Hard carbon composite material, as well as preparation method and application thereof

A composite material and hard carbon technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of active lithium consumption, low first coulombic efficiency and cycle performance of lithium-ion batteries, and achieve improved stability and improved first coulombic efficiency And cycle performance, the effect of improving the rate charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

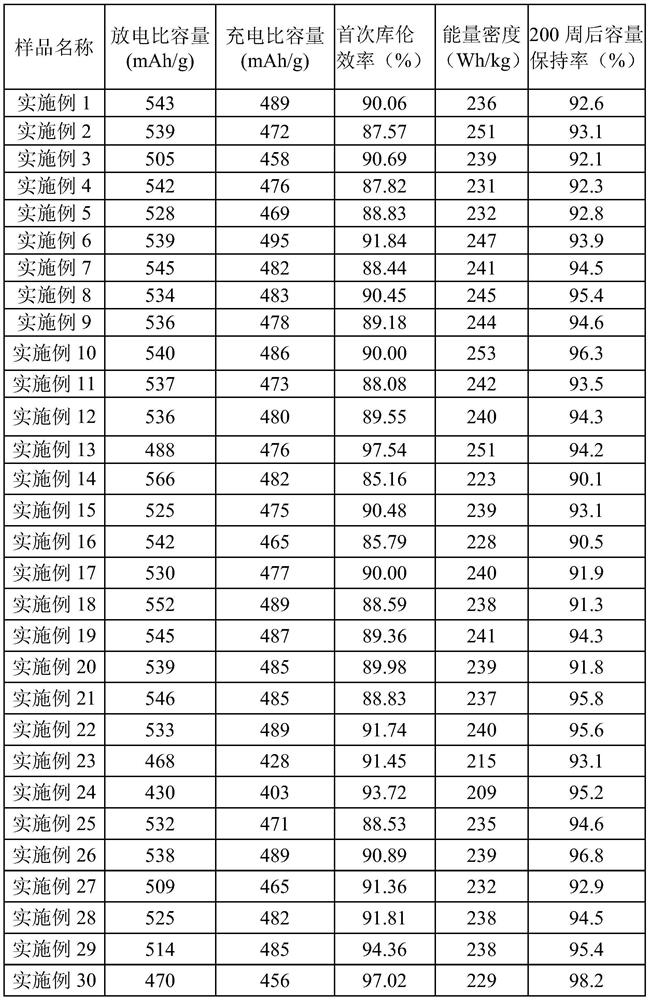

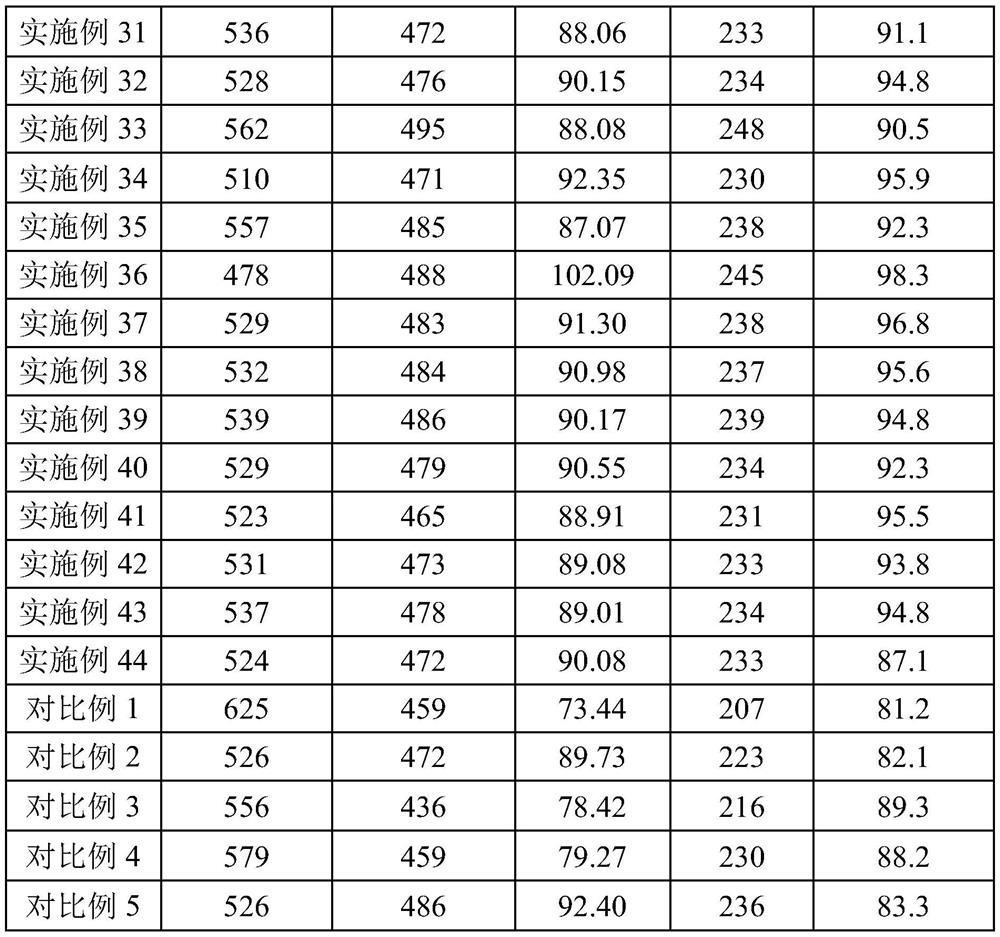

Examples

preparation example Construction

[0039] A second aspect of the present invention provides a method for preparing a hard carbon composite material, comprising the following steps:

[0040] 1) heat-treating the first carbon-containing material to obtain a hard carbon precursor;

[0041] 2) Carrying out carbonization treatment on the hard carbon precursor to obtain the hard carbon material;

[0042] 3) in a sealed ball mill containing an inert gas, the hard carbon material, the second carbonaceous material and metal lithium are ball milled to obtain an intermediate hard carbon material;

[0043] 4) Coating the intermediate hard carbon material to obtain a hard carbon composite material; the coating material in the coating treatment includes at least the third carbonaceous material.

[0044] It can be understood that the preparation method of the hard carbon composite material of the present invention may specifically include the following steps: 1) screening, cleaning, drying and pulverizing the first carbonace...

Embodiment 1

[0097] The preparation method of the hard carbon composite material of the present embodiment comprises the following steps:

[0098] 1) 100g sucrose (the first carbon-containing material) is heat-treated under air atmosphere to obtain a hard carbon precursor;

[0099] Wherein, the temperature of heat treatment is 250°C, and the time of heat treatment is 12h;

[0100] 2) the hard carbon precursor obtained in step 1) is pulverized, and in an Ar atmosphere, the pulverized hard carbon precursor is carbonized to obtain a hard carbon material;

[0101] Wherein, the D50 of the pulverized hard carbon precursor is 20 μm, the temperature of the carbonization treatment is 750° C., and the time of the carbonization treatment is 5 hours;

[0102] 3) in a sealed ball mill filled with argon, the hard carbon material, lithium metal and conductive carbon black obtained in step 2) are ball milled to obtain an intermediate hard carbon material;

[0103] Wherein, the mass ratio of hard carbon ...

Embodiment 2

[0107] The preparation method of the hard carbon composite material of this embodiment is basically the same as that of Example 1, the only difference being that the first carbonaceous material in step 1) is bagasse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com