Preparation method of carbon-coated lithium titanate composite material for lithium ion power battery

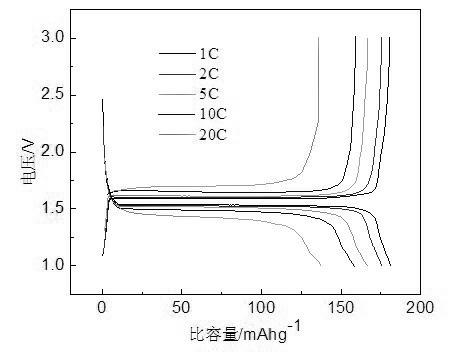

A power battery and lithium titanate-coated technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor electronic conductivity, poor rate performance, and severe polarization, and achieve low production costs and stable cycle performance , The effect of high charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

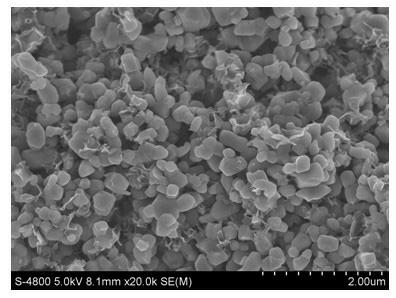

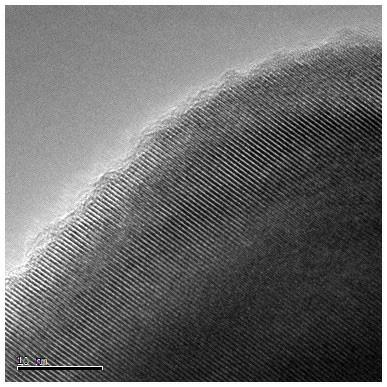

Image

Examples

Embodiment 1

[0016] 1. Using needle coke as raw material, the amphiphilic carbon material was prepared by a general known preparation method. The specific preparation process was as follows: 100 mL of mixed acid (concentrated nitric acid with a mass concentration of 65% and concentrated sulfuric acid with a mass concentration of 98% by volume ratio of 3:7) heated to 80°C, stirred at a stirring rate of 300r / min, added 10g of needle coke, reacted for 1h, poured the reactant into 1L of deionized water to terminate the reaction, and filtered it with a vacuum filtration device to obtain The filter cake was washed with deionized water until neutral; the obtained solid matter was added to 500ml of NaOH solution with a concentration of 1mol / L, stirred at 80°C at a speed of 300r / min for 1h, and filtered under reduced pressure. The pH value of the solution is always greater than 12; collect the filtrate, add 1mol / L HCl dropwise to the obtained filtrate, and adjust the pH value to 1, at this time, a p...

Embodiment 2

[0020] 1. The difference is that the initial raw material is coal tar pitch. The coal tar pitch-based amphiphilic carbon material is prepared according to the method in step 1 of Example 1.

[0021] 2. Dissolve 2.4g of the coal tar pitch-based amphiphilic carbon material prepared in step 1 in 300ml of deionized water, add 1 drop of ammonia water to make the solution alkaline, add 30g of lithium titanate powder, and heat up to 90°C at 200r / min After stirring for 5 hours at a certain stirring speed, the water was evaporated to dryness, and then dried in an oven at 100°C for 24 hours. The obtained composite material was placed in a high-temperature carbonization furnace, and under the protection of nitrogen, the temperature was raised to 700°C at a heating rate of 5°C / min, and after being kept for 4 hours, it was naturally cooled to room temperature to obtain an amphiphilic carbon material coated lithium titanate Composite electrode material.

[0022] 3. Mix 0.8g of the composit...

Embodiment 3

[0024] 1. The difference is that the initial raw material is petroleum coke, and the petroleum coke-based amphiphilic carbon material is prepared according to the method of step 1 of Example 1.

[0025] 2. Dissolve 1.6g of the petroleum coke-based amphiphilic carbon material prepared in step 1 in 200ml of deionized water, add 1 drop of ammonia water to make the solution alkaline, add 20g of lithium titanate powder, heat up to 85°C at 200r / min After stirring for 5 hours at a certain stirring rate, the water was evaporated to dryness, and then dried in an oven at 120°C for 18 hours. The obtained composite material was placed in a high-temperature carbonization furnace, and under the protection of nitrogen, the temperature was raised to 1000°C at a heating rate of 5°C / min, and after being kept for 0.5h, it was naturally cooled to room temperature to obtain amphiphilic carbon material coated titanic acid Lithium composite electrode material.

[0026] 3. Mix 0.8g of the composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com