Three-dimensional lithium ion battery and preparation method

A lithium-ion battery, three-dimensional technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of restricting the development of two-dimensional flat-electrode lithium-ion batteries, short cycle life, poor rate performance, etc. Charge and discharge requirements, sufficient active material properties, and the effect of increasing the conductive interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

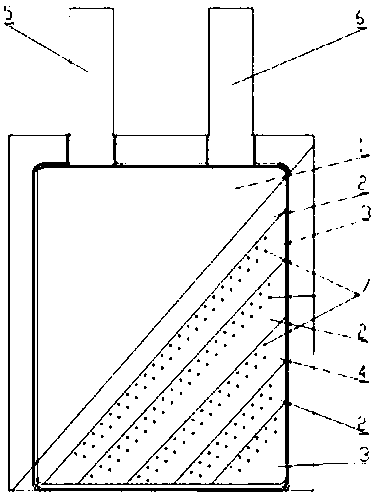

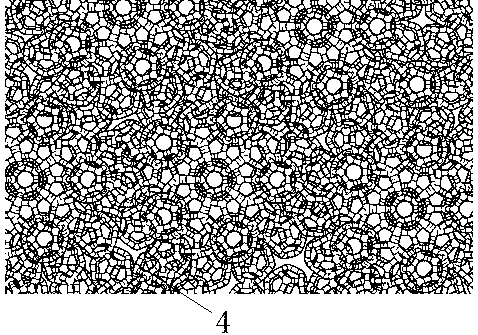

[0029] A, positive electrode sheet 4 preparation method:

[0030] A1. Add 97% nickel-cobalt-aluminate lithium (NCA), positive electrode additive nano-Al 2 o 3 1%, 1% positive electrode conductive agent, 1% positive electrode binder by weight, add to the mixer barrel and mix evenly, then add N-methylpyrrolidone (NMP) according to the weight of 40% solid content, stir and mix evenly to prepare positive electrode slurry material;

[0031] A2, and then use a coating machine, the positive electrode slurry according to 40mg / cm 2 The surface density weight is uniformly coated on the three-dimensional foam porous aluminum foil with a thickness of 0.1mm, a pore diameter of 0.05mm, and a porosity of 80%, and is dried in a coating machine oven to prepare a positive electrode sheet with uniform surface density and thickness.

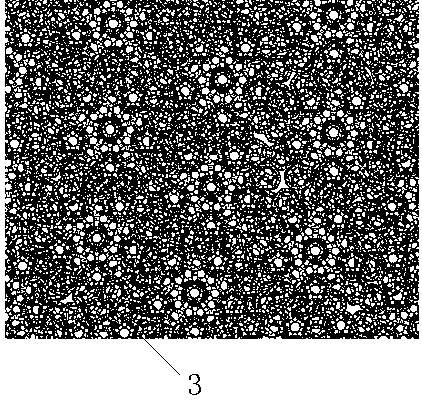

[0032] B, preparation method of negative electrode sheet 3:

[0033] B1. Add 95% silicon-carbon anode material (Si-C), and anode additive nano-Al 2 o 3 1%, 1%...

Embodiment 2

[0037] A, positive electrode sheet 4 preparation method:

[0038] A1. Add 94% nickel-cobalt-manganese-manganese oxide (NCM), positive electrode additive nano-Al 2 o 3 1.5%, positive electrode conductive agent 2%, positive electrode binder 2.5% by weight, add to the mixer barrel and mix evenly, then add N-methylpyrrolidone (NMP) according to the weight of 55% solid content, stir and mix evenly to prepare positive electrode slurry material;

[0039] A2, and then use a coating machine, the positive electrode slurry according to 50mg / cm 2 The areal density weight is uniformly coated on a three-dimensional foamed porous aluminum foil with a thickness of 2mm, a pore diameter of 5mm, and a porosity of 50%, and is dried in a coating machine oven to prepare a positive electrode sheet 4 with uniform areal density and thickness.

[0040] B, preparation method of negative electrode sheet 3:

[0041]B1. The silicon-oxygen negative electrode material (SiO) is 93.5%, and the negative ele...

Embodiment 3

[0045] A, positive electrode sheet 4 preparation method:

[0046] A1. Mix 90% of the mixture of nickel-cobalt-lithium-aluminate (NCA) and nickel-cobalt-lithium-manganate (NCM) at a ratio of 1:1, and the positive electrode additive nano-Al 2 o 3 2%, positive electrode conductive agent 3%, positive electrode binder 5% proportioning weight into the mixer barrel and mix evenly, then add N-methylpyrrolidone (NMP) according to the weight of 68% solid content, stir and mix evenly to prepare positive electrode slurry material;

[0047] A2, and then use a coating machine, the positive electrode slurry according to 60mg / cm 2 The areal density weight is evenly coated on the three-dimensional foamed porous aluminum foil with a thickness of 5mm, a pore diameter of 10mm, and a porosity of 30%, and is dried in a coating machine oven to prepare a positive electrode sheet 4 with uniform areal density and thickness.

[0048] B, preparation method of negative electrode sheet 3:

[0049] B1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com