Coal-based composite negative electrode material used for power lithium ion battery and preparation method of composite negative electrode material

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficulty in meeting the high demand for energy density of power lithium-ion batteries, easy corrosion and purification of equipment, and unfavorable industrialization. The effect of easy control of process conditions, low production cost and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

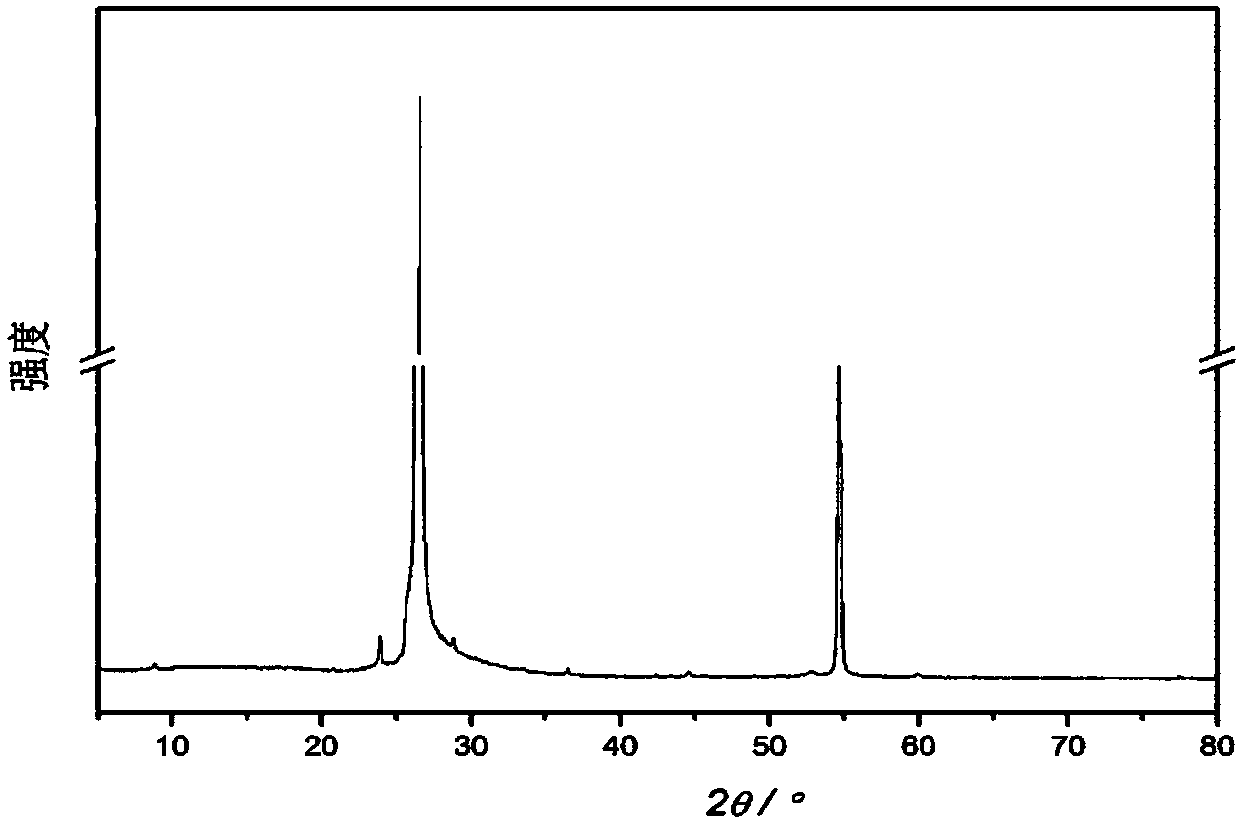

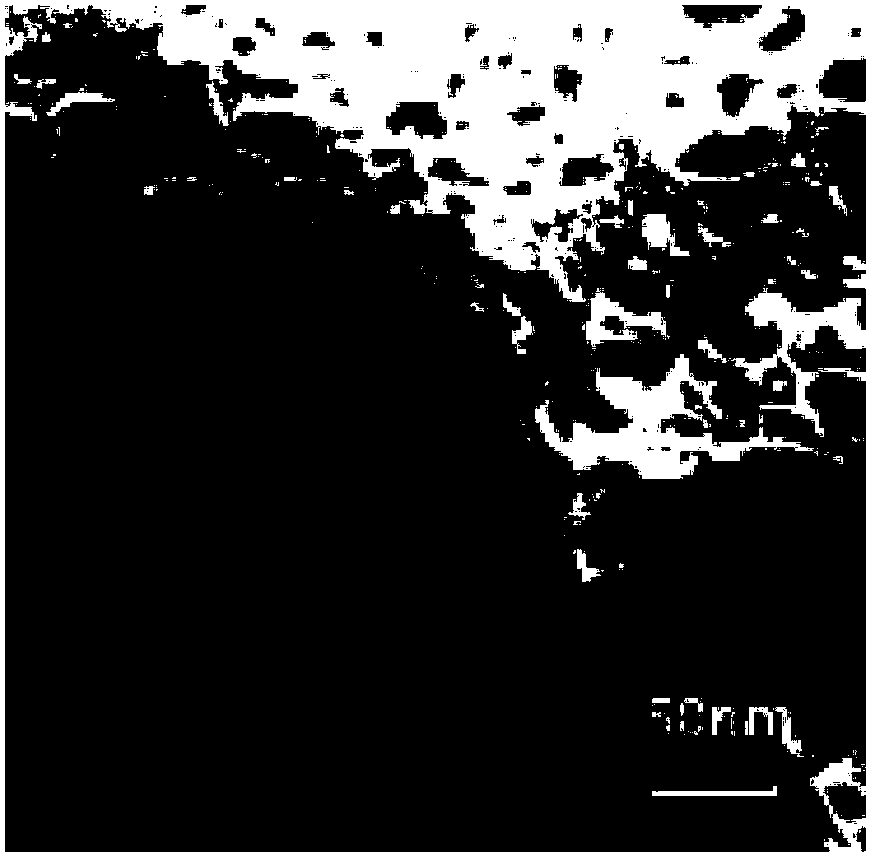

[0035] In the preparation method of the coal-based composite negative electrode material for power lithium-ion batteries of the present invention, the matrix uses Ningxia Taixi coal as a raw material, and under the action of light metal halide salt purification additives and carbonizable binders, it undergoes crushing and shaping, batching, compacting, High-temperature graphitization prepares a high-purity secondary particle coal-based negative electrode material precursor, which is then pulverized and sieved, and then combined with soluble phenolic resin, ethoxy and propoxy under the action of an alcohol solvent The amphoteric triblock copolymer pore-forming additive liquid phase is uniformly dispersed, and after solidification and pyrolysis treatment, a coal-based composite negative electrode material for power lithium-ion batteries with a mesoporous carbon-coated matrix is finally prepared. The specific steps are:

[0036] 1. Crush

[0037] At room temperature (20° C.), ...

Embodiment 1

[0073] 1. Crush

[0074] The anthracite Ningxia Taixi coal was pulverized into anthracite fine powder with an average particle diameter D50 of 2.0 μm by a universal pulverizer.

[0075] 2. Ingredients mixing

[0076] Weigh 1000g of anthracite micropowder, 20.0g of furan resin, and 10.0g of sodium chloride, respectively, and add them to a drum mixer at a heating rate of 0°C / min and a rotation speed of 1100rpm, and mix at 25°C for 180min to obtain a mixed material.

[0077] 3. Compacted

[0078] Utilize a press to forge the mixed material at a pressure of 10MPa for 10h to obtain a green body with a diameter of 300×a height of 200mm.

[0079] 4. High temperature graphitization

[0080] Place the green body in an intermediate frequency induction graphitization furnace, and feed nitrogen with a flow rate of 1.0m 3 / h, at a heating rate of 5 °C / min, the temperature was raised to 2000 °C, graphitized for 9 h, cooled naturally in the furnace to room temperature, crushed and sieved...

Embodiment 2

[0088] 1. Crush

[0089] Anthracite Ningxia Taixi coal was pulverized into anthracite fine powder with an average particle diameter D50 of 3.0 μm by a universal pulverizer.

[0090] 2. Ingredients mixing

[0091] Weigh 1000g of anthracite micropowder, 56.0g of furan resin, and 23.0g of sodium fluoride, respectively, and add them to a conical mixer with a heating rate of 1°C / min and a rotation speed of 900rpm, and mix at 50°C for 150min to obtain a mixed material.

[0092] 3. Compacted

[0093] The mixed material was forged under a pressure of 28 MPa for 8 hours by a hydraulic press to obtain a green body with a diameter of 300×a height of 200 mm.

[0094] 4. High temperature graphitization

[0095] Place the green body in a medium frequency induction graphitization furnace, inject helium gas with a flow rate of 1.3m 3 / h, at a heating rate of 7 °C / min, the temperature was raised to 2200 °C, graphitized for 8 h, cooled naturally in the furnace to room temperature, crushed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com