Lithium-containing composite oxide and process for its production

A composite oxide, manufacturing method technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve problems such as low output characteristics, and achieve the effect of excellent low temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

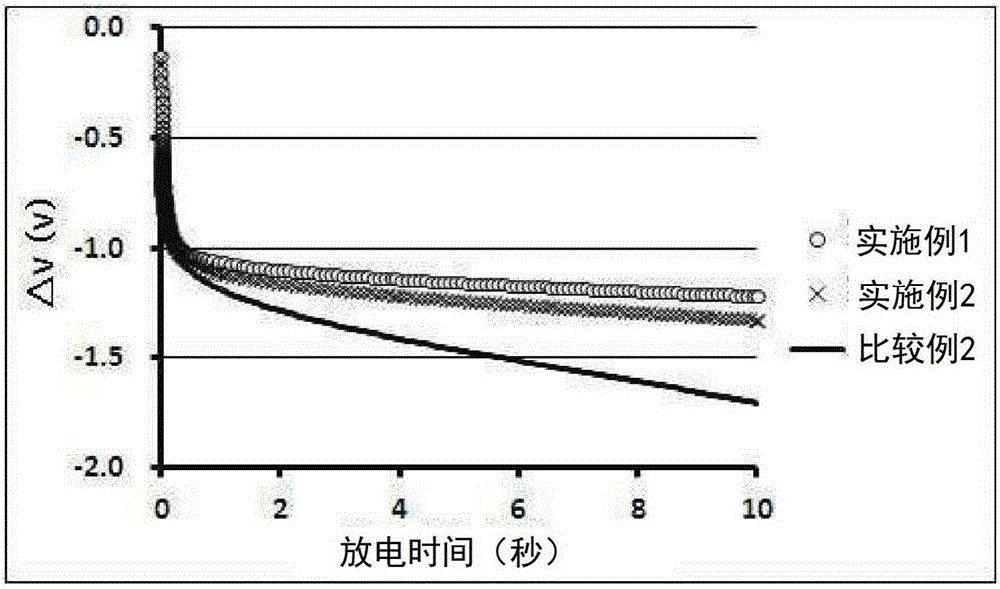

[0146] Hereinafter, examples of the present invention will be described. Examples 1-8 are examples of the present invention, and Examples 9-16 are comparative examples.

[0147] Various physical properties of the composite hydroxides and lithium-containing composite oxides used as precursors were measured by the following methods. Table 1 shows the physical properties of the composite hydroxide which is the precursor of the lithium-containing composite oxide, and Tables 2 and 3 show the physical properties of the lithium-containing composite oxide.

[0148]

[0149] The composition ratio of the metal components contained in the composite hydroxide and the lithium-containing composite oxide was measured by ICP analysis. The composition ratio (p, x, y, z, q) of the lithium-containing composite oxide in Table 2 is Li p Ni x co y mn z Zr q o 2 represents the coefficient of the chemical formula.

[0150]

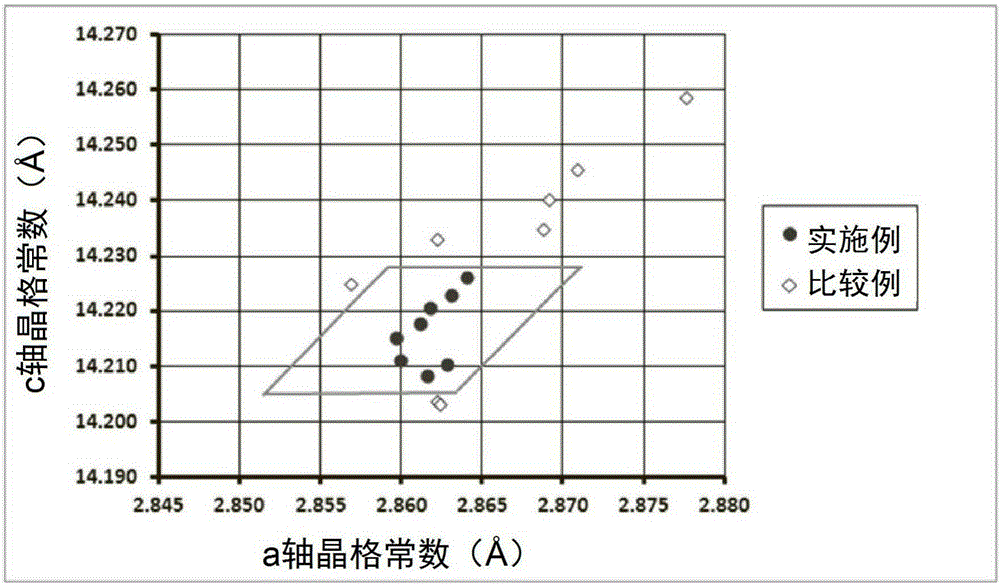

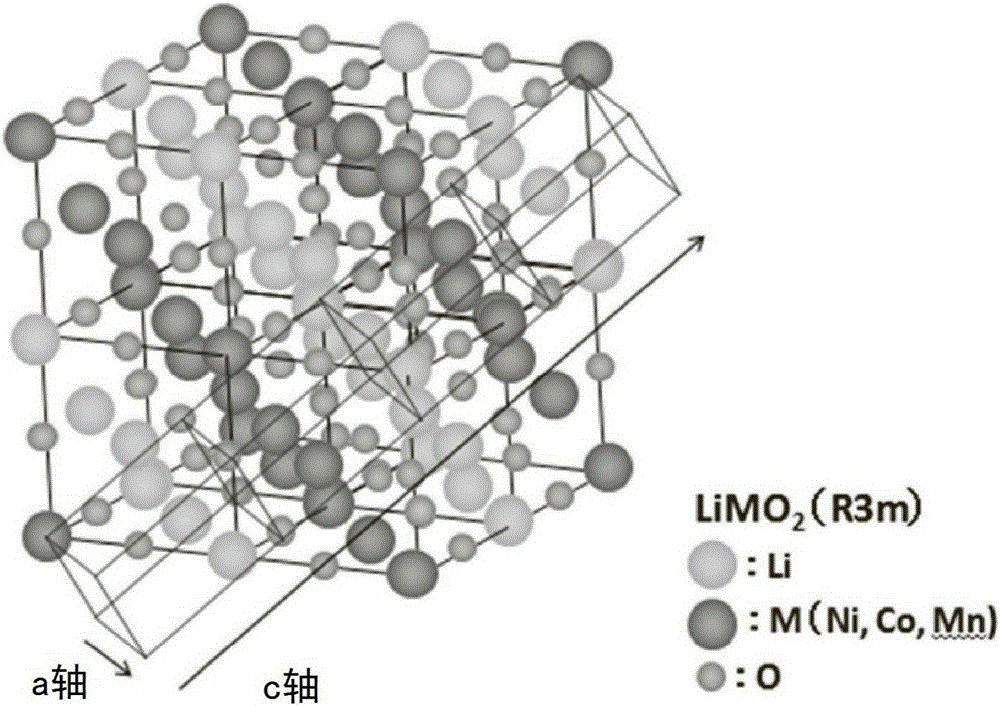

[0151] The XRD measurement of the composite hydroxide and the li...

example 1

[0170] Nickel sulfate (nickel sulfate (II) hexahydrate, manufactured by Wako Pure Chemical Industries, Ltd. (Wako Pure Chemical Industries, Ltd.)), cobalt sulfate (cobalt sulfate (II) heptahydrate, manufactured by Wako Pure Chemical Industries, Ltd. ), and manganese sulfate (manganese sulfate (II) pentahydrate, manufactured by Wako Pure Chemical Industries, Ltd.) dissolved in ion-exchanged water and filtered to prepare 2.15mol / L nickel sulfate, 1.60mol / L sulfuric acid Cobalt, and 1.25mol / L manganese sulfate aqueous sulfate solution.

[0171] Next, 500 g of ion-exchanged water was placed in the first reaction tank with a capacity of 1 L, and stirring was performed at 400 rpm while maintaining 60° C. while bubbling nitrogen gas. While continuously supplying the above-mentioned sulfate aqueous solution at 1.2 L / hour and 28% by mass ammonia solution at 0.03 L / hour in this ion-exchanged water, an aqueous sodium hydroxide solution of 18 mol / L is supplied to maintain the pH value in ...

example 2

[0175] Composite hydroxide was produced in the same manner as in Example 1, except that the concentration of sulfate contained in the sulfate solution was set to 2.25 mol / L of nickel sulfate, 1.50 mol / L of cobalt sulfate, and 1.25 mol / L of manganese sulfate. powder.

[0176] A lithium-containing composite oxide was obtained in the same manner as in Example 1, except that 200.00 g of the composite hydroxide, 83.73 g of lithium carbonate, and 0.81 g of zirconia were used, and the firing temperature was set to 919°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com