbon-coated nano-particle lithium titanate electrode material

A microsphere lithium titanate, electrode material technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of affecting high-rate charge and discharge performance, poor electronic conduction, low electronic conductivity, etc., to achieve easy control. and automatic operation, excellent electrochemical performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the carbon-coated nano-microsphere lithium titanate electrode material of the present embodiment comprises the following steps:

[0031] 1) Preparation of raw material solution: weigh lithium carbonate and nano-TiO according to the molar ratio of 1:1:10 2 And polyethylene glycol, add deionized water, be mixed with the mixed solution of mass fraction 7%;

[0032] 2) Spray drying: Use ammonia water to adjust the pH of the mixed solution obtained in step 1) to 7.0, keep it warm at 40°C, and continue stirring at 300rpm for 1h, pass through a spray dryer, and spray dry at 150°C to obtain polyethylene glycol-coated Nano-microsphere lithium titanate precursor, drying the pre-coated precursor in a vacuum oven at 120°C for 4 hours to obtain the precursor powder;

[0033] 3) Sintering: Sinter the precursor powder obtained in step 2) in an atmosphere rotary furnace under the protection of high-purity nitrogen, control the temperature at 100°C, sinter for...

Embodiment 2

[0036] The preparation method of the carbon-coated nano-microsphere lithium titanate electrode material of the present embodiment comprises the following steps:

[0037] 1) Preparation of raw material solution: weigh lithium citrate and nano-TiO according to the molar ratio of 1:1:5 2 And polypropanol, add in dehydrated ethanol, be mixed with the mixed solution of mass fraction 5%;

[0038] 2) Spray drying: Use ammonia water to adjust the pH of the mixed solution obtained in step 1) to 8.0, keep it warm at 30°C, and continue stirring at 300rpm for 1.5h, and spray dry it through a spray dryer at 180°C to obtain polypropanol-coated nano Microspherical lithium titanate precursor, drying the pre-coated precursor in a vacuum oven at 120°C for 3 hours to obtain the precursor powder;

[0039] 3) Sintering: Sinter the precursor powder obtained in step 2) in an atmosphere rotary furnace under the protection of high-purity nitrogen, control the temperature at 200°C, sinter for 2 hours,...

Embodiment 3

[0041] The preparation method of the carbon-coated nano-microsphere lithium titanate electrode material of the present embodiment comprises the following steps:

[0042]1) Preparation of raw material solution: weigh lithium nitrate and nano-TiO according to the molar ratio of 1:1:20 2 And polyglycolic acid, add in the mixed solution of deionized water and dehydrated alcohol, be mixed with the mixed solution of mass fraction 10%;

[0043] 2) Spray drying: use ammonia water to adjust the pH of the mixed solution obtained in step 1) to 7.0, keep it warm at 20°C, and continue stirring at 300rpm for 2h, pass through a spray dryer, and spray dry at 200°C to obtain polyglycolic acid-coated nanoparticles. Microspherical lithium titanate precursor, drying the pre-coated precursor in a vacuum oven at 120°C for 2 hours to obtain the precursor powder;

[0044] 3) Sintering: Sinter the precursor powder obtained in step 2) in an atmosphere rotary furnace under the protection of high-purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com