Lithium ion power battery and preparation method thereof

A technology for lithium-ion batteries and power batteries, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve problems such as low conductivity, limited lithium ion migration rate, and low lithium ion migration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

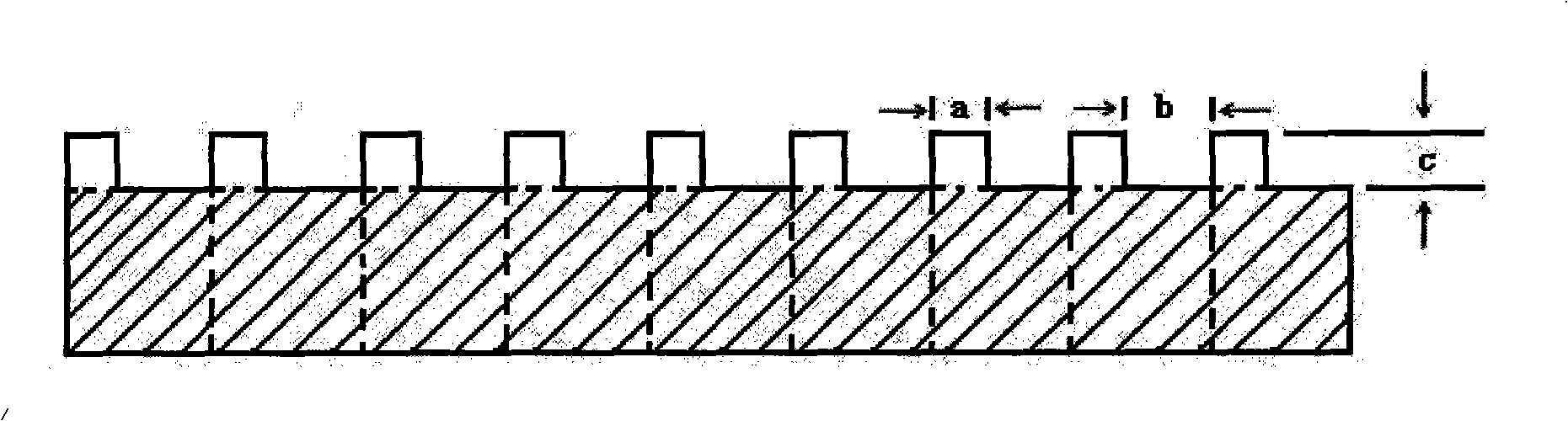

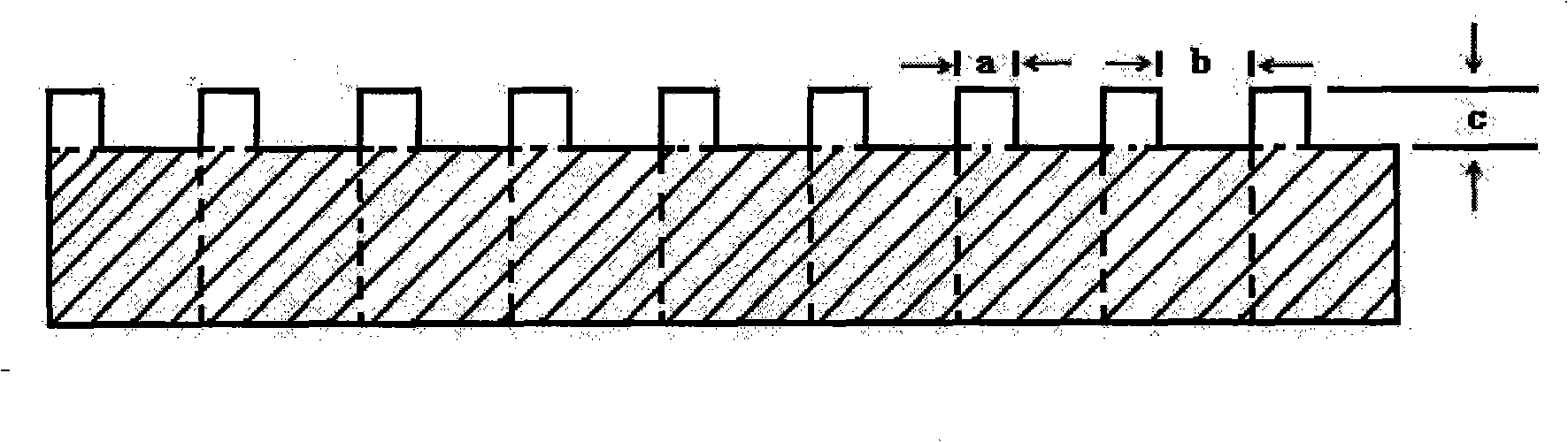

[0017] 1) Take 94% doped Mn, La cations and F anions by mass percentage and surface carbon-coated modified LiFePO 4 , 3% carbon nanofibers, 3% water-soluble binder (the mixture of CMC and AMAC mixed in a mass ratio of 1:1), wherein, LiFePO 4 The mass percent content of doping elements Mn, La, F and surface-coated carbon are respectively LiFePO 4 0.33%, 0.67%, 0.23% and 4% of the total. After adding deionized water and stirring evenly, coat on the aluminum foil, leave 15mm uncoated aluminum foil on one side during the coating process, dry and roll continuously; then roll cut the uncoated aluminum foil continuously to form a continuous Square-wave current collectors with single-sided current collectors (see figure 1 ) to make a positive electrode sheet; in this example, the width a of the unilateral current collector is 8mm, the spacing b is 20mm, and the height c is 15mm.

[0018] 2) Weigh the artificial graphite and water-soluble binder CMC according to the mass ratio of 95...

Embodiment 2

[0021] 1) Take 96% doped Mn, La cations and F anions by mass percentage and surface carbon-coated modified LiFePO 4 , 2% carbon nanofibers, 2% water-soluble binder (the mixture of CMC and AMAC mixed in a mass ratio of 1:1), wherein, LiFePO 4 The mass percent content of doping elements Mn, La, F and surface-coated carbon are respectively LiFePO 4 0.33%, 0.67%, 0.23% and 4% of the total. After adding deionized water and stirring evenly, coat it on the aluminum foil, leave 13mm uncoated aluminum foil on one side during the coating process, dry and roll continuously; then roll cut the uncoated aluminum foil continuously to form a continuous Square-wave current collectors with single-sided current collectors (see figure 1 ) to make a positive electrode sheet; in this example, the width a of the unilateral current collector is 5mm, the spacing b is 15mm, and the height c is 13mm.

[0022] 2) Weigh the artificial graphite and water-soluble binder CMC according to the mass ratio of...

Embodiment 3

[0025] 1) Take 98% doped Mn, La cations and F anions by mass percentage and surface carbon-coated modified LiFePO 4 , 1% carbon nanofiber, 1% water-soluble binder (the mixture of CMC and AMAC mixed in a mass ratio of 1:1), wherein, LiFePO 4 The mass percent content of doping elements Mn, La, F and surface-coated carbon are respectively LiFePO 4 0.33%, 0.67%, 0.23% and 4% of the total. After adding deionized water and stirring evenly, coat on the aluminum foil, leave 15mm uncoated aluminum foil on one side during the coating process, dry and roll continuously; then roll cut the uncoated aluminum foil continuously to form a continuous Square-wave current collectors with single-sided current collectors (see figure 1 ) to make a positive electrode sheet; in this example, the width a of the unilateral current collector is 3mm, the spacing b is 10mm, and the height c is 10mm.

[0026] 2) Weigh the artificial graphite and water-soluble binder CMC according to the mass ratio of 95:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com