Preparation method of flower-like lithium titanate-titanium dioxide composite electrode material

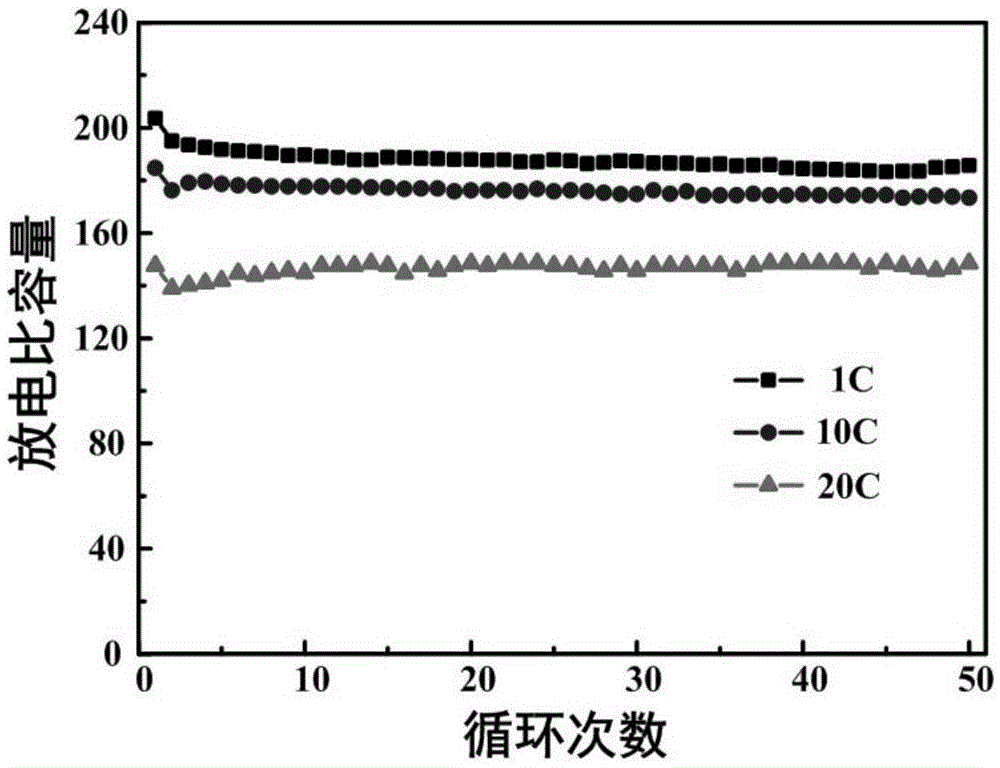

A composite electrode and flower-shaped technology, applied in the field of new energy materials, can solve the problems of fast capacity decay, low specific capacity, poor rate performance, etc., and achieve the effect of short diffusion path, high specific capacity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] a. Under magnetic stirring, add potassium titanium oxalate into n-hexane to form a uniform solution, so that the concentration of titanium ions in it is 0.1mol / L;

[0039] B. Take sodium lauryl sulfate and dissolve it in deionized water, so that the concentration of sodium lauryl sulfate is 0.023mol / L;

[0040] C, take by weighing lithium oxalate, be dissolved in the aqueous solution of step (b) gained under magnetic stirring, make wherein the concentration of lithium ion be 0.07mol / L;

[0041] d. Under magnetic stirring, slowly add the lithium-containing aqueous solution obtained in step (c) to the titanium-containing solution obtained in step (a);

[0042] e. Transfer the mixed solution obtained in step (d) to a polytetrafluoroethylene-lined stainless steel reaction kettle, seal it, place it in an oven, and react at 100° C. for 72 hours.

[0043] f. After the reaction, cool to room temperature, wash the obtained white precipitate several times with deionized water an...

Embodiment 2

[0046] a. Under magnetic stirring, add butyl titanate to toluene to form a uniform solution, so that the concentration of titanium ions in it is 0.28mol / L;

[0047] b. Take cetyltrimethylammonium bromide and dissolve it in deionized water, so that the concentration of cetyltrimethylammonium bromide is 0.55mol / L;

[0048] c, take lithium acetate and lithium hydroxide, dissolve in the aqueous solution of step (b) gained under magnetic stirring, make wherein the concentration of lithium ion be 1.2mol / L;

[0049] d. Under magnetic stirring, slowly add the lithium-containing aqueous solution obtained in step (c) to the titanium ion-containing solution obtained in step (a);

[0050] e. Transfer the mixed liquid obtained in step (d) to a polytetrafluoroethylene-lined stainless steel reaction kettle, seal it, place it in an oven, and react at 110° C. for 60 hours.

[0051] f. After the reaction, cool to room temperature, wash the obtained white precipitate several times with deionize...

Embodiment 3

[0054] a. Under magnetic stirring, add titanyl sulfate to propylene oxide to form a uniform solution, so that the concentration of titanium ions is 4mol / L;

[0055] b. Weigh the alkylphenol polyoxyethylene (10) ether and dissolve it in deionized water, so that the concentration of the alkylphenol polyoxyethylene (10) ether is 1mol / L;

[0056] c, take lithium hydroxide by weighing, be dissolved in the aqueous solution of step (b) gained under magnetic stirring, make wherein the concentration of lithium ion be 3.8mol / L;

[0057] d. Under magnetic stirring, slowly add the lithium-containing aqueous solution obtained in step (c) to the titanium-containing solution obtained in step (a);

[0058] e. Transfer the mixed solution obtained in step (d) to a polytetrafluoroethylene-lined stainless steel reaction kettle, seal it, place it in an oven, and react at 200° C. for 36 hours.

[0059] f. After the reaction, cool to room temperature, wash the obtained white precipitate several tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com