Compositions of hydrochlorofluoroolefins

A technology for hydrochlorofluoroolefins and compositions, applied in detergent compositions, non-surface-active detergent compositions, organic non-surface-active detergent compositions, etc., can solve problems such as residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 3E-1233

[0036] Flammability of Example 3E-1233zd

[0037] A solvent's flammability is related to its safety in use. For most applications, it is desirable for a solvent to have as low a flammability as possible. The flammability of E-1233zd is characterized by the flash point measured according to ASTM D3278-96. The flash points of TDCE and HCFC 225 were used as comparative examples. Table 3 summarizes the results.

[0038] Table 3E-1233zd compares flash points of TDCE and HCFC 225

[0039] molecular

[0040] The presence of chlorine is thought to reduce the flammability of the molecule, while hydrogen is thought to increase it. The data in Table 3 show that E-1233zd, which has a relatively low chlorine to hydrogen ratio, unexpectedly does not exhibit a flash point.

example 4E-1233

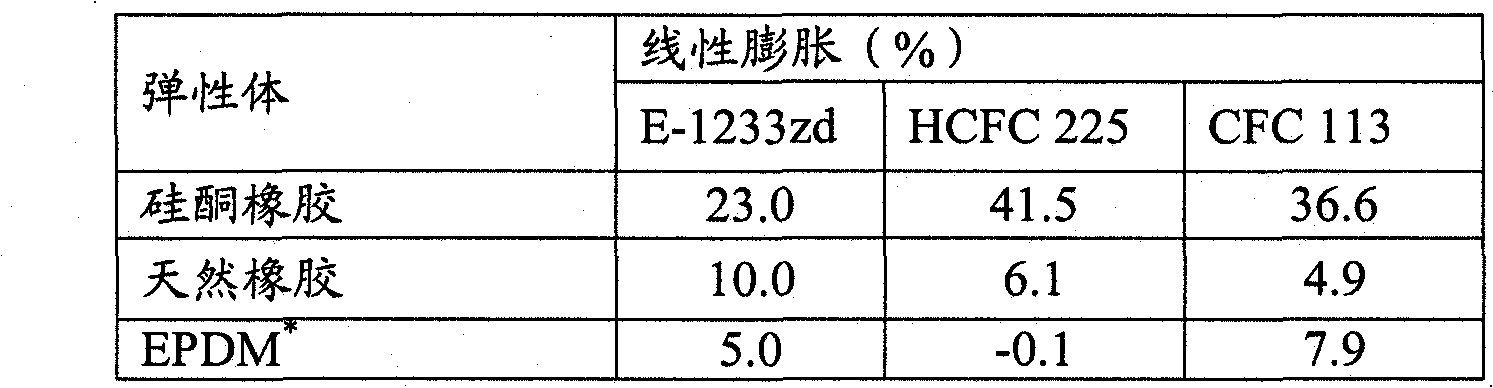

[0041] Material Compatibility of Example 4E-1233zd with Elastomers

[0042] Compatibility of E-1233zd with different elastomers was measured by measuring linear expansion at the boiling point of E-1233zd for more than 72 hours. The results are summarized in Table 4.

[0043] Table 4E-1233zd Compatibility with Elastomers

[0044]

[0045] * Ethylene Propylene Diene Monomer (EPDM)

[0046] E-1233zd shows compatibility with natural rubber and EPDM comparable to HCFC 225 and CFC 113. However, E-1233zd is much more compatible with silicone rubber than HCFC 225 and CFC 113.

example 5

[0047] Example 5 Using E-1233zd to degrease lubricating oil

[0048] A small amount of commercial lubricating oil was deposited on the surface of several 30 x 10 mm stainless steel plates. The mass of each plate was determined with an accuracy of 0.1 mg before and after deposition. The difference between these two values corresponds to the initial mass of the lubricating oil.

[0049] Once the initial mass had been obtained, each panel was immersed for 5 minutes at ambient temperature in a beaker filled with a cleaning composition. Thereafter, the panels were removed from the beakers and dried in the open air for 5 minutes. Thereafter, the mass of each plate was measured to assess the percentage of lubricant removed during the test. Table 5 summarizes the results.

[0050] Table 5 Cleaning of lubricating oil

[0051] test product

[0052] E-1233zd exhibited comparable cleaning results to HCFC 141b.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com