Lithium ion battery cathode material of anatase TiO2 mixed carbon nanotube

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle performance and rate charge-discharge performance, and achieve the first charge-discharge efficiency improvement, electrical conductivity improvement, and preparation. Simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

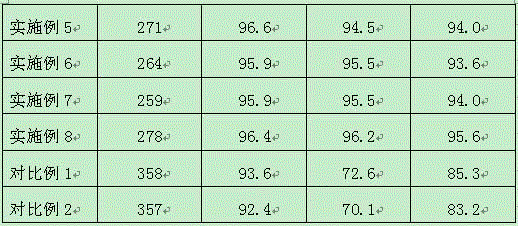

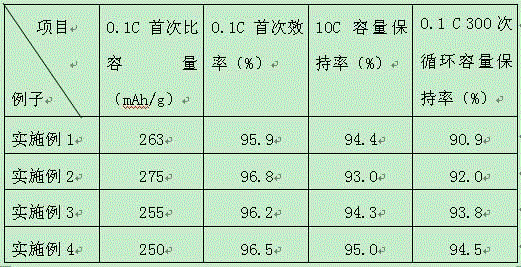

Examples

Embodiment 1

[0025] An anatase TiO 2 The lithium-ion battery negative electrode material mixed with carbon nanotubes is made of the following raw materials in parts by weight: anatase TiO 2 360, carbon nanotubes 50, graphite 45, gallium powder 6, cesium powder 4, lithium cobalt oxide 4, cerium oxide 2 and ammonium persulfate 2. The carbon nanotubes are single-wall carbon nanotubes, the diameter of the carbon nanotubes is 50 nm, and the tube length is 10 μm. Described graphite is natural graphite.

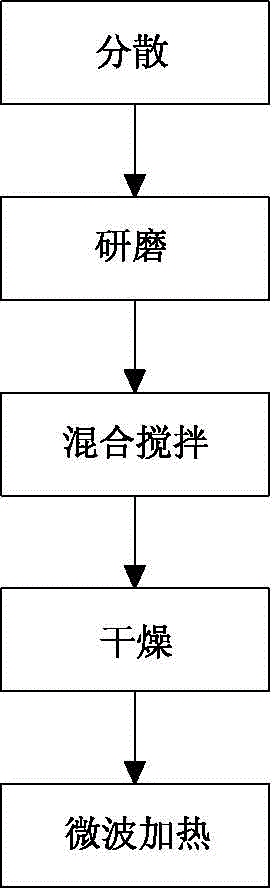

[0026] During preparation, the following steps are included:

[0027] (1) Dispersion: Anatase TiO 2 , graphite, gallium powder, cesium powder, lithium cobaltate, cerium oxide and ammonium persulfate are dispersed in a solvent, and ultrasonic 1h is obtained to obtain a mixed slurry;

[0028] (2) Grinding: Grind the mixed slurry with a sand mill for 2 h at a grinding speed of 1000 r / min, then add a solvent to adjust the solid mass content of the mixed slurry to 10%;

[0029] (3) Mixing and s...

Embodiment 2

[0033] An anatase TiO 2 The lithium-ion battery negative electrode material mixed with carbon nanotubes is made of the following raw materials in parts by weight: anatase TiO 2 390, carbon nanotubes 60, graphite 55, gallium powder 8, cesium powder 6, lithium cobalt oxide 6, cerium oxide 4 and ammonium persulfate 3. The carbon nanotubes are double-walled carbon nanotubes, the diameter of the carbon nanotubes is 80 nm, and the length of the carbon nanotubes is 25 μm. The graphite is artificial graphite.

[0034] During preparation, the following steps are included:

[0035] (1) Dispersion: Anatase TiO 2 , graphite, gallium powder, cesium powder, lithium cobaltate, cerium oxide and ammonium persulfate are dispersed in a solvent, and ultrasonicated for 3 hours to obtain a mixed slurry;

[0036] (2) Grinding: Grind the mixed slurry with a sand mill for 4 h at a grinding speed of 2200 r / min, then add a solvent to adjust the solid mass content of the mixed slurry to 30%;

[003...

Embodiment 3

[0041] An anatase TiO 2 The lithium-ion battery negative electrode material mixed with carbon nanotubes is made of the following raw materials in parts by weight: anatase TiO2 375, carbon nanotubes 55, graphite 50, gallium powder 7, cesium powder 5, lithium cobaltate 5, cerium oxide 3 and ammonium persulfate 2.5. The carbon nanotubes are multi-walled carbon nanotubes, the diameter of the carbon nanotubes is 65 nm, and the tube length is 17.5 μm. The graphite is a mixture of natural graphite and artificial graphite.

[0042] During preparation, the following steps are included:

[0043] (1) Dispersion: Anatase TiO 2 , graphite, gallium powder, cesium powder, lithium cobaltate, cerium oxide and ammonium persulfate were dispersed in the solvent, and ultrasonically 2.5h to obtain a mixed slurry;

[0044] (2) Grinding: Grind the mixed slurry with a sand mill for 3 h at a grinding speed of 1600 r / min, then add solvent to adjust the solid mass content of the mixed slurry to 20%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com