Methods of using hydrofluoroethers as heat transfer fluids

A heat transfer fluid, heat transfer technology, used in heat exchange materials, chemical instruments and methods, organic chemistry, etc., can solve problems such as difficult to predict performance, achieve good heat transfer characteristics, low conductivity, high dielectric strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

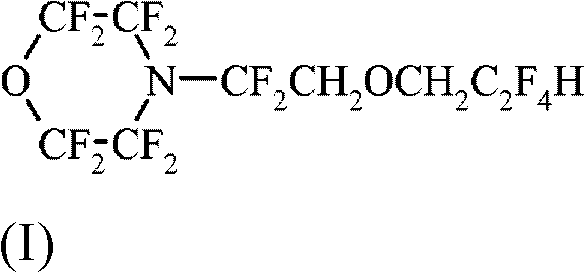

Method used

Image

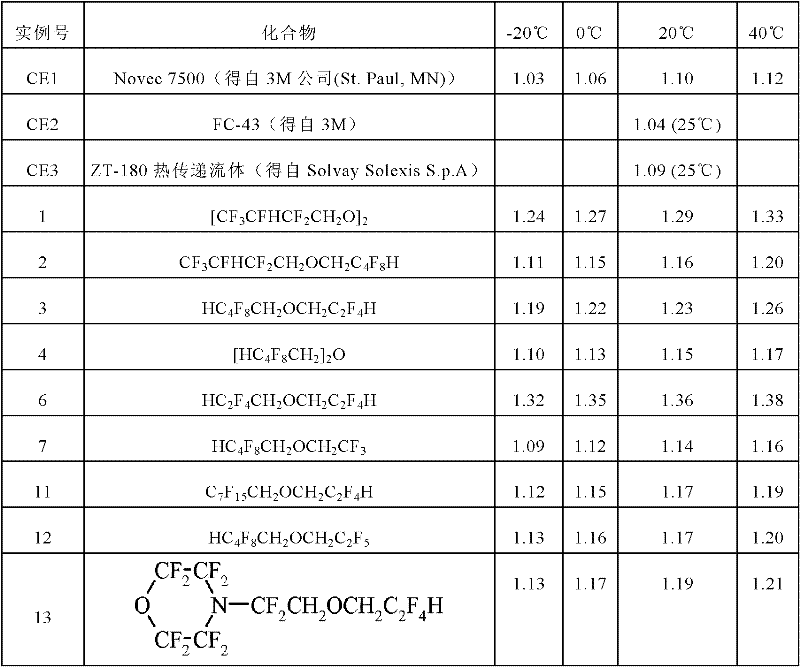

Examples

example

[0063] All parts, percentages, ratios, etc. in the examples, as well as in the remainder of this specification, are by weight unless otherwise indicated. In the following examples, the abbreviation "GC" refers to gas chromatography with flame ionization detector (uncorrected response factor); "IR" refers to infrared spectroscopy, and "GC / MS" refers to combined gas chromatography-mass spectrometry method; "NMR" (eg, 1 H. 19 F. 13 C) means nuclear magnetic resonance spectroscopy; "mL" means milliliter, "mol" means mole; and "g" means gram.

[0064] The specific heat capacity (Cp) was determined using a Perkin Elmer Pyris 1 DSC (Differential Scanning Calorimeter, DSC) (Analytical Instruments No. 294). Samples were weighed using a Perkin Elmer microbalance (Analytical Instruments No. 289). A "three-curve" method was employed, in which an empty DSC pan, a sapphire heat capacity calibration pan, and the sample material were scanned. Perkin Elmer thermal analysis software calcul...

preparation example A

[0066] Preparation of 1,1,2,2,3,3,4,4,4-nonafluorobutane-1-sulfonic acid-2,2,3,4,4,4-hexafluorobutyl ester .

[0067]2,2,3,4,4,4-hexafluorobutan-1-ol (202 g, 1.1 mol, obtained from Sinochem Company (Beijing, China)), 1,1,2,2,3,3,4 , 4,4-nonafluorobutane-1-sulfonyl fluoride (332 g, 1.1 mol, from 3M Company, Saint Paul, Minnesota) and water (300 g) were combined in a 3 L, 3 necked round bottom flask. The flask was equipped with a magnetic stirrer, cold water condenser, thermocouple and a 250 mL addition funnel. Aqueous potassium hydroxide solution (149.3 g, 45 wt%, 1.22 equiv) was added dropwise via an addition funnel at such a rate that the temperature did not exceed 35°C. Once the base addition was complete, the mixture was stirred at room temperature for 16 hours. The precipitated salts are then filtered off from the mixture, and the lower liquid fluorochemical product phase is separated from the upper aqueous phase. Remove unreacted 2,2,3,4,4,4-hexafluorobutan-1-ol and ...

preparation example B

[0069] Preparation of 1,1,2,2,3,3,4,4,4-nonafluorobutane-1-sulfonic acid-2,2,3,3-tetrafluoropropyl ester .

[0070] 2,2,3,3-tetrafluoropropan-1-ol (202g, 1.52mol, obtained from Sinochem Company), 1,1,2,2,3,3,4,4,4-nonafluorobutane - 1-sulfonyl fluoride (465 g, 1.52 mol, from 3M Company) and water (500 g) were combined in a 3-liter, 3-neck round bottom flask. The flask was equipped with a magnetic stirrer, cold water condenser, thermocouple and addition funnel. Aqueous potassium hydroxide solution (45 wt%, 211.5 g, 1.7 mol, from Aldrich Chemical Co. (Milwaukee, Wisconsin)) was added dropwise via an addition funnel at such a rate that the temperature did not exceed 35°C. Once the potassium hydroxide addition was complete, the mixture was stirred at room temperature for 16 hours. The precipitated salts are then filtered off from the mixture, and the lower liquid fluorochemical product phase is separated from the upper aqueous phase. Removal of unreacted 2,2,3,3-tetrafluoropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com