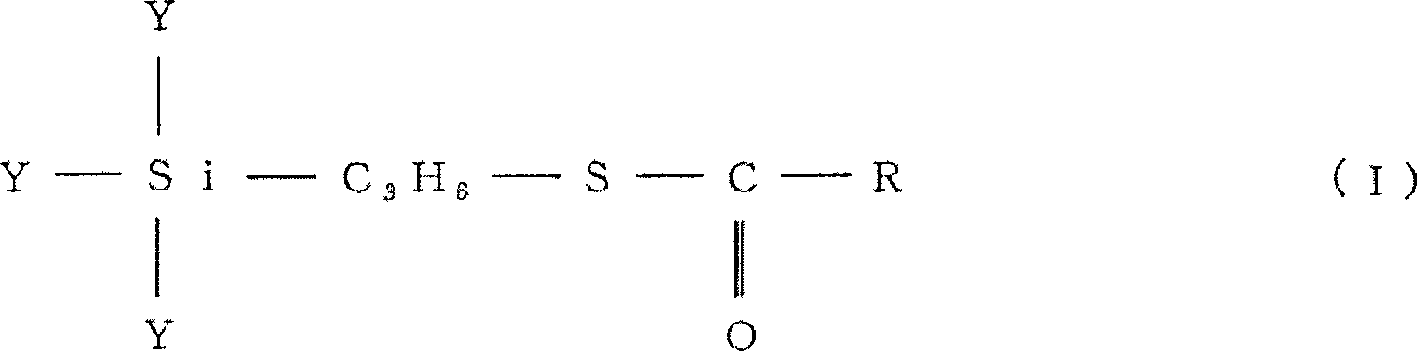

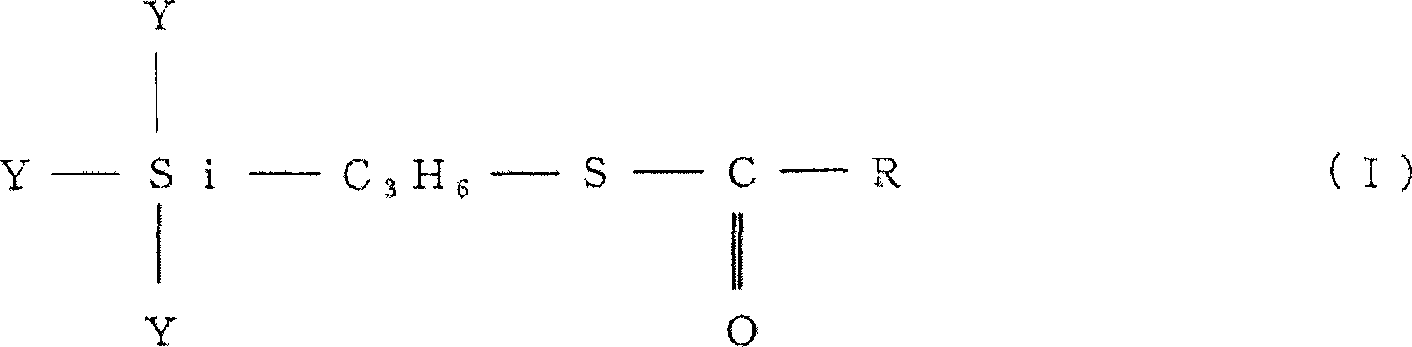

Silica treated with silane coupling agent and rubber composition containing same

A technology of silane coupling agent and rubber composition, which is applied in the treatment of silica, silicon oxide, and dyed organosilicon compounds, etc., and can solve the problems of wear resistance, reduced handling stability, coagulation, and increased viscosity of rubber compositions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Hereinafter, the present invention will be further described through examples, but it is not meant that the scope of the present invention is limited to these examples.

[0032] Standard example 1, embodiment 1~5 and comparative example 1~4

[0033] sample preparation

[0034] In the compounding shown in Table I, the components other than the vulcanization accelerator and sulfur were kneaded in a 3-liter internal mixer for 5 minutes, and released when the temperature reached 165±5°C to obtain a masterbatch. A vulcanization accelerator and sulfur were kneaded into this master batch in an open roll to obtain a rubber composition. Using this rubber composition, the unvulcanized property was evaluated by the following test method. The results are shown in Table I.

[0035] Next, the obtained rubber composition was vulcanized at 160° C. for 30 minutes in a mold of 15×15×0.2 cm to prepare a vulcanized rubber sheet, and the physical properties of the vulcanized rubber were ...

Embodiment 6

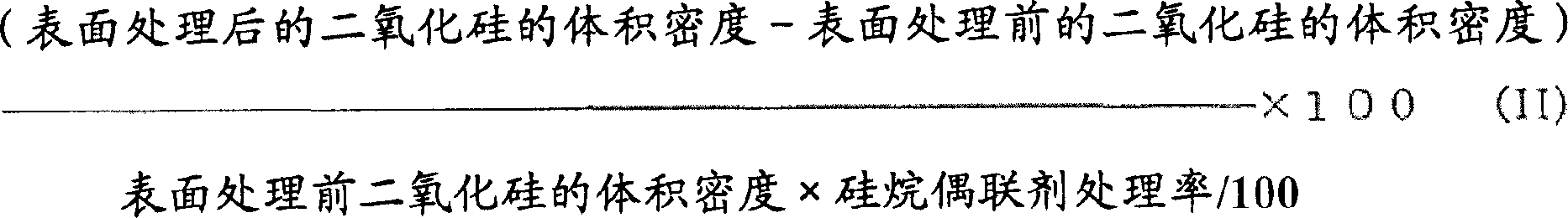

[0080] Example 6: 30g of 3-octanoylthiopropyltriethoxysilane (NXT silane) is slowly added to 300g of Nipsil AQ (Nippon Sirika Industry) stirred by a Henschel mixer to prepare a dry formula Surface treated silica particles. The silane coupling agent surface-treated silica particles were dried for 1 hour in an explosion-proof oven set at 150°C. The range of the bulk density retention was measured by the same method as Standard Example 2, and it was confirmed to be 95% to 98%. (handling method 2)

Embodiment 7

[0081] Example 7: Treatment The same treatment as in Example 6 was performed except that the silane coupling agent surface-treated silica particles in Example 6 were not dried in an explosion-proof furnace. The range of the bulk density retention was measured by the same method as Standard Example 2, and it was confirmed to be 96 to 99%. (treatment method 3) standard example 3, embodiment 8~12 and comparative example 6~9

[0082] sample preparation

[0083] In the formulation shown in Table III, the components other than the vulcanization accelerator and sulfur were kneaded in a 3-liter internal mixer for 5 minutes, and released when the temperature reached 165±5° C. to obtain a masterbatch. A vulcanization accelerator and sulfur were kneaded into this master batch in an open drum to obtain a rubber composition. Using this rubber composition, the unvulcanized property was evaluated by the test method described above. The results are shown in Table III.

[0084] Next, the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com