Non-aqueous washing apparatus and method

a technology of non-aqueous washing and washing receptacles, applied in the field of non-aqueous washing equipment, can solve the problems of inconvenient water-based methods, large amount of water consumed by conventional home laundring methods, and the inability to home launder garments and fabrics. , to achieve the effect of less noise, less sorting, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

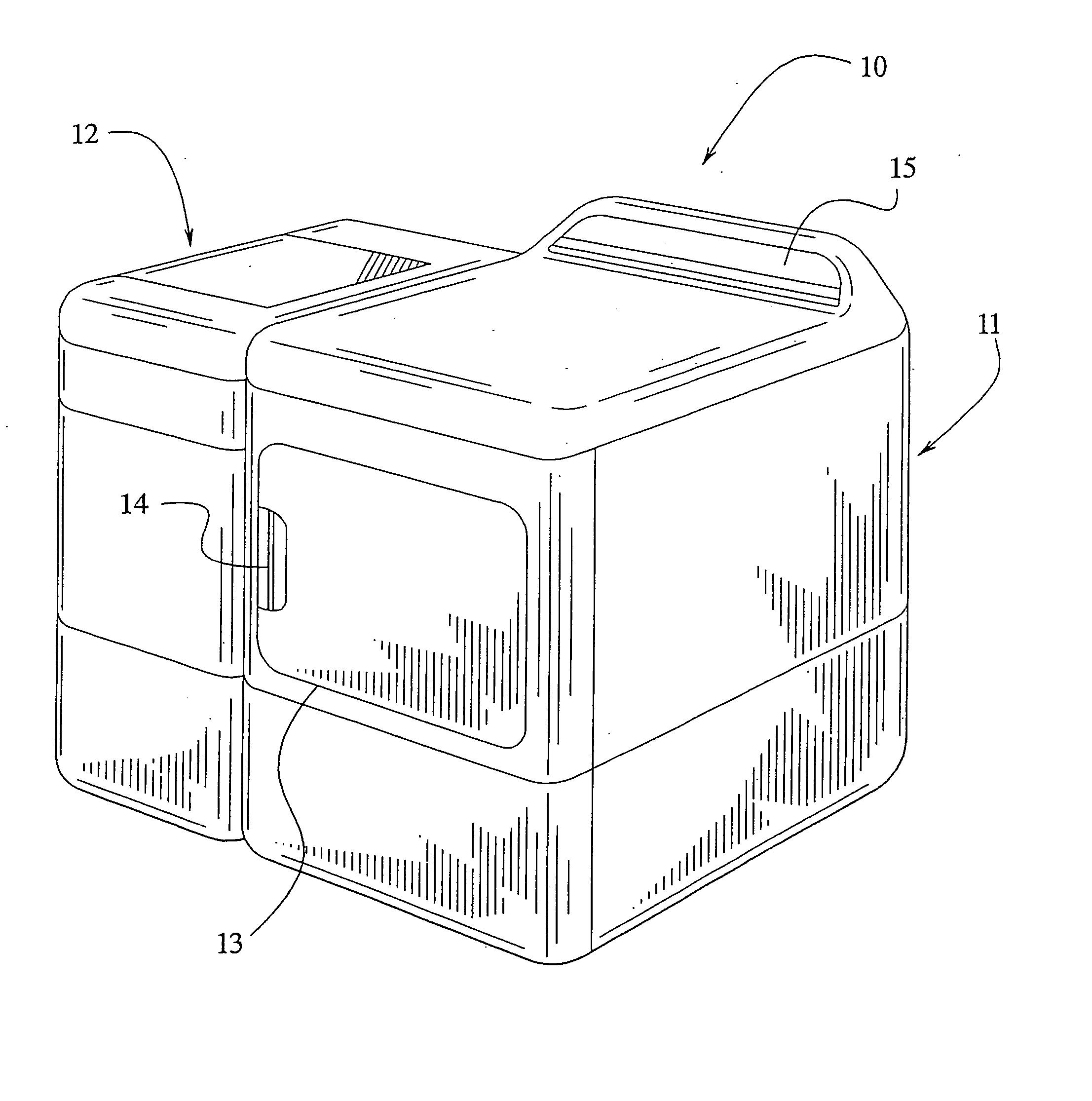

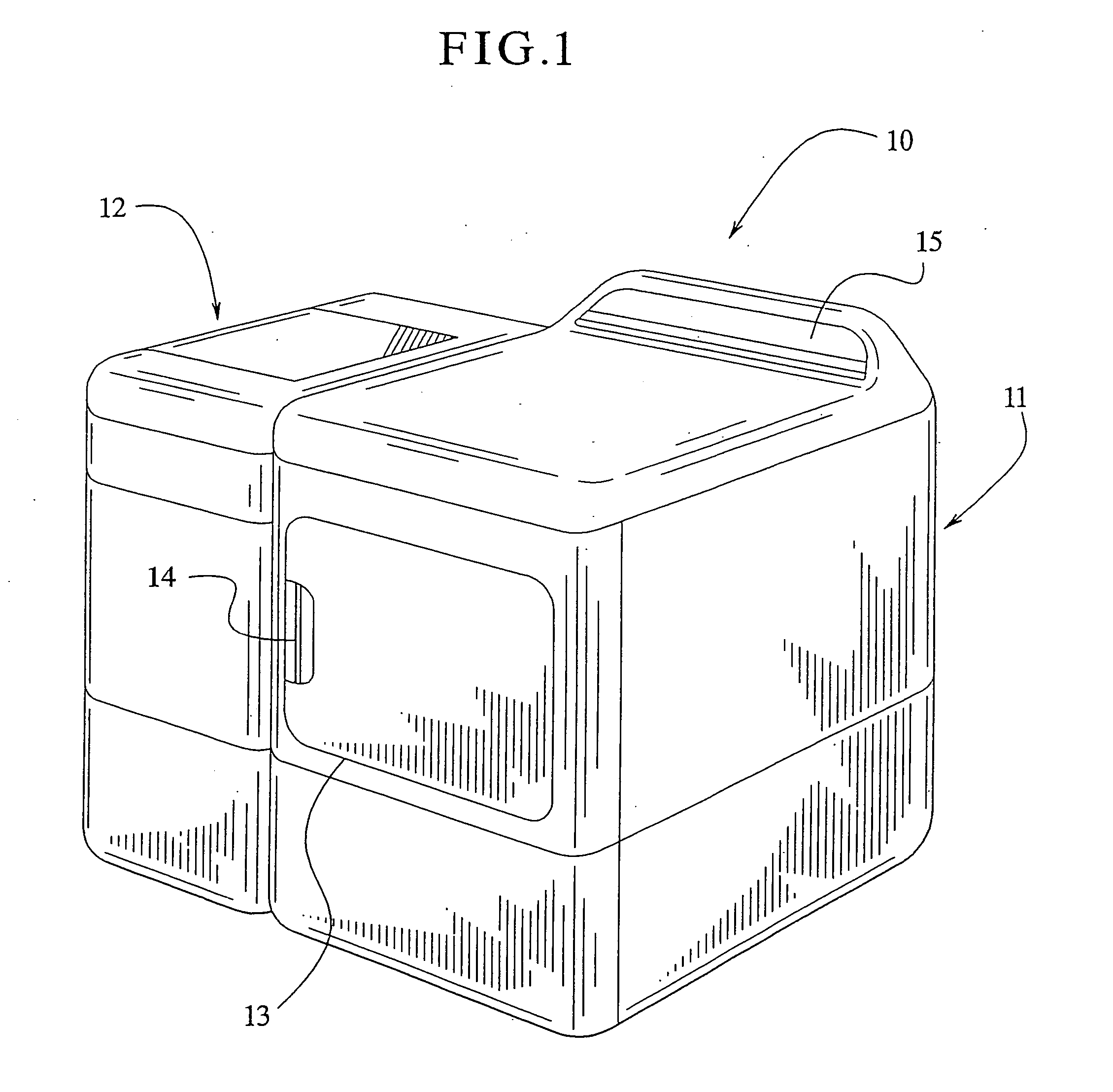

An apparatus 10 for carrying out the method of laundering fabric loads in accordance with the present invention is illustrated. The apparatus 10 includes a washing apparatus 11 disposed adjacent to a working fluid storage unit 12. The washing apparatus 11 includes a front door 13, preferably with a handle 14, for placing a fabric load (not shown) in the washer 11. A control panel 15 is disposed along the top of the washer 11, preferably along a back edge.

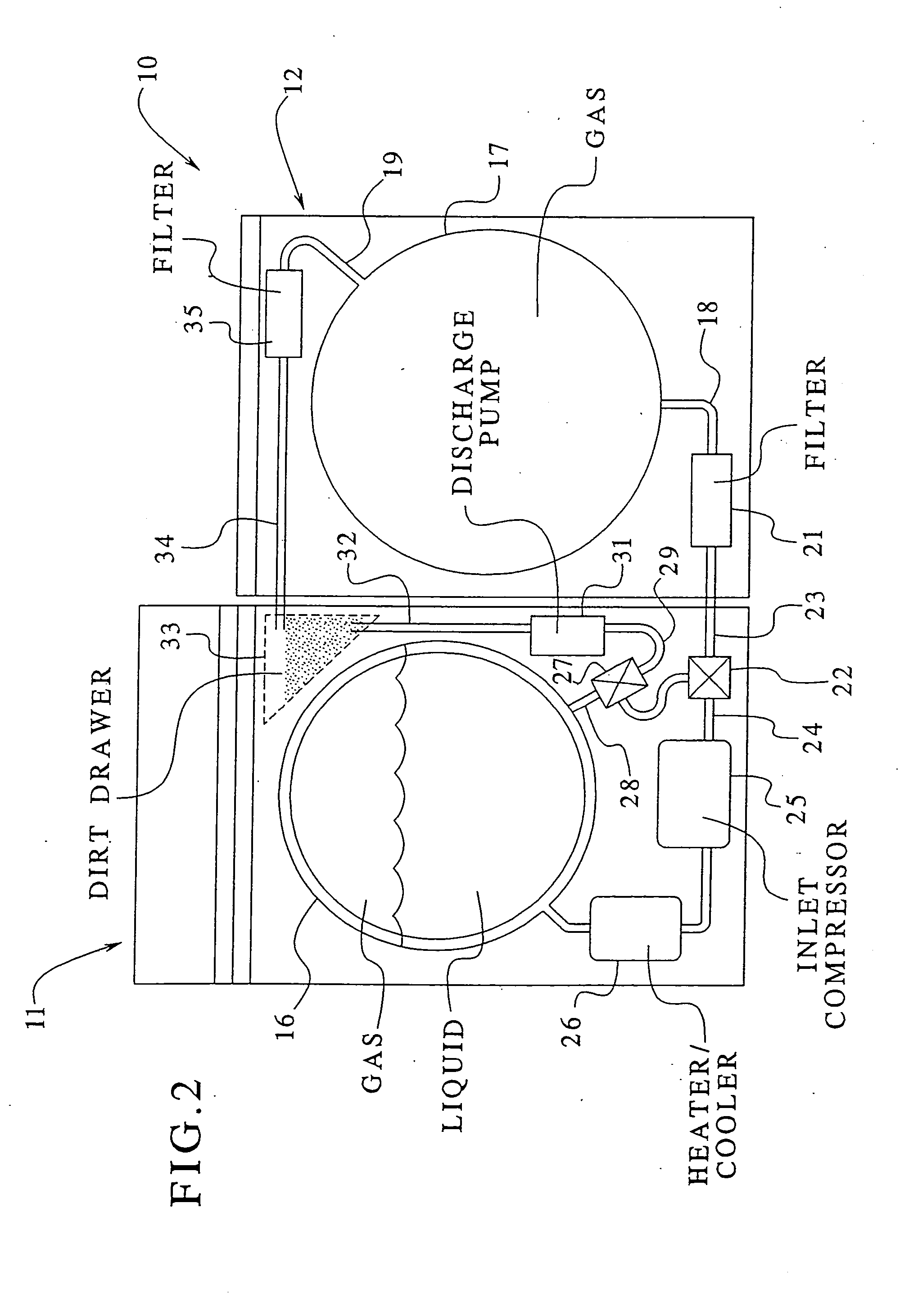

As illustrated in FIG. 2, the washing apparatus 11 includes a centrally disposed wash chamber 16 which receives a fabric load (not shown). Working fluid is supplied to the wash chamber 16 from the working fluid storage unit 12. The storage unit 12 includes a generally centrally disposed tank 17 with an outlet conduit 18 and an inlet conduit 19. In the embodiment illustrated in FIG. 2, the working fluid is stored in the unit 12 in a gas form. Gaseous fluid passes through the outlet 18, through a filter 21 and through a three-way v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com