Leadless tellurate low melting sealing glass

A technology of lead-free tellurite and low-melting glass, which is applied in the field of lead-free tellurate low-melting glass, can solve the problems that the application of low-melting sealing glass has not been reported, and achieve good hardness and chemical stability, and sintering temperature Low, good sealing strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

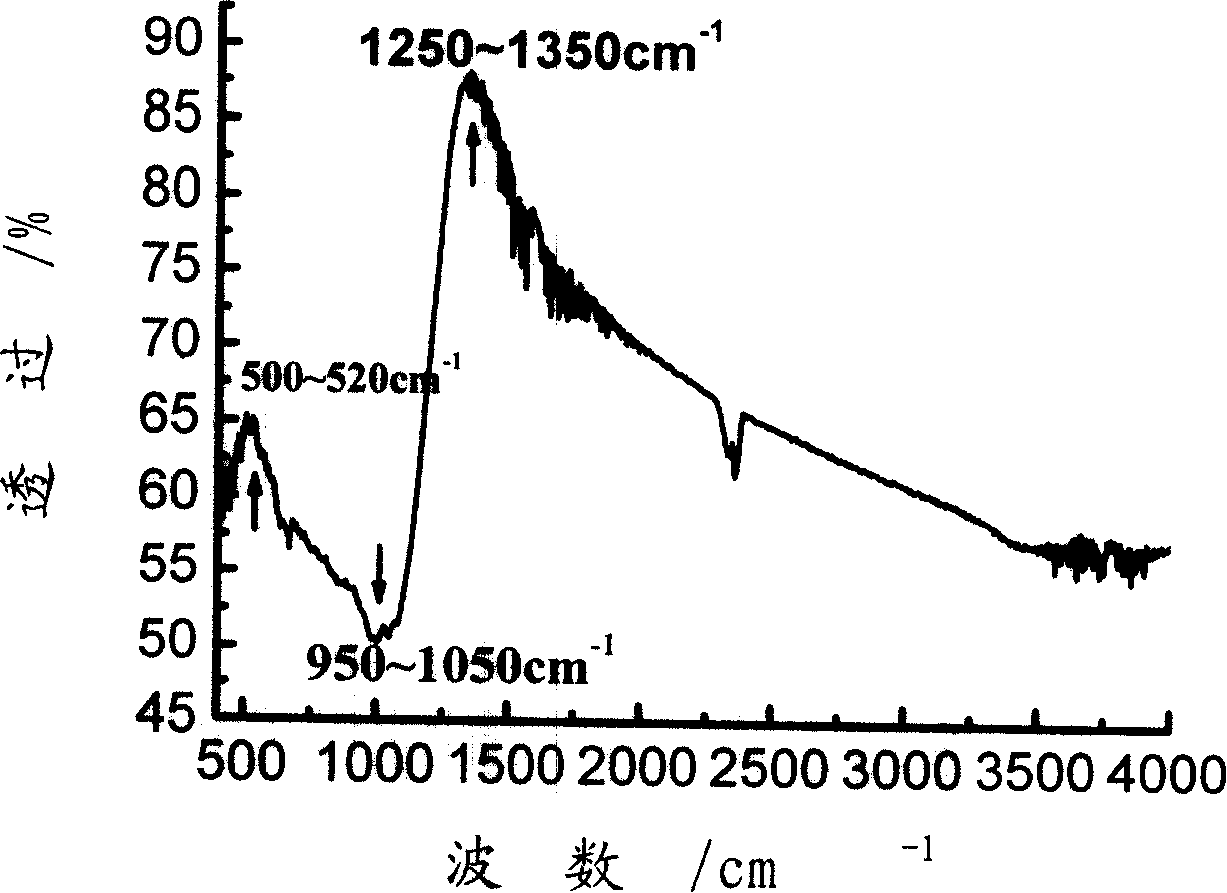

Image

Examples

Embodiment 1

[0029] The various raw materials in the glass composition use the corresponding industrial grade oxide or carbonate powder, and the glass composition is: TeO 2 85%, V 2 o 5 5%, Bi 2 o 3 3%, Sb 2 o 3 2%, Na 2 O 5%. Commercially available industrial-grade tellurium oxide, vanadium pentoxide, bismuth oxide, antimony oxide and sodium carbonate are ground, accurately measured according to the formula, and mixed evenly. Melt in an alumina crucible at 750°C for 30 minutes, and then pour and press the molten glass into thin sheets. After the glass flakes are ground, pass through a 200-mesh sieve for later use.

[0030] The glass transition temperature of the glass obtained by differential thermal analysis was 270°C.

[0031] Low-melting glass and ZrSiO 4Mixing evenly according to the mass ratio of 65:35 is the prepared sealing glass powder. The sealing glass has good fluidity when kept at 350°C, and the average thermal expansion coefficient of the sintered body from roo...

Embodiment 2

[0033] The various raw materials in the glass composition use the corresponding industrial grade oxide or carbonate powder, and the glass composition is: TeO 2 55%, V 2 o 5 30%, Bi 2 o 3 3%, B 2 o 3 1%, ZnO 2%, SnO 2 3%, Ag 2 O 2%, CaO 2%, BaO 2%. Grind commercially available industrial grade tellurium oxide, vanadium pentoxide, bismuth oxide, boric anhydride, zinc oxide, stannous oxide, silver oxide, calcium carbonate and barium carbonate, accurately measure according to the formula, and mix evenly. Melt in an alumina crucible at 850°C for 40 minutes, and then pour and press the molten glass into thin sheets. After the glass flakes are ground, pass through a 300-mesh sieve for later use.

[0034] The glass transition temperature of the glass obtained by differential thermal analysis was 323°C.

[0035] Low-melting glass and ZnSiO 4 Mixing evenly according to the mass ratio of 70:30 is the prepared sealing glass powder. The sealing glass has good fluidity when...

Embodiment 3

[0037] The various raw materials in the glass composition use the corresponding industrial grade oxide or carbonate powder, and the glass composition is: TeO 2 25%, V 2 o 5 25%, Bi 2 o 3 15%, Al 2 o 3 2%, SiO 2 2%, SnO 2 5%, BaO 5%, ZnO 8%, Sb 2 o 3 4%, MgO 2%, CaO 2%, Na 2 O 2%, K 2 O 3%. Commercially available industrial grade tellurium oxide, vanadium pentoxide, bismuth oxide, aluminum oxide, silicon oxide, zinc oxide, stannous oxide, antimony oxide, magnesium carbonate, barium carbonate, calcium carbonate, sodium carbonate, potassium carbonate , after accurate measurement according to the formula, mix well. Melt in a quartz crucible at 950°C for 50 minutes, and then pour the molten glass into clean water. After drying in an oven at 130°C, the glass particles were ground and passed through a 250-mesh sieve for use.

[0038] The glass transition temperature of the glass obtained by differential thermal analysis was 341°C.

[0039] Mix low-melting glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com