Patents

Literature

54results about "Book binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

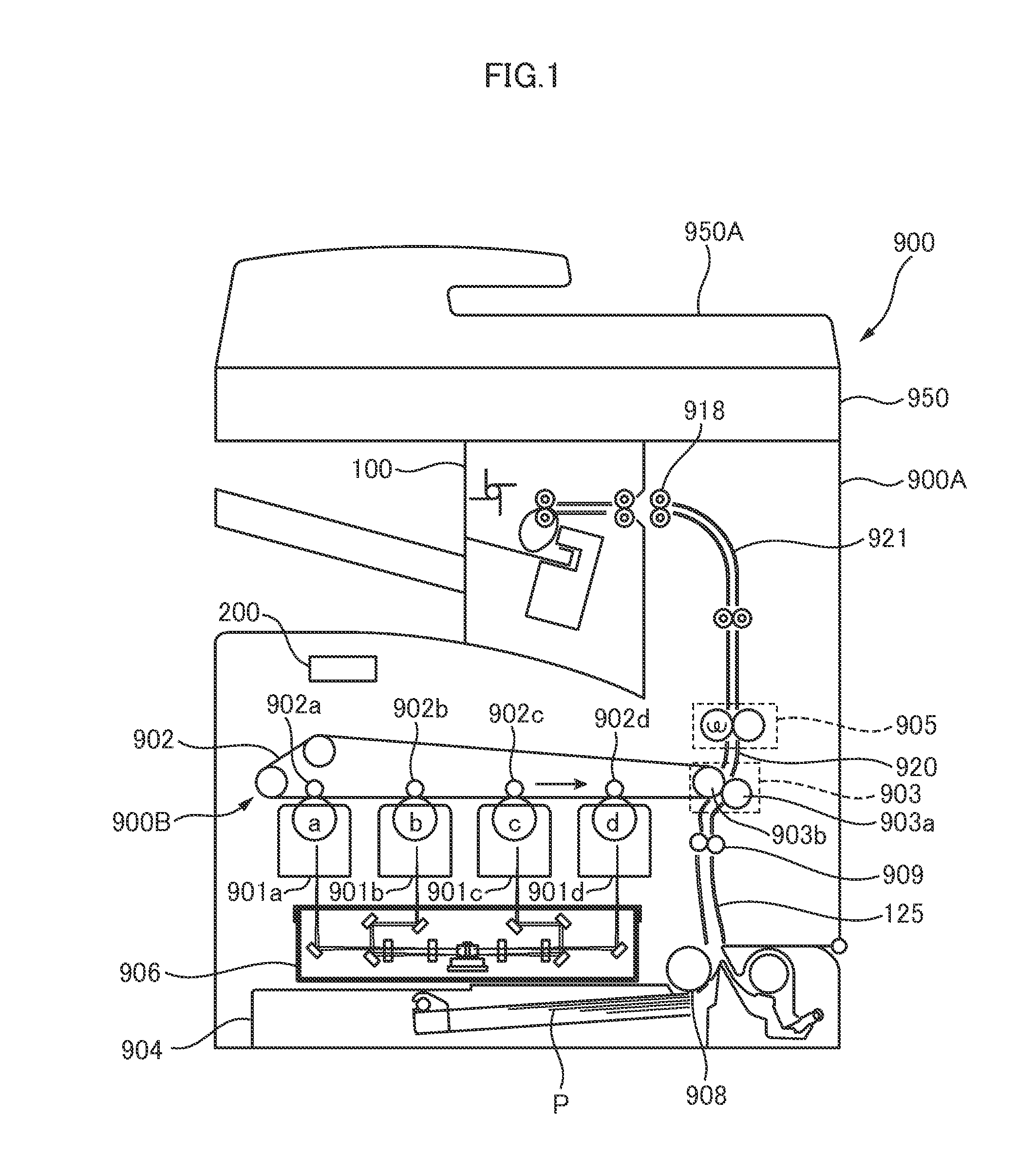

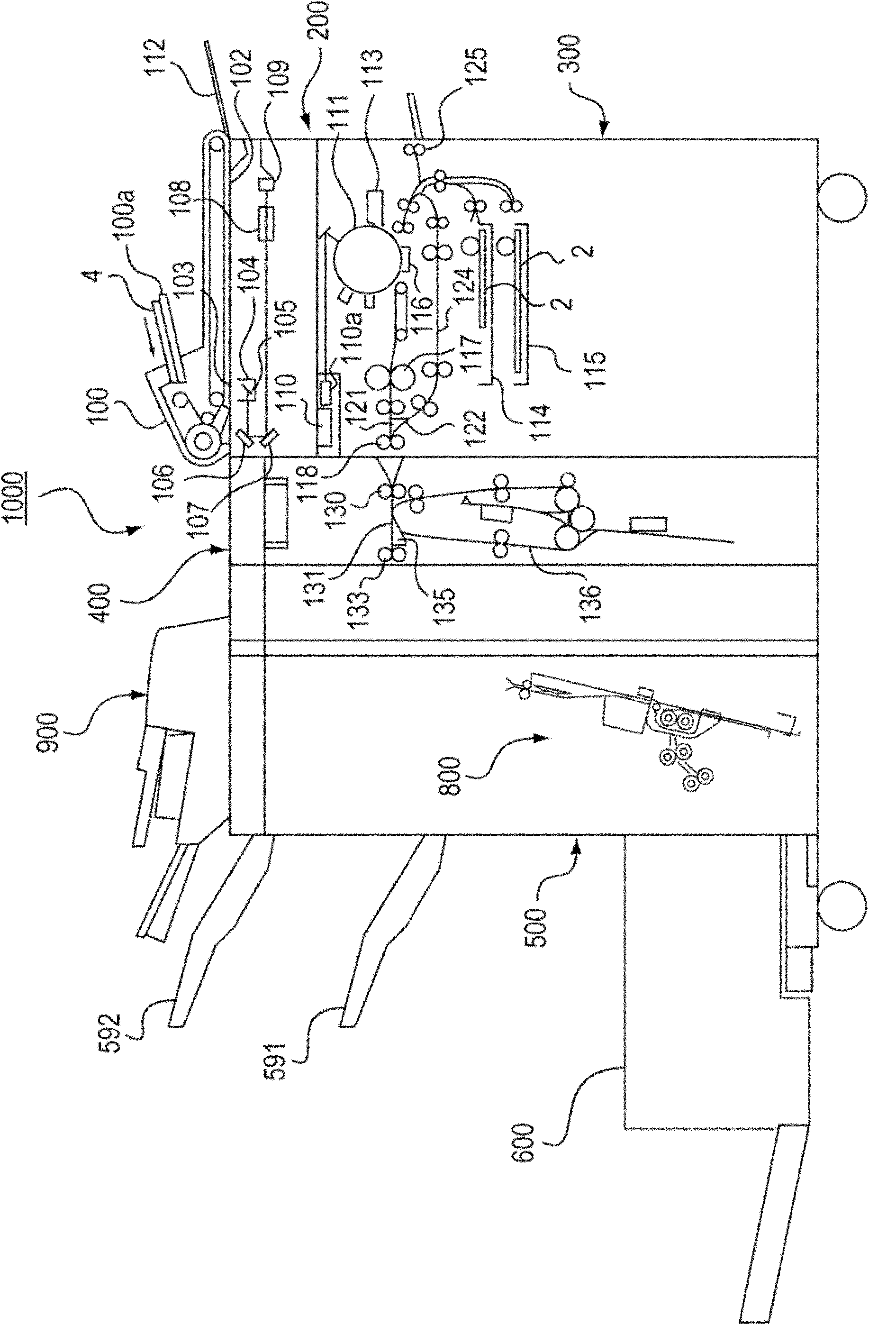

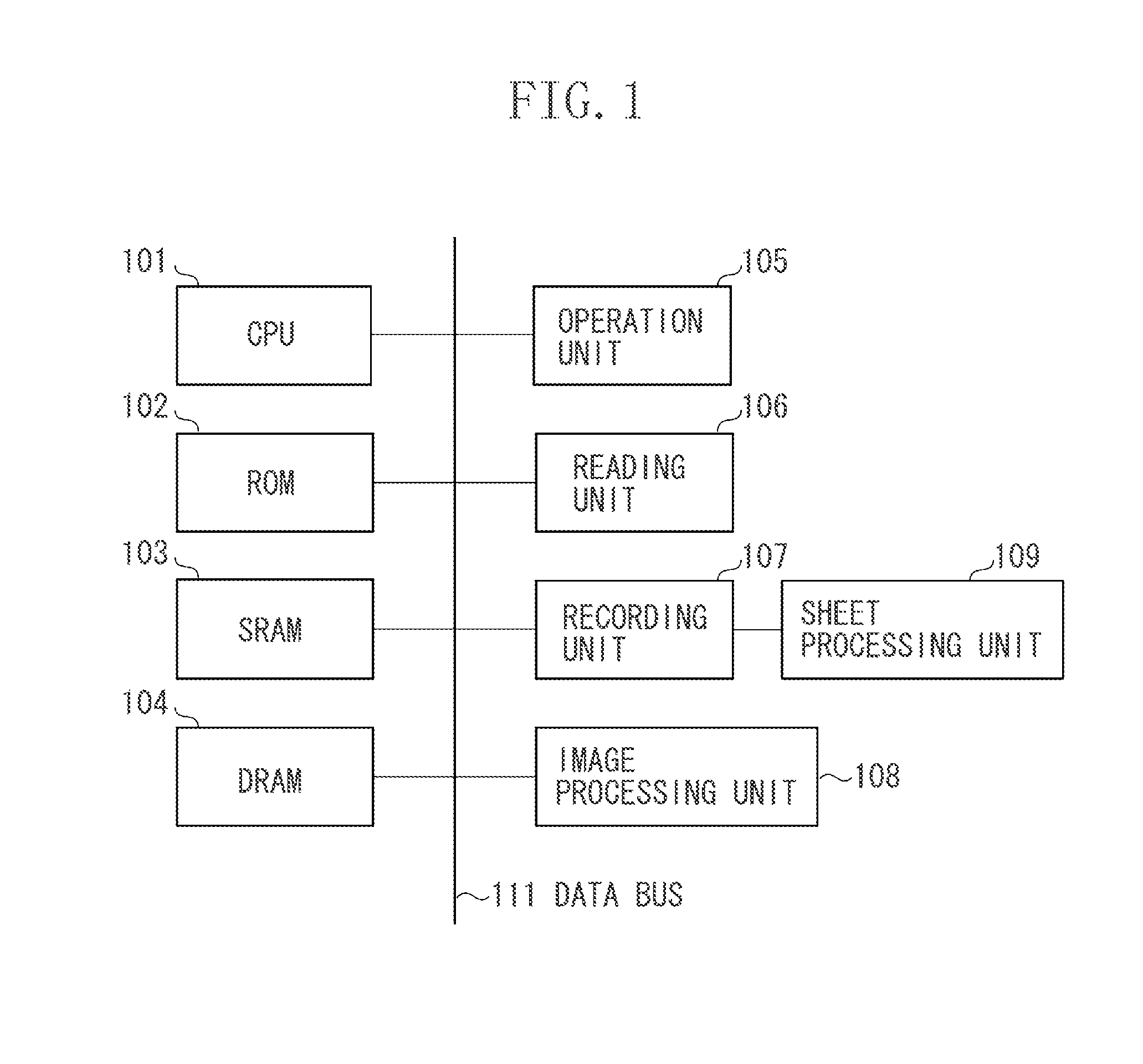

Sheet-bundle spine treatment apparatus, sheet-bundle treatment apparatus, and image-forming apparatus

Owner:CANON KK

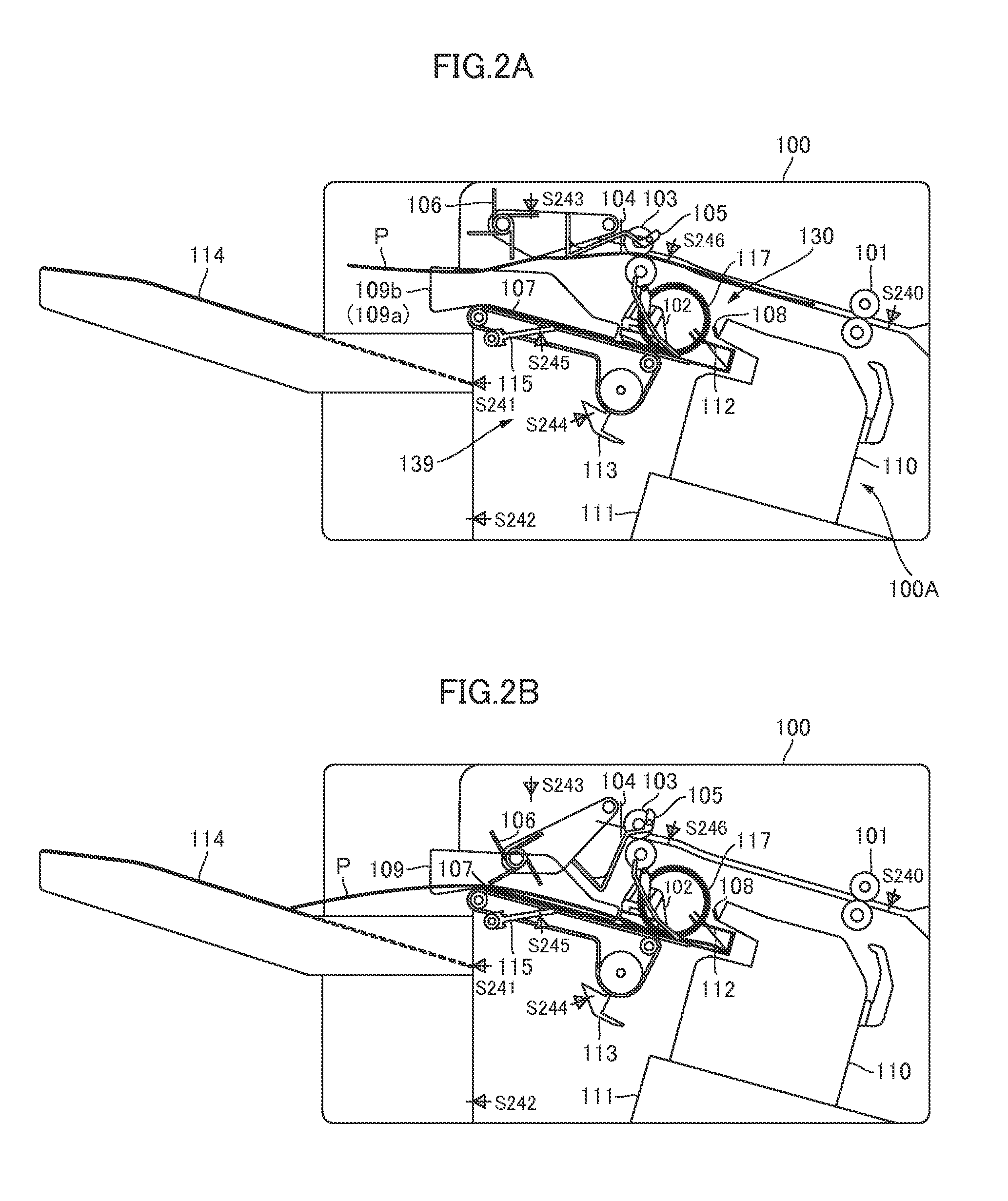

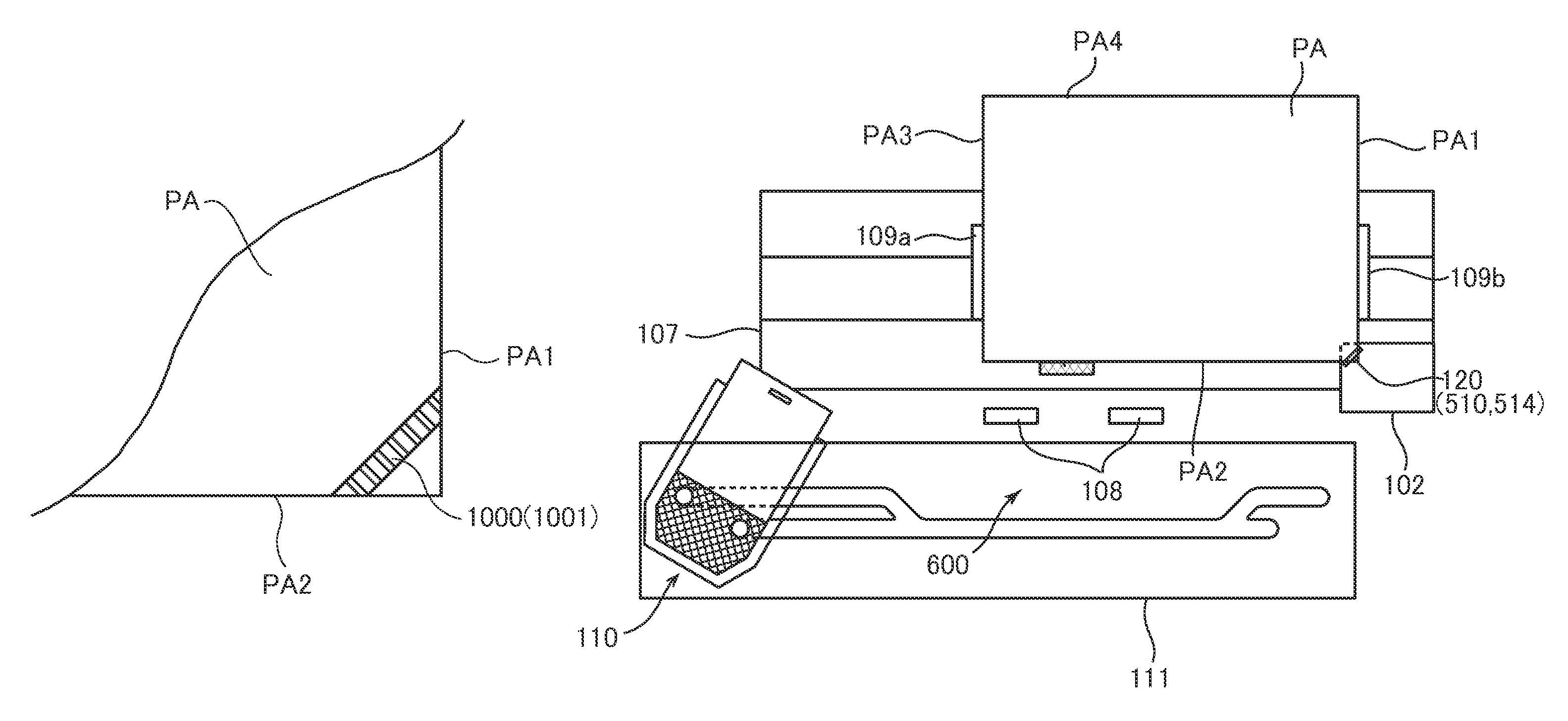

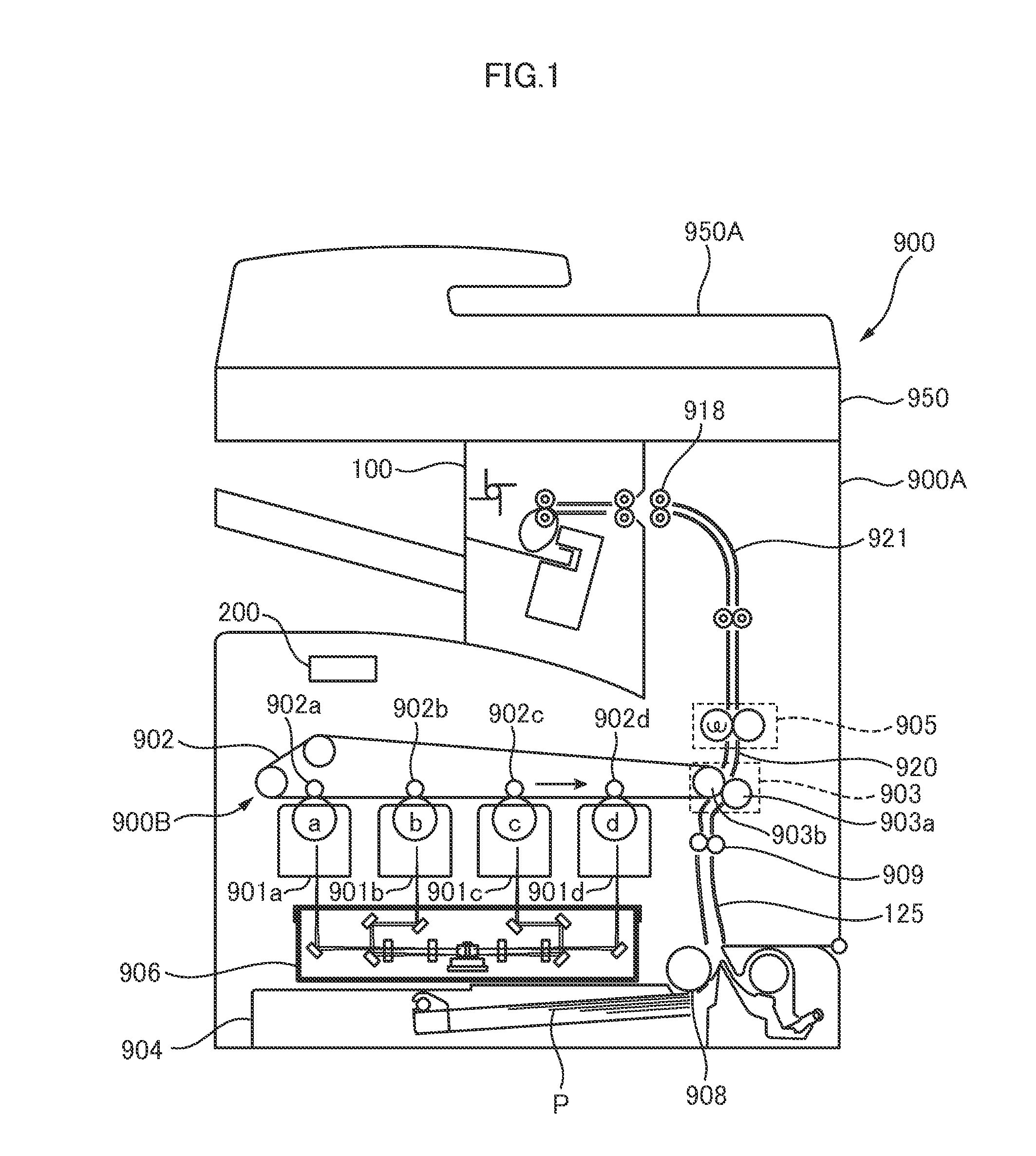

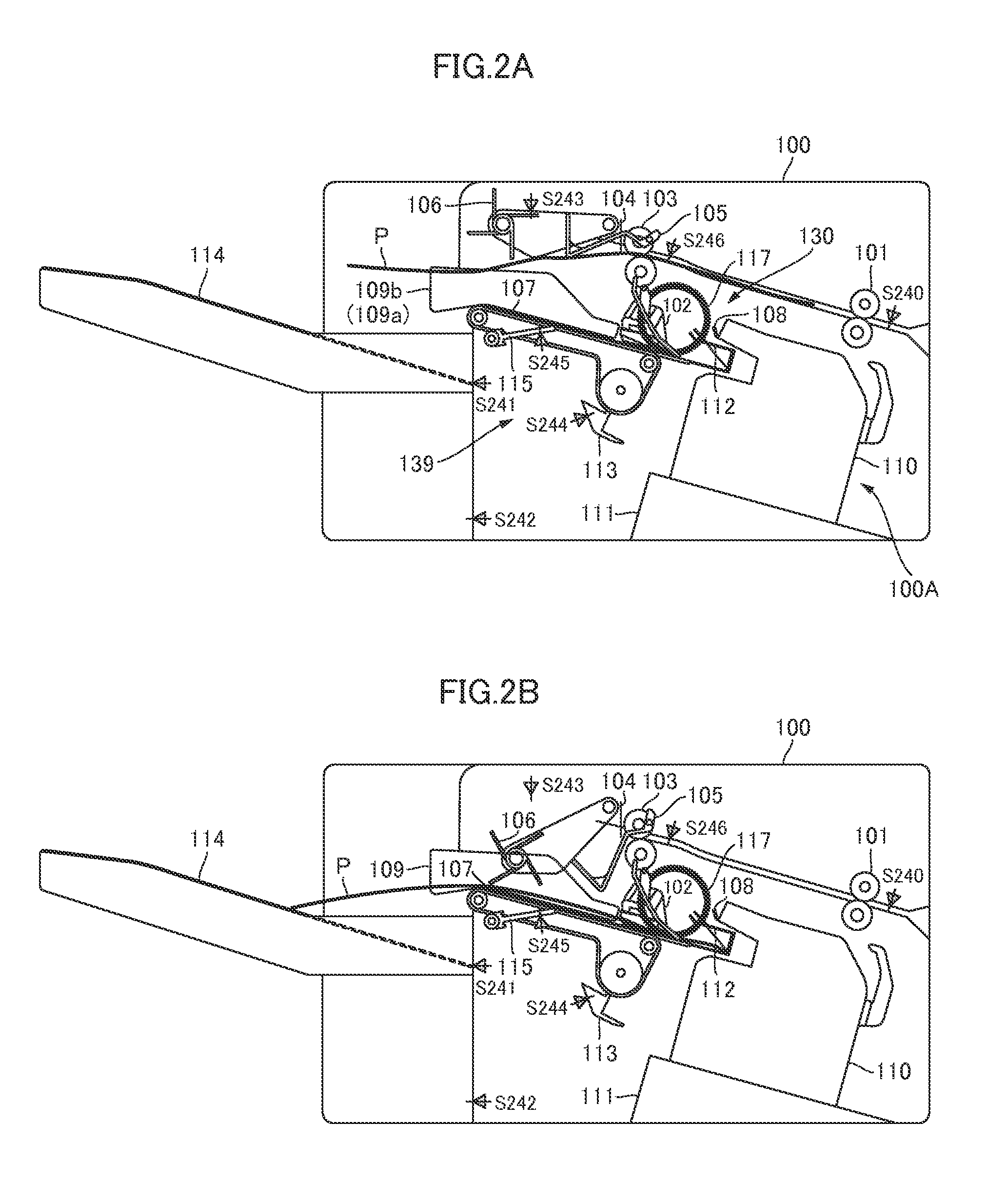

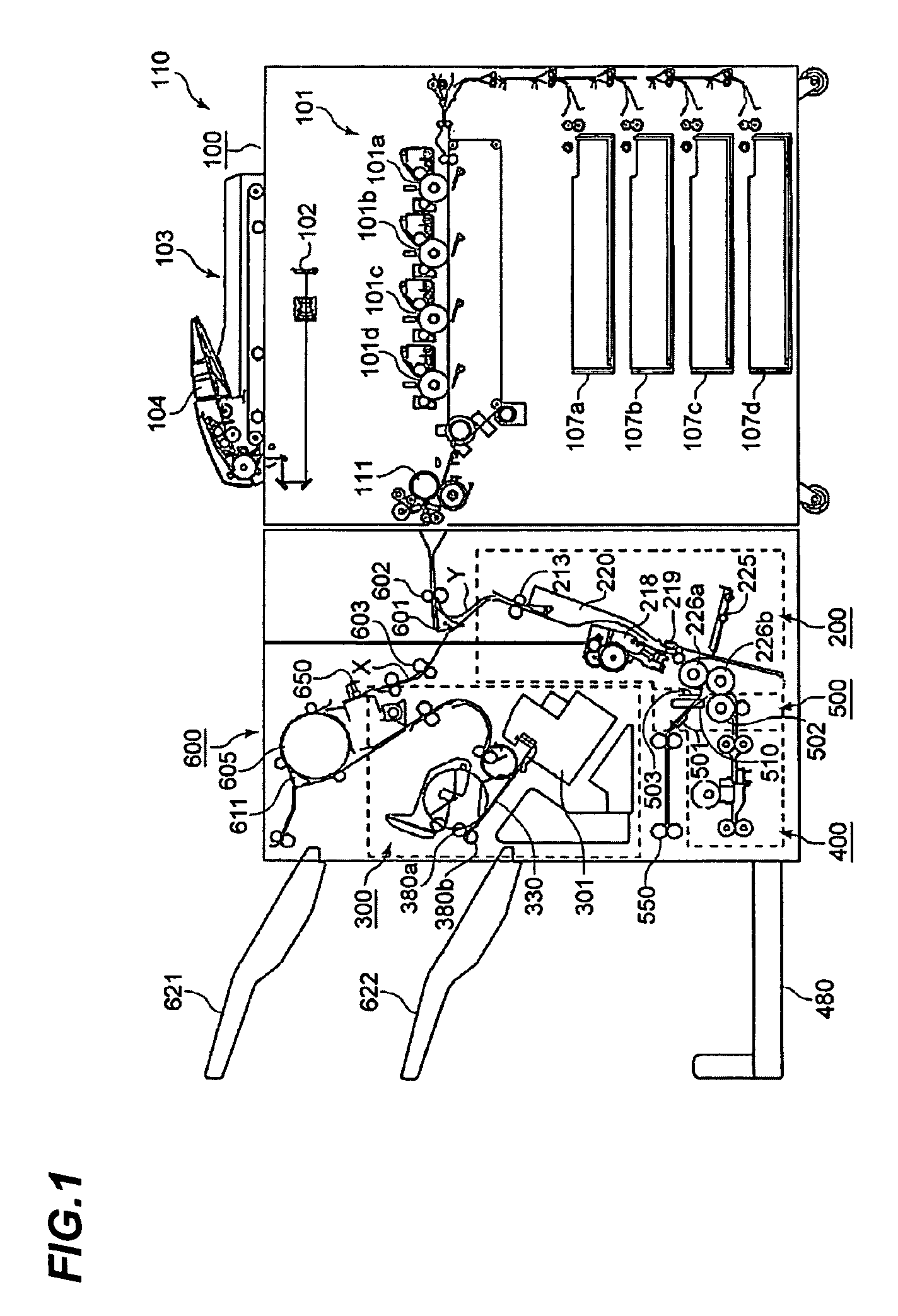

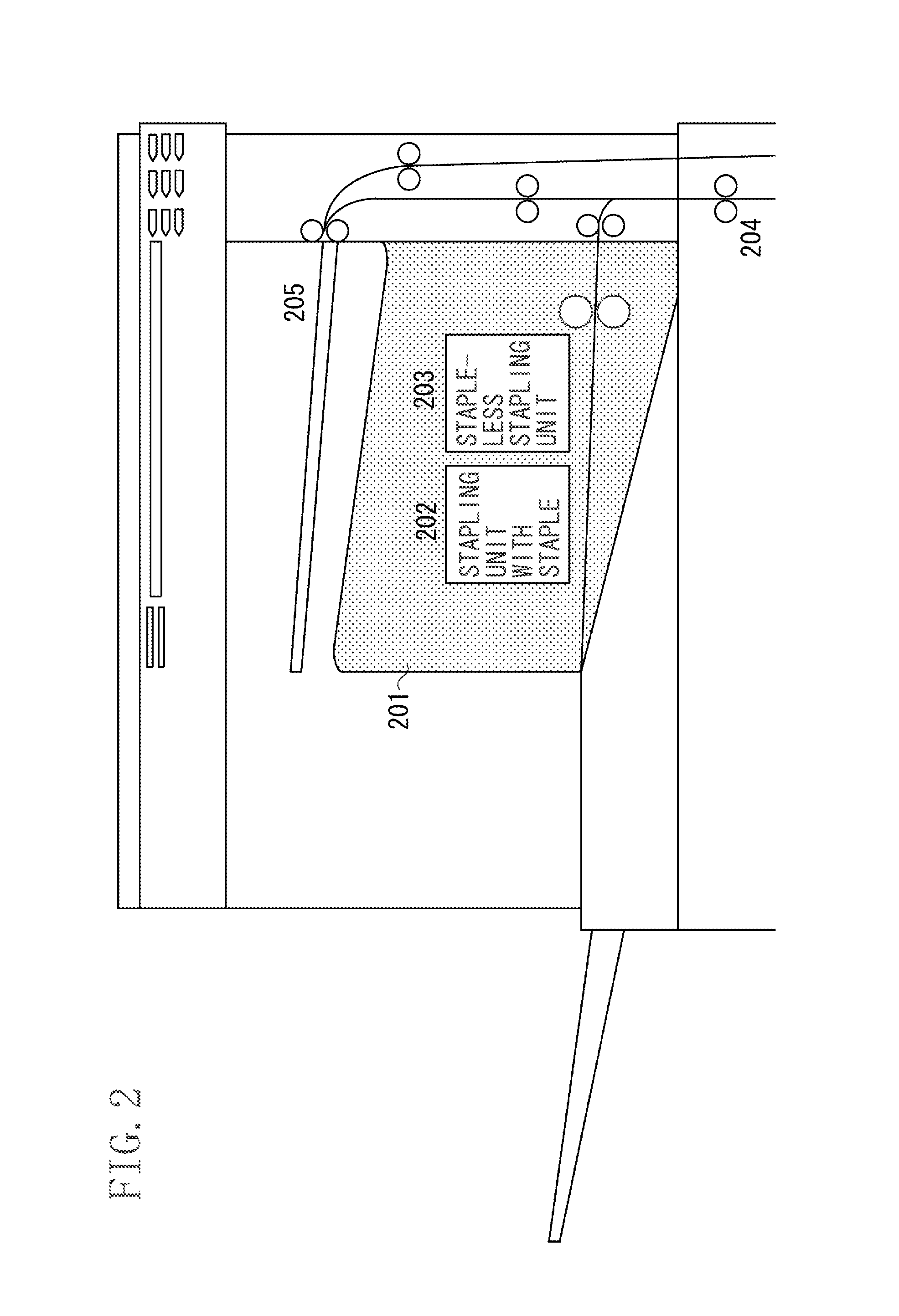

Sheet processing apparatus and image forming apparatus

A staple-less binding unit including a pair of upper and lower teeth binds a sheet bundle which is discharged to an intermediate processing tray by a sheet discharge portion and whose one edge abuts against a rear edge stopper. A control portion switches a binding mode of the staple-less binding unit that implements the binding process on the sheet bundle in a first binding mode of binding the sheet bundle without any staple such that the pair of upper and lower teeth bite across an edge of the sheet bundle and in a second binding mode of binding the sheet bundle without any staple such that the pair of upper and lower teeth do not bite across any edge of the sheet bundle.

Owner:CANON KK

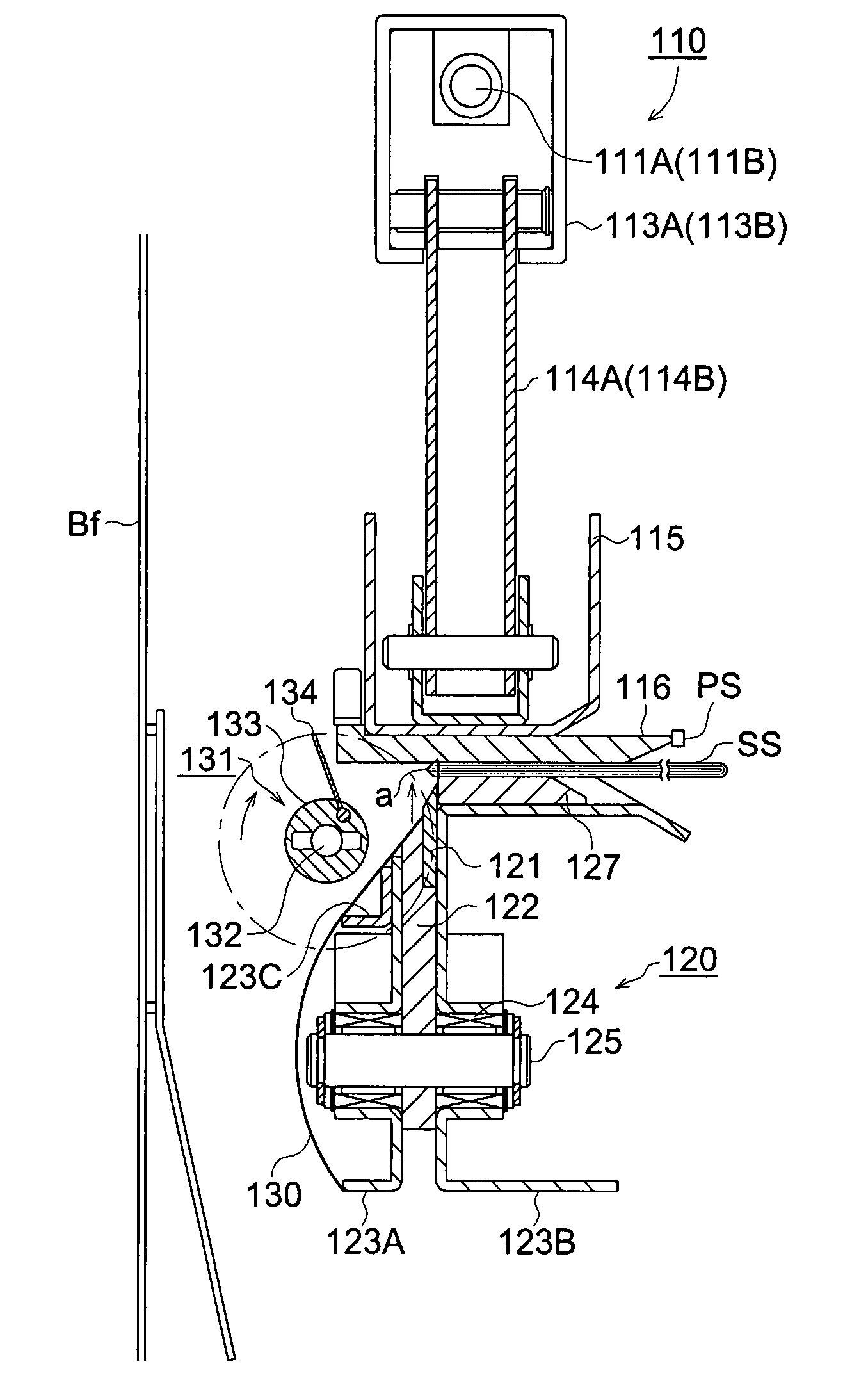

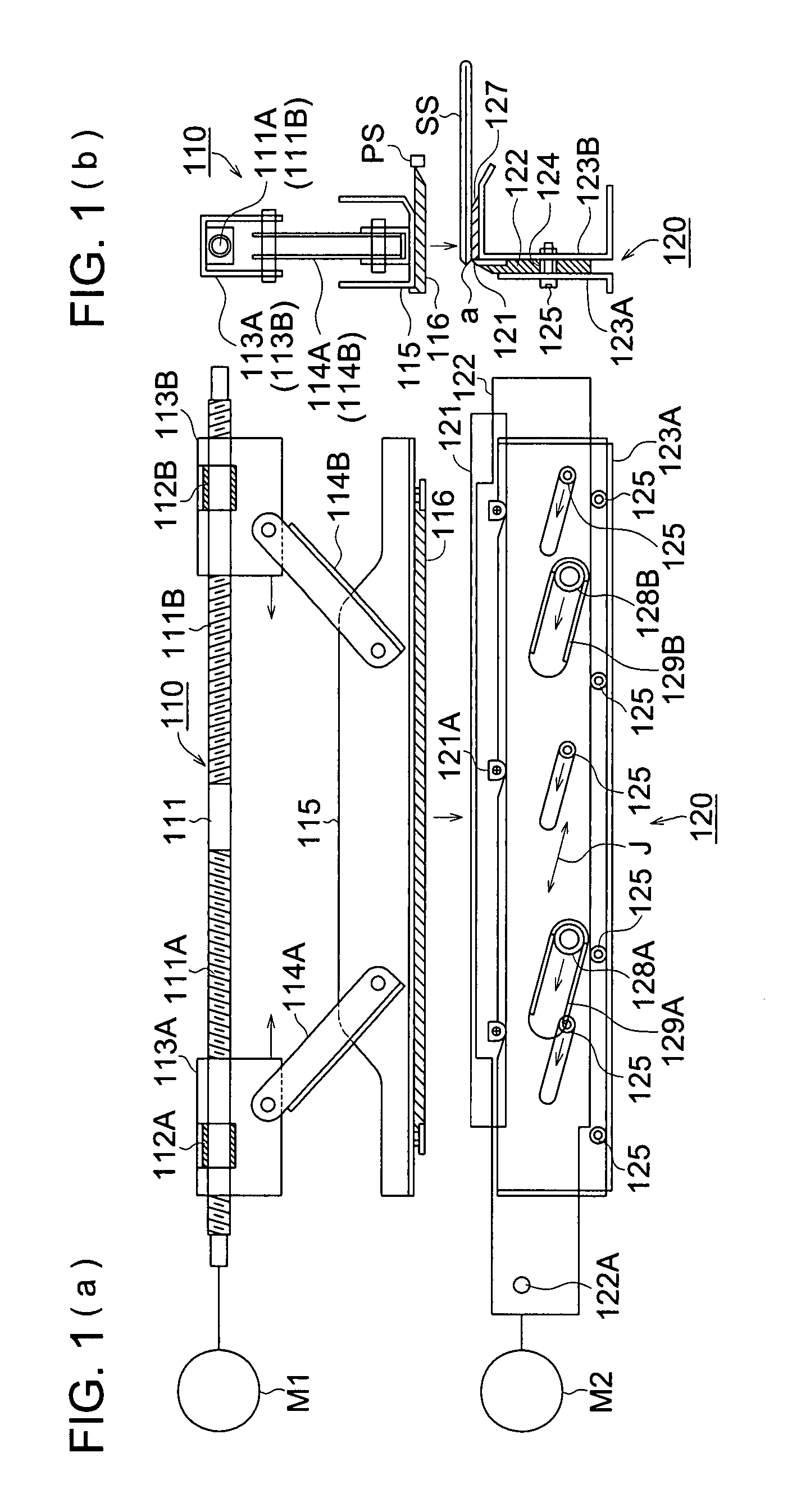

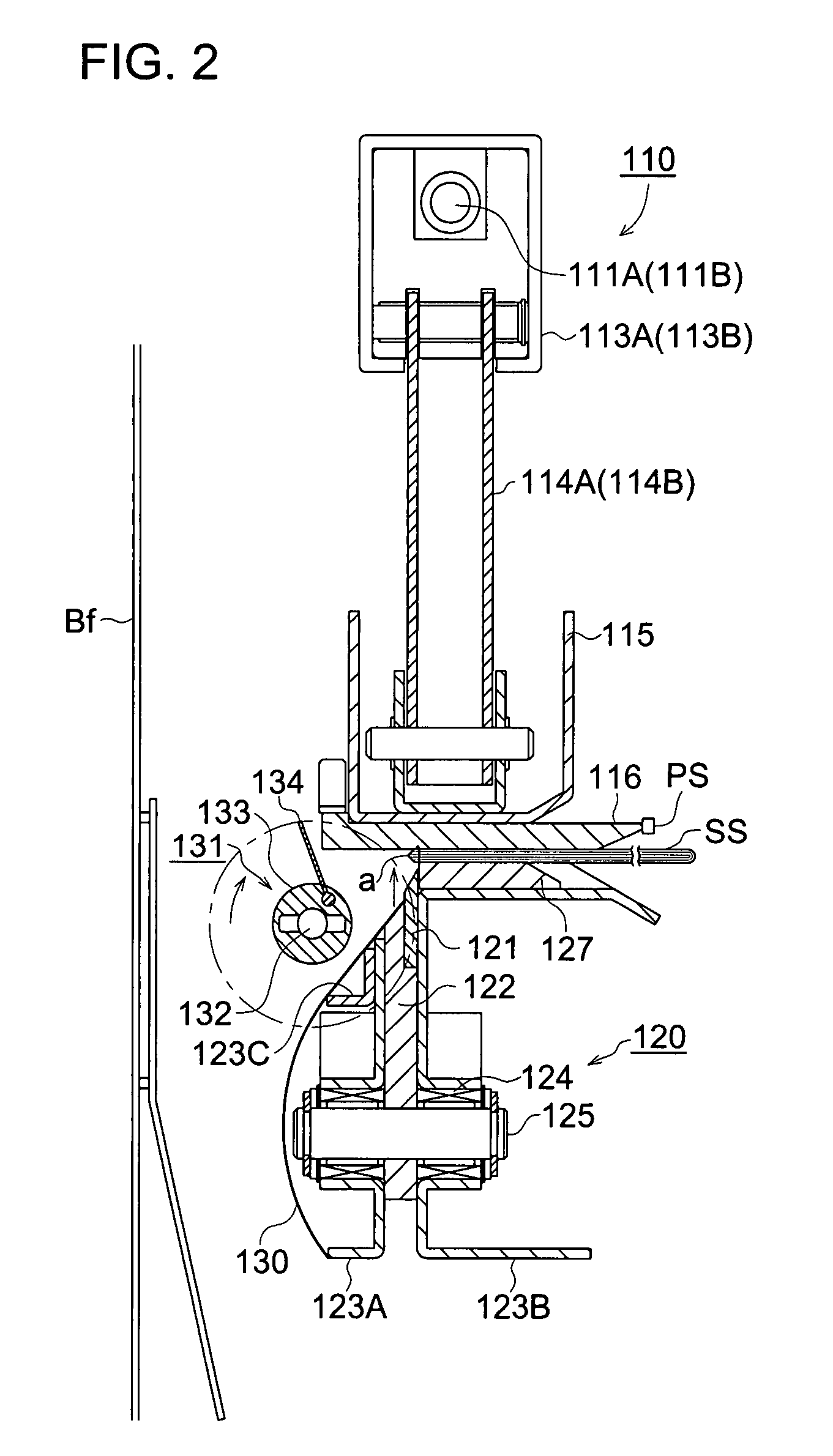

Book binding apparatus and image forming apparatus having this

InactiveUS20080101836A1Efficiently obtainedReduce production efficiencyBook bindingToysMechanical engineeringThin section

Owner:CANON KK

Cutting device, finisher and bookbinding system provided therewith

ActiveUS20070267801A1Avoid failureStable operation reductionBook bindingElectrographic process apparatusEngineeringKnife blades

A cutting device that cuts an edge portion of a sheet bundle having plural sheets stacked, includes: a cutting blade; a paddle provided on a side of the cutting blade, which removes chips attached to the cutting blade by rubbing a side surface of the cutting blade; a controller which controls drive of the paddle. The controller includes a judging section which compares a length of the chips in a direction perpendicular to an edge side of the sheet bundle to be cut by the cutting blade with a predetermined length that has been preset. When the length of the chips is shorter than the predetermined length, the controller makes the paddle to rotate in a predetermined direction, and when the length of the chips is longer than the predetermined length, the controller makes the paddle to rotate in a reverse direction.

Owner:KONICA MINOLTA BUSINESS TECH INC

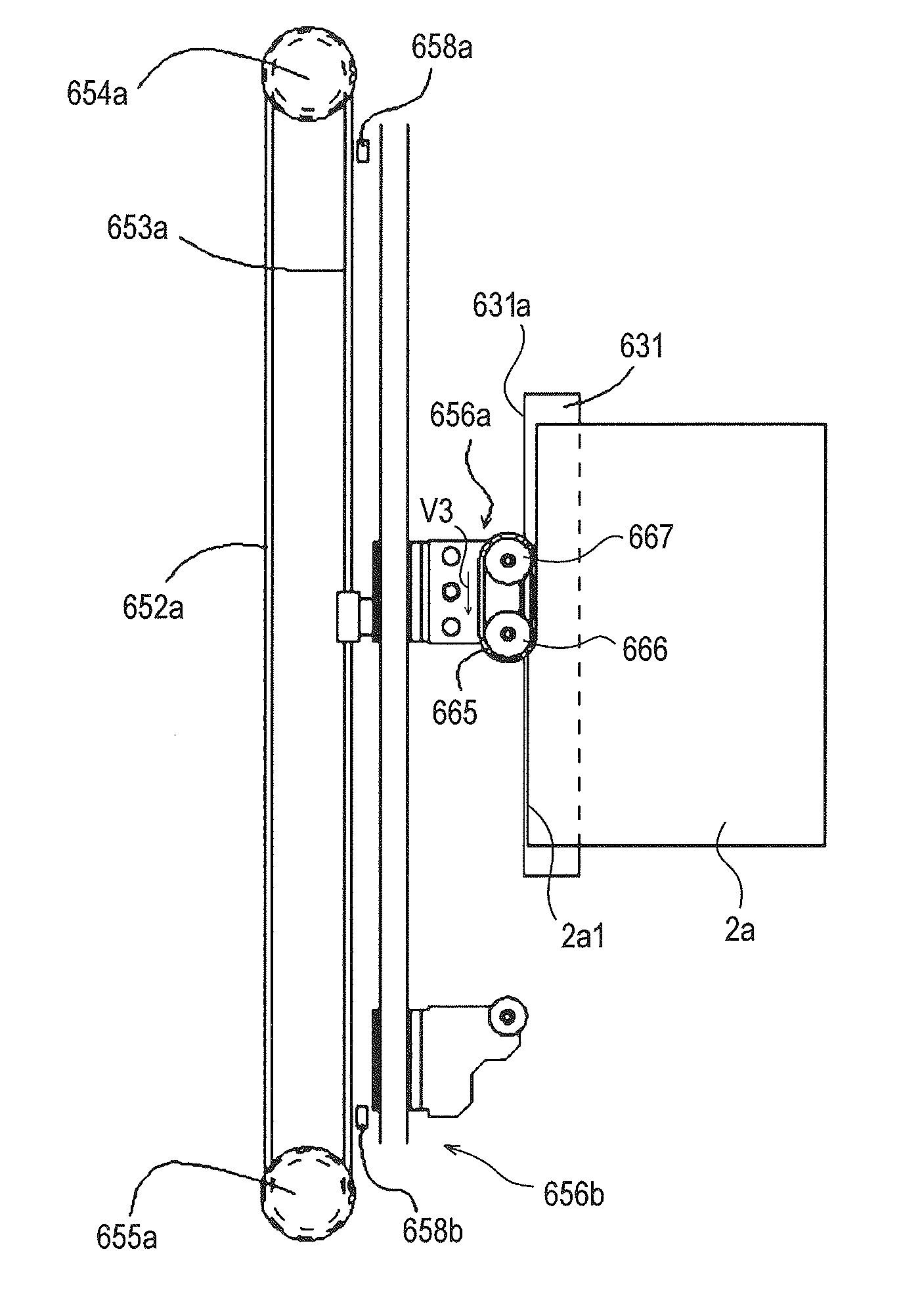

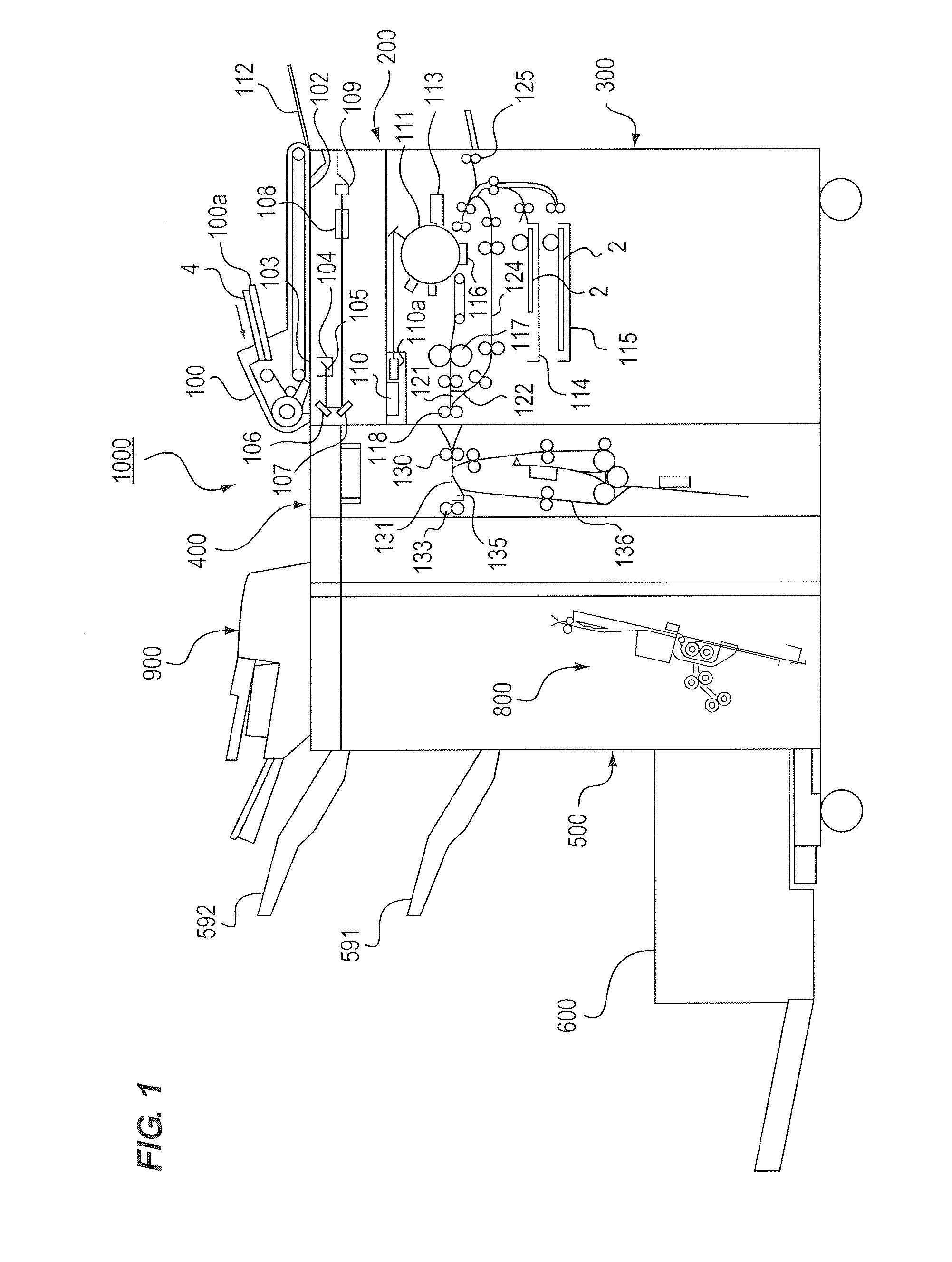

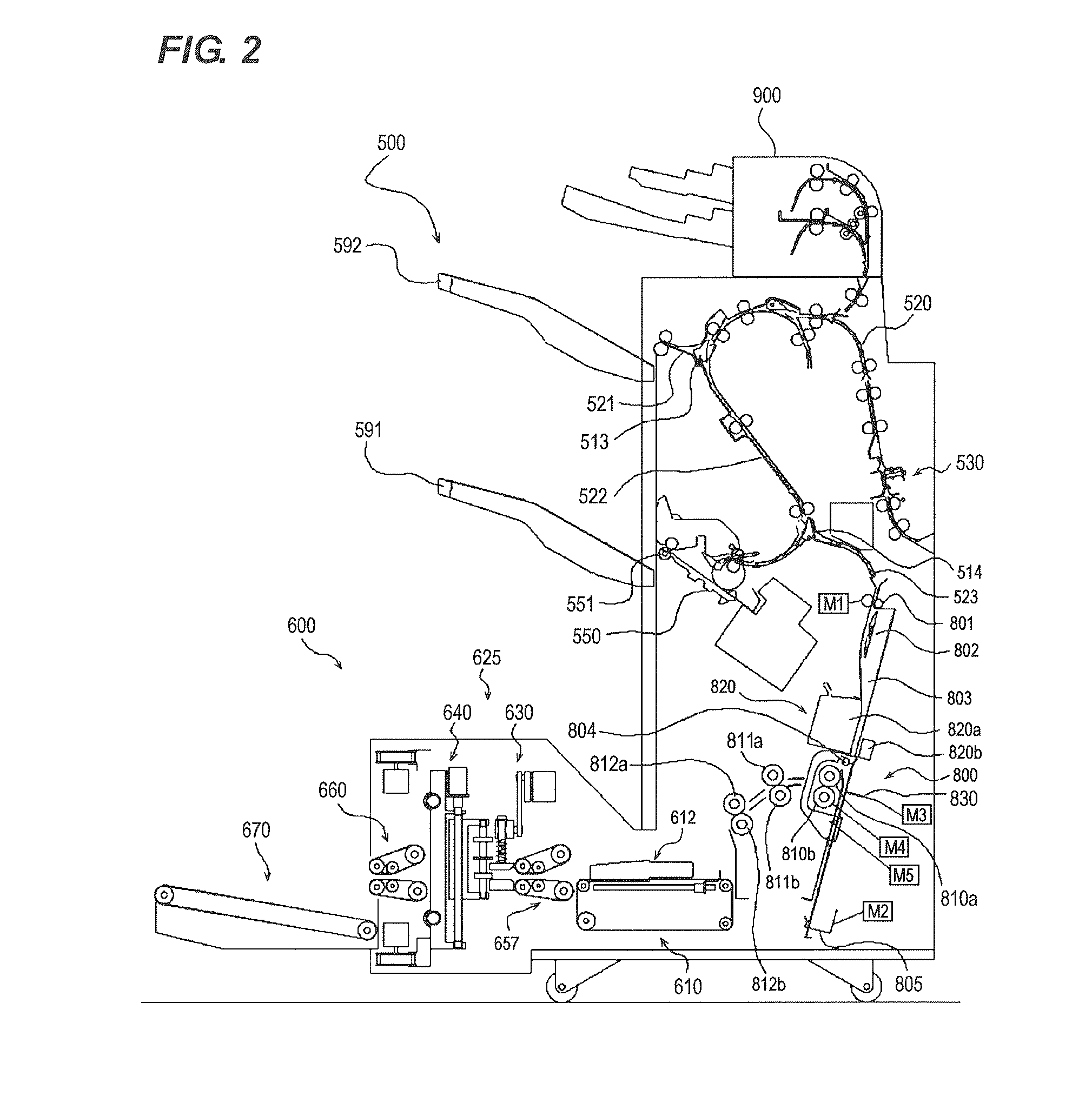

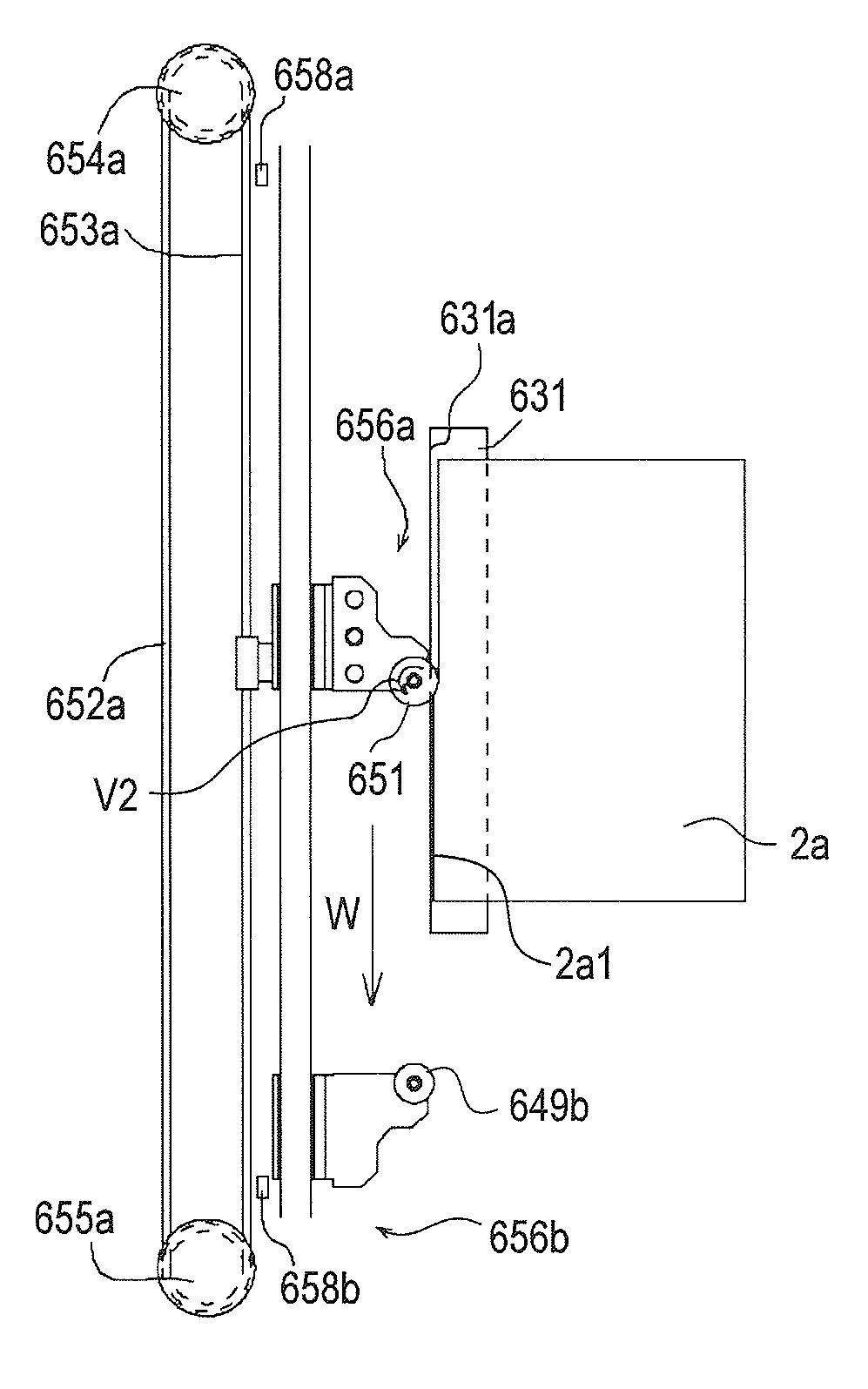

Sheet-bundle spine treatment apparatus, sheet-bundle treatment apparatus, and image-forming apparatus

Owner:CANON KK

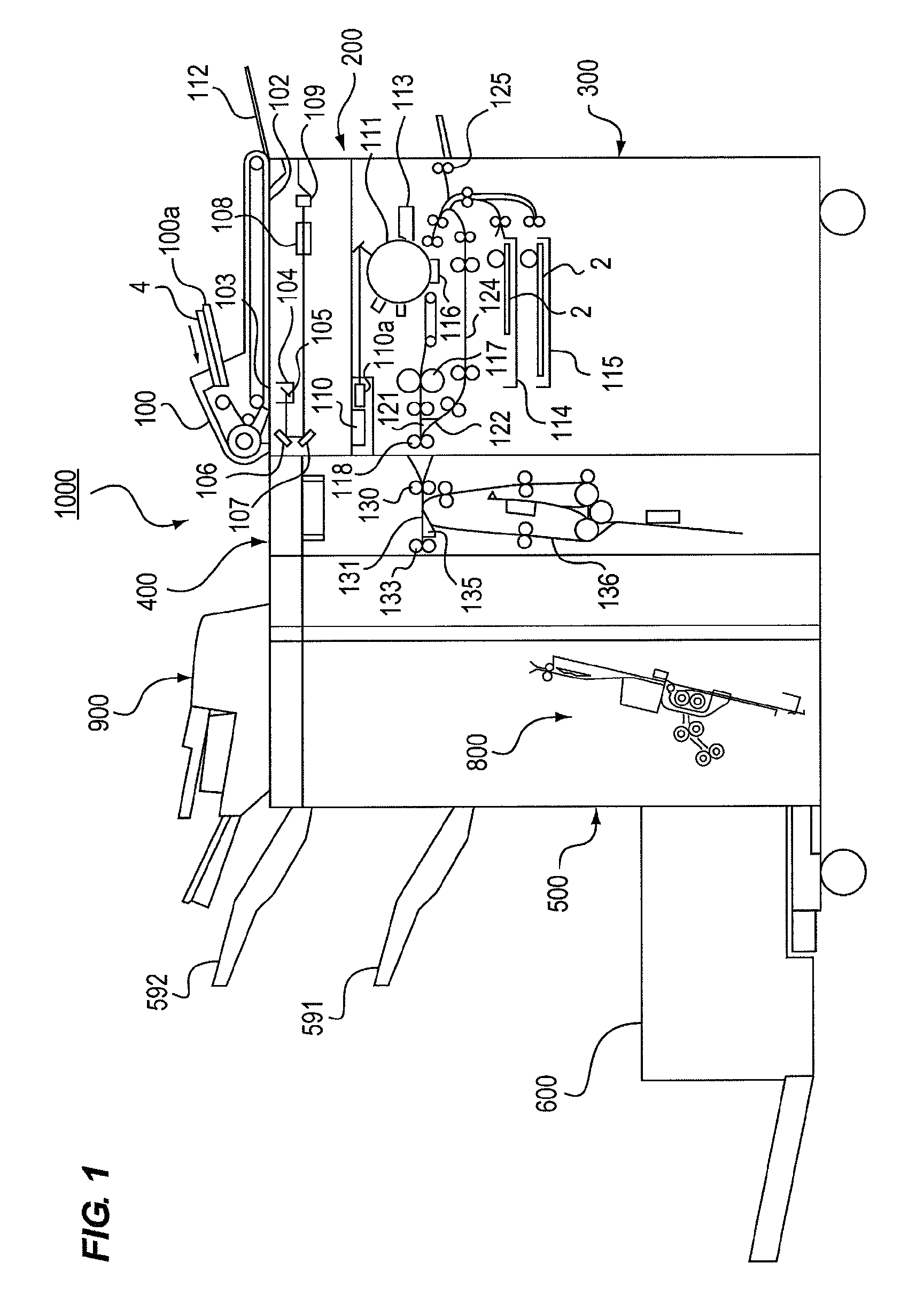

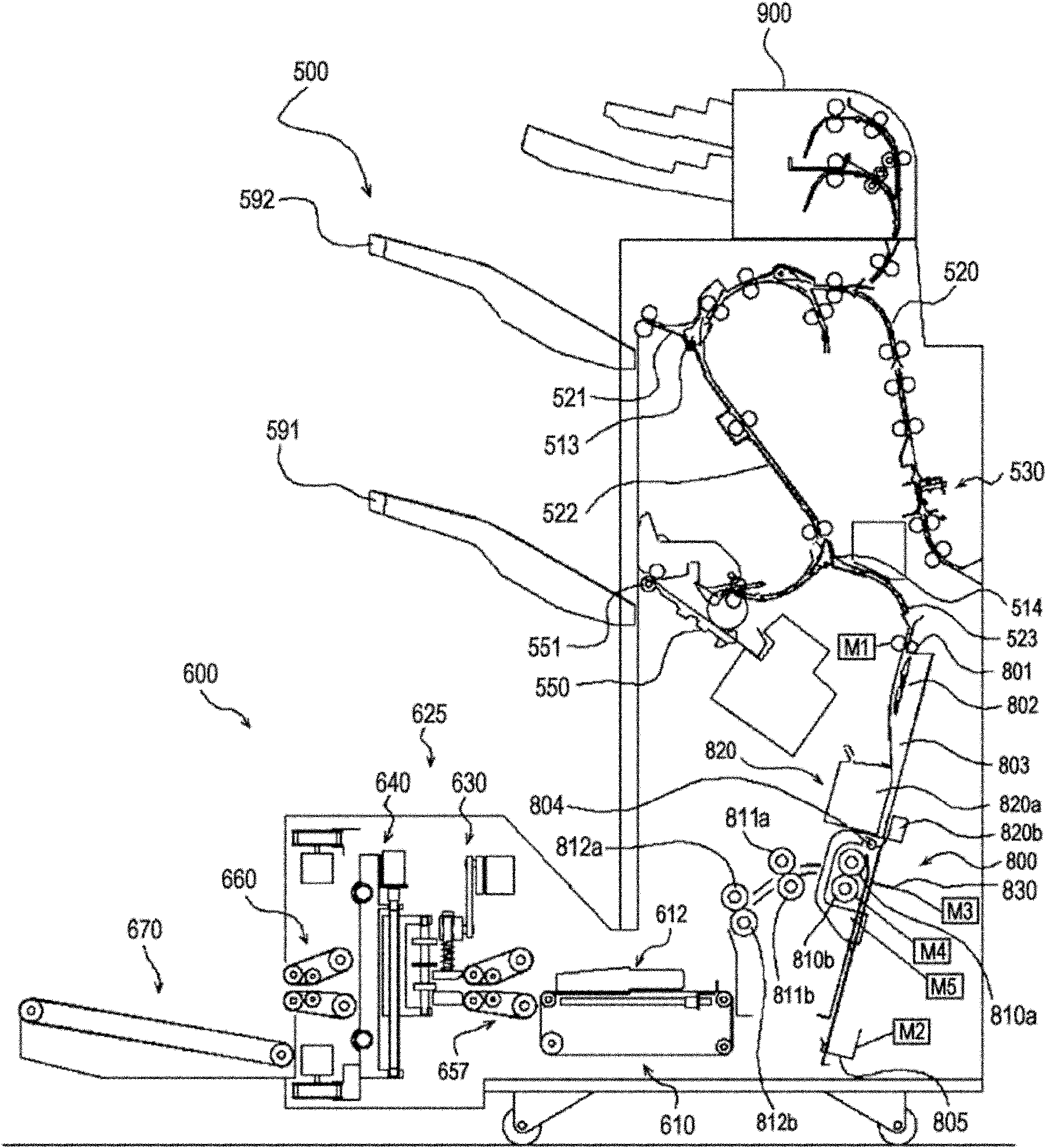

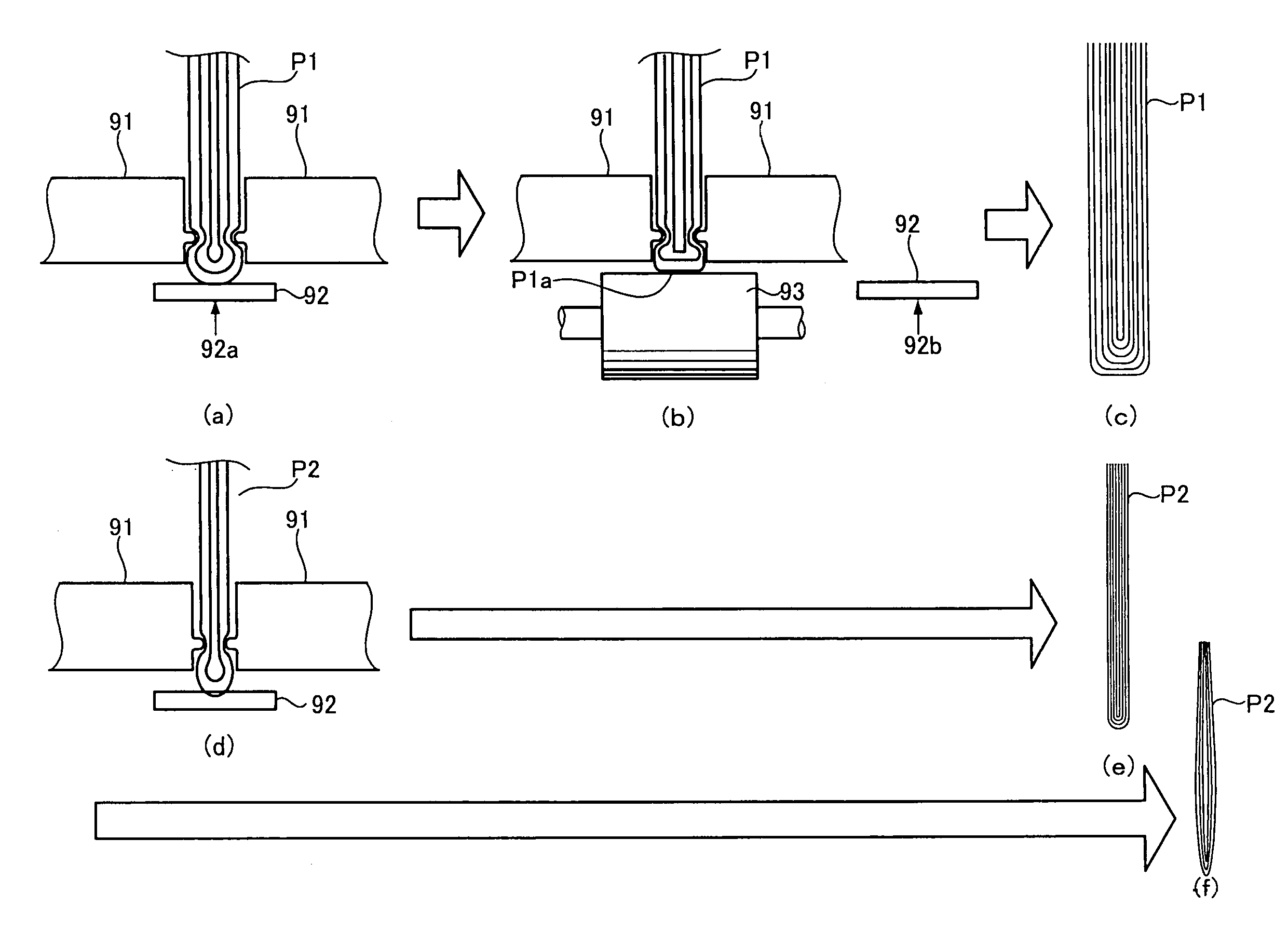

Sheet processing apparatus and image forming apparatus

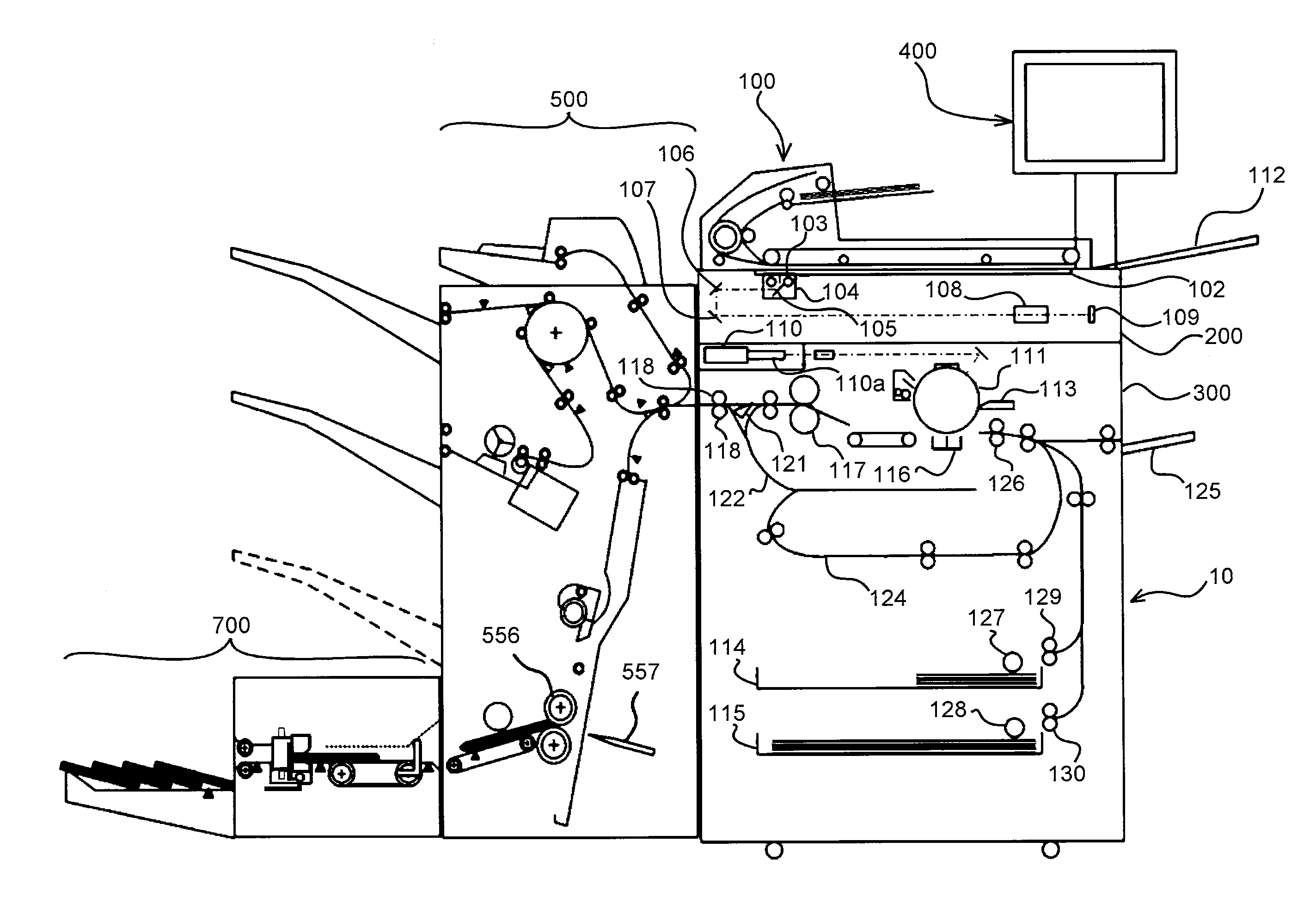

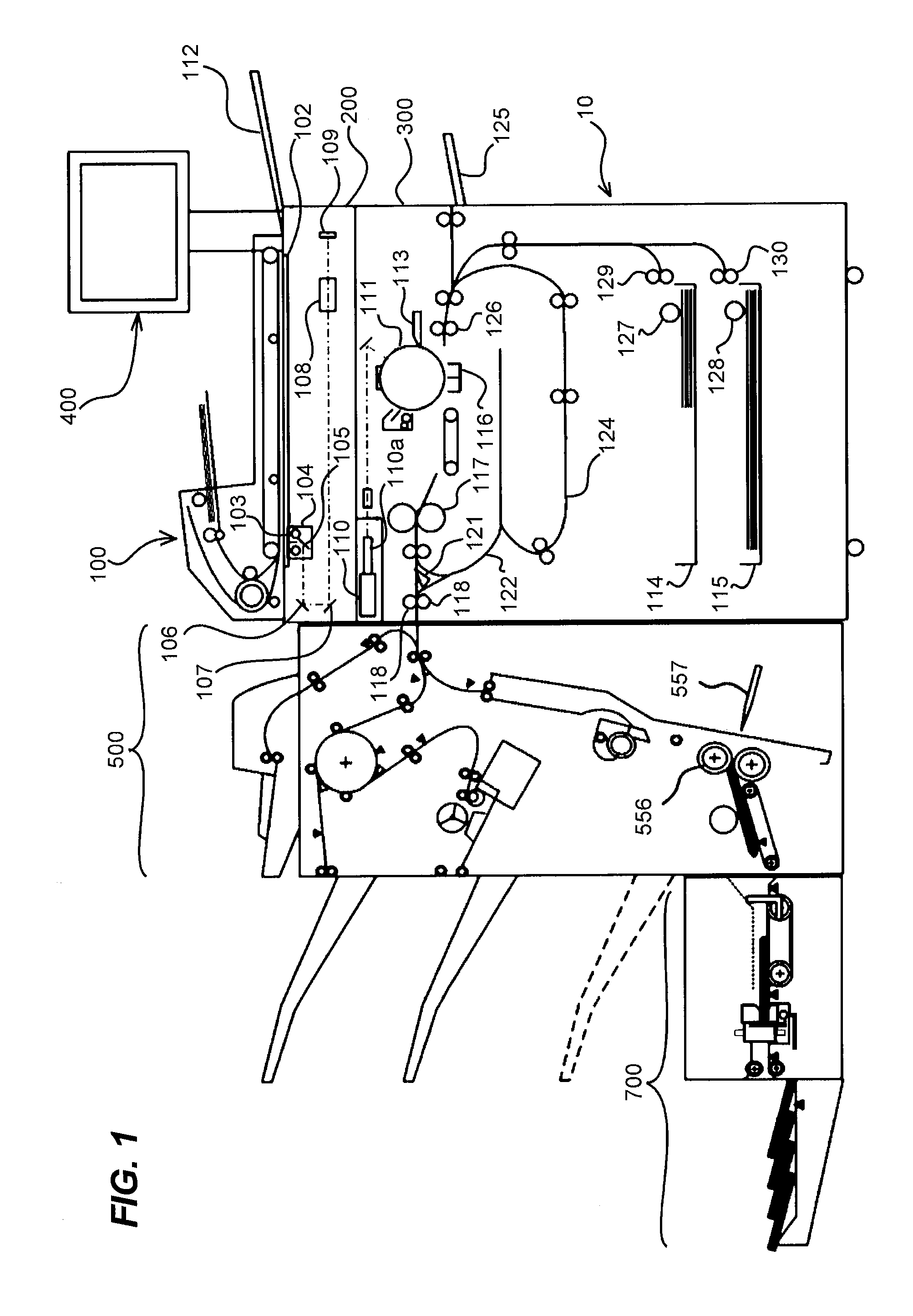

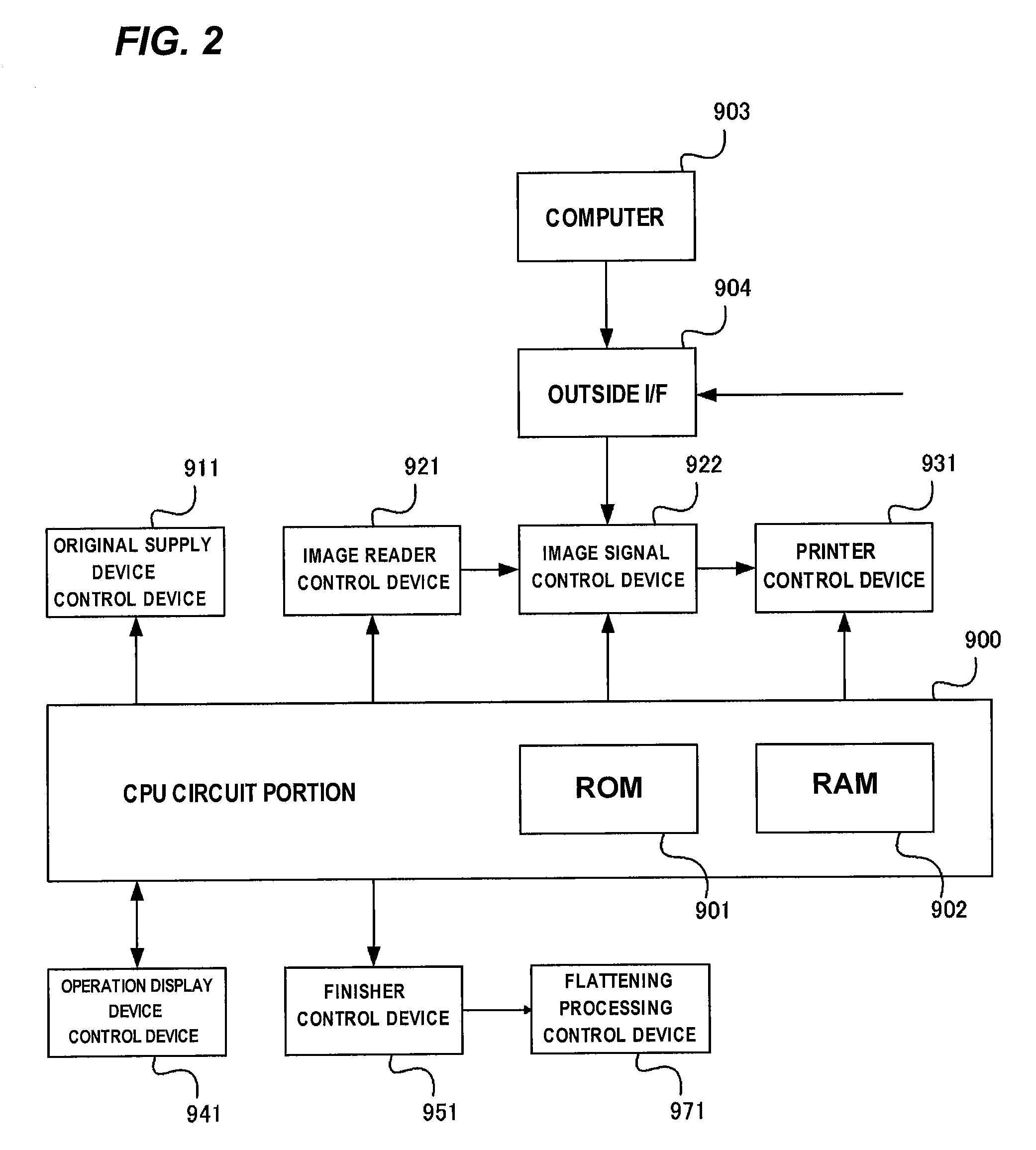

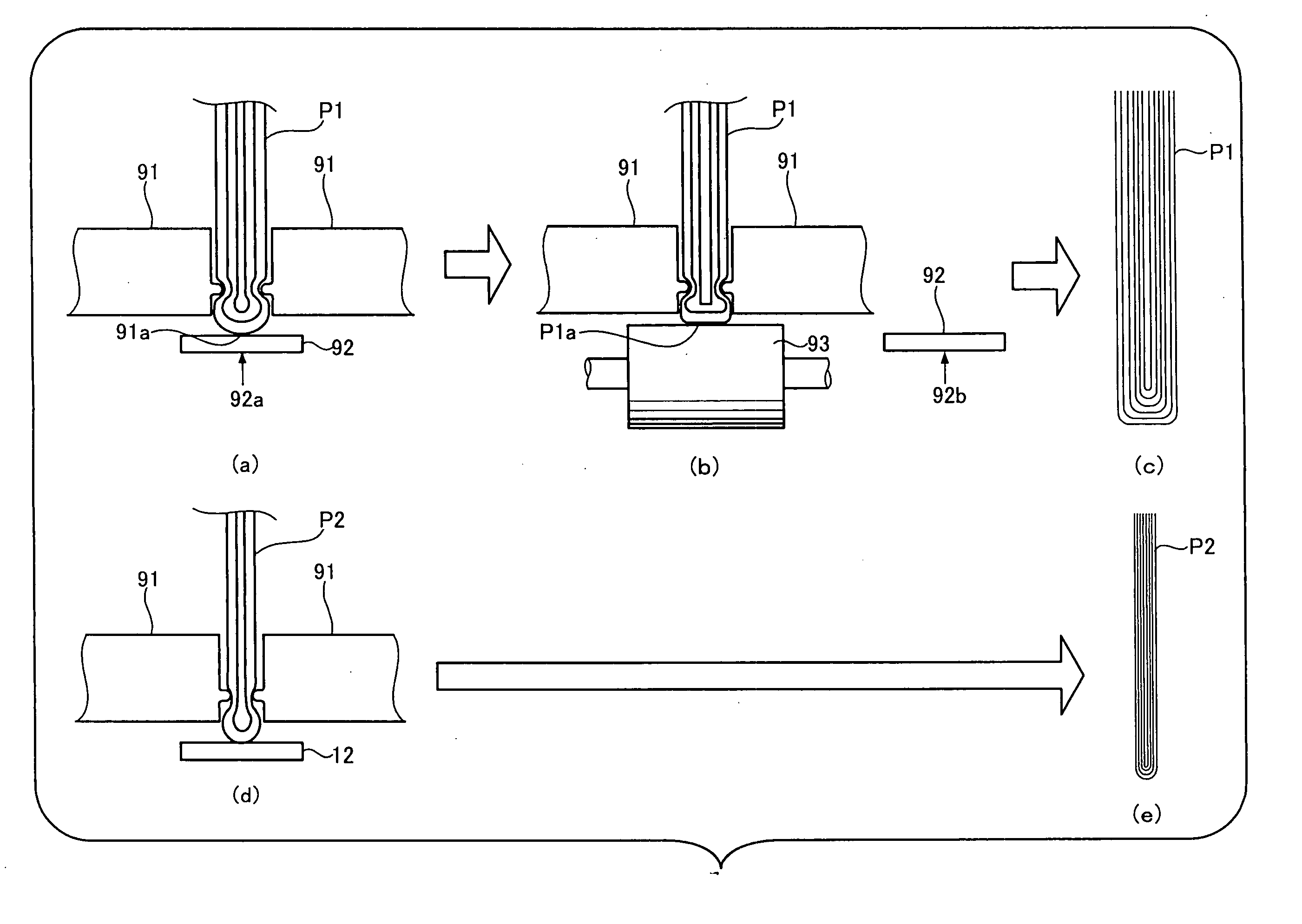

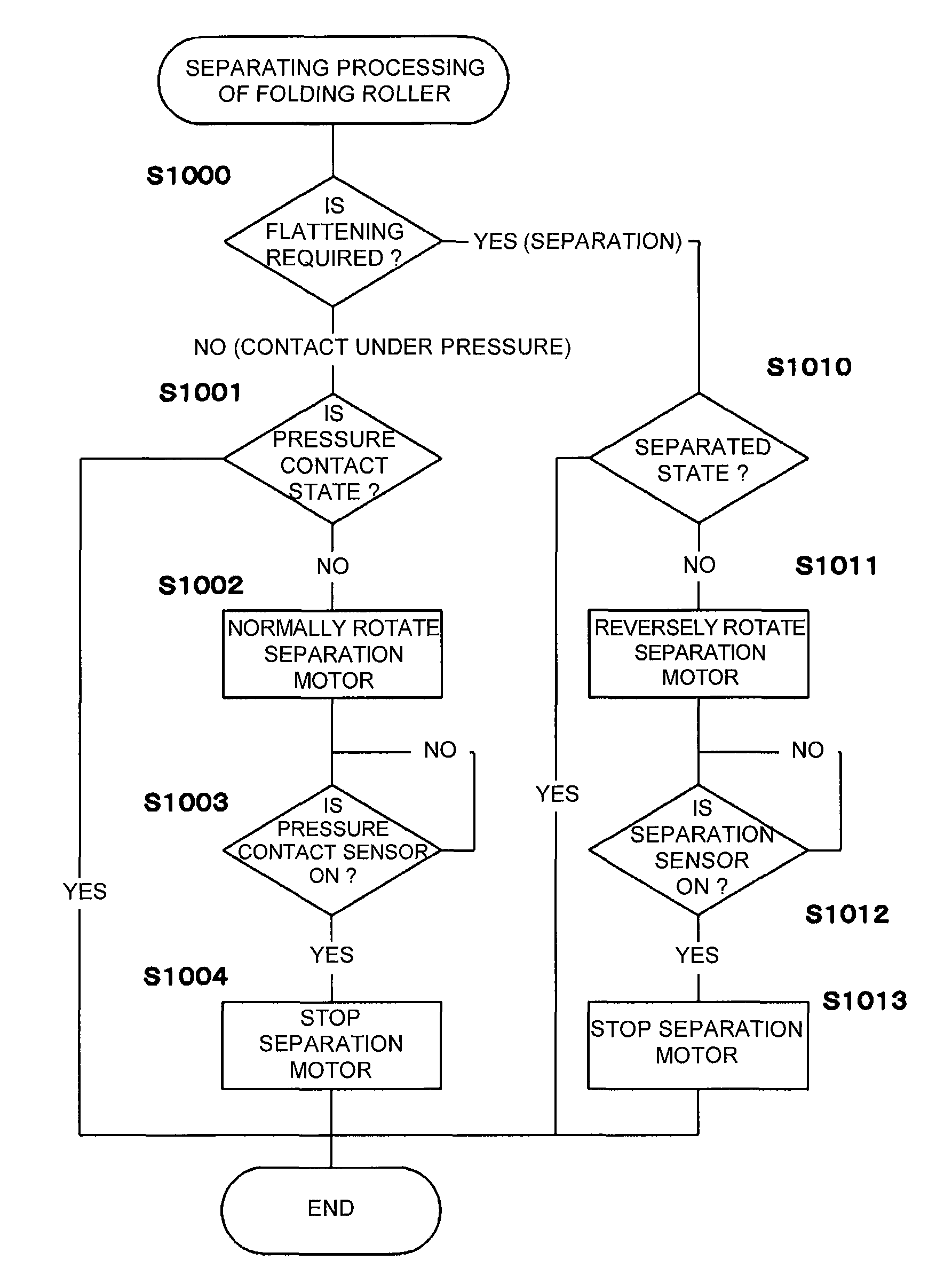

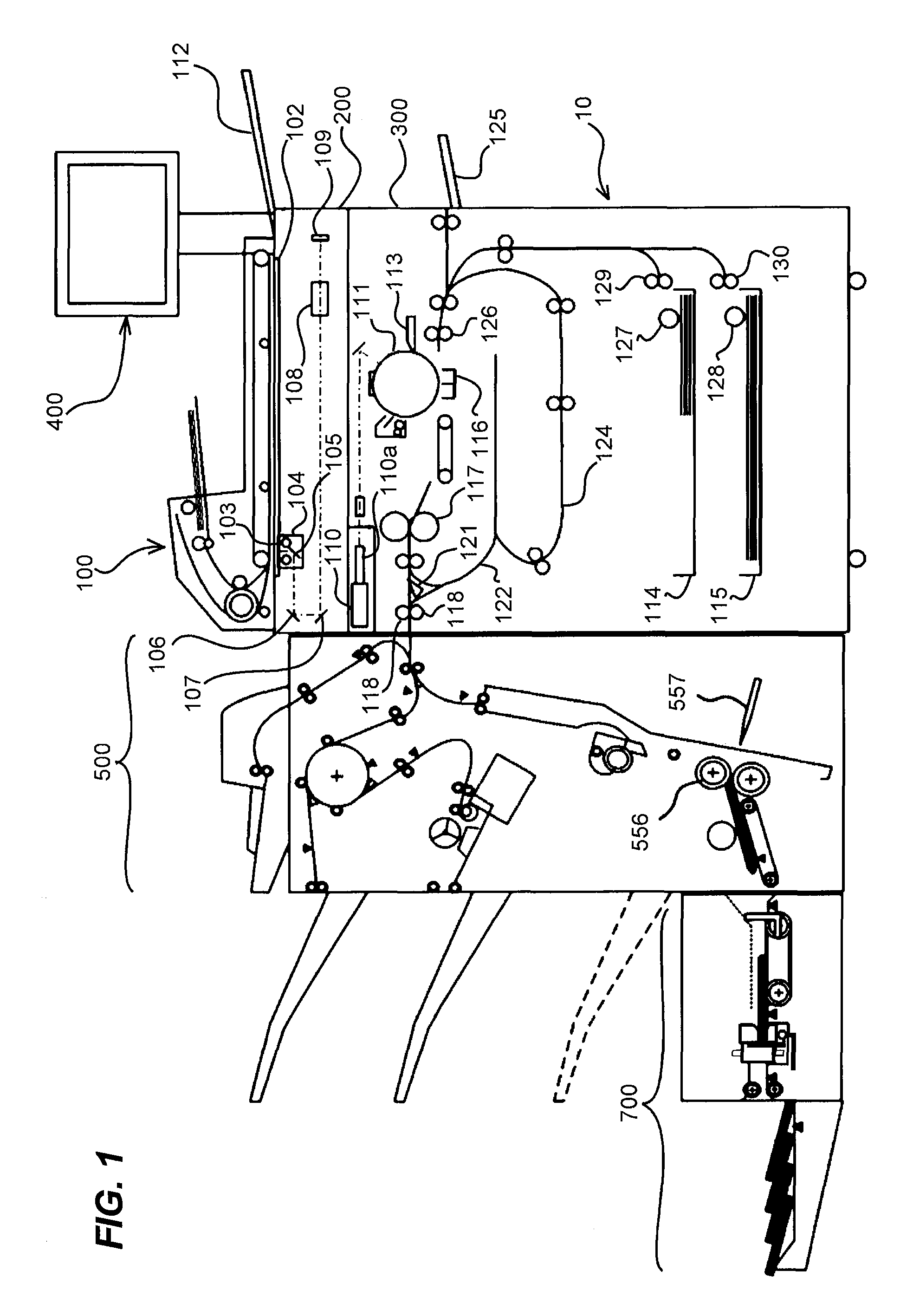

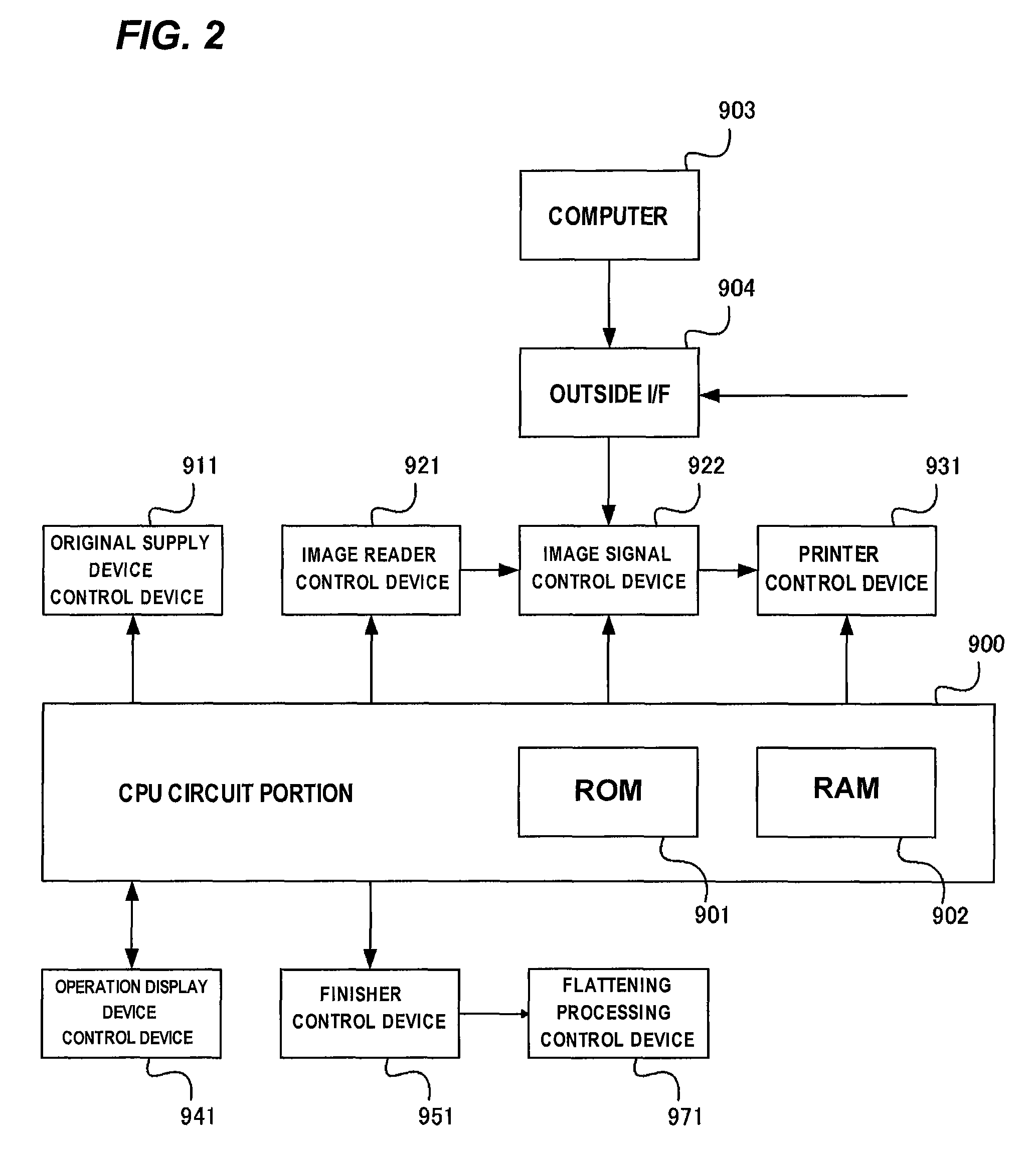

InactiveUS20090103962A1Avoid crackingEffectively elimiBook bindingFolding thin materialsEngineeringSheet material

A sheet processing apparatus includes a folding apparatus 556 which folds a sheet bundle, a switching portion which switches a nipping pressure by the folding apparatus 556 against the sheet bundle, and a flattening apparatus 700 which presses and flattens a folded-back portion of the folded sheet bundle, and the switching portion operates such that the nipping pressure by the folding apparatus 556 against the sheet bundle when the flattening processing is executed becomes weaker than that of the folding apparatus 556 when the flattening processing is not executed.

Owner:CANON KK

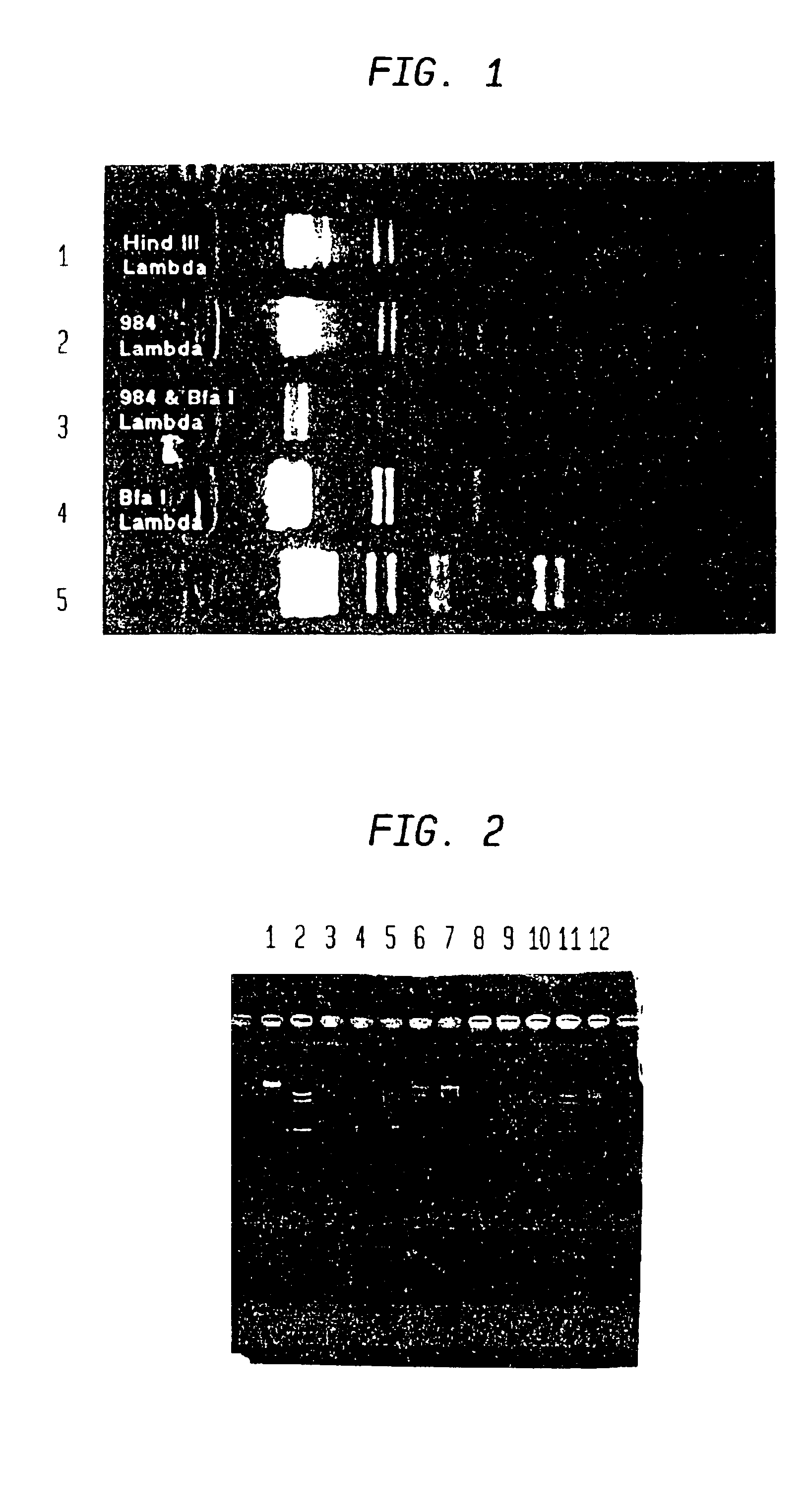

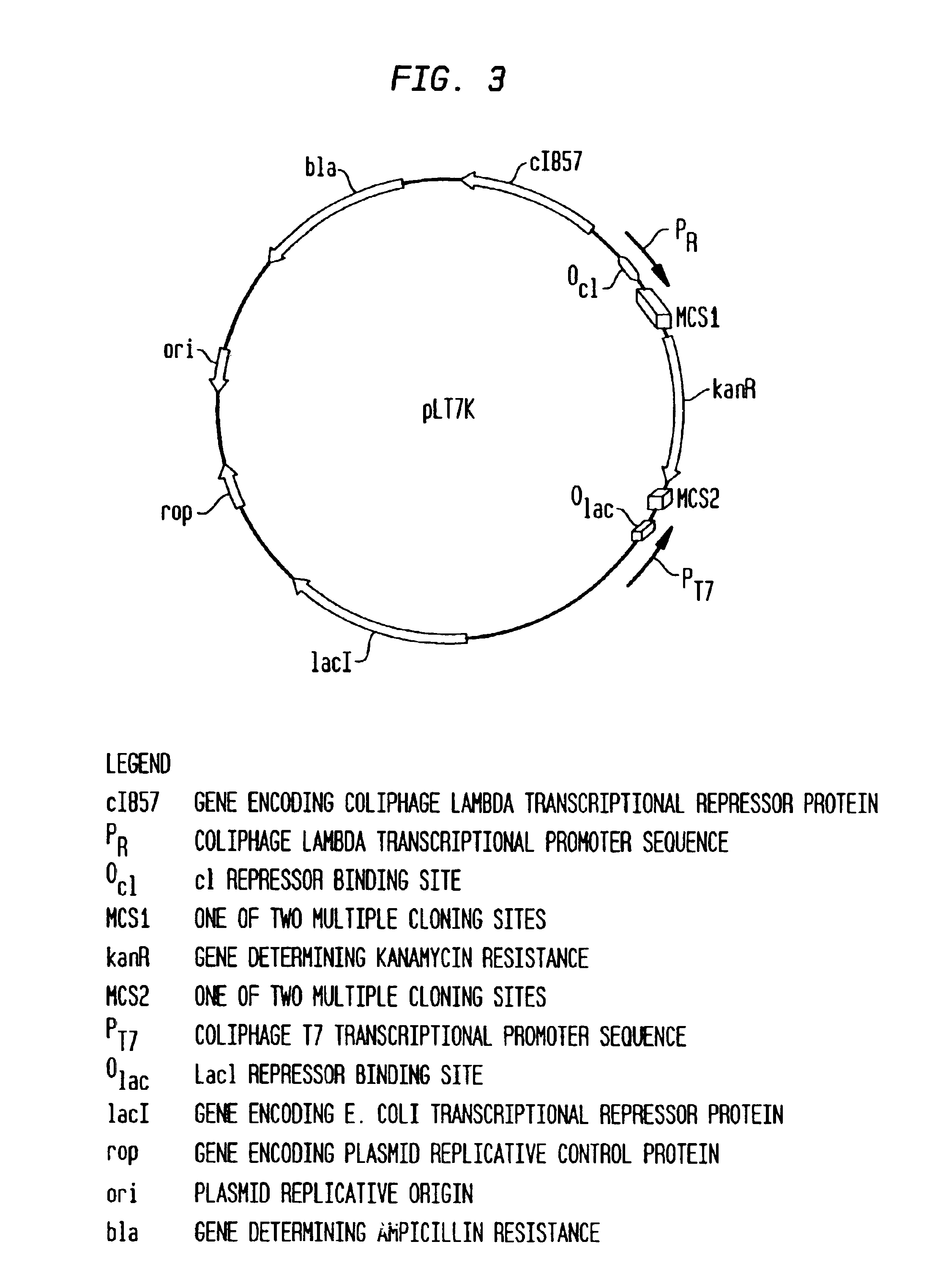

Method for screening restriction endonucleases

InactiveUS6905837B2Facilitate characterizationPromote productionSugar derivativesHydrolasesOpen reading frameCytotoxicity

A method is provided for identifying a restriction endonuclease, which includes the steps of (a) screening a target DNA sequence for the presence of known methylase sequence motifs, (b) identifying any open reading frames which lie close to the methylase sequence motifs screened in step (a), and (c) assaying the protein products of these open reading frames for restriction endonuclease activity.Methods for identifying isoschizomers of known restriction endonucleases, which isoschizomers possess a desired physical property, such as thermostability, are also provided by the present invention, as are several novel restriction endonucleases isolated from M. jannaschii, MjaIII and MjaIV. Additionally, a gene was identified that encoded a previously observed endonuclease activity, designated MjaII.Also provided by the present invention are vectors suitable for cloning a DNA sequence encoding a cytotoxic protein, via independent transcription promotors which may be selectively controlled by several conditions. A method for producing these cytotoxic proteins using such vectors is also provided, as are stable clones of PacI and NlaIII.

Owner:GOSS INT AMERICAS

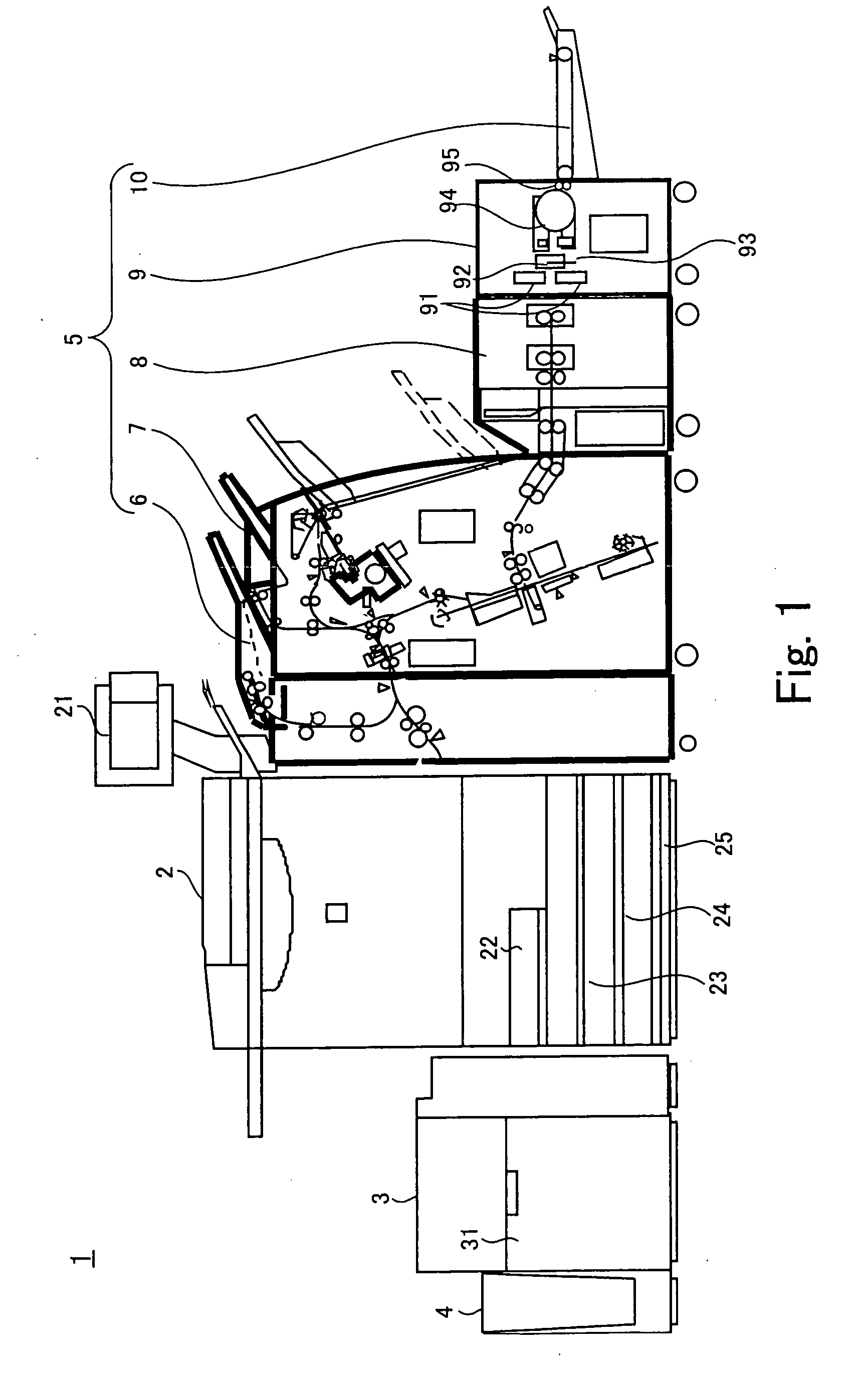

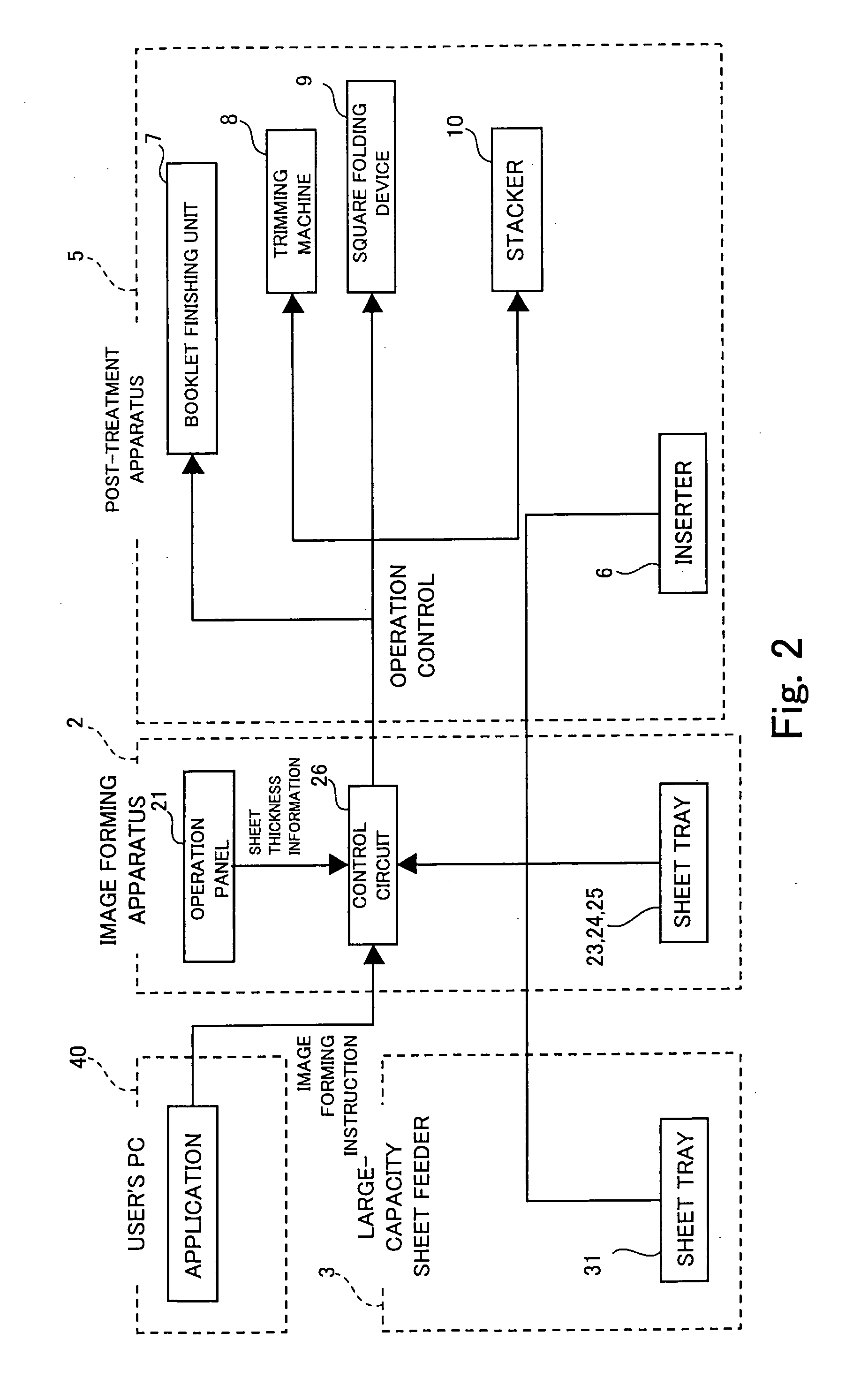

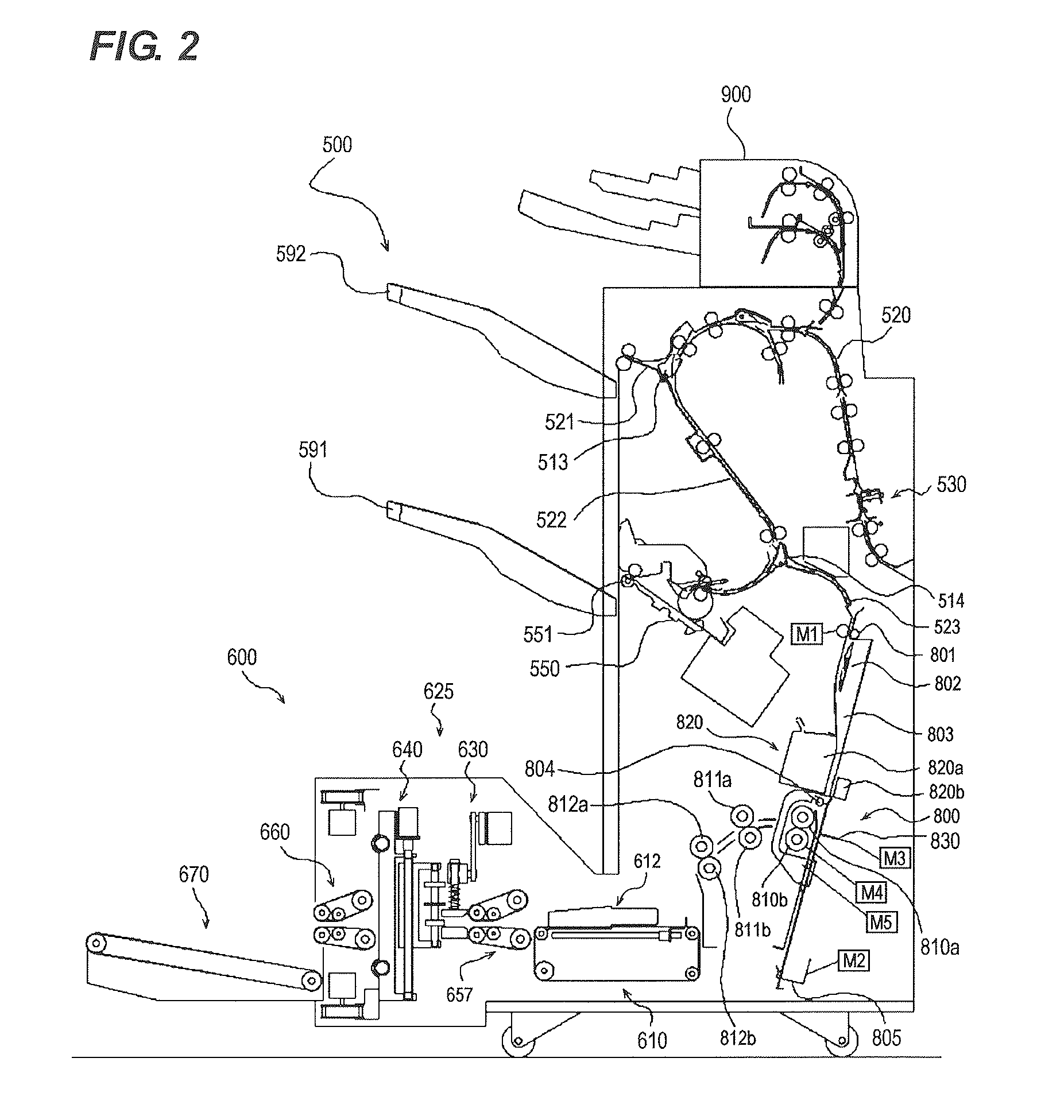

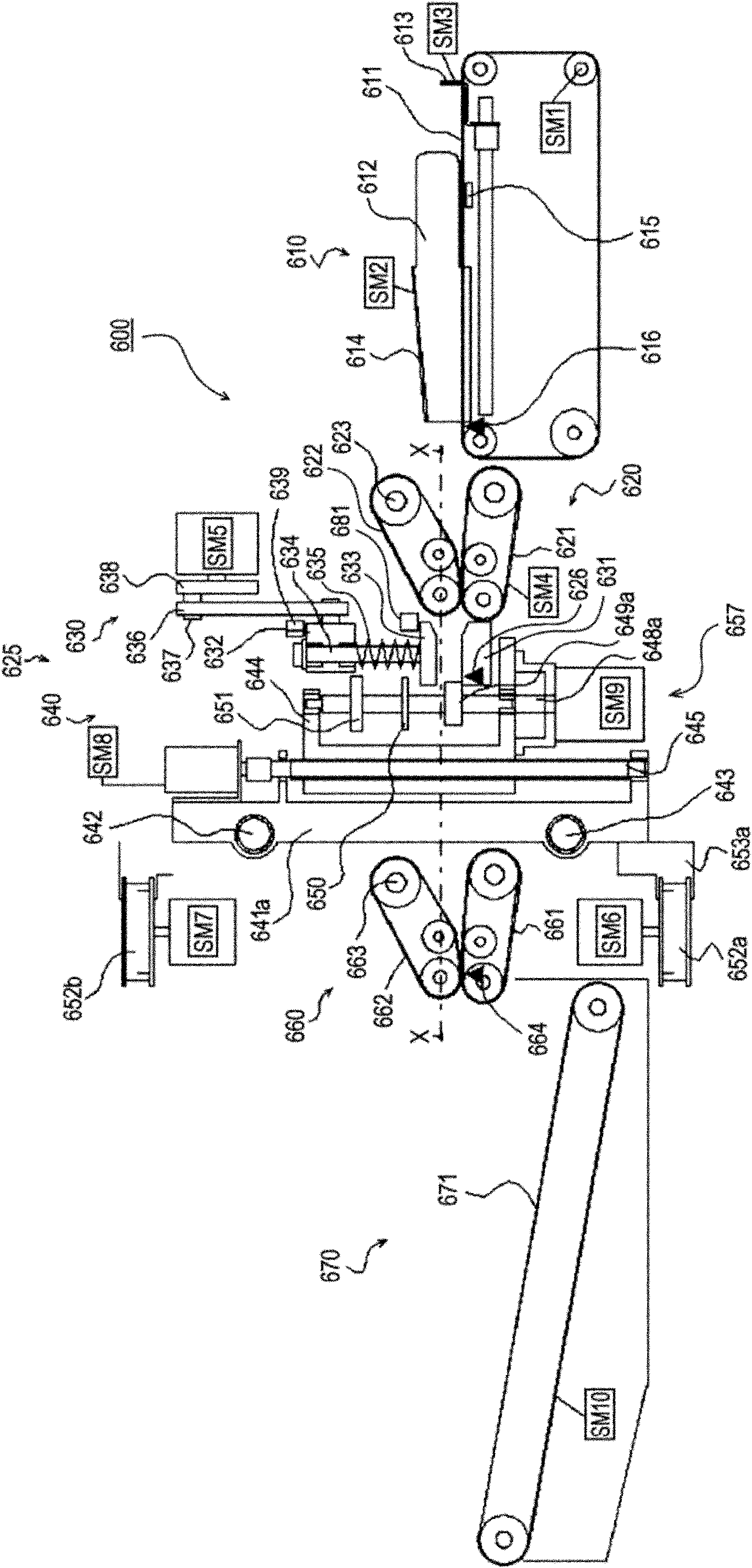

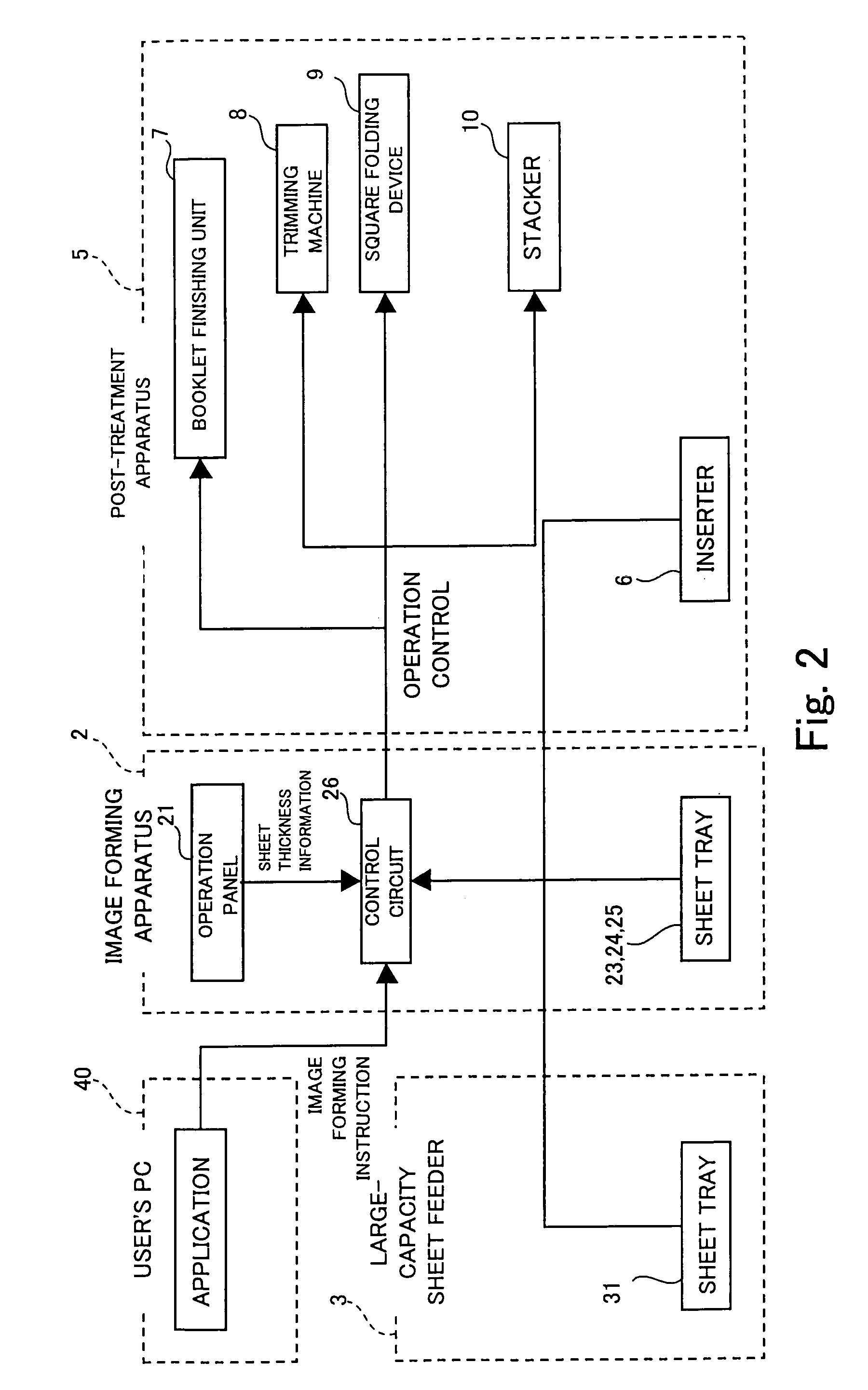

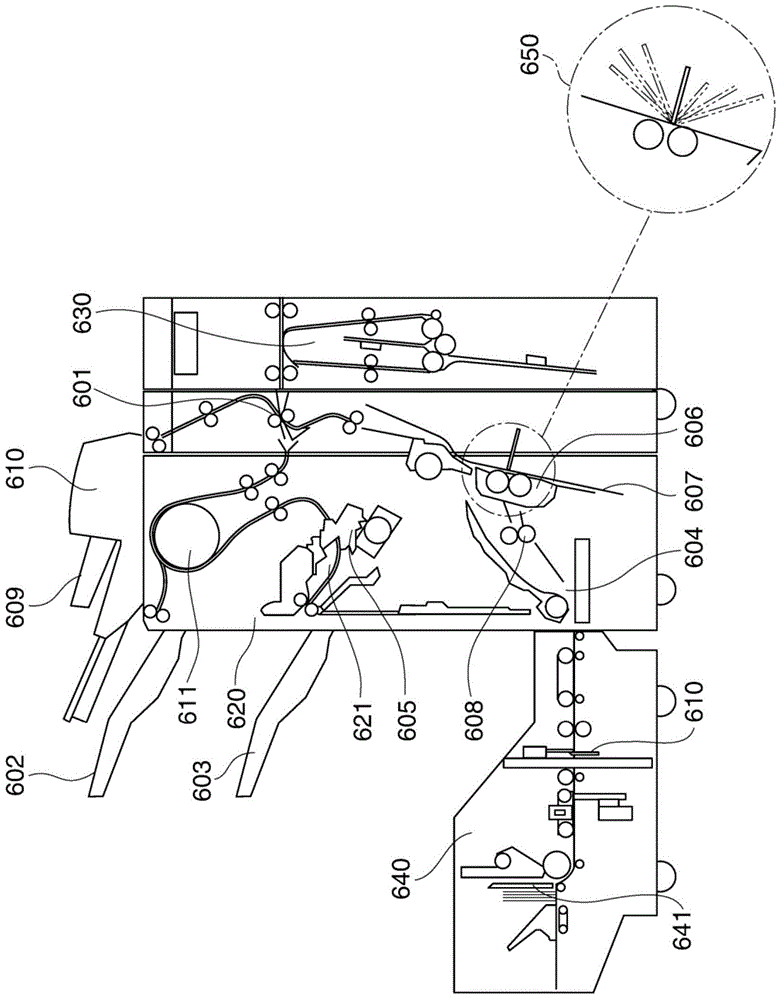

Booklet finishing apparatus, post-treatment apparatus and image forming system

A booklet finishing apparatus has a clamping unit that flattens a booklet of folded sheets by clamping at least on portion adjacent to a back of the booklet from both surfaces of the booklet, a forming unit that flattens the back of the booklet by pressing the back of the booklet, and a switching unit that has a plurality of modes to control the forming unit and switches between the plurality of modes.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Sheet processing apparatus and image forming apparatus

InactiveUS7938388B2Avoid crackingEffectively elimiBook bindingFolding thin materialsEngineeringMechanical engineering

A sheet processing apparatus includes a folding apparatus which folds a sheet bundle, a switching portion which switches a nipping pressure of the folding apparatus against the sheet bundle, and a flattening apparatus which presses and flattens a folded-back portion of the folded sheet bundle. The switching portion operates such that the nipping pressure of the folding apparatus against the sheet bundle when the flattening processing is executed becomes weaker than that of the folding apparatus when the flattening processing is not executed.

Owner:CANON KK

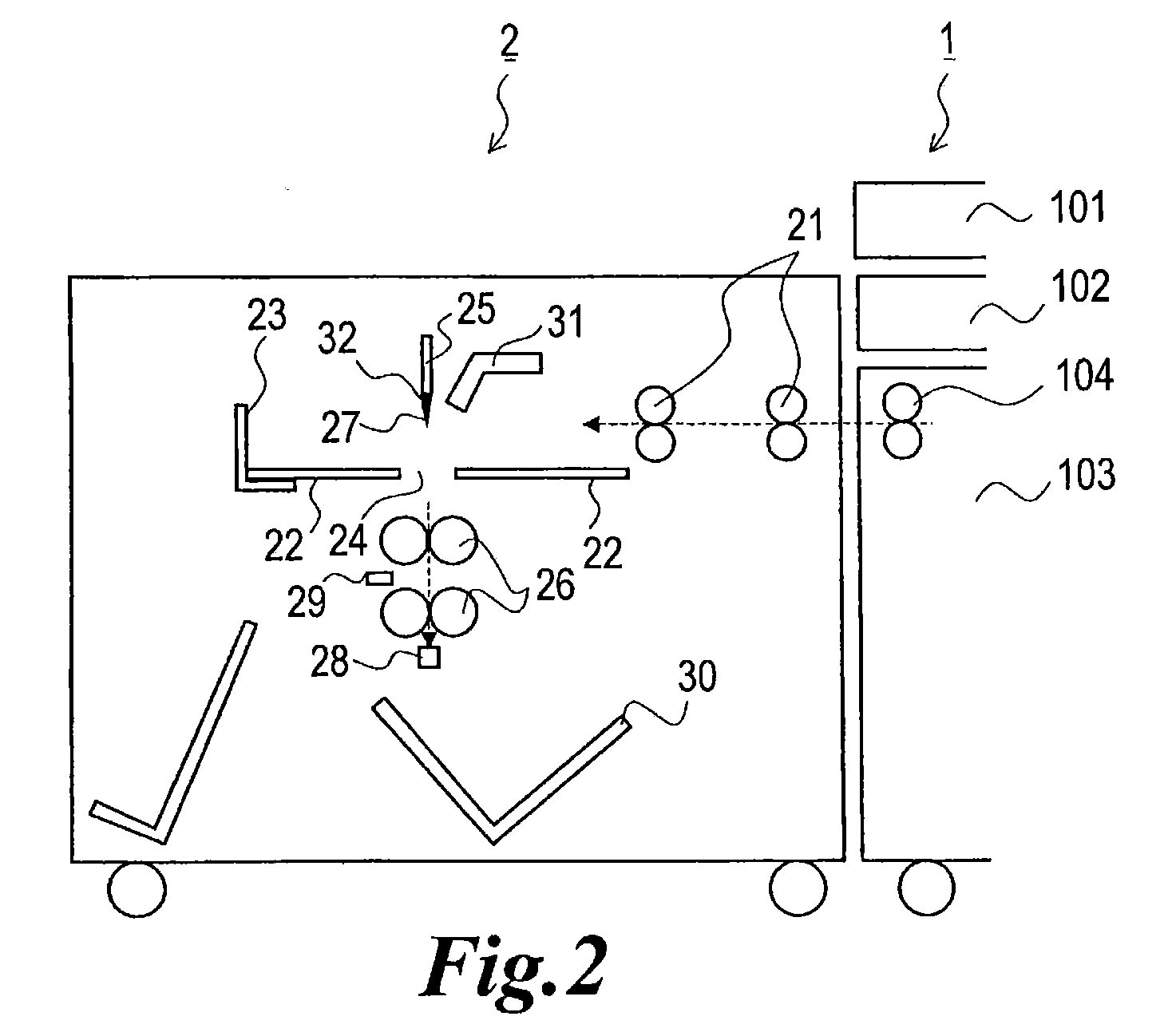

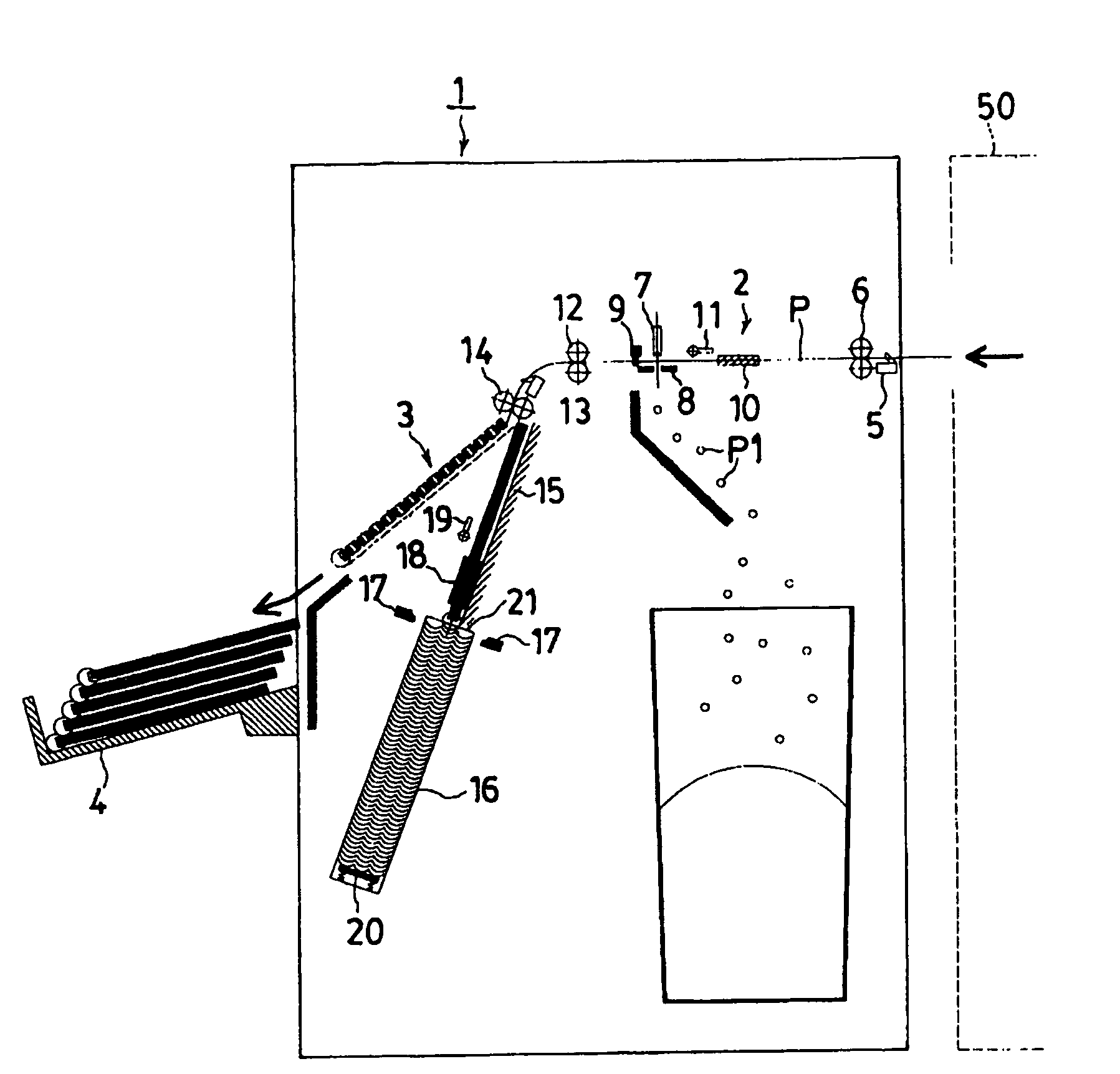

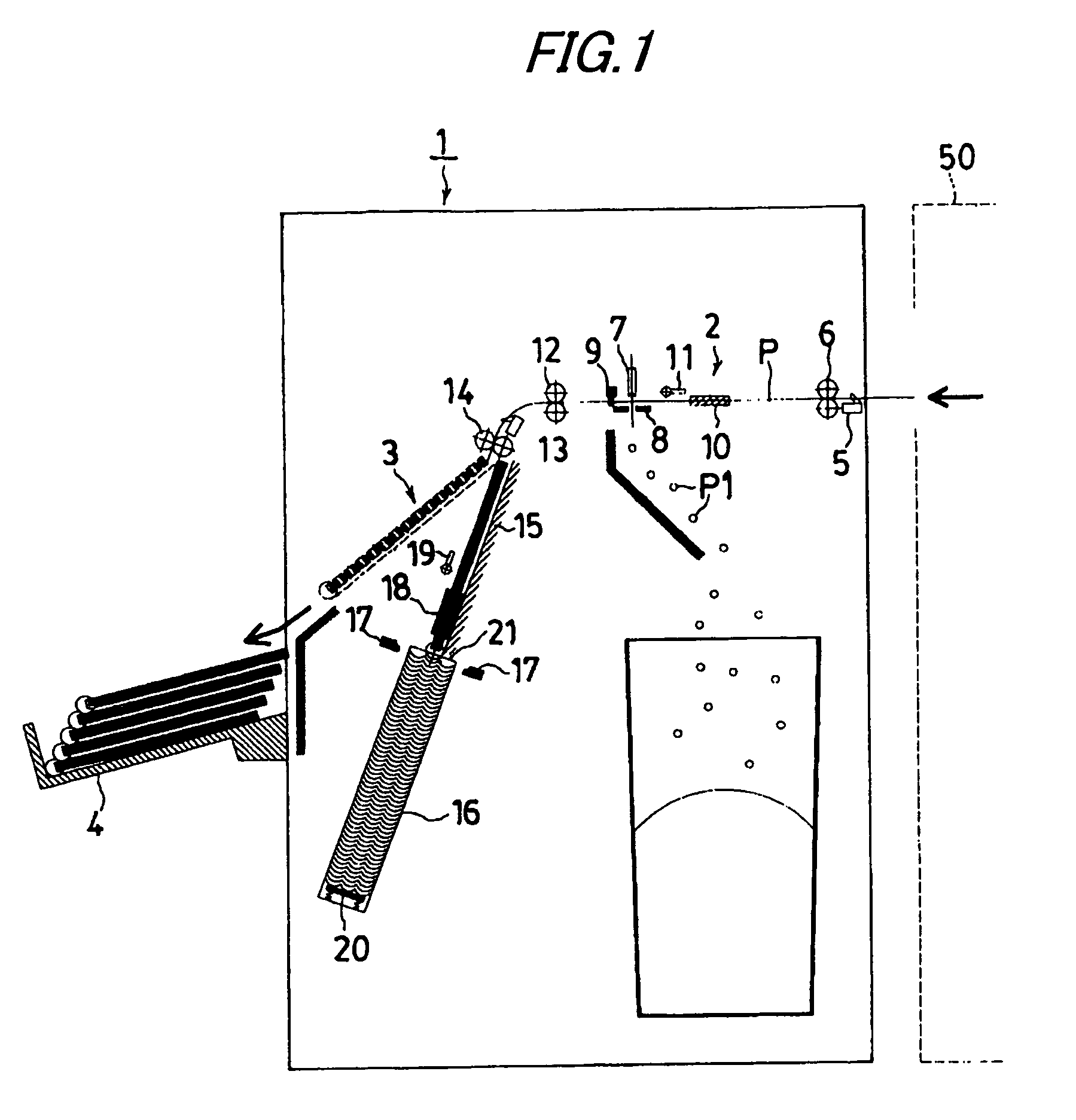

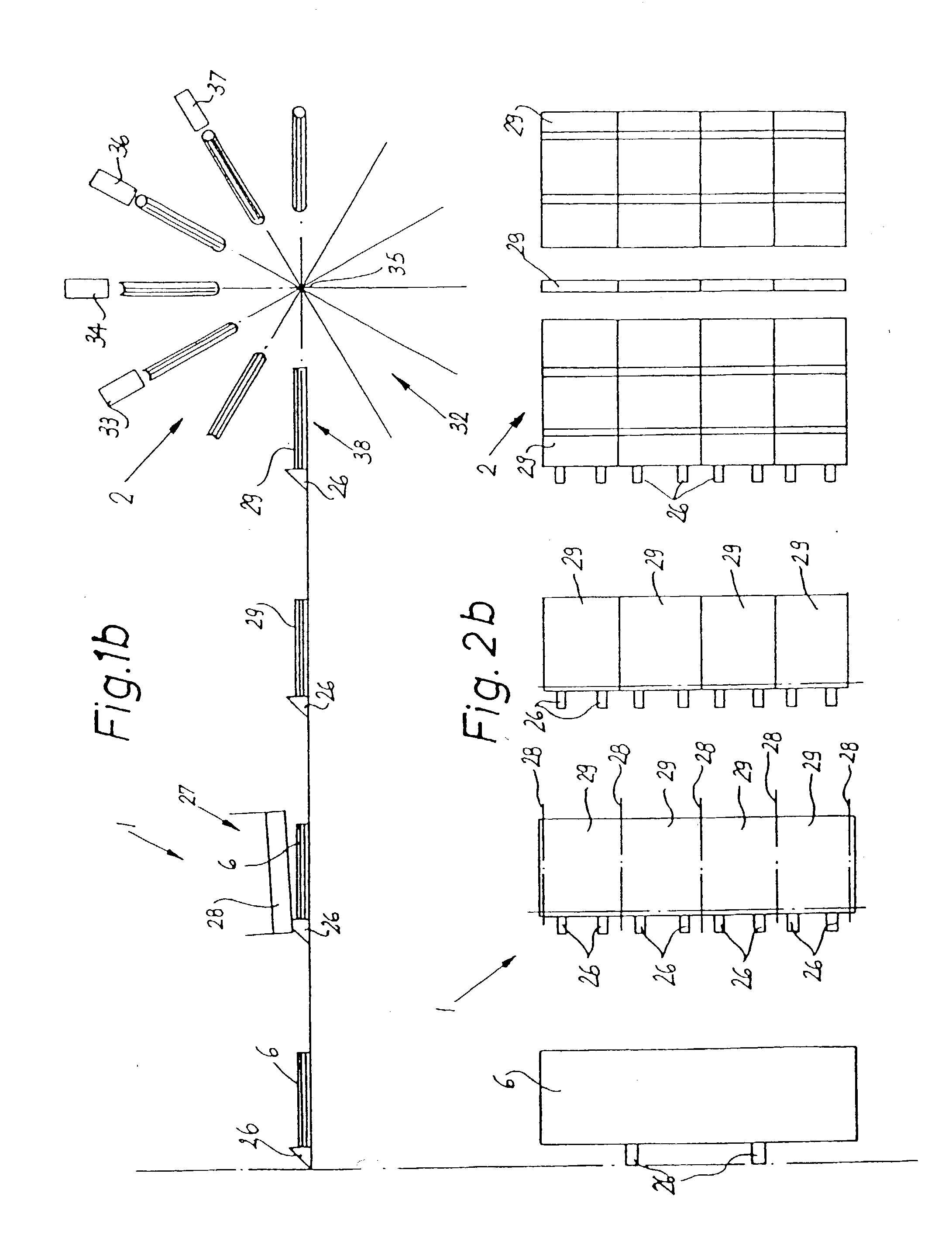

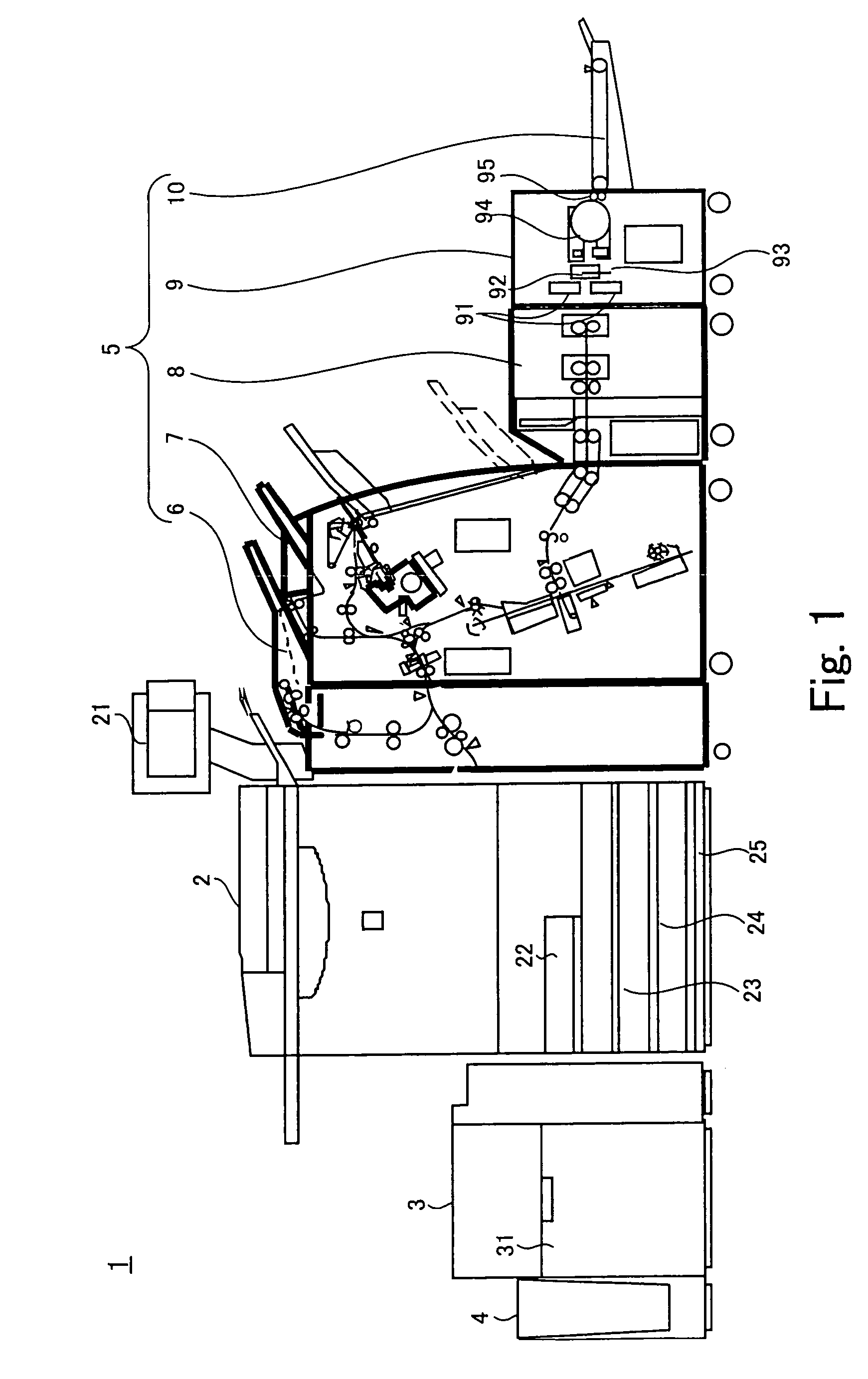

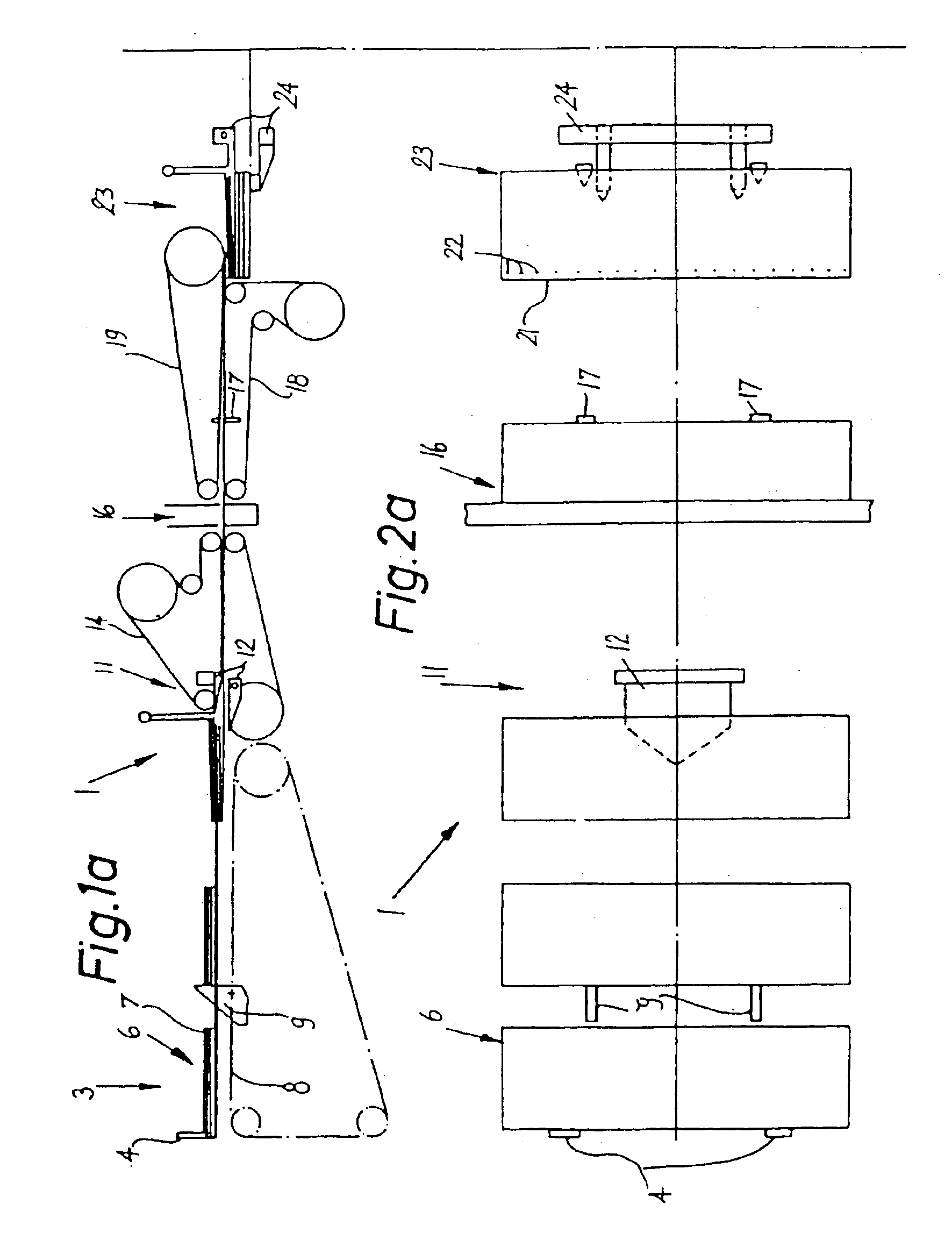

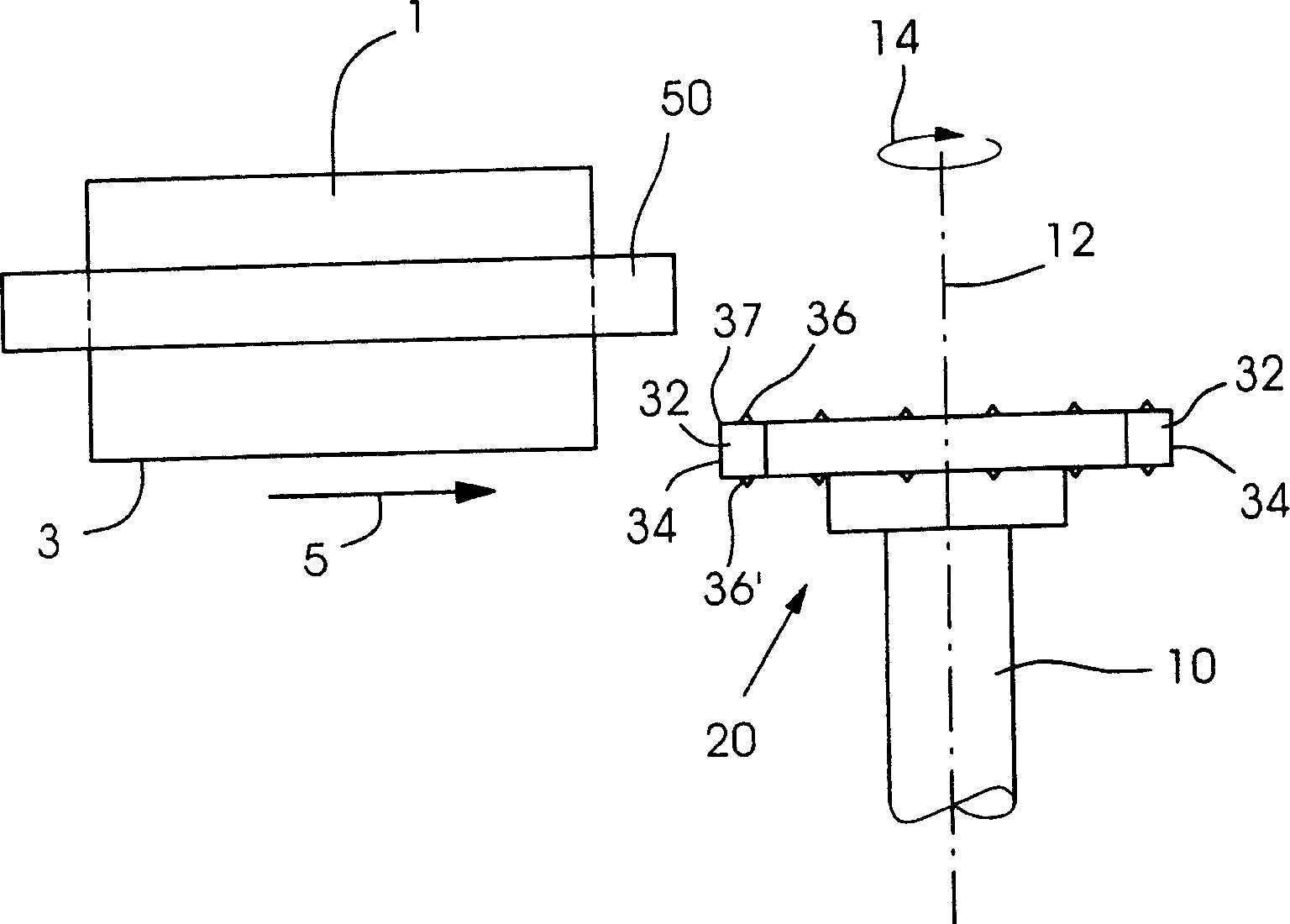

Binding processing apparatus

A binding processing apparatus 1 is provided with a punch mechanism 2 and a binding processing mechanism 3 for executing a binding processing by a binder. When a sheet P is fed from a printing apparatus 50 of a copier or the like, the sheet is butted to a stopper plate 9 of the punch mechanism, sheet aligning sliders 10 push both left and right sides thereof to position and punch holes are formed by a punch block 7 and a die 8. Thereafter, the sheet is fed to a sheet tray 15 of the binding processing mechanism, one set of the sheets are aligned and a ring shape binder is pinched by a pusher 17 to fit the ring shape binder to the punch holes of the sheets, and a brochure subjected to a binding processing is discharged to a stack tray 4. A binder cartridge 16 can contain a number of the binders and the binding processing can be executed continuously.

Owner:MAX CO LTD

Sheet processing apparatus and image forming apparatus

A staple-less binding unit including a pair of upper and lower teeth binds a sheet bundle which is discharged to an intermediate processing tray by a sheet discharge portion and whose one edge abuts against a rear edge stopper. A control portion switches a binding mode of the staple-less binding unit that implements the binding process on the sheet bundle in a first binding mode of binding the sheet bundle without any staple such that the pair of upper and lower teeth bite across an edge of the sheet bundle and in a second binding mode of binding the sheet bundle without any staple such that the pair of upper and lower teeth do not bite across any edge of the sheet bundle.

Owner:CANON KK

Sheet Post-Processing Apparatus and Image Forming Apparatus

InactiveUS20110176892A1Quality improvementBook bindingFolding thin materialsWrinkle skinImage formation

There is a need to provide a sheet post-processing apparatus capable of neatly squaring a booklet spine without any damage such as a wrinkle on the spine and an image forming apparatus having the sheet post-processing apparatus.According to the sheet post-processing apparatus, a drive motor drives first and second pressing members. A circumferential velocity of the pressing member on a pressing surface pressed against the booklet spine is configured to be reverse to and greater than a moving velocity of a moving portion.

Owner:CANON KK

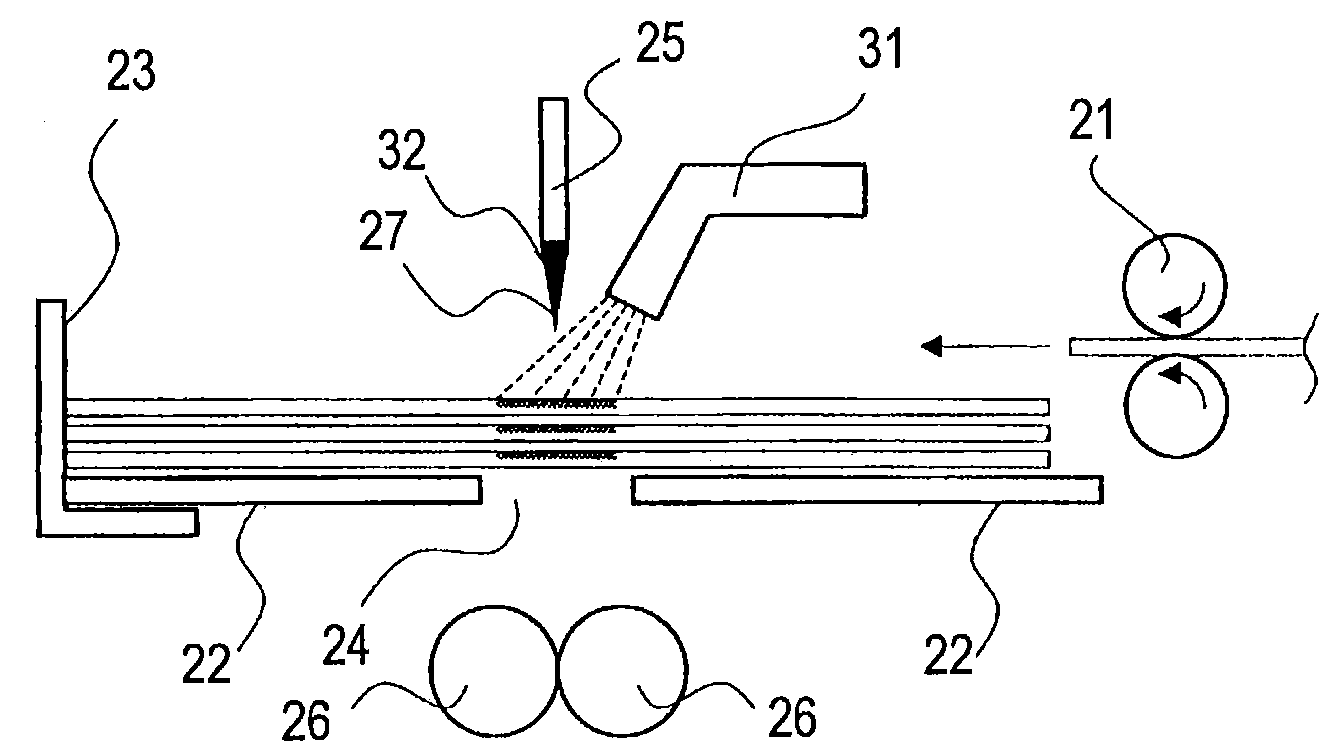

Milling apparatus

Owner:HORIZON INTERNATIONAL INC

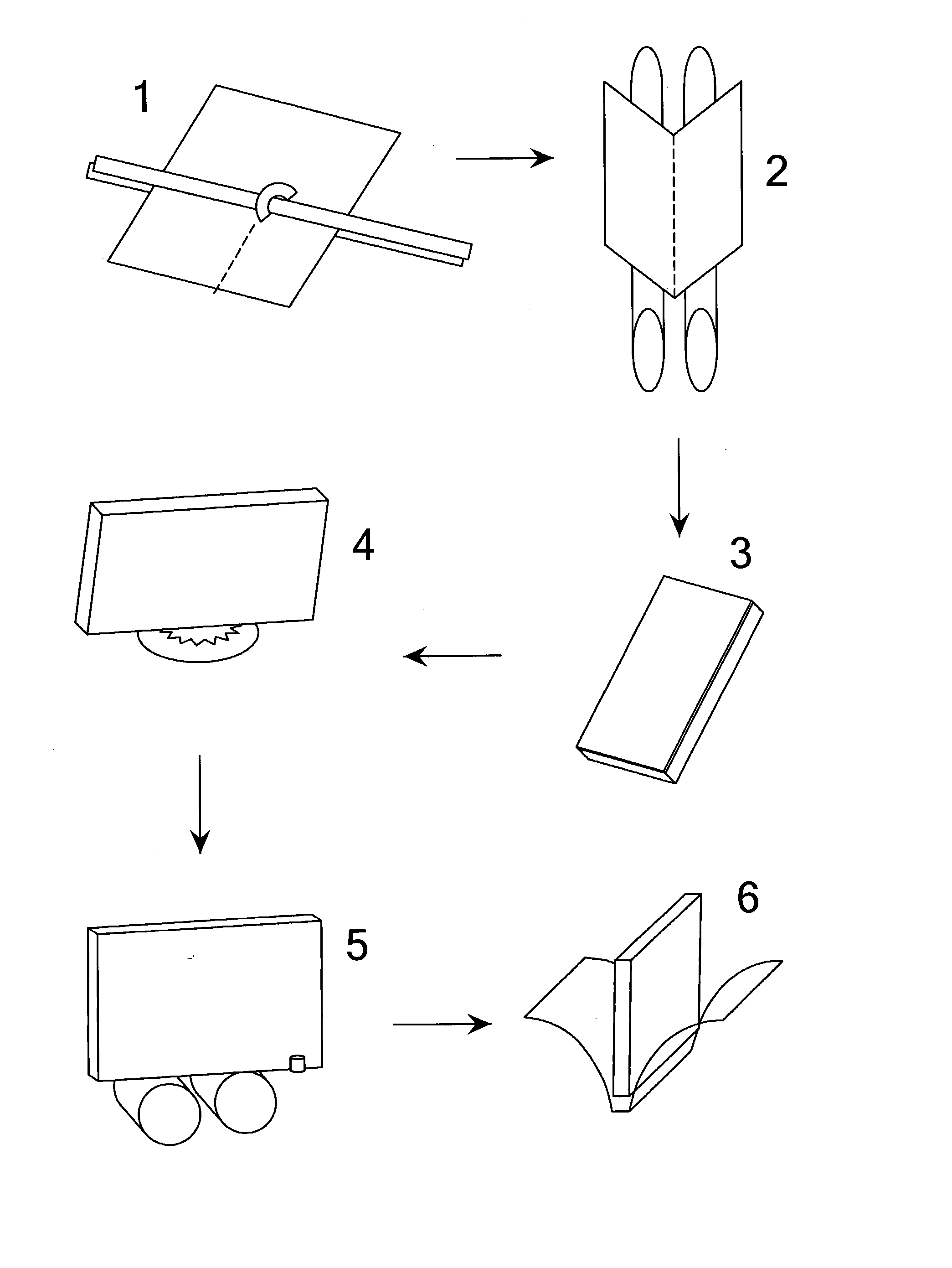

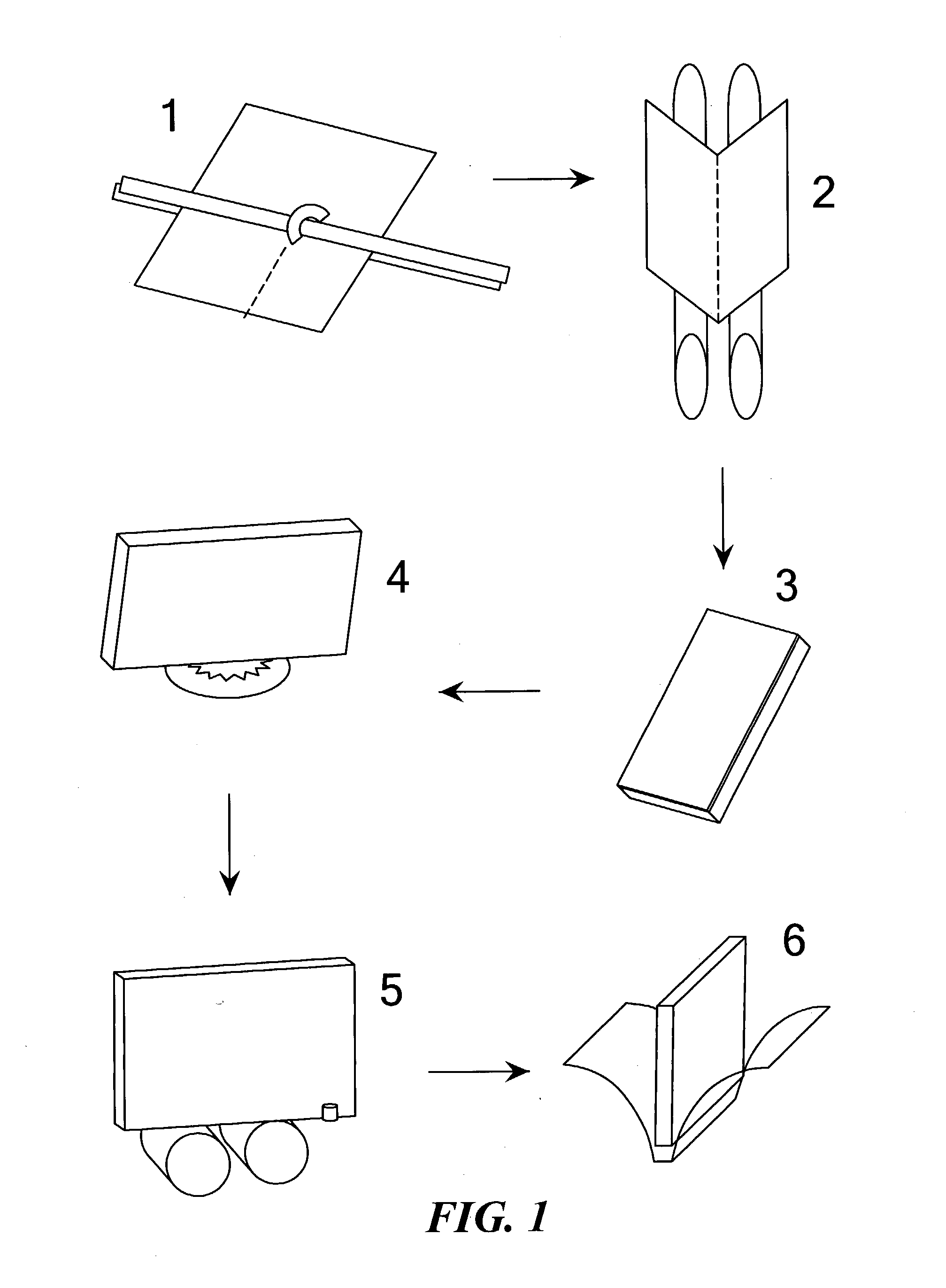

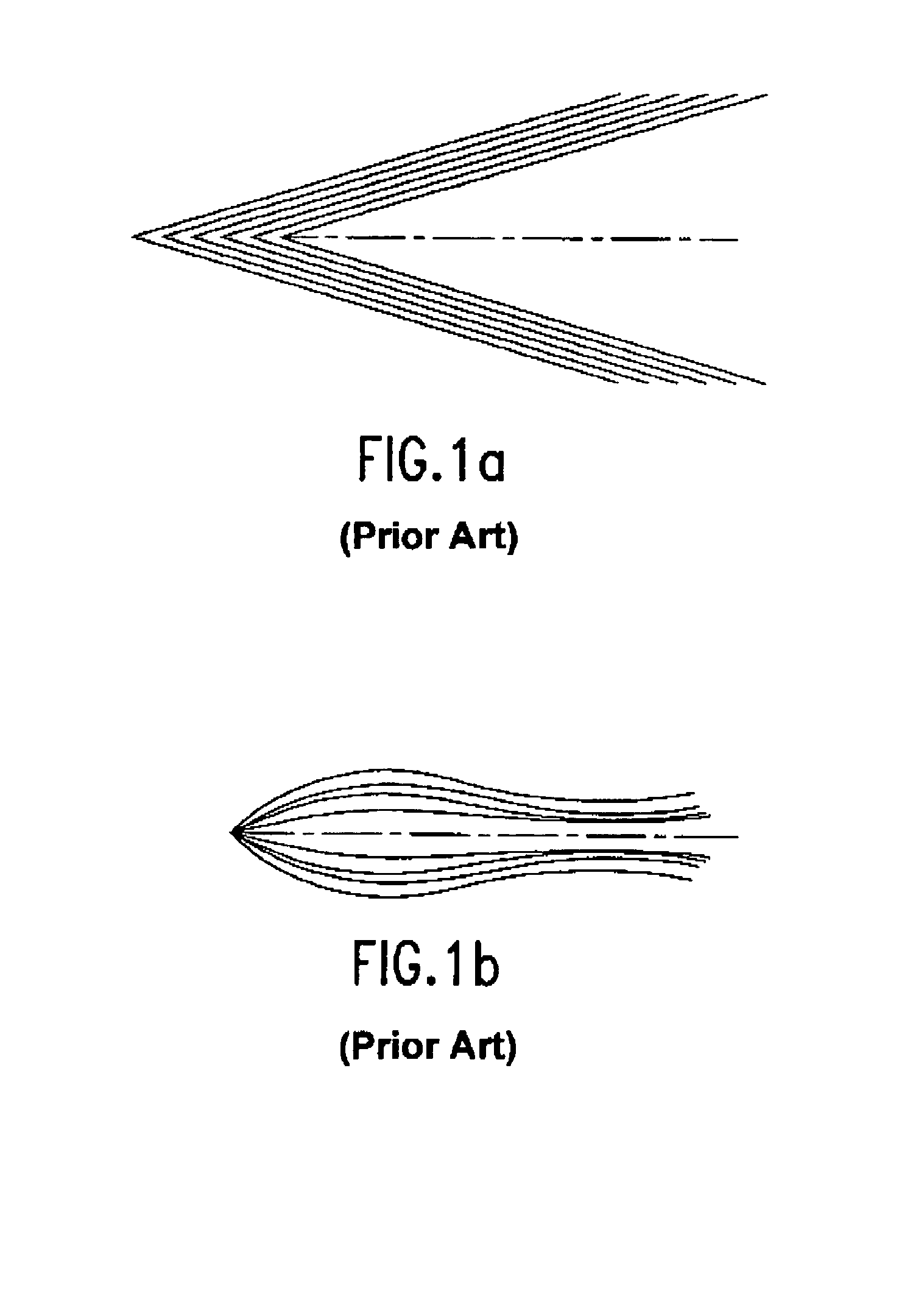

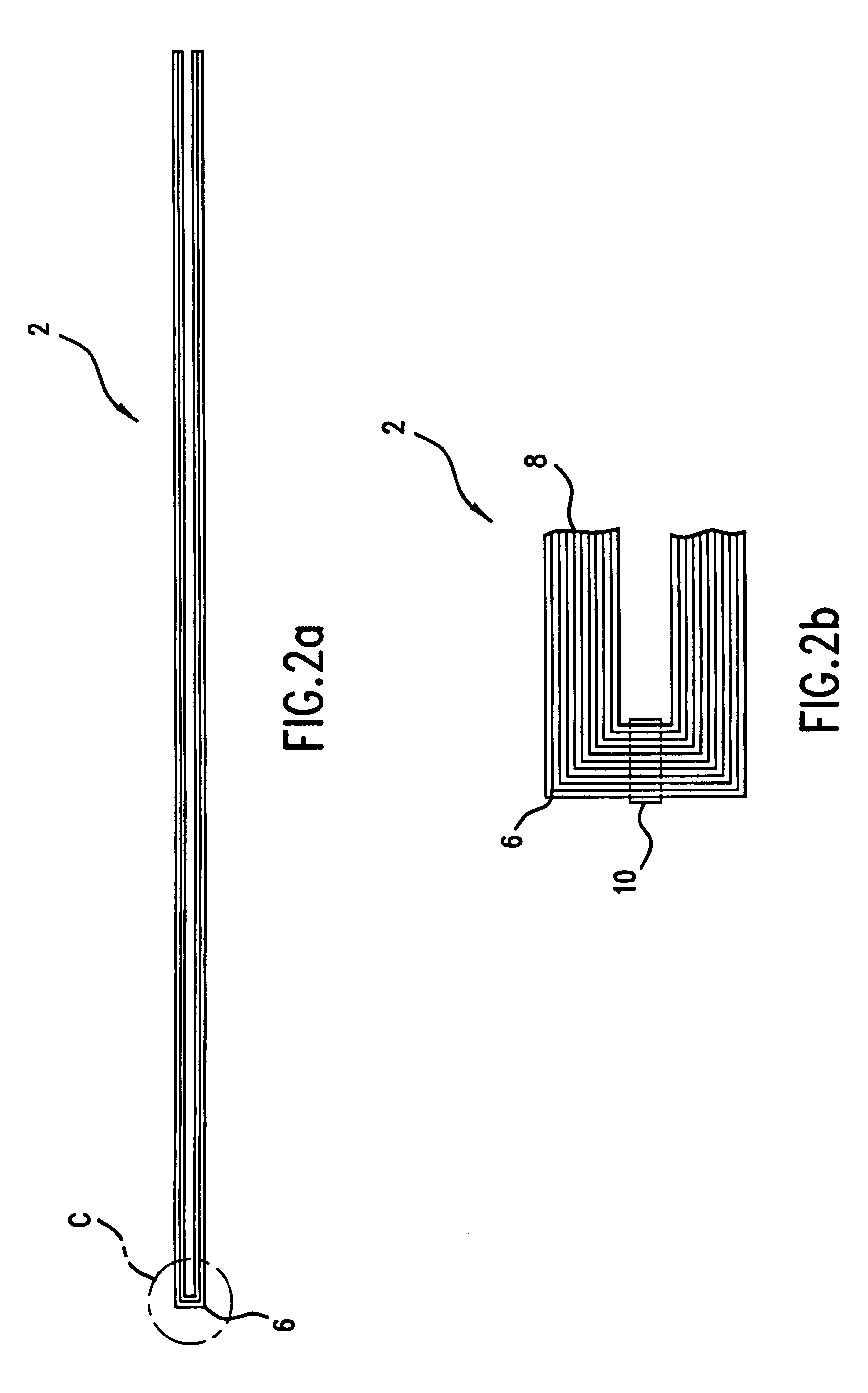

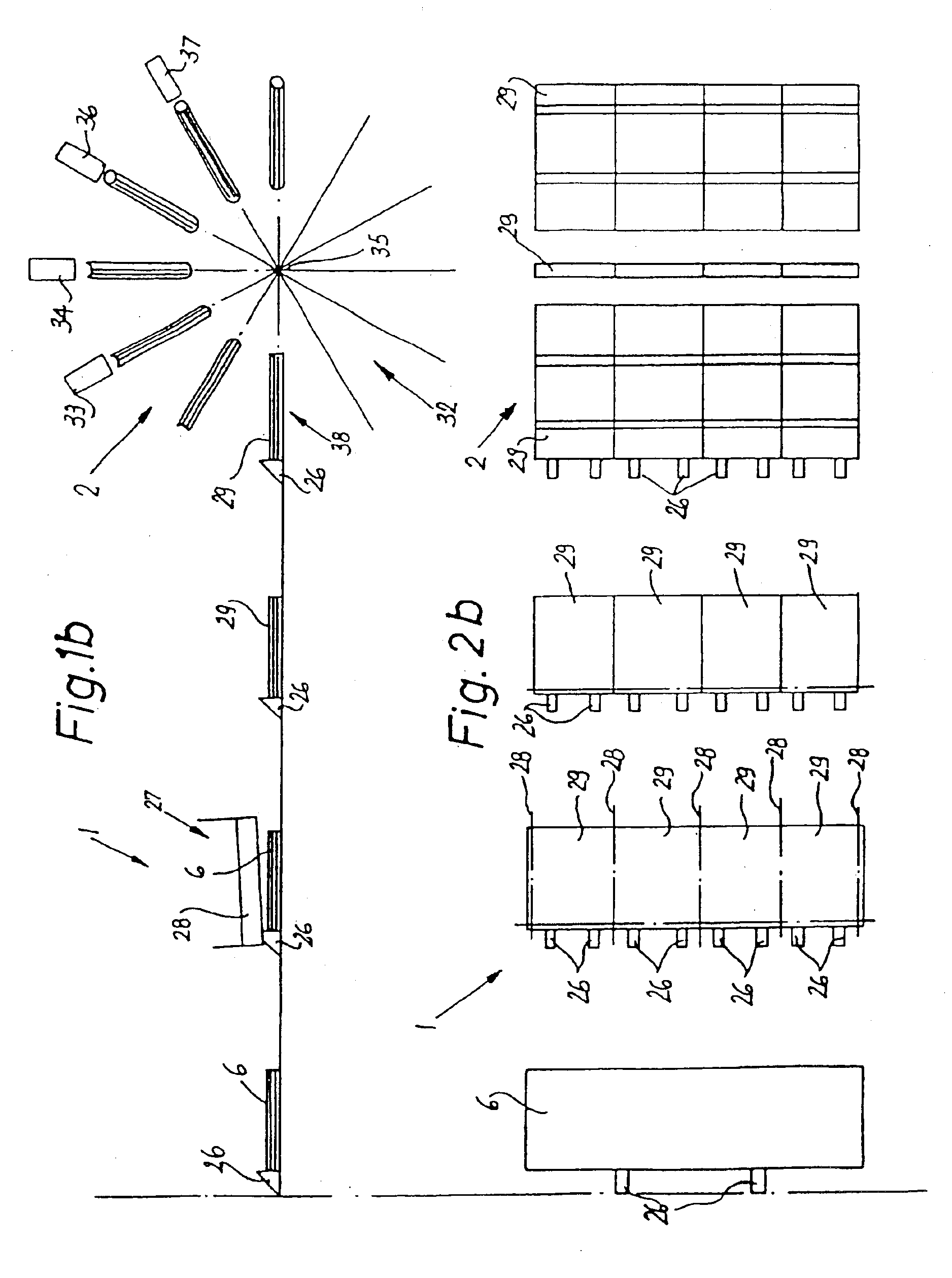

Method for binding books and a cutter therefor

InactiveUS20030170094A1Minimal pressureHigh bonding strengthBook bindingSheet bindingEngineeringAdhesive

There is disclosed a new method for binding a book and a new cutter therefore. The method comprises perforating a plurality of signatures along a spine, bending the plurality of signatures along the spine, compiling the plurality of signatures into a book text and applying adhesive to the book text. A cutter for making perforation adapted for the method is also disclosed.

Owner:YEW LAI CHEAN

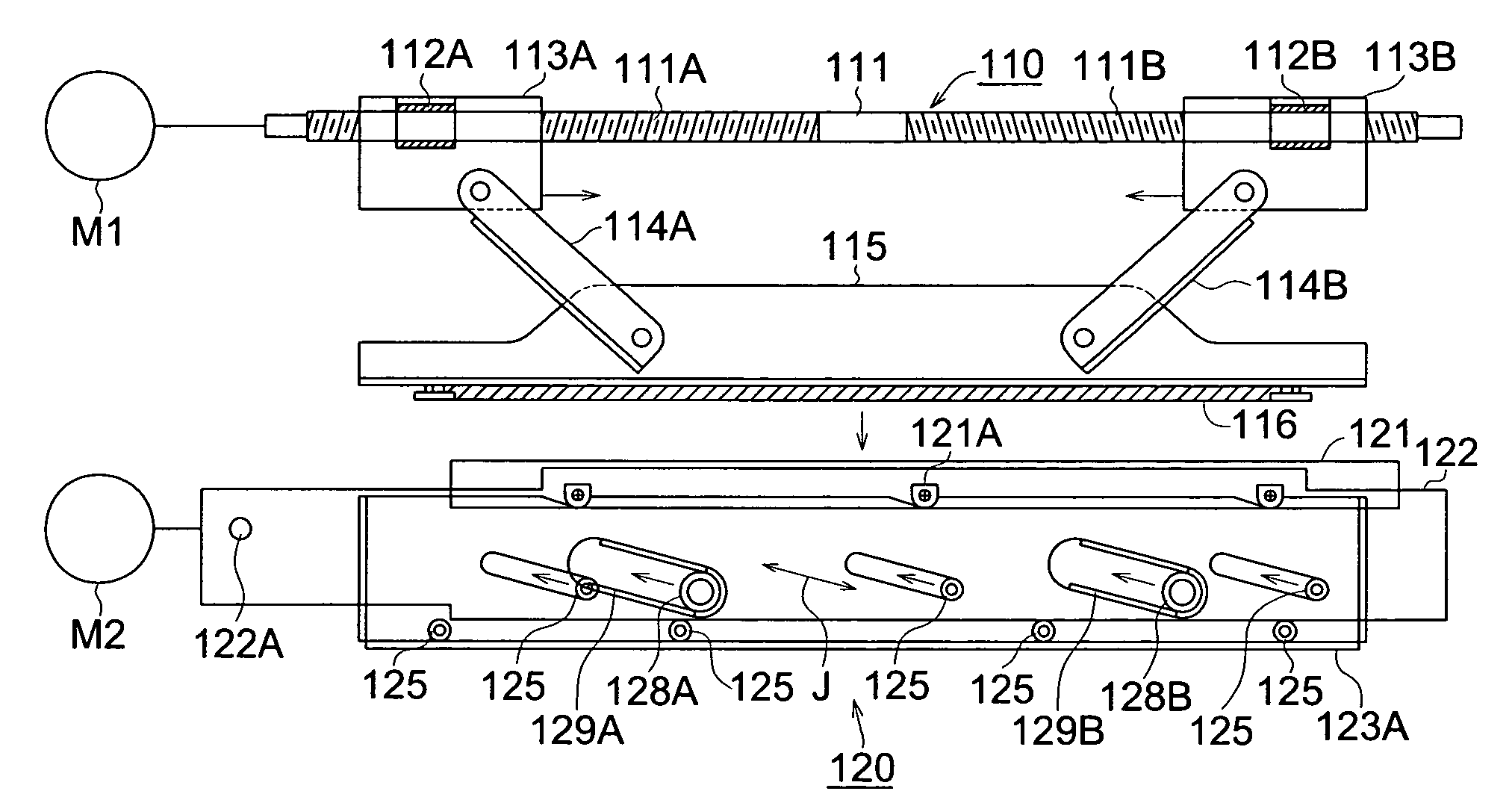

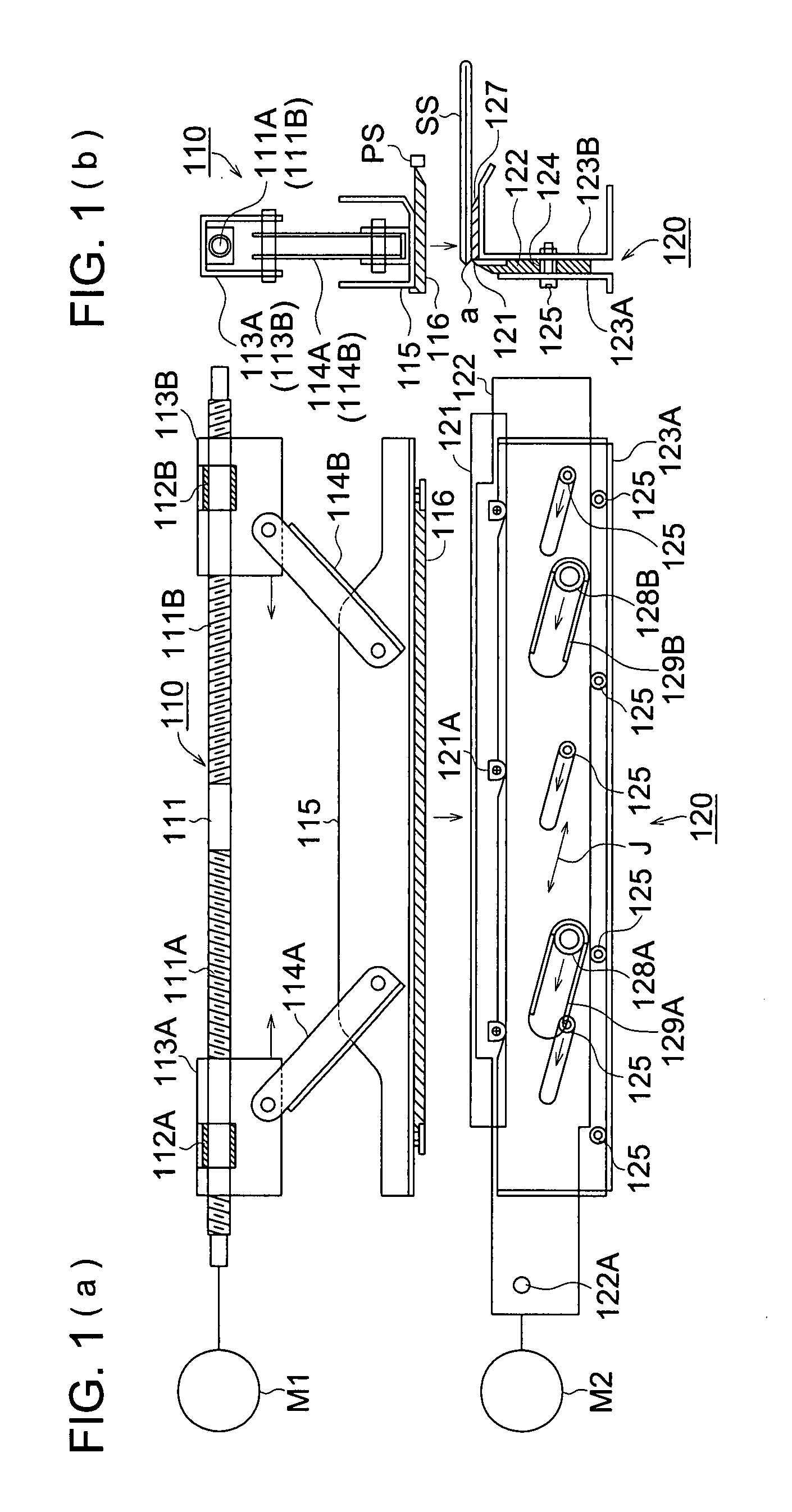

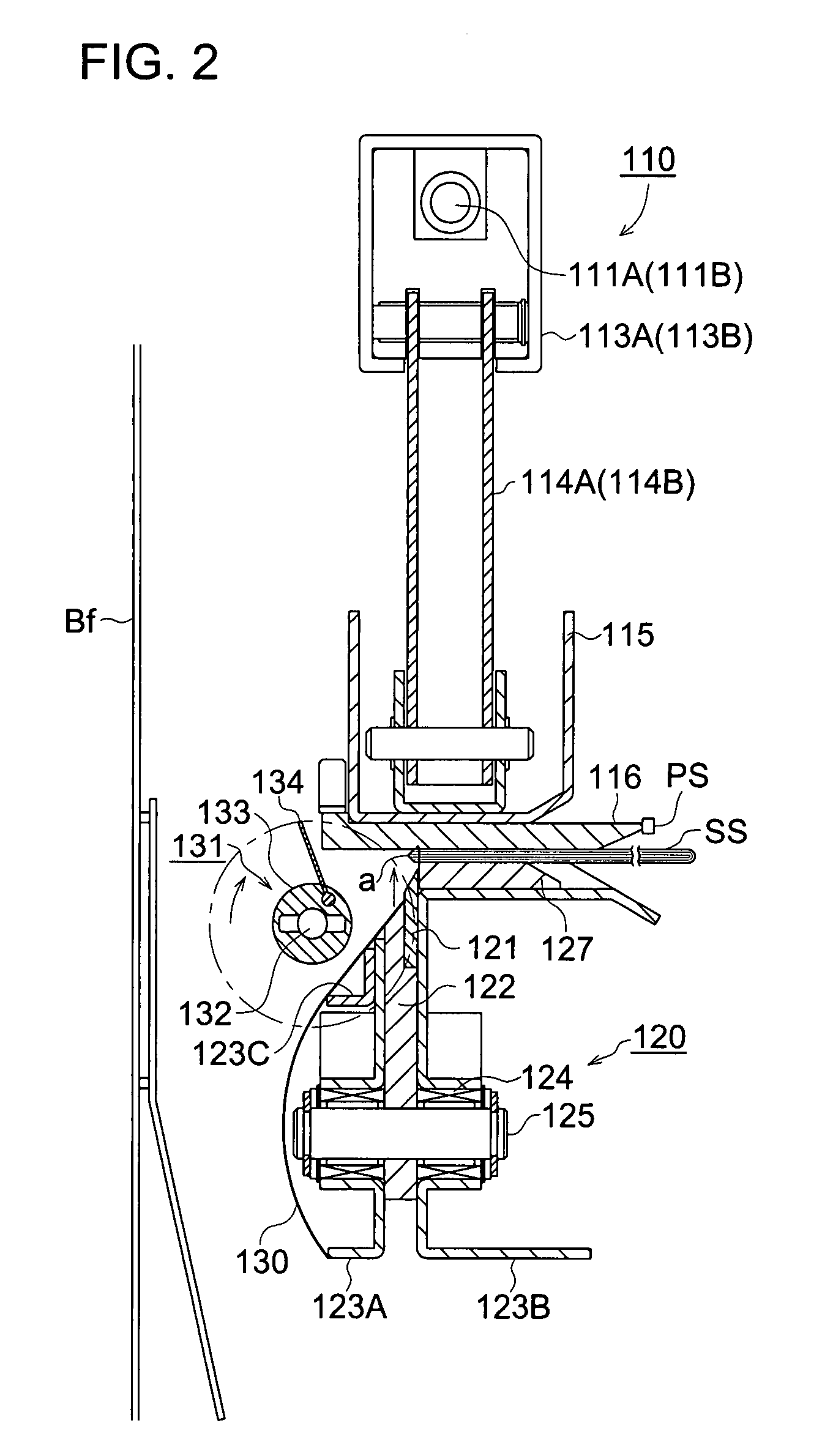

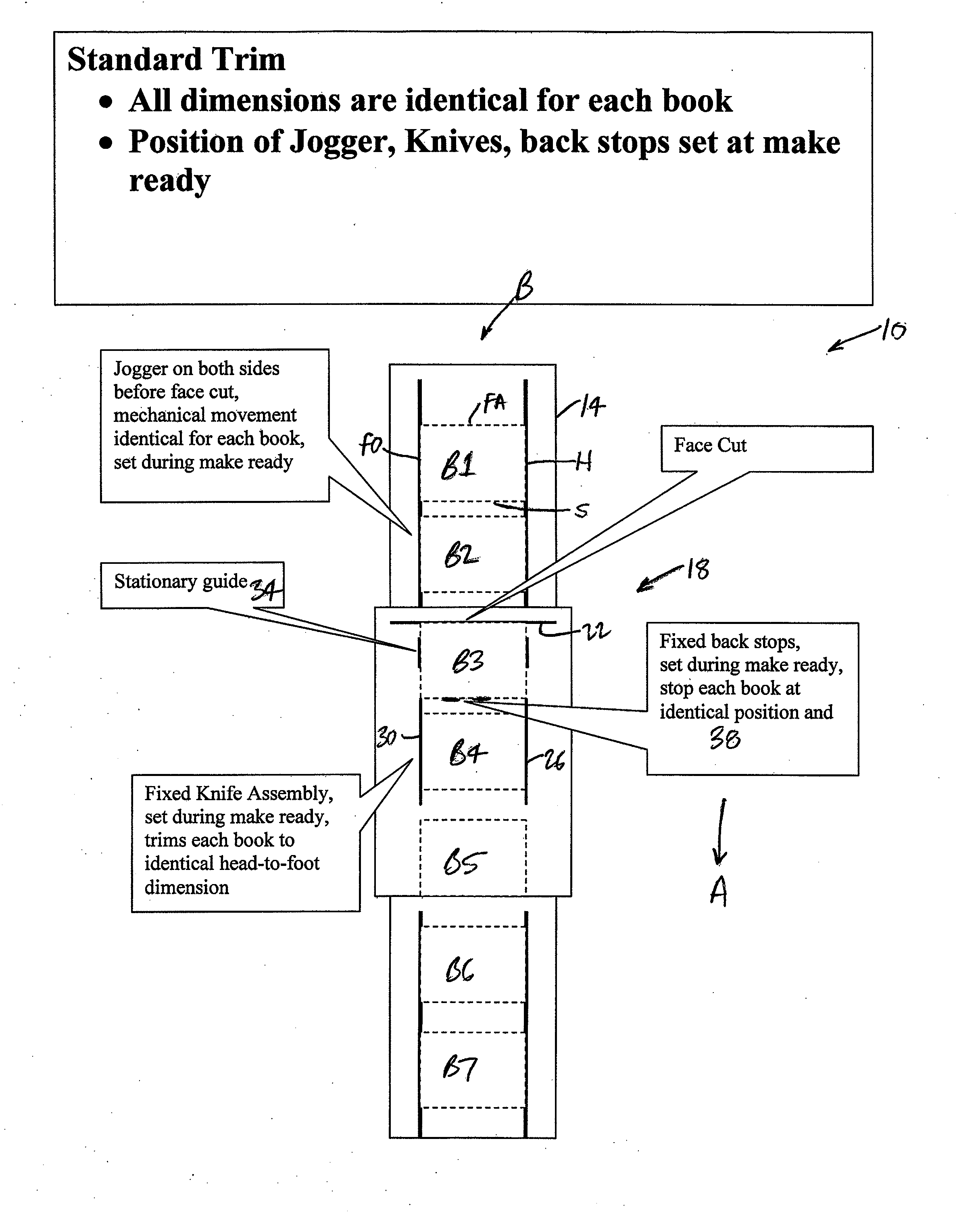

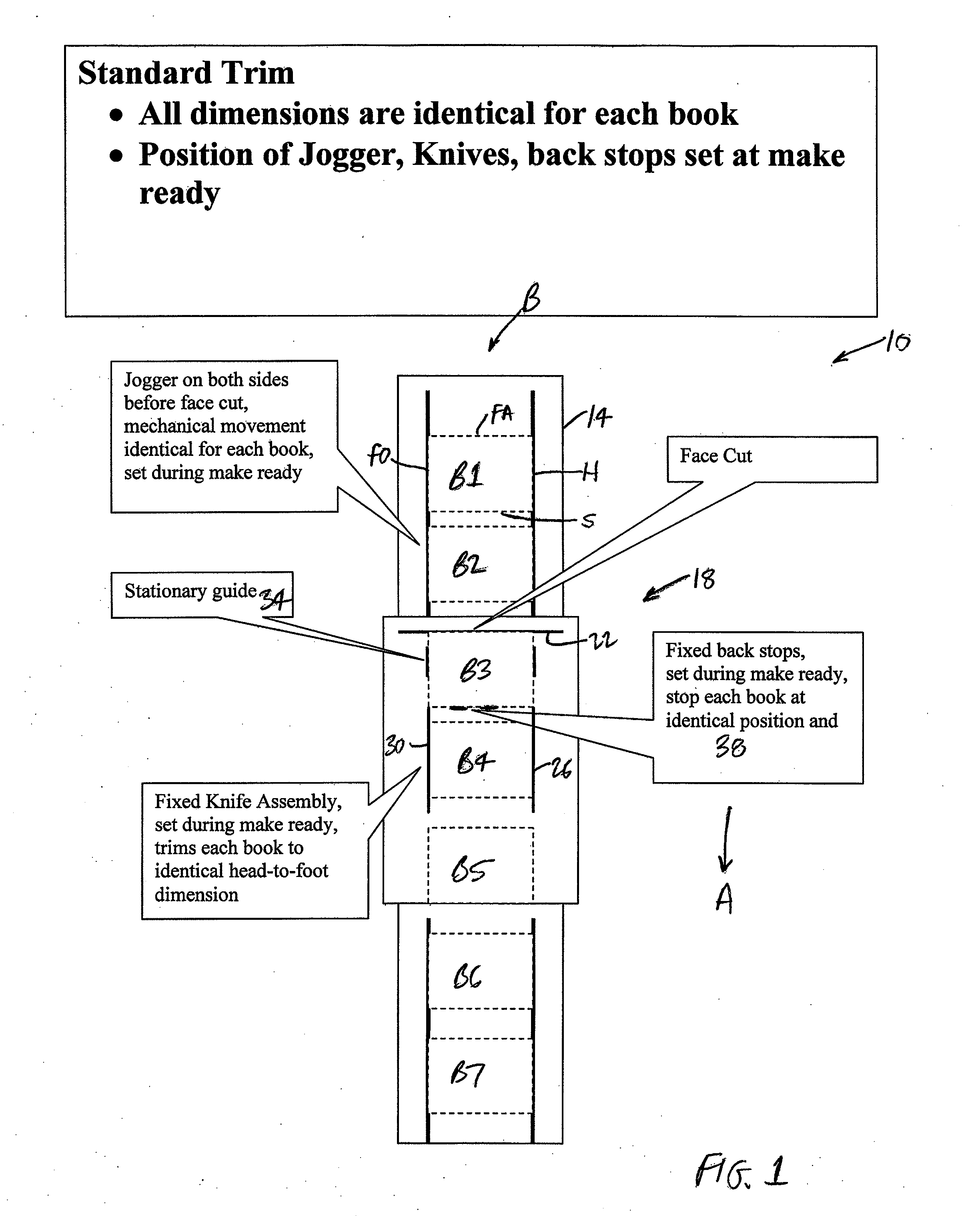

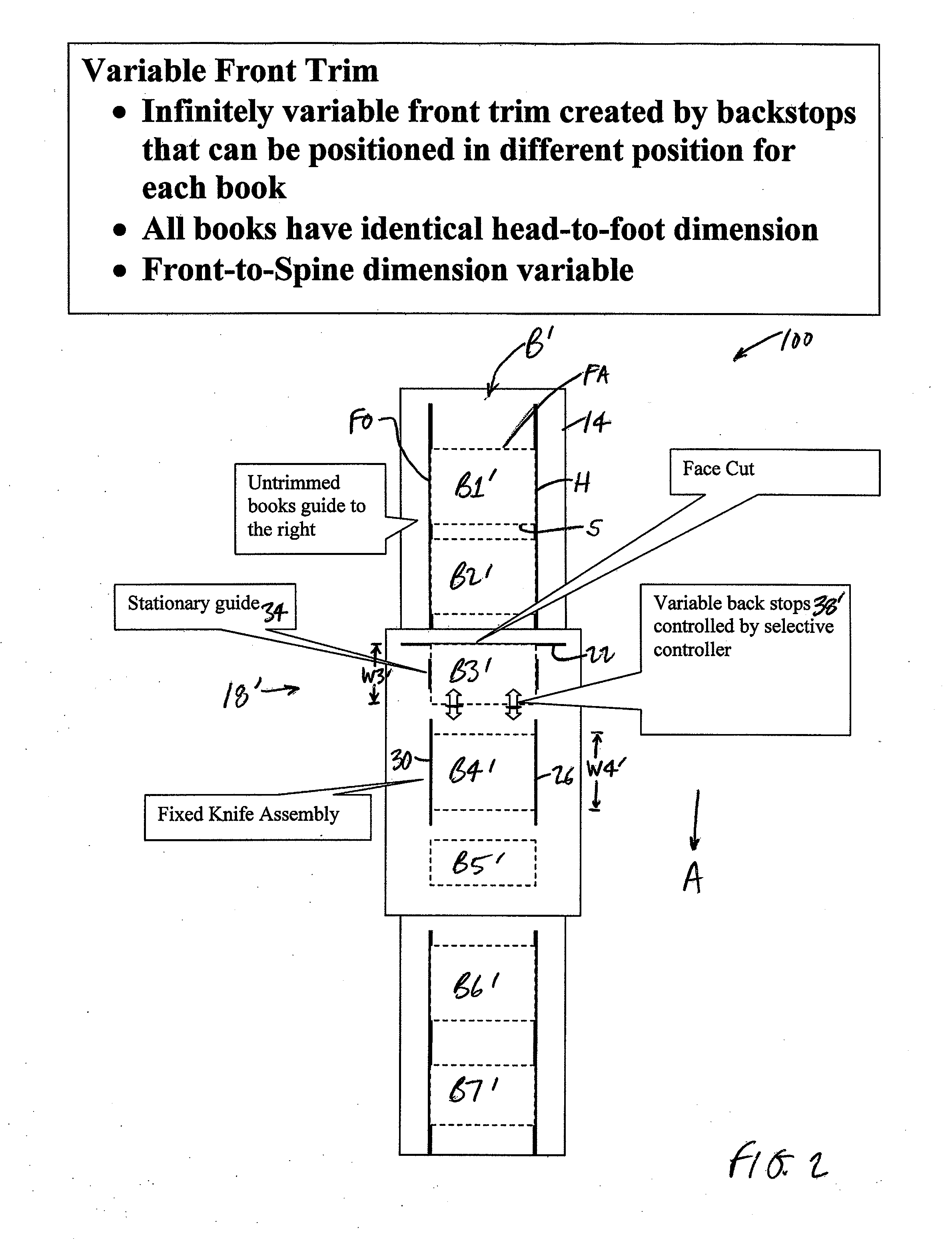

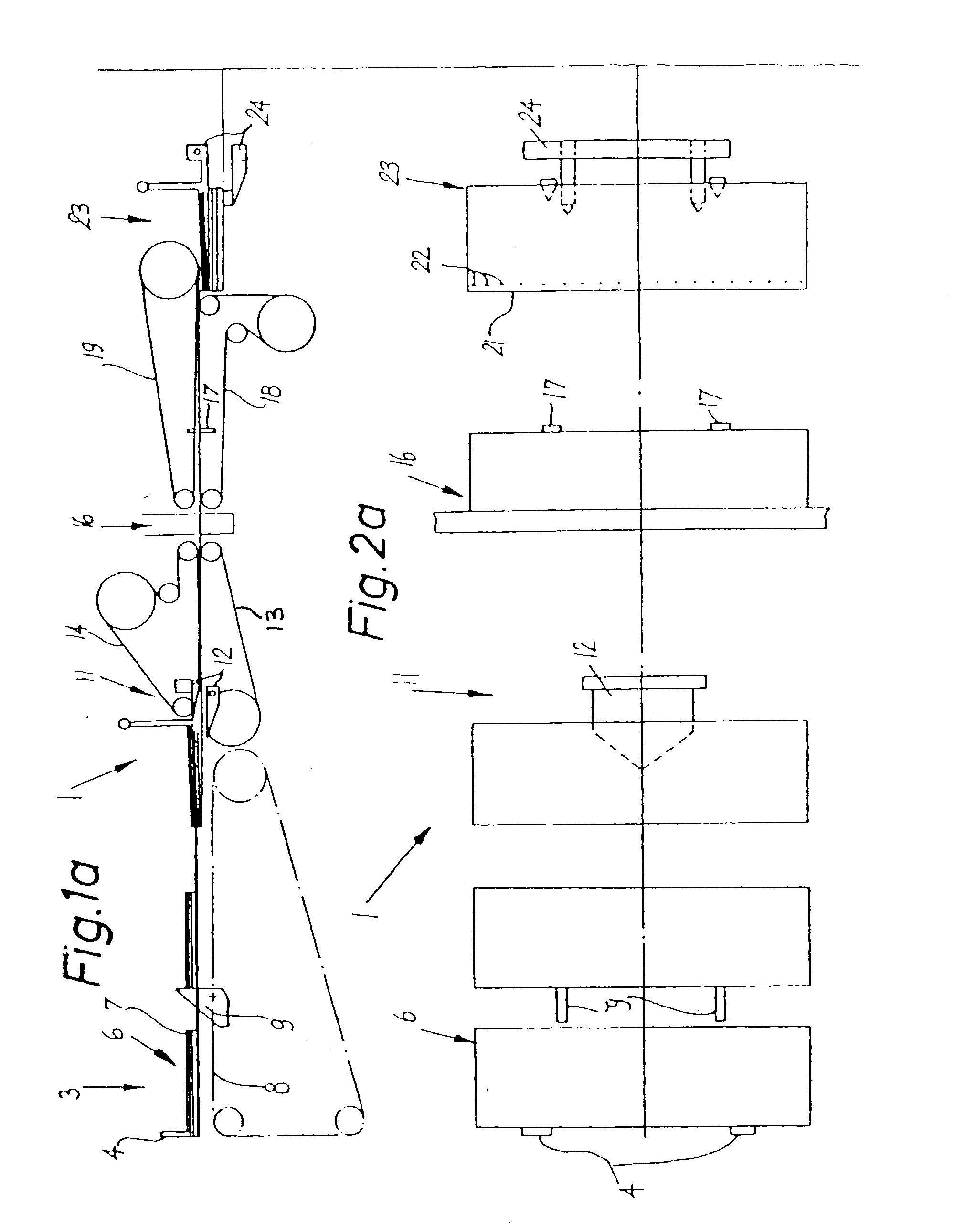

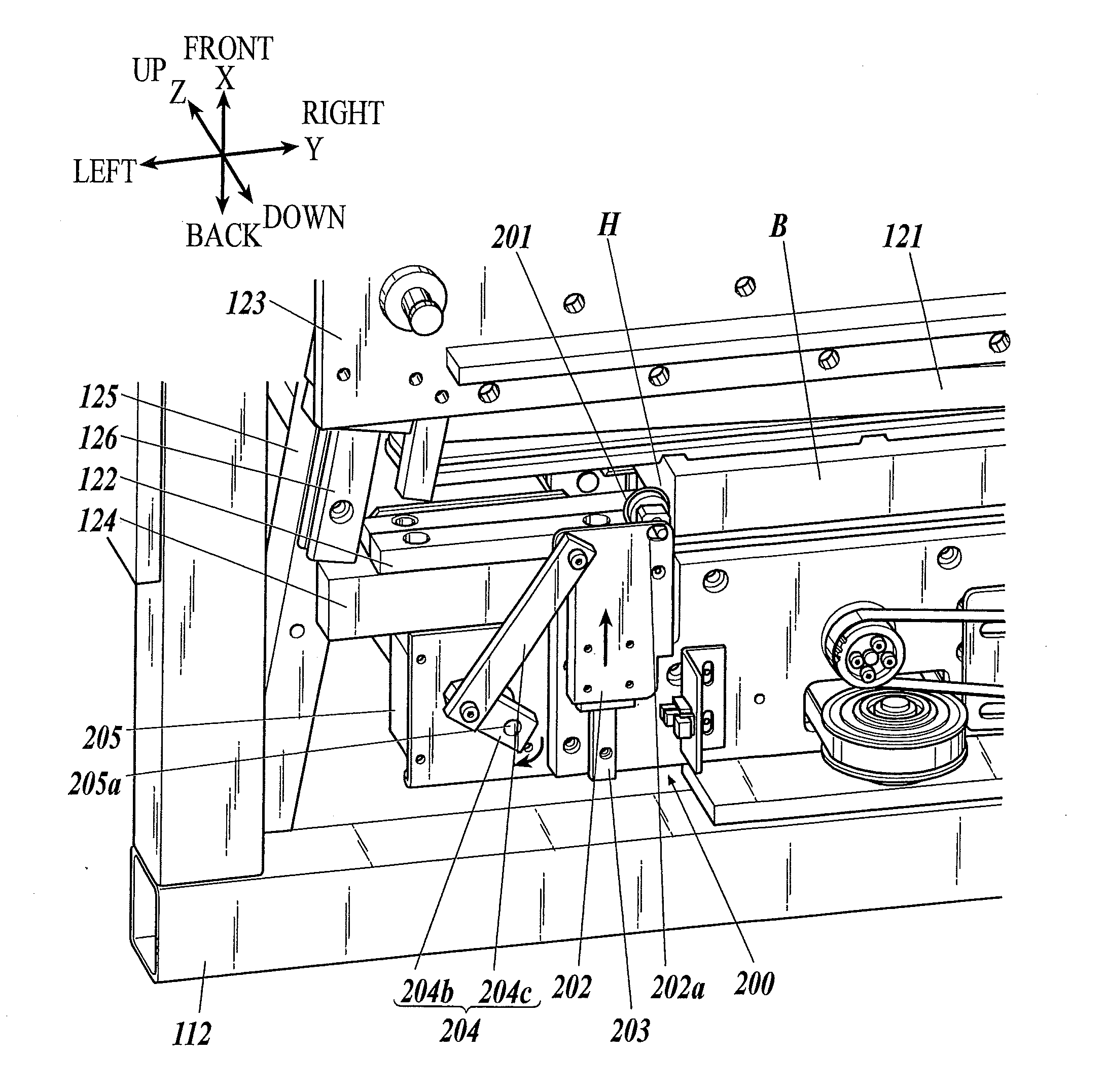

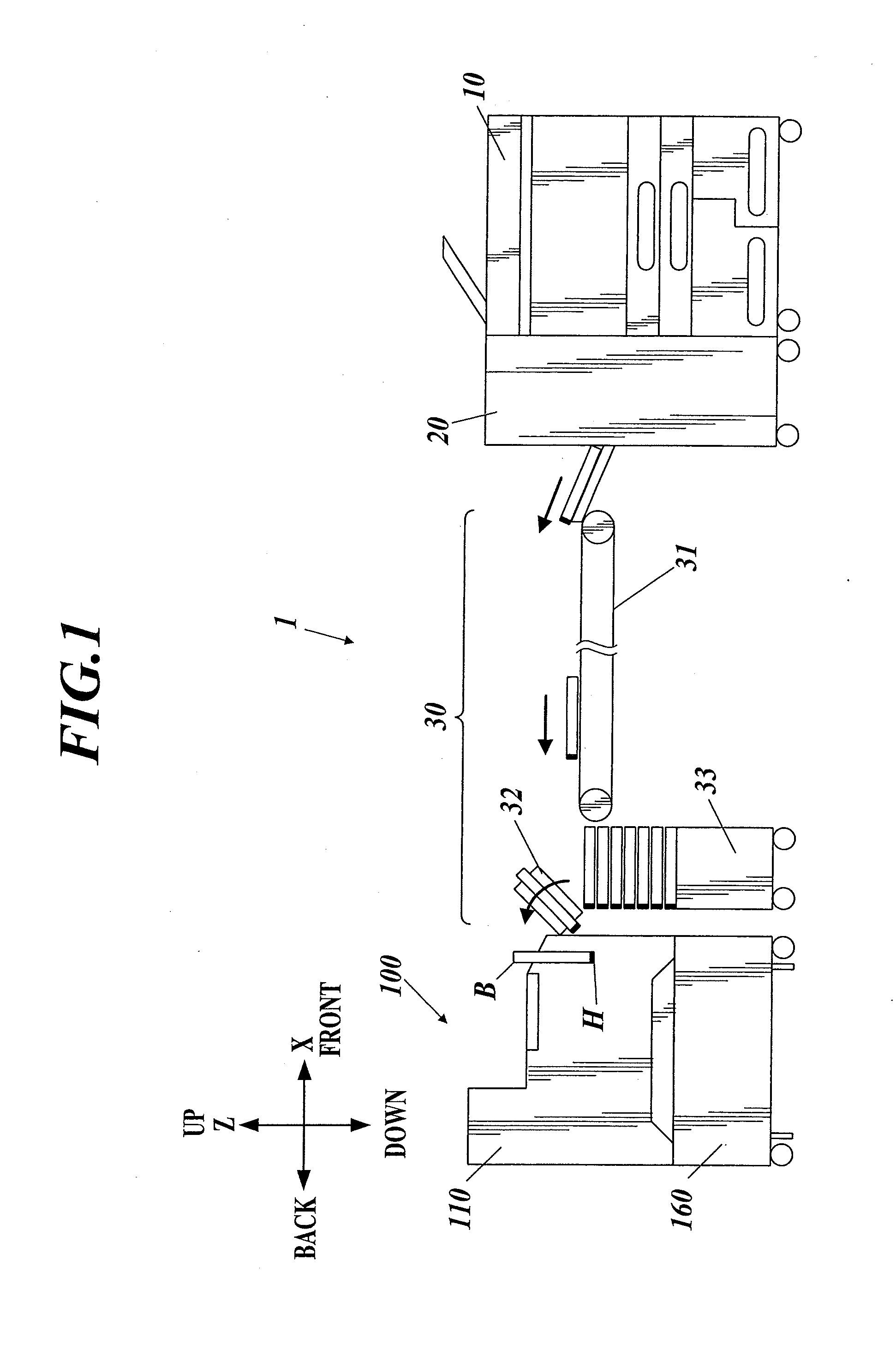

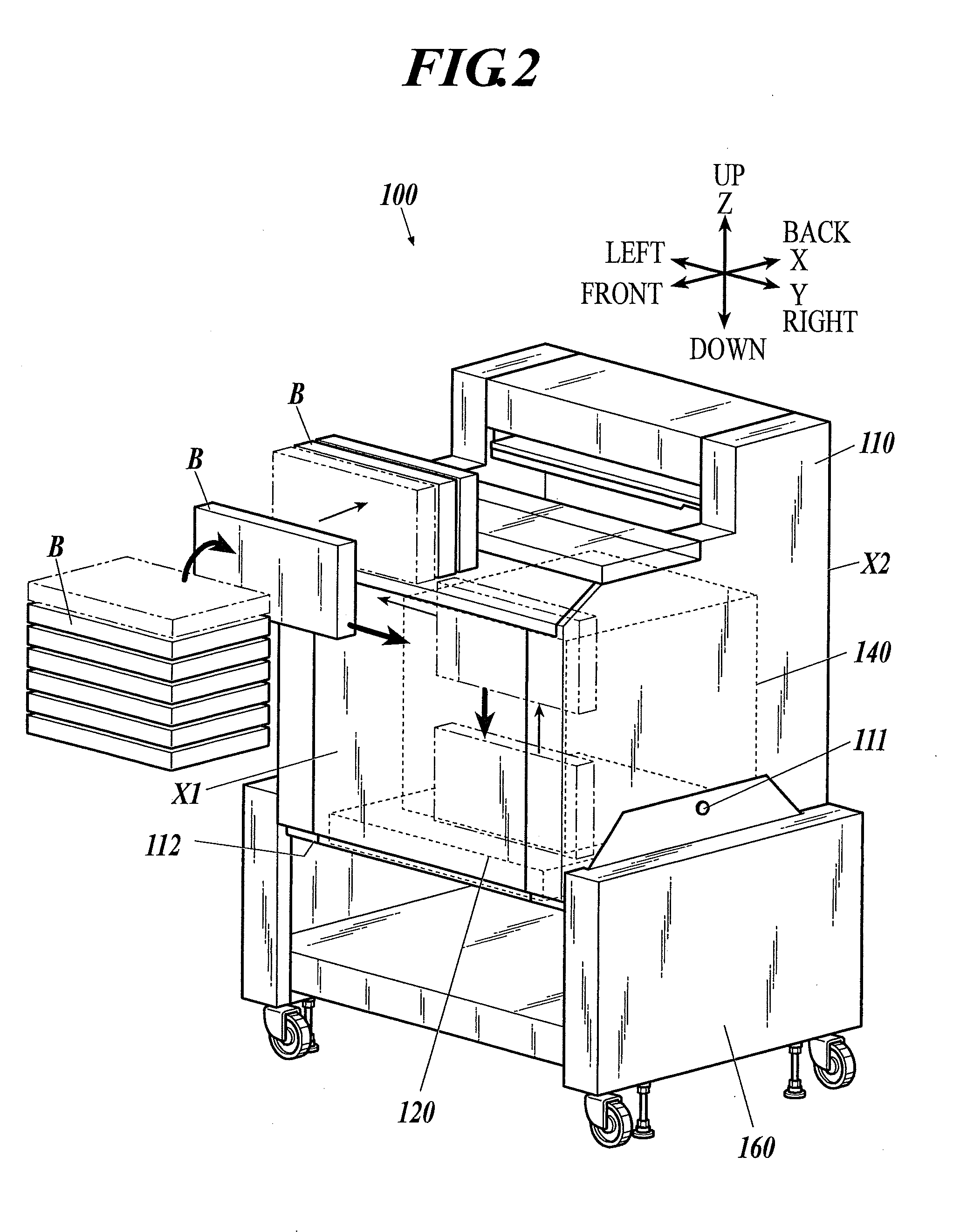

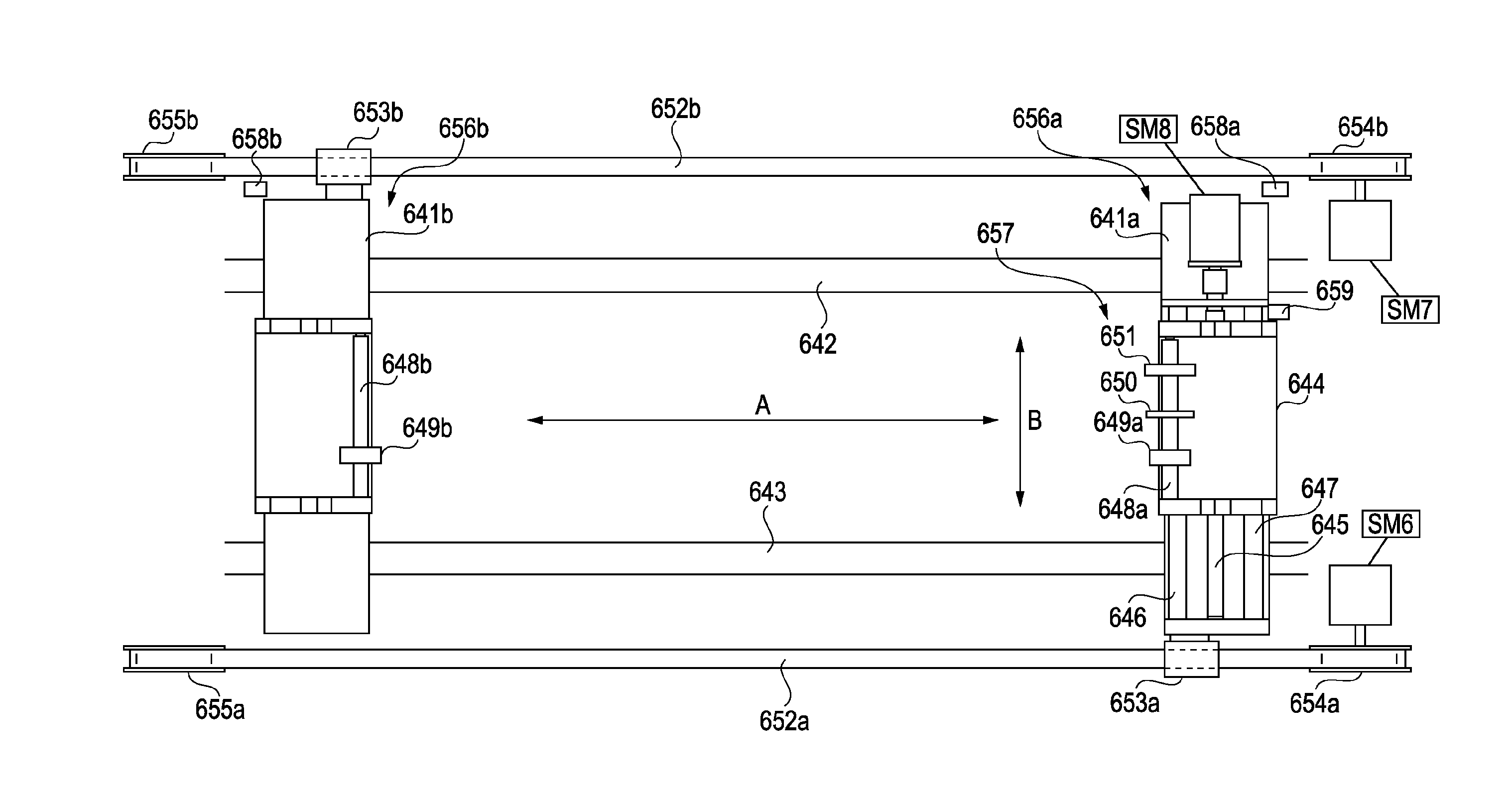

Variable trimming equipment, systems, and methods

InactiveUS20110017032A1Improve overall utilizationEasy to handleBook bindingMetal working apparatusEngineeringStops device

Trimming apparatus for books and similar materials are detailed. Dynamic variability of the apparatus allows sizes of successive materials to differ in two dimensions—both from spine to face and from head to foot. The result is a processing system with substantially greater utility than presently available, as the system may process respective materials of multiple different sizes without stopping the apparatus to adjust positions of the cutting implements.

Owner:QUAD GRAPHICS

Sheet post-processing apparatus and image forming apparatus

InactiveUS8342498B2Quality improvementMechanical working/deformationBook bindingWrinkle skinImage formation

Owner:CANON KK

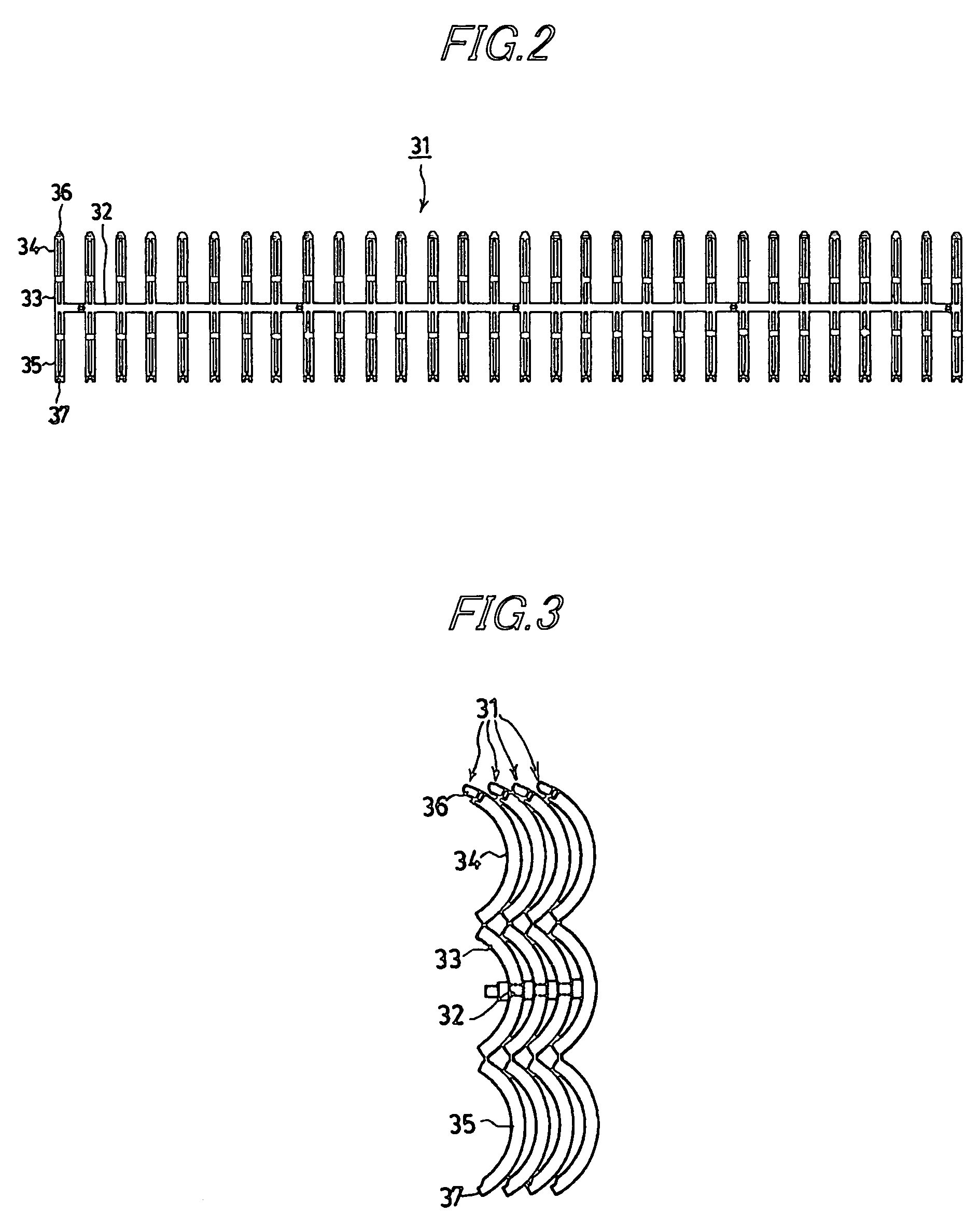

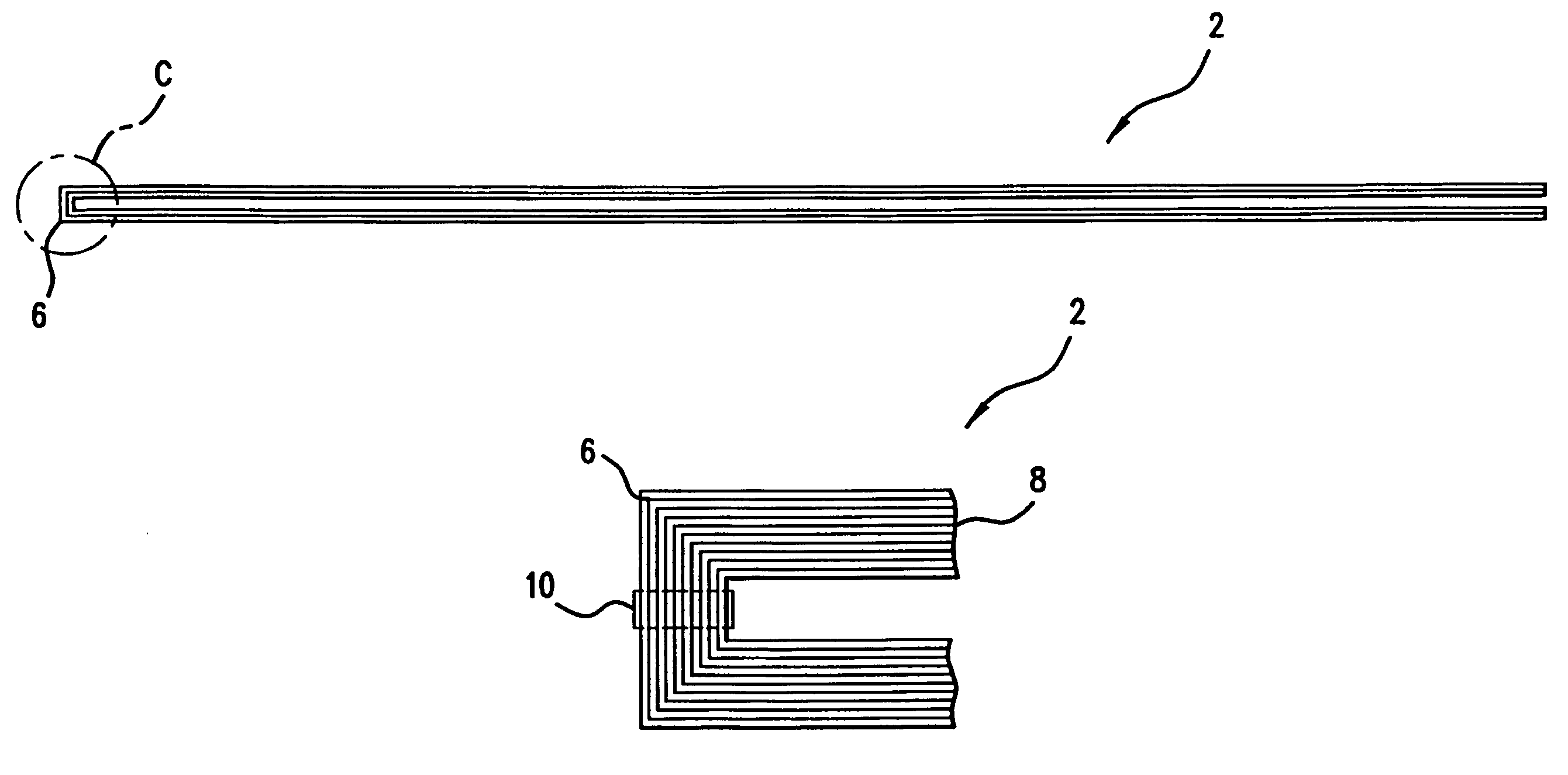

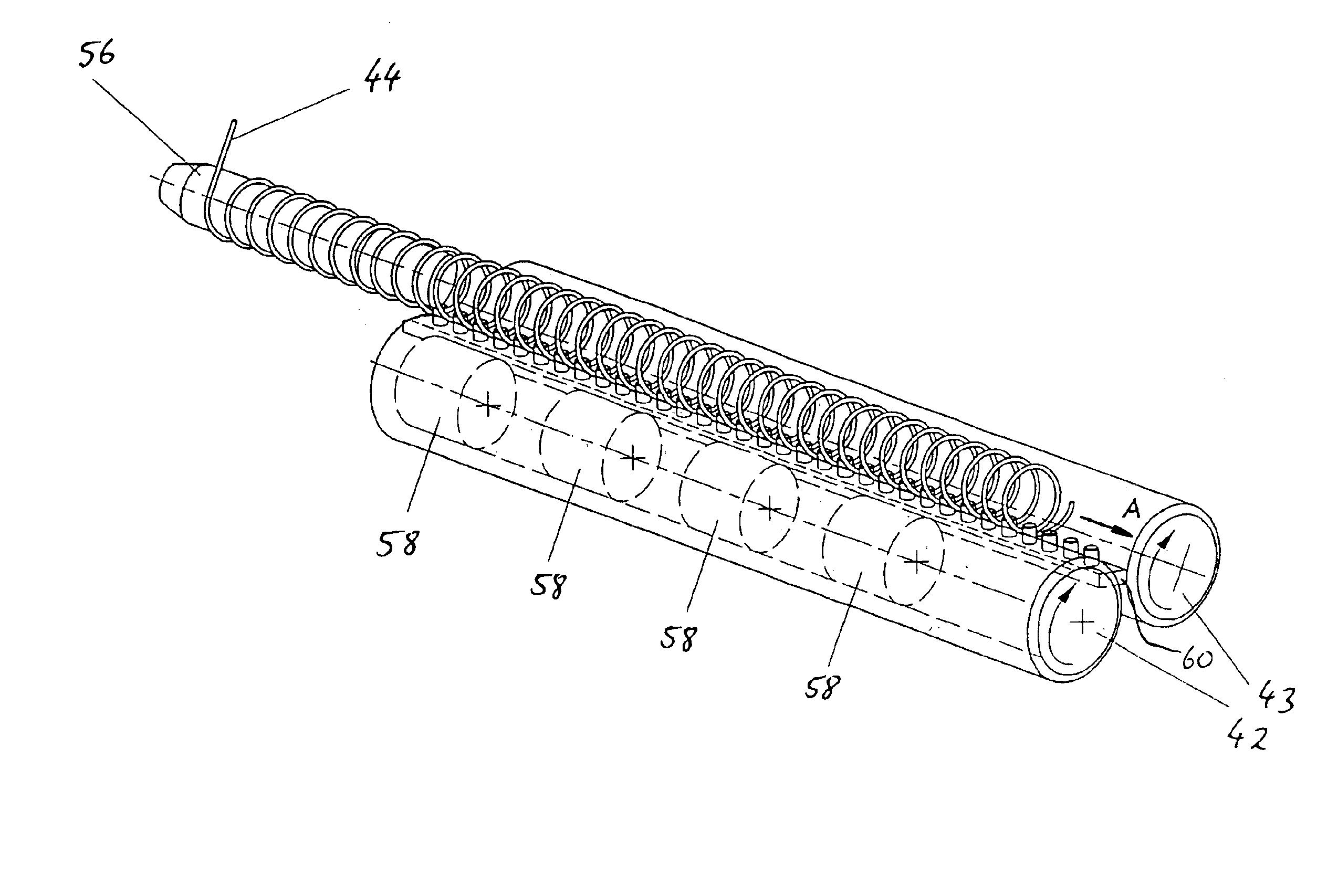

Apparatus for coupling stacked sheets

Apparatus for introducing magnetic spirals into rows of neighboring perforations in the spines of stacks of overlapping sheets which are to form discrete calendars, memo pads or analogous commodities employs an elongated guide for a continuous magnetic coil spring. The coil spring is rotated about its longitudinal axis and is moved lengthwise so that its convolutions enter successive perforations of the row of perforations in the stack being held in the guide. The guide embodies or cooperates with magnets which maintain the convolutions of the coil spring in the path defined therefor by the guide. The magnets can be embedded in antimagnetic tubes forming part of or constituting the guide.

Owner:KUGLER WOMAKO

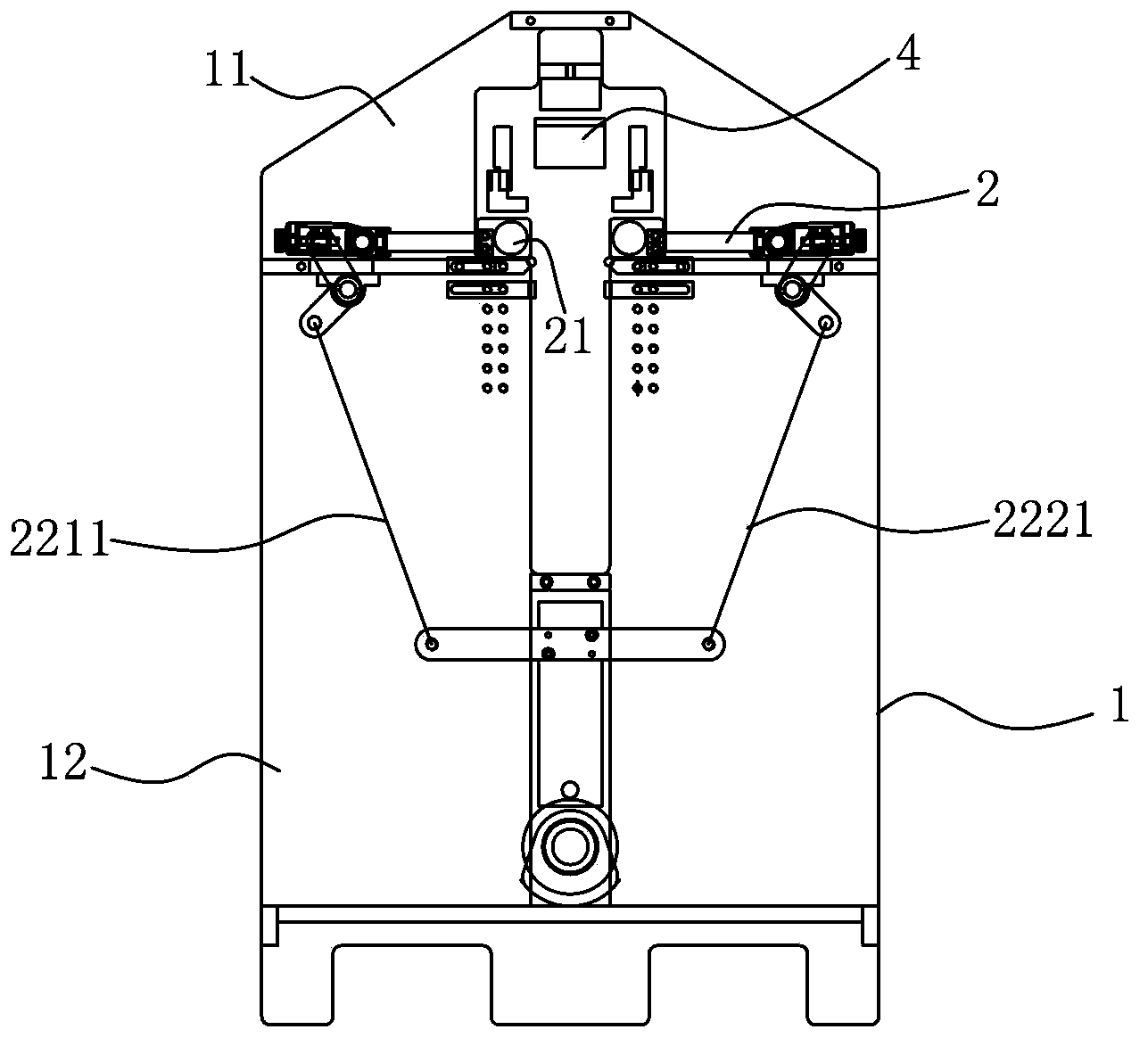

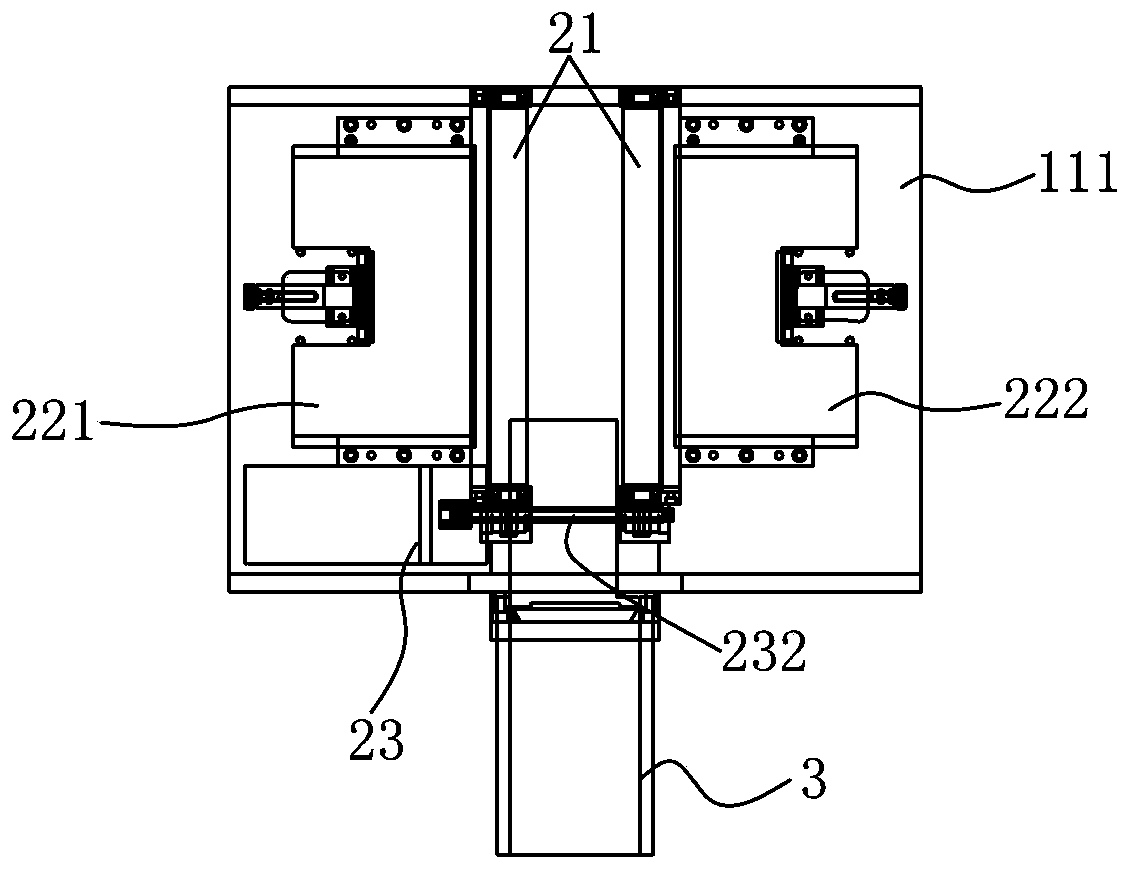

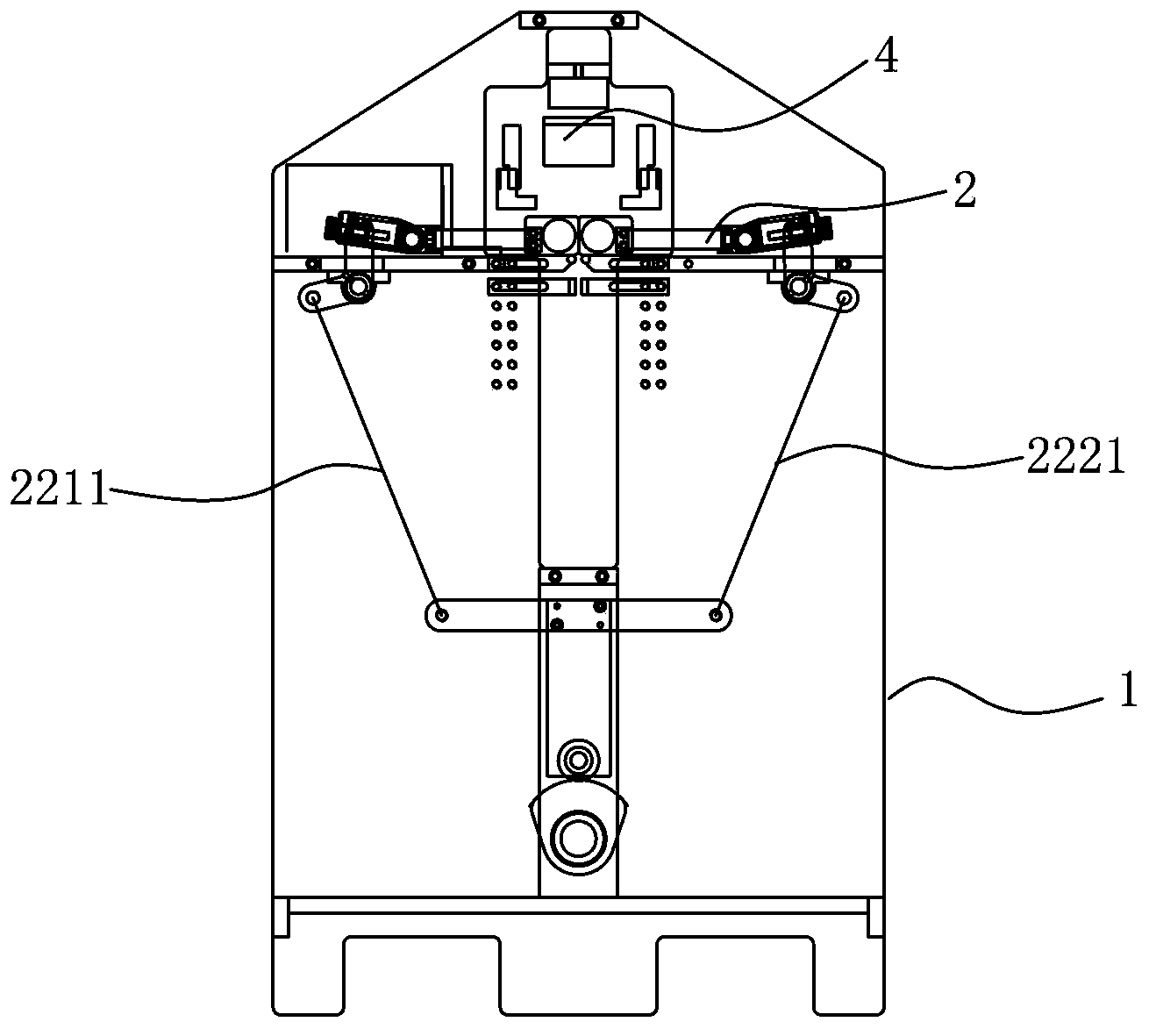

Semi-automatic bookblock rounding machine

The invention discloses a semi-automatic bookblock rounding machine which comprises a rack, a rounding mechanism, a transferring track and a book output mechanism, wherein the transferring track, the rounding mechanism and the book output mechanism circularly operate under the control of a sensor, a book is transferred by the transferring track to the rounding mechanism, a slide block device drives rounding rollers to clamp the book, a worm and gear structure drives the two rounding rollers to rotate oppositely to round the book, the book output mechanism clamps the rounded book through a pneumatic finger to the book output device, and the operation is repeated. According to the roller type rounding principle, the advantages of machine, electricity and air are fully used, so that the complex working principle is achieved on the basis of simplifying the mechanical structure of the whole machine, the machine can round 15 books at the most in one minute, an advanced PLC (Programmable Logic Control) automatic program is adopted for control, the size of a rounding arc on a bookblock is digitally processed, so that an author can conveniently and intuitively regulate the rounding arc of the book, and the rounding requirements of the books with different thicknesses can be well met.

Owner:东莞市利佳装订设备有限公司

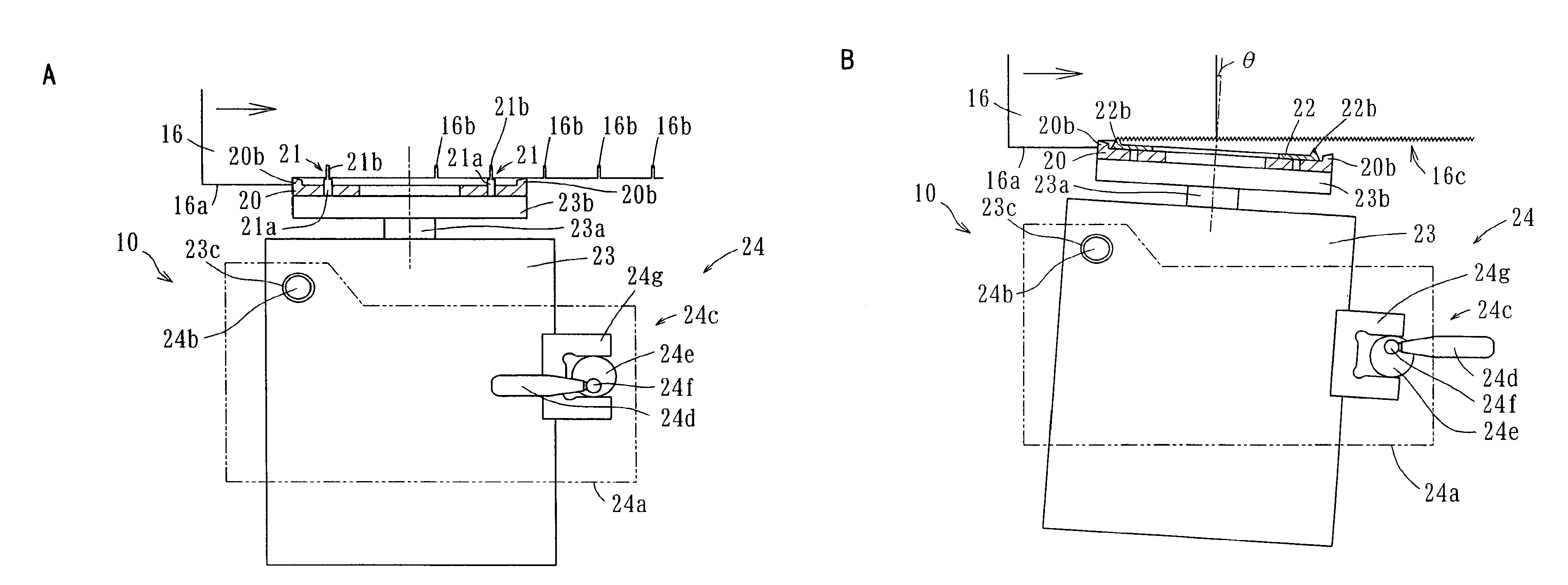

Apparatus and method for creasing media to make booklets

InactiveUS7077797B2Reduce creepReduce stepsEnvelopes/bags making machineryMechanical working/deformationComputer science

Owner:HEWLETT PACKARD DEV CO LP

Sheet post-processing apparatus and image forming apparatus

There is a need to provide a sheet post-processing apparatus capable of neatly squaring a booklet spine without any damage such as a wrinkle on the spine and an image forming apparatus having the sheet post-processing apparatus. According to the sheet post-processing apparatus, a drive motor drives first and second pressing members. A circumferential velocity of the pressing member on a pressing surface pressed against the booklet spine is configured to be reverse to and greater than a moving velocity of a moving portion.

Owner:CANON KK

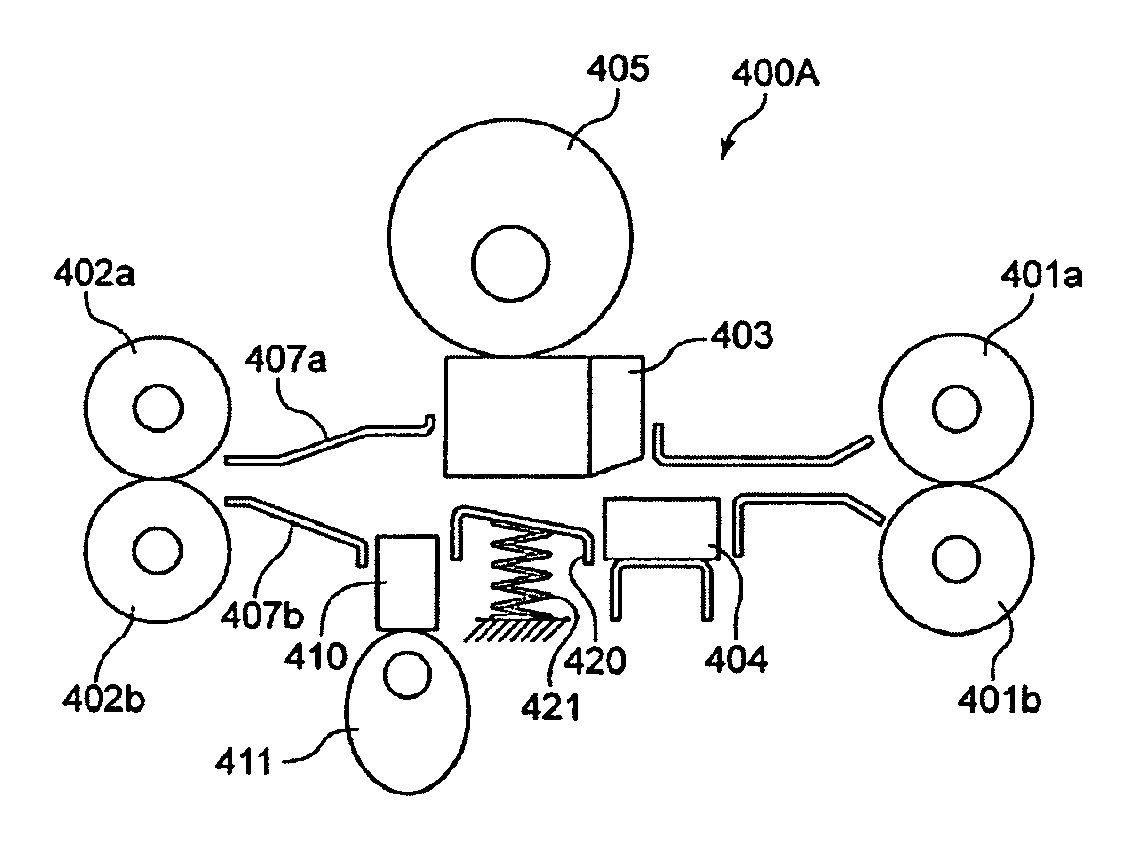

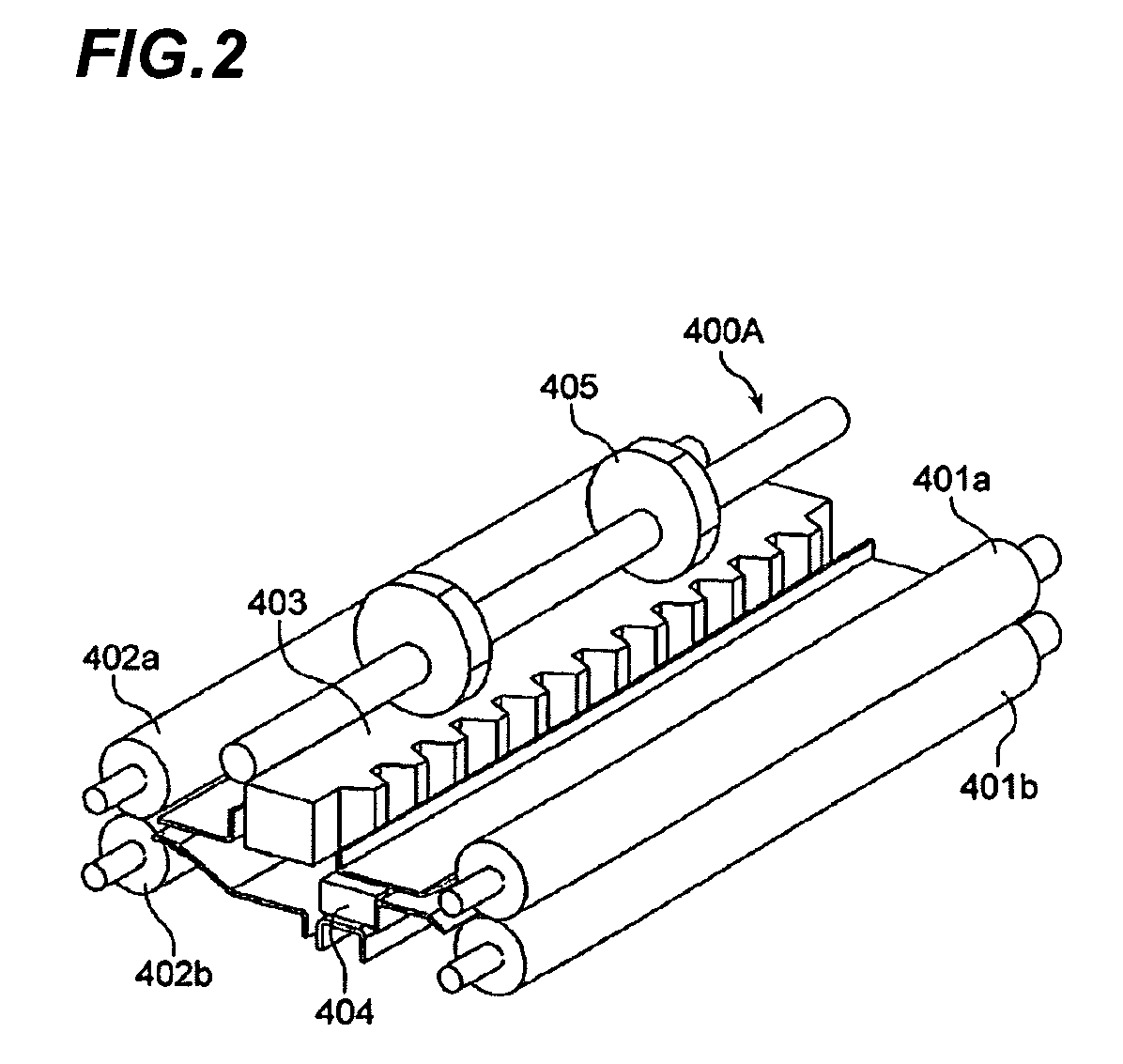

Sheet processing apparatus and image forming apparatus

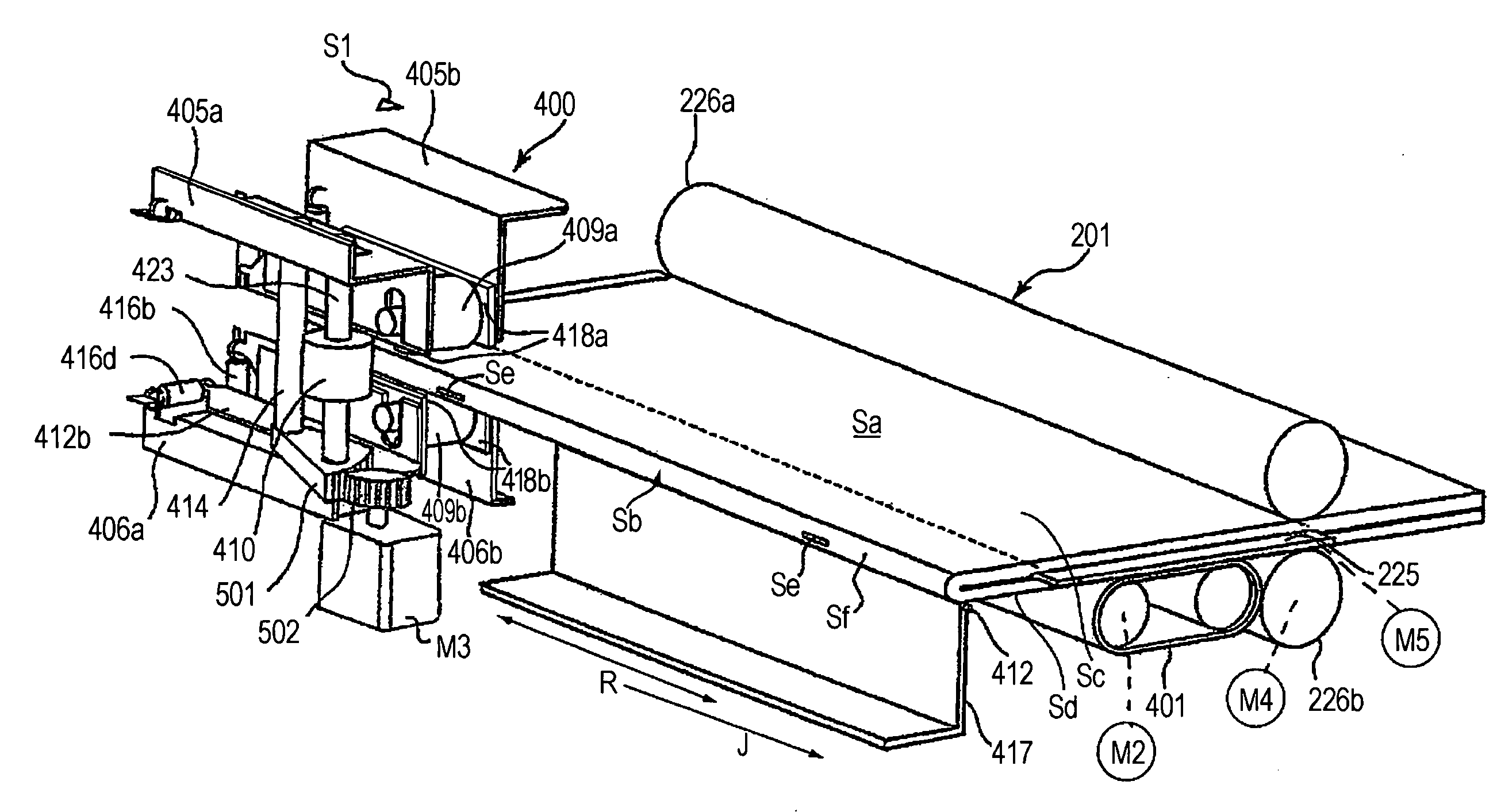

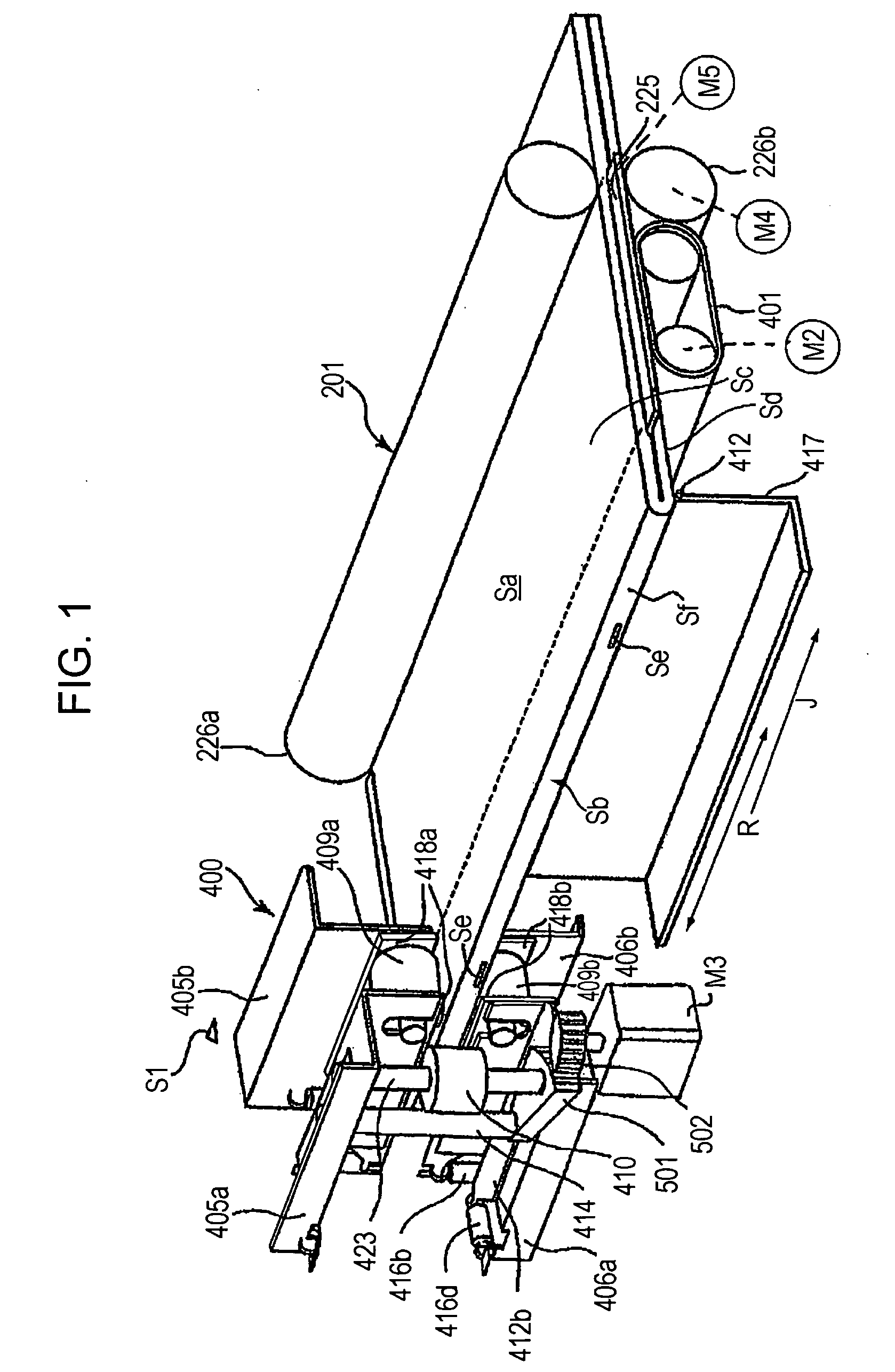

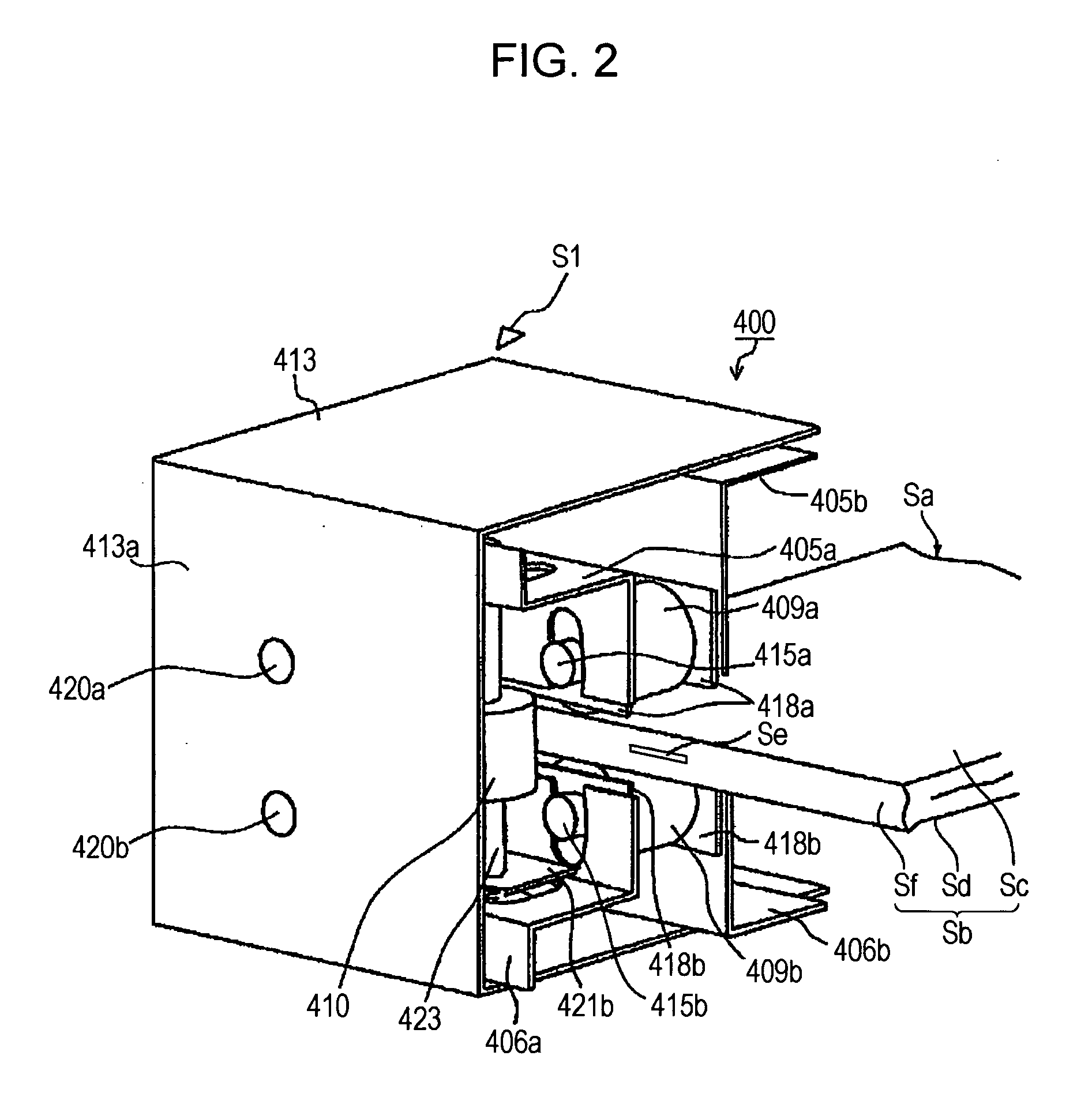

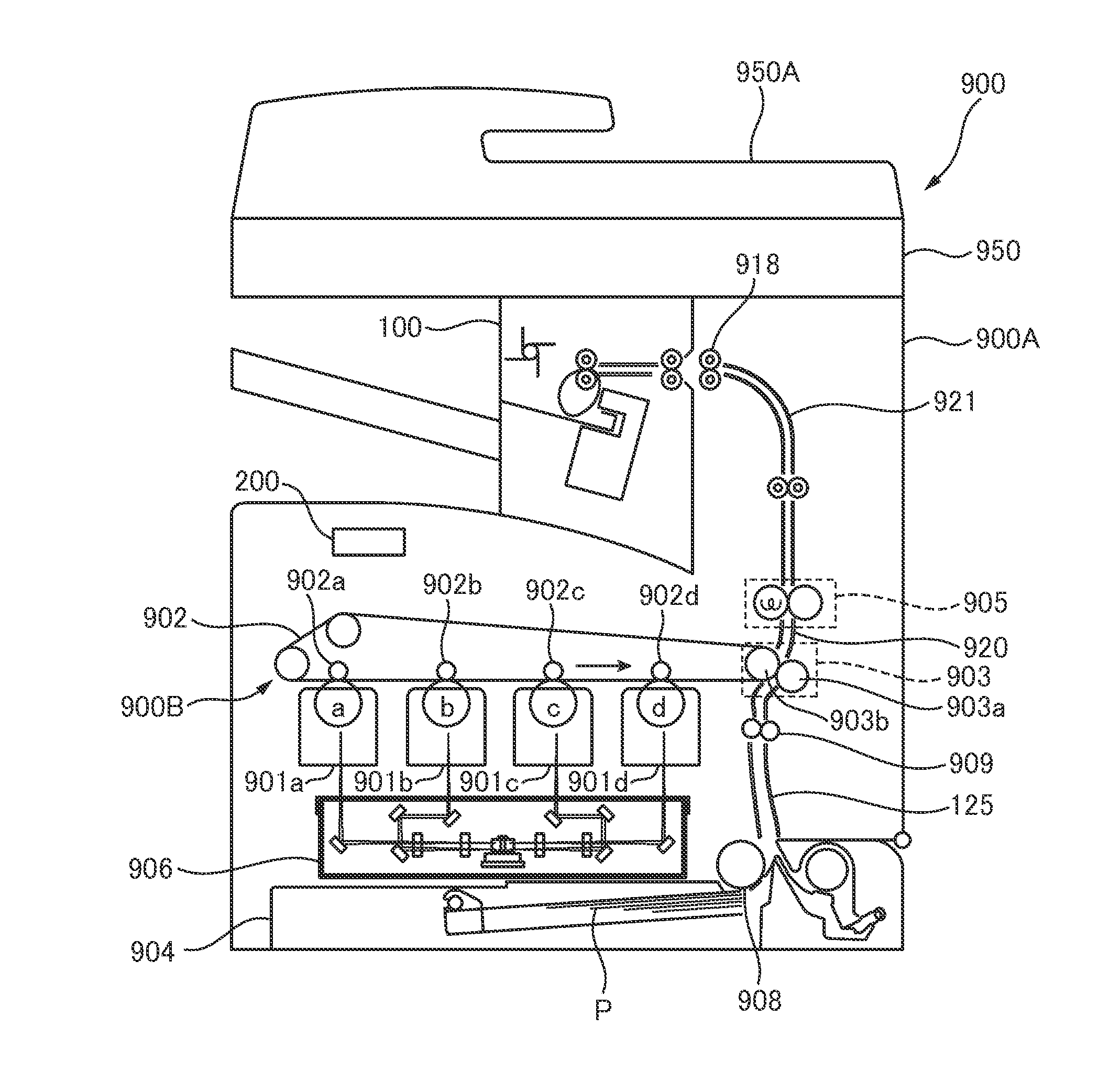

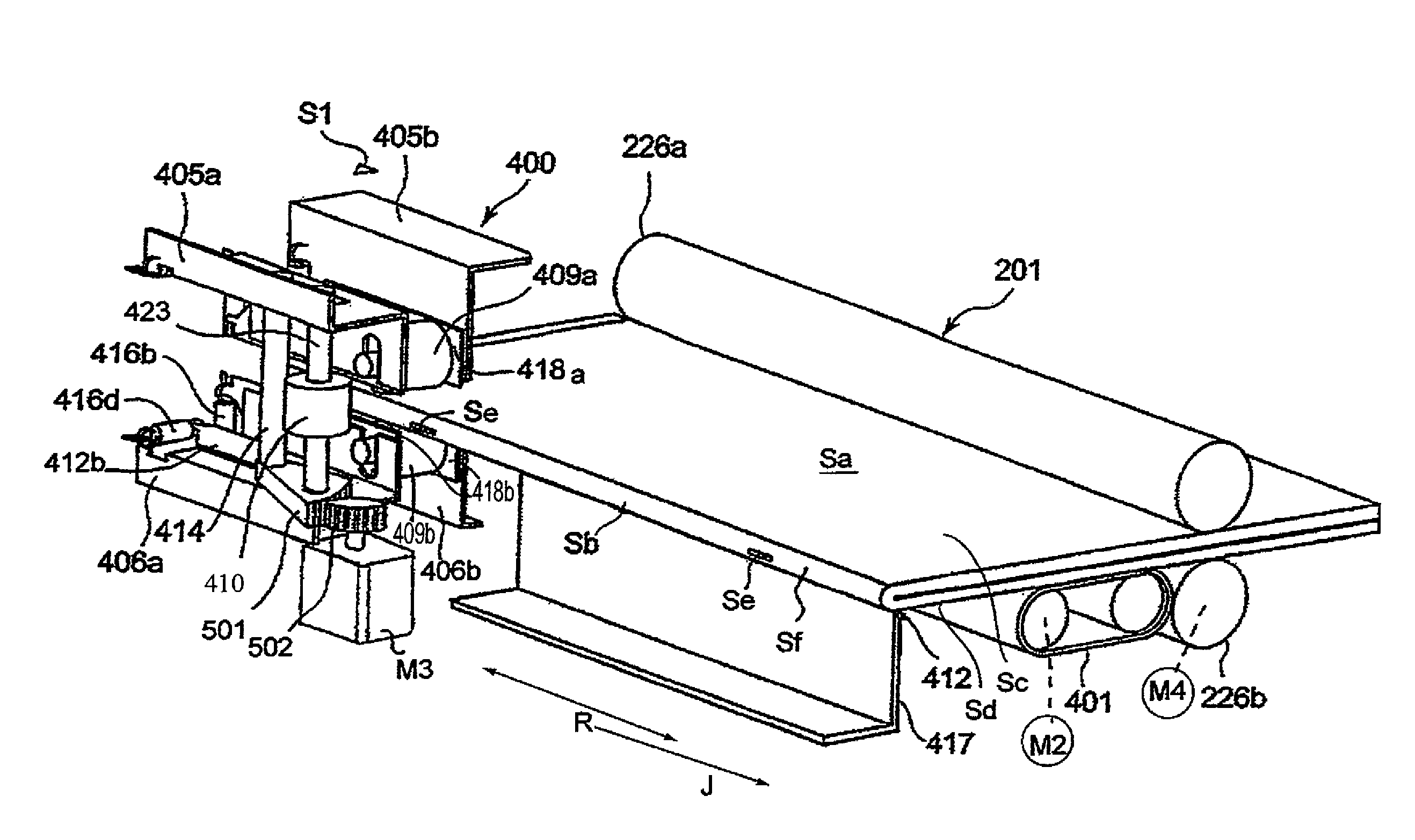

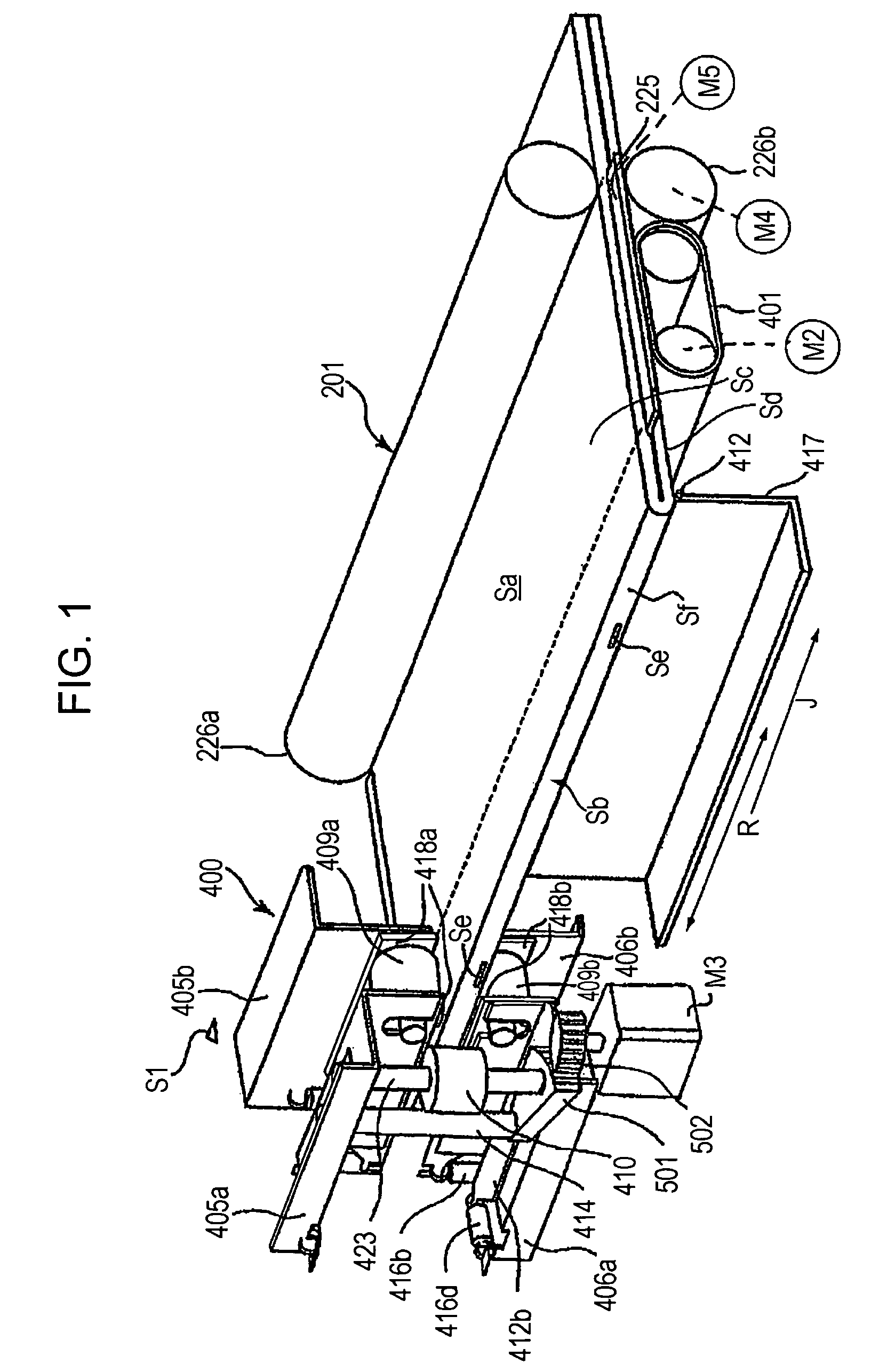

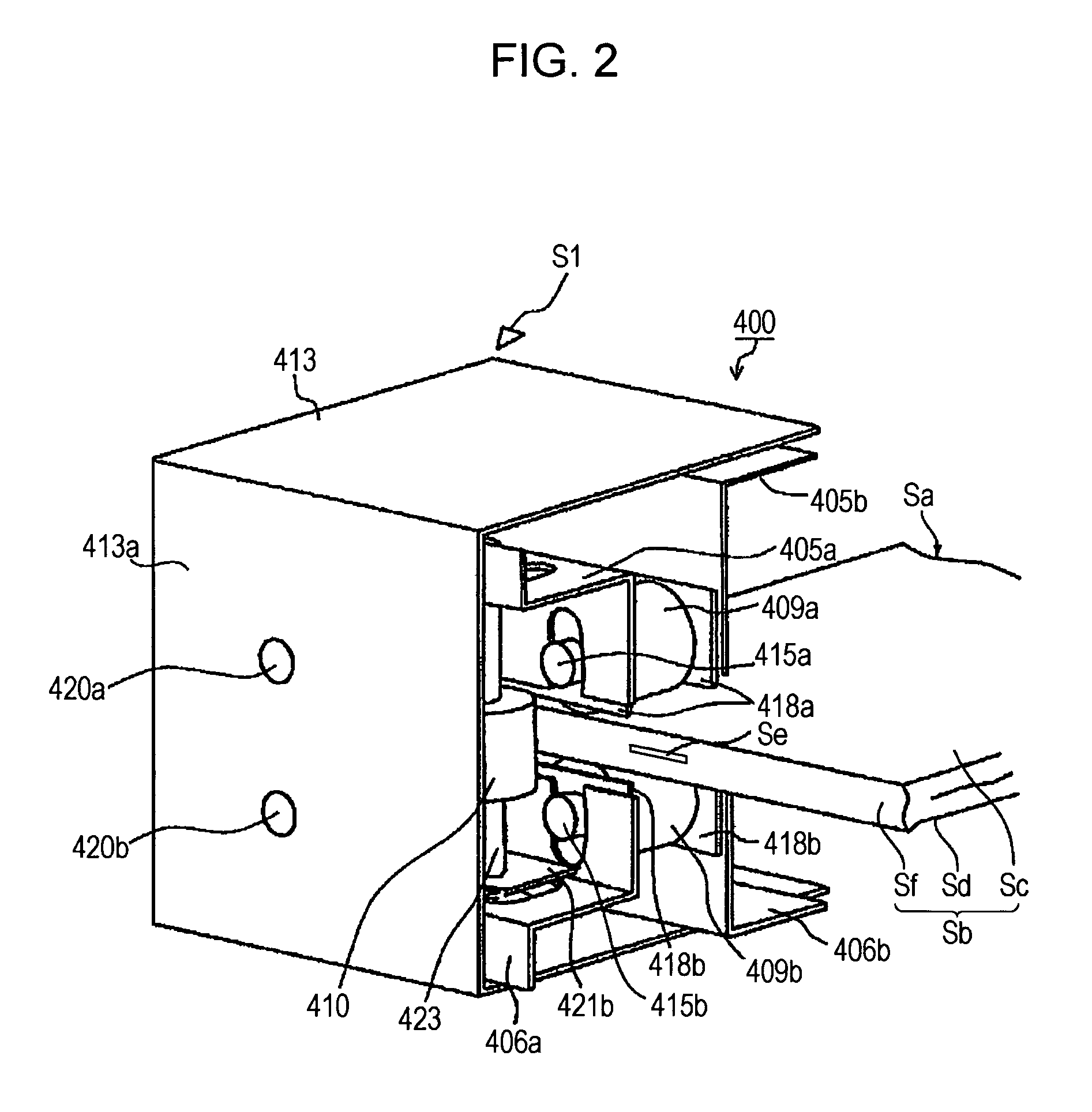

The present invention provides a sheet processing apparatus and an image forming apparatus which can achieve reduction of running cost. A notch part forming portion 400A including a punch 403 and a die 404 forms plural notch parts in an end part of a sheet bundle folded by a sheet folding portion. A discharge roller pair 402a and 402b turns back the notch parts to bind the sheet bundle. As a result, the sheet bundle can easily be opened and the reduction of the running cost can be achieved because stapling is not performed.

Owner:CANON KK

Booklet finishing apparatus, post-treatment apparatus and image forming system

A booklet finishing apparatus has a clamping unit that flattens a booklet of folded sheets by clamping at least on portion adjacent to a back of the booklet from both surfaces of the booklet, a forming unit that flattens the back of the booklet by pressing the back of the booklet, and a switching unit that has a plurality of modes to control the forming unit and switches between the plurality of modes.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Apparatus for coupling stacked sheets

Apparatus for introducing magnetic spirals into rows of neighboring perforations in the spines of stacks of overlapping sheets which are to form discrete calendars, memo pads or analogous commodities employs an elongated guide for a continuous magnetic coil spring. The coil spring is rotated about its longitudinal axis and is moved lengthwise so that its convolutions enter successive perforations of the row of perforations in the stack being held in the guide. The guide embodies or cooperates with magnets which maintain the convolutions of the coil spring in the path defined therefor by the guide. The magnets can be embedded in antimagnetic tubes forming part of or constituting the guide.

Owner:KUGLER WOMAKO

Cutting device, finisher and bookbinding system provided therewith

ActiveUS7506864B2Avoid failureStable operation reductionBook bindingElectrographic process apparatusEngineeringKnife blades

A cutting device that cuts an edge portion of a sheet bundle having plural sheets stacked, includes: a cutting blade; a paddle provided on a side of the cutting blade, which removes chips attached to the cutting blade by rubbing a side surface of the cutting blade; a controller which controls drive of the paddle. The controller includes a judging section which compares a length of the chips in a direction perpendicular to an edge side of the sheet bundle to be cut by the cutting blade with a predetermined length that has been preset. When the length of the chips is shorter than the predetermined length, the controller makes the paddle to rotate in a predetermined direction, and when the length of the chips is longer than the predetermined length, the controller makes the paddle to rotate in a reverse direction.

Owner:KONICA MINOLTA BUSINESS TECH INC

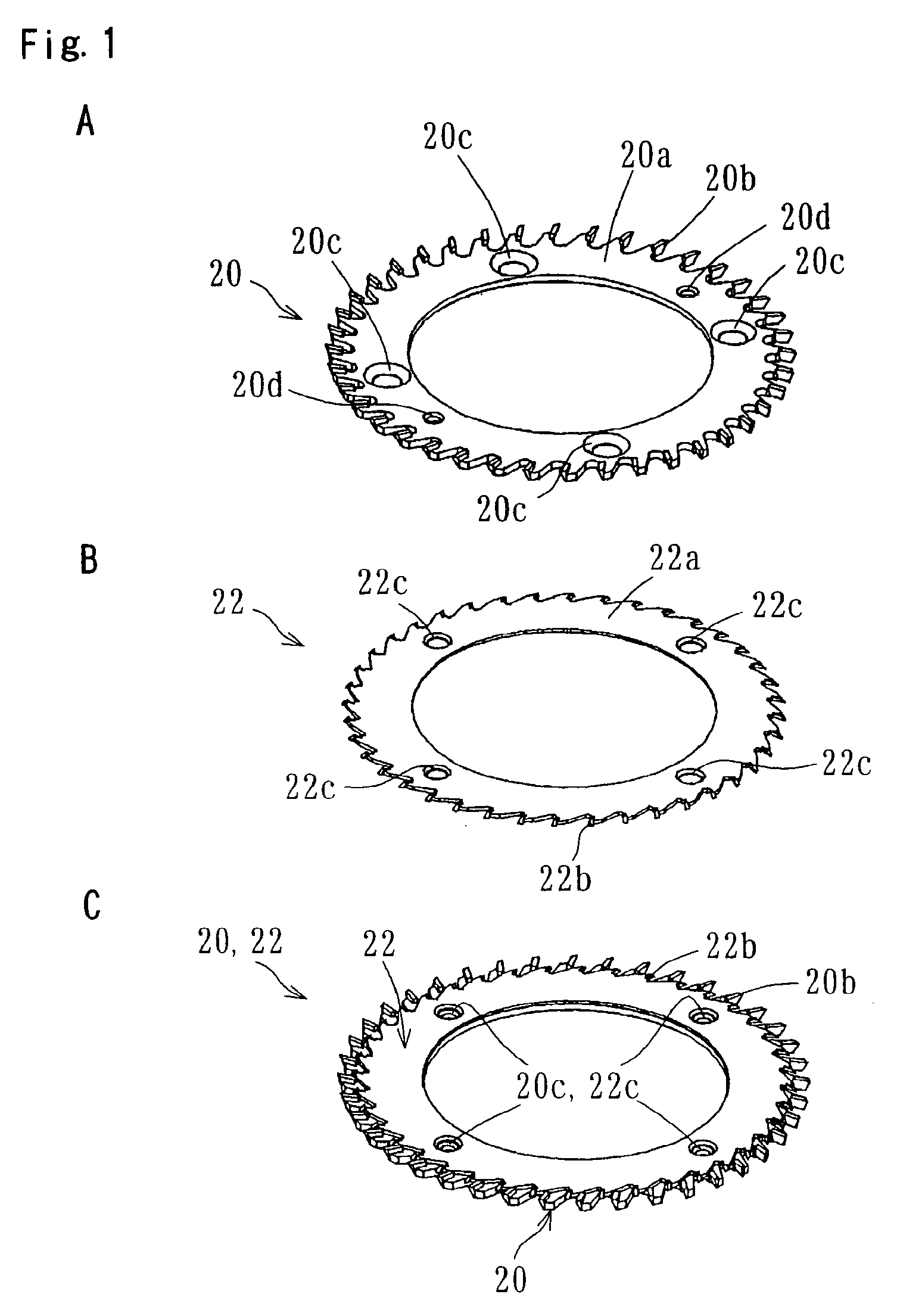

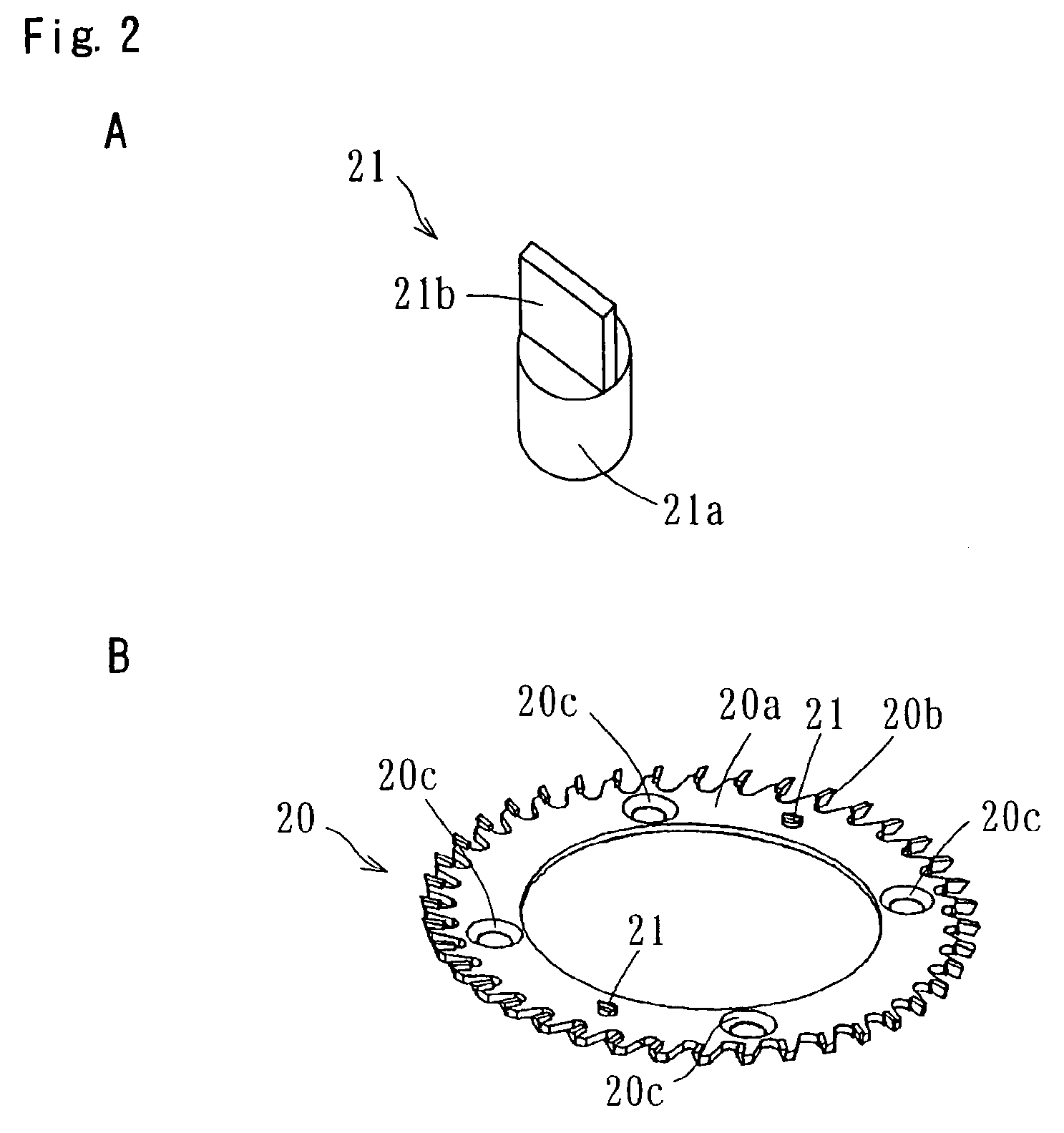

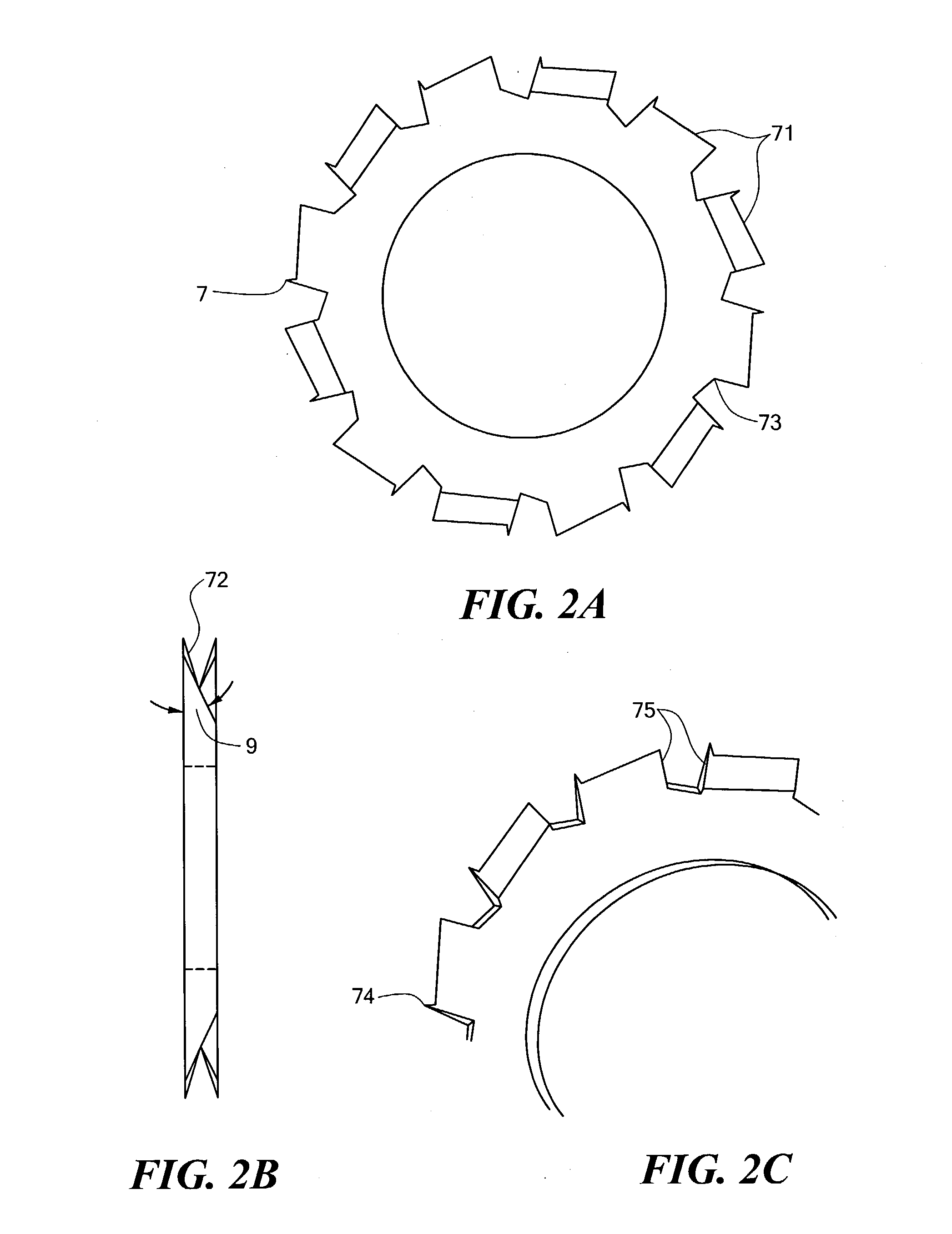

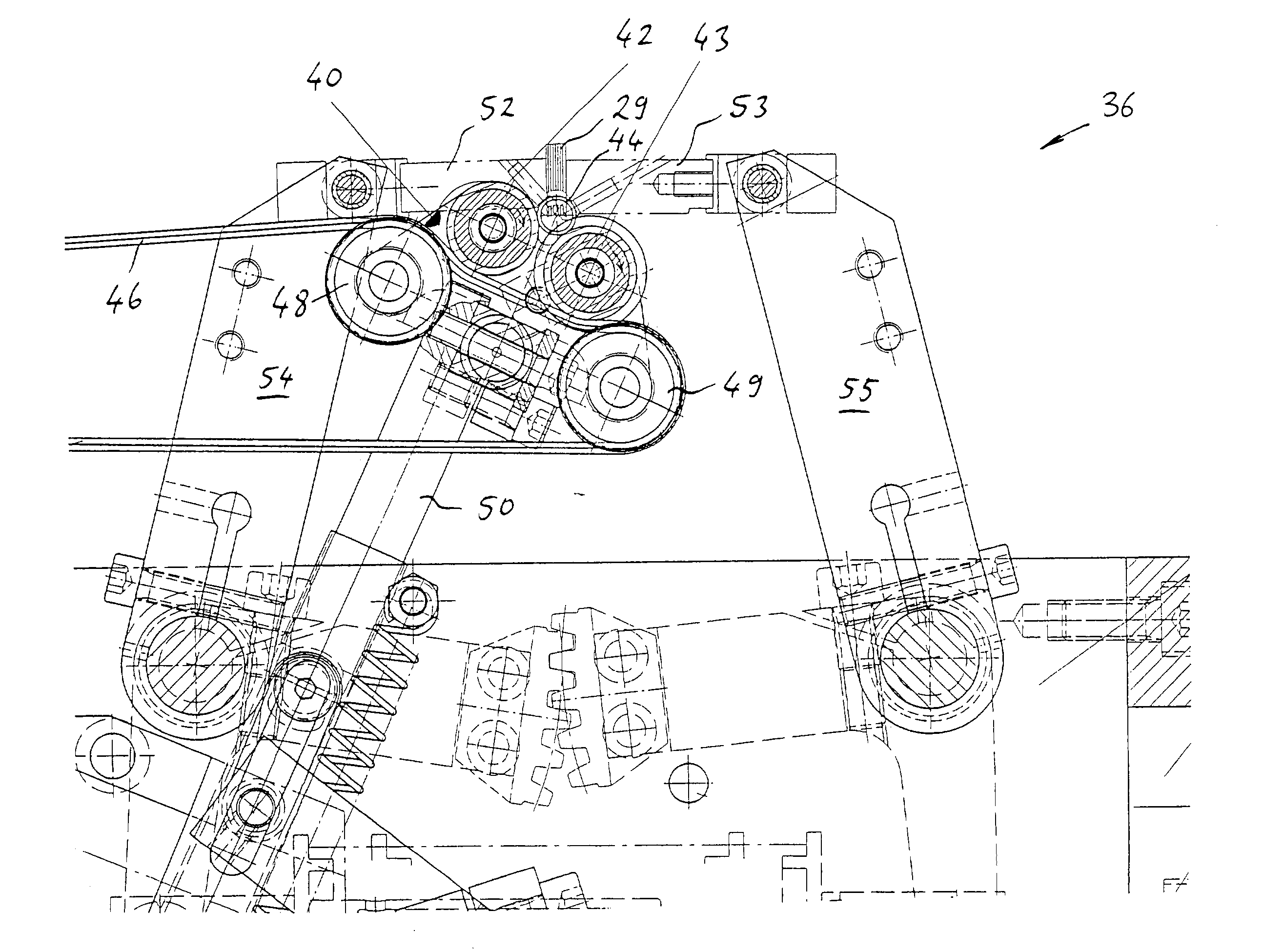

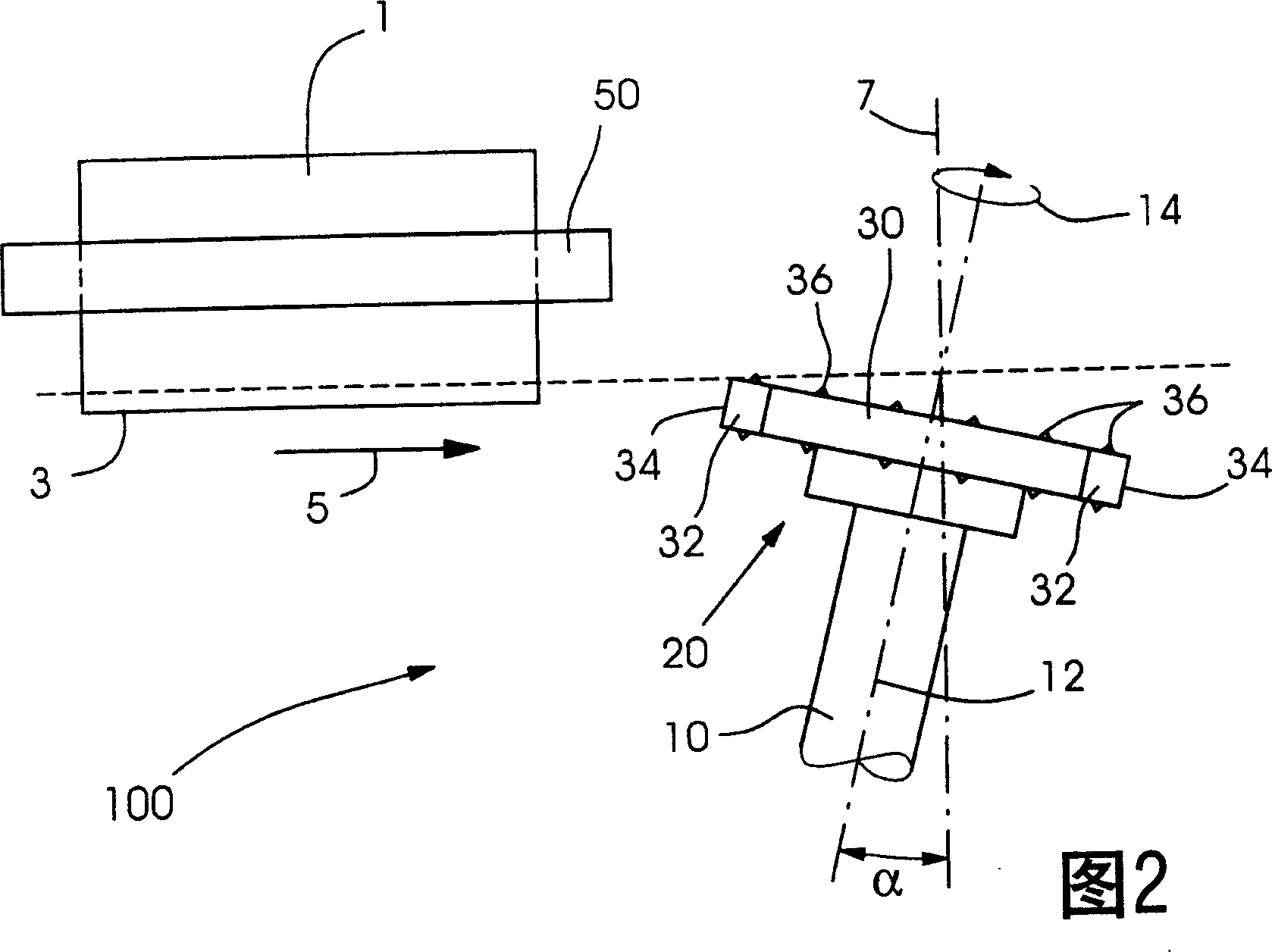

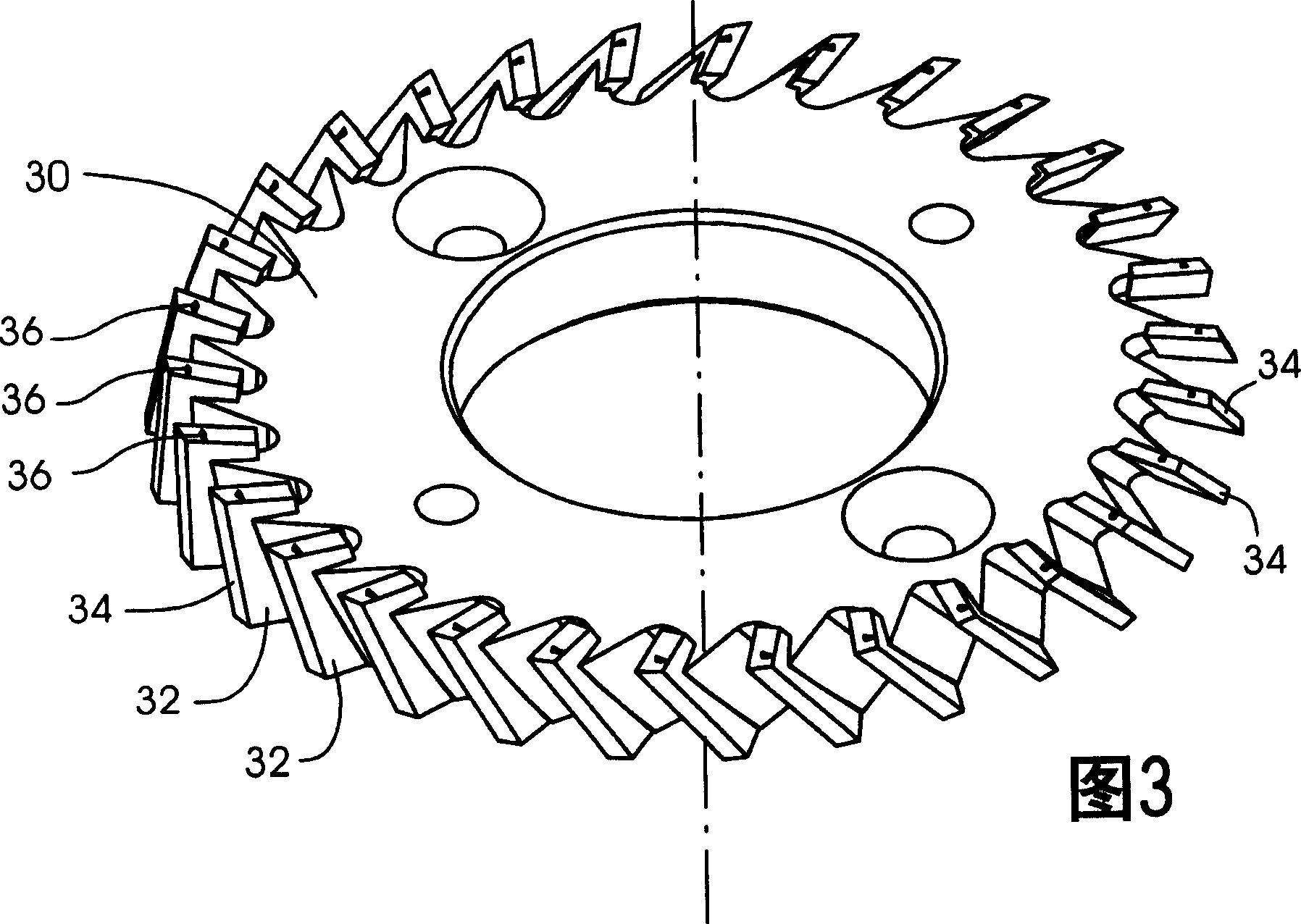

Apparatus for rotary working to material

InactiveCN1470398ABeneficial performance characteristicsHigh speedMilling cuttersBook bindingEngineeringNotching

A device treats a side edge of the pile of a body to be printed which makes a cutting face move along the direction of movement and is provided with a tool head supporting a cutting ring which is rotated around a rotary shaft. A plurality of a treating member are arranged at the circumference of the cutting ring and the member has at least one cutting part which cuts the material in order. The cutting part has at least one cutting corner, turning to the material, which defines the cutting face. At least one of the treating member has at least one notching part which is turning to the material in view toward the axial direction and projecting across the cutting corner on the cutting face.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

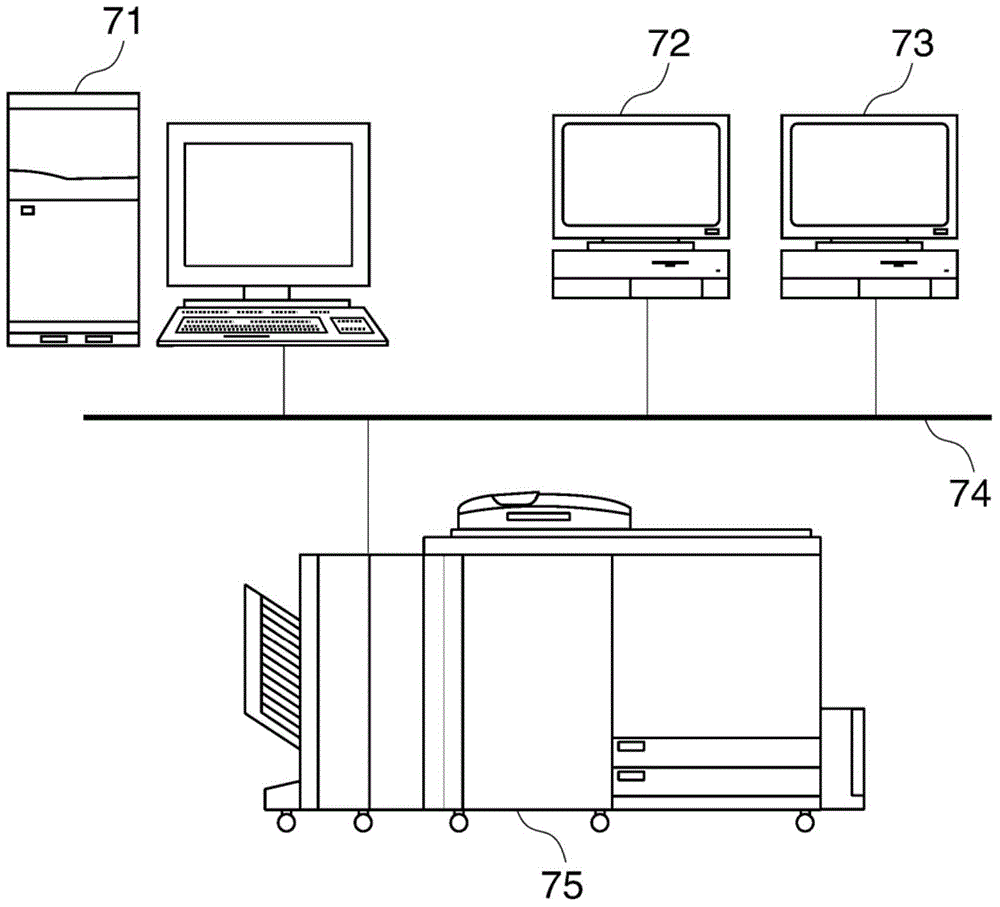

Cutting device and image forming system

InactiveUS20130280016A1Excellent cut surfaceOptimization mechanismBook bindingMetal working apparatusLeading edgeEngineering

A cutting device includes a cutting unit and a pre-processing unit. The cutting unit performs fore-edge cutting processing and top-edge / tail-edge cutting processing in a state in which a blade inclines toward a paper surface of a booklet. The fore-edge cutting processing is to cut off a first edge part of the booklet parallel to a spine of the booklet. The top-edge / tail-edge cutting processing is to cut off a second edge part of the booklet perpendicular to the spine. Of the top-edge / tail-edge cutting processing, in first top-edge / tail-edge cutting processing in which the blade cuts the booklet from a side opposite to the spine, before the blade abuts the spine, the pre-processing unit makes a cut at a point of the spine along a cutting direction in which the blade cuts the spine, the point where the blade abuts the spine.

Owner:KONICA MINOLTA INC

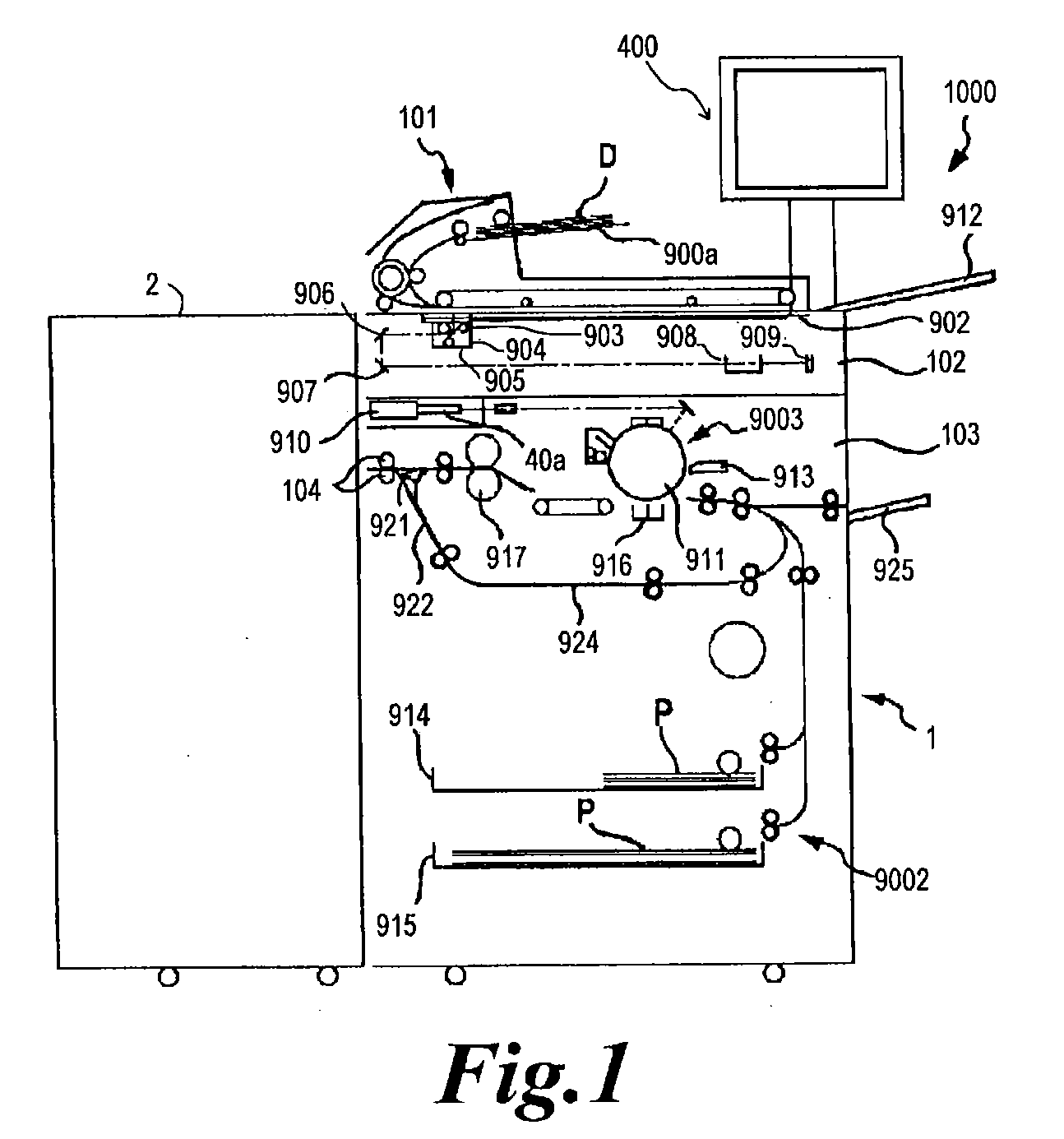

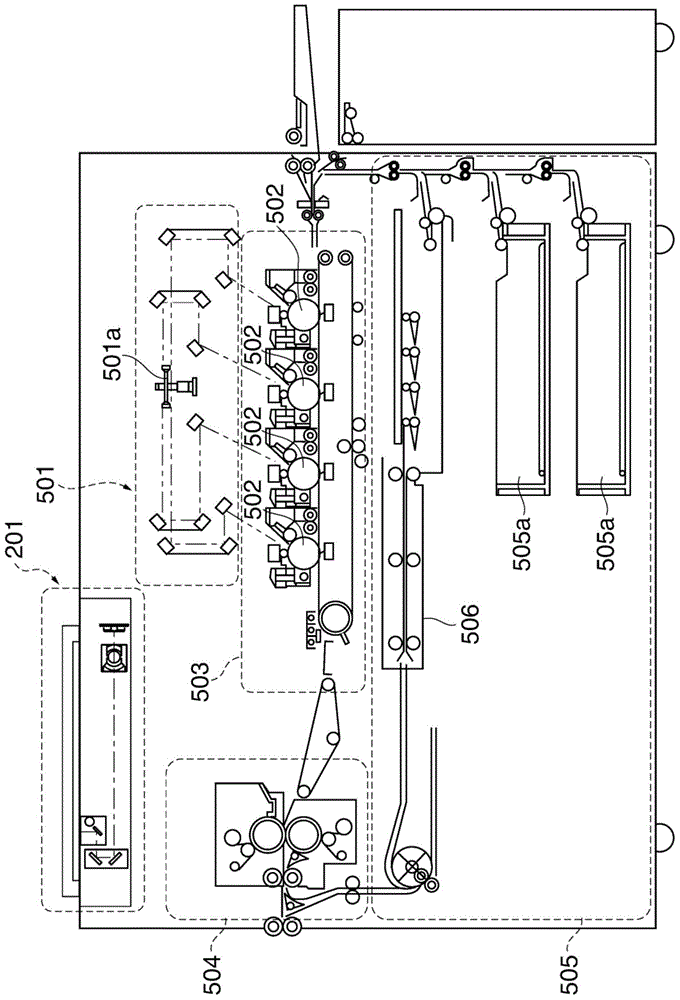

Printing system and control method therefor

InactiveCN103853508AAvoid offsetBook bindingElectrographic process apparatusControl unitElectrical and Electronics engineering

A printing system and a control method therefor are provided. The printing system is capable of producing a bookbound matter with good appearance when producing the bookbound matter by covering a first sheet bundle with a second sheet bundle. A determination unit determines whether it is specified so that images are printed on sheets of first and second sheet bundles in page order in which a bookbound matter is produced by covering the second sheet bundle folded by the first sheet bundle folded. A control unit controls so as to cut the first sheet bundle at a first position and to cut the second sheet bundle at a second position that is different from the first position, when the determination unit determines to be specified.

Owner:CANON KK

Sheet processing apparatus and image forming apparatus equipped with the same

InactiveUS20120321414A1Avoid deformationGood lookingBook bindingFolding thin materialsEngineeringSmooth surface

A folded spine of a booklet held by a pair of opposing holding members is deformed by entering a pressing member into a gap between the pair of holding members and bringing the pressing member into pressure contact with the folded spine. In consequence, the folded spine is prevented from receiving an excessive pressing force, and a smooth surface with a width substantially equal to the thickness of the booklet is thus formed on the folded spine, whereby a booklet with a good appearance can be made.

Owner:CANON KK

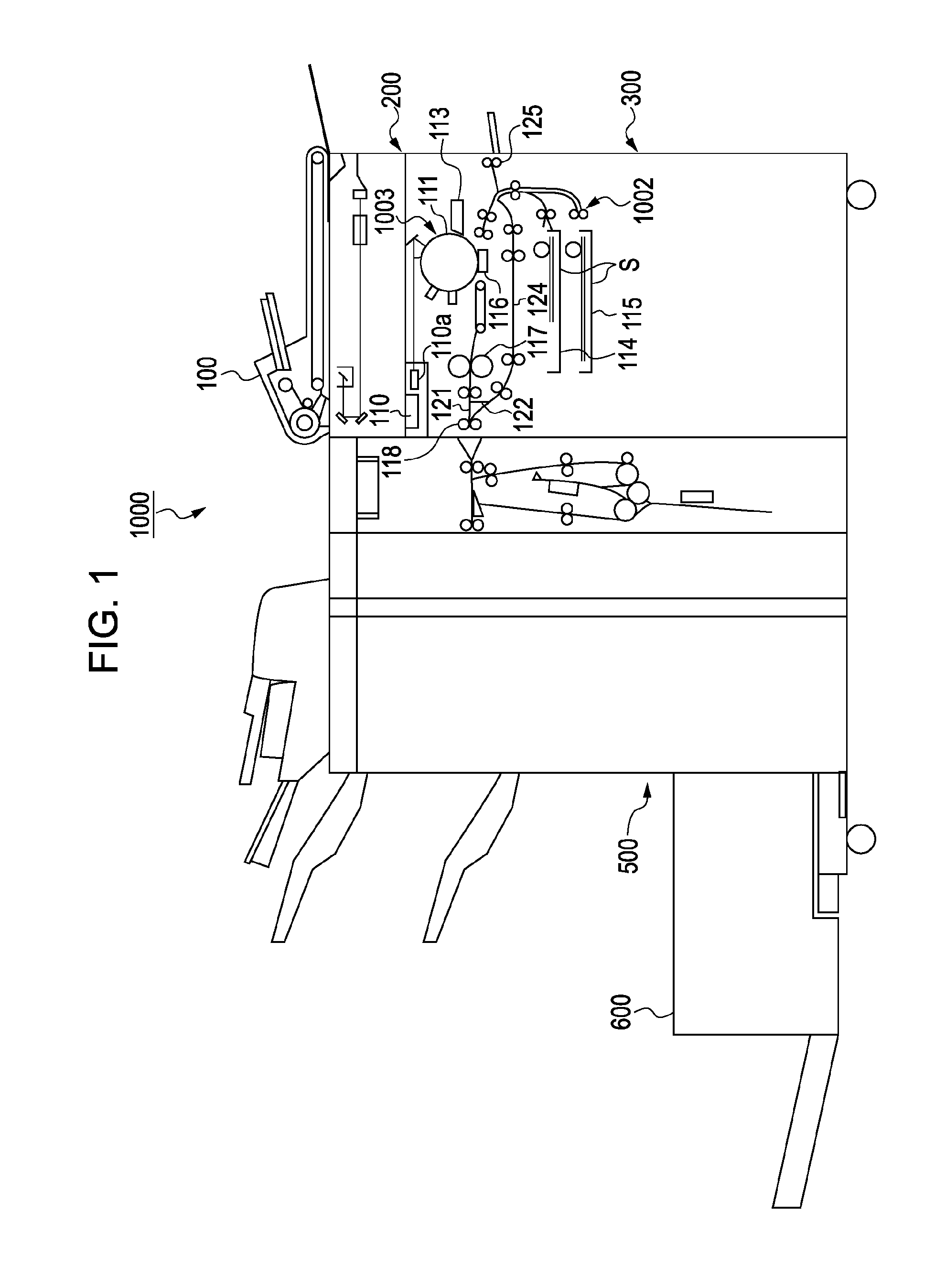

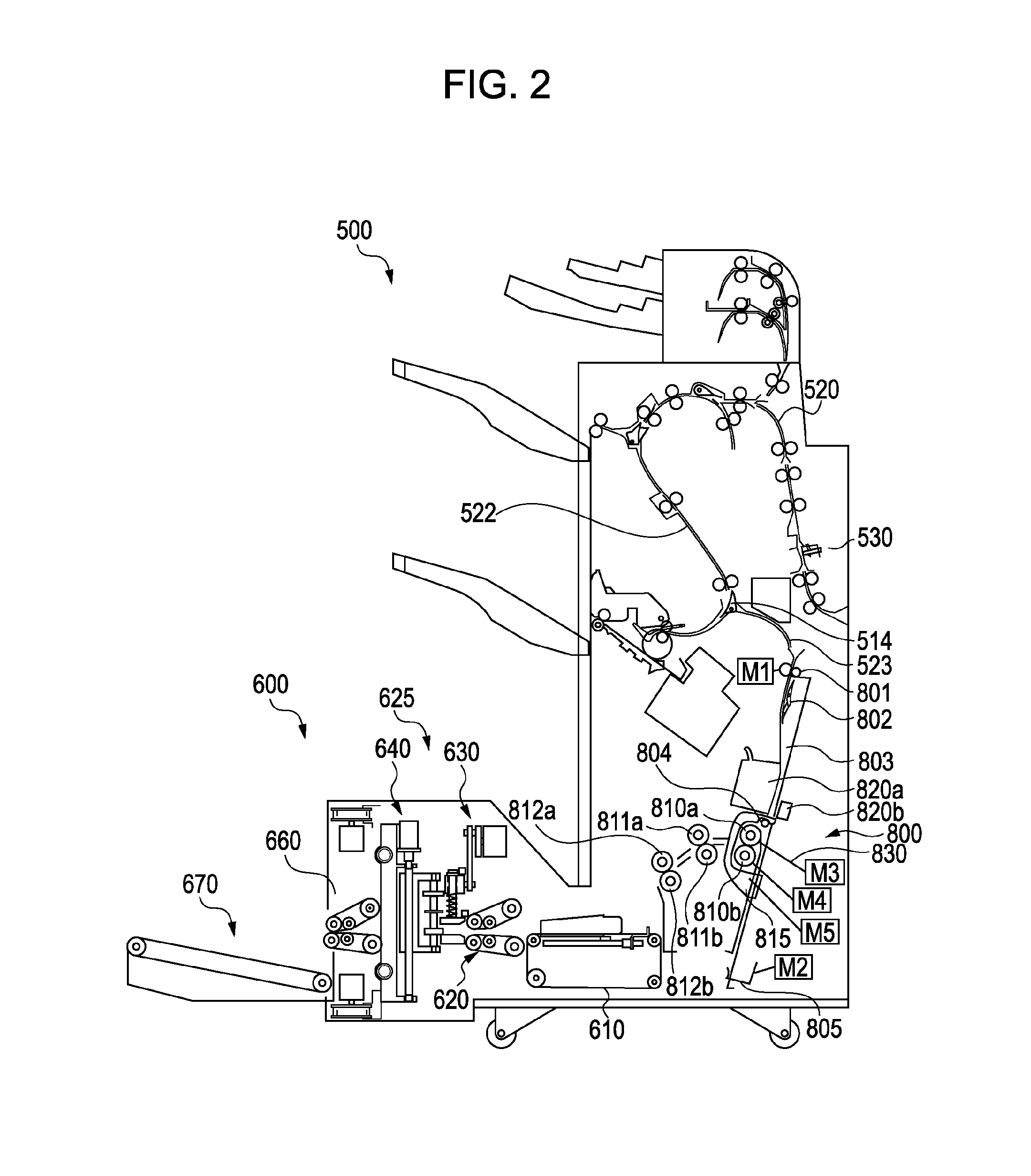

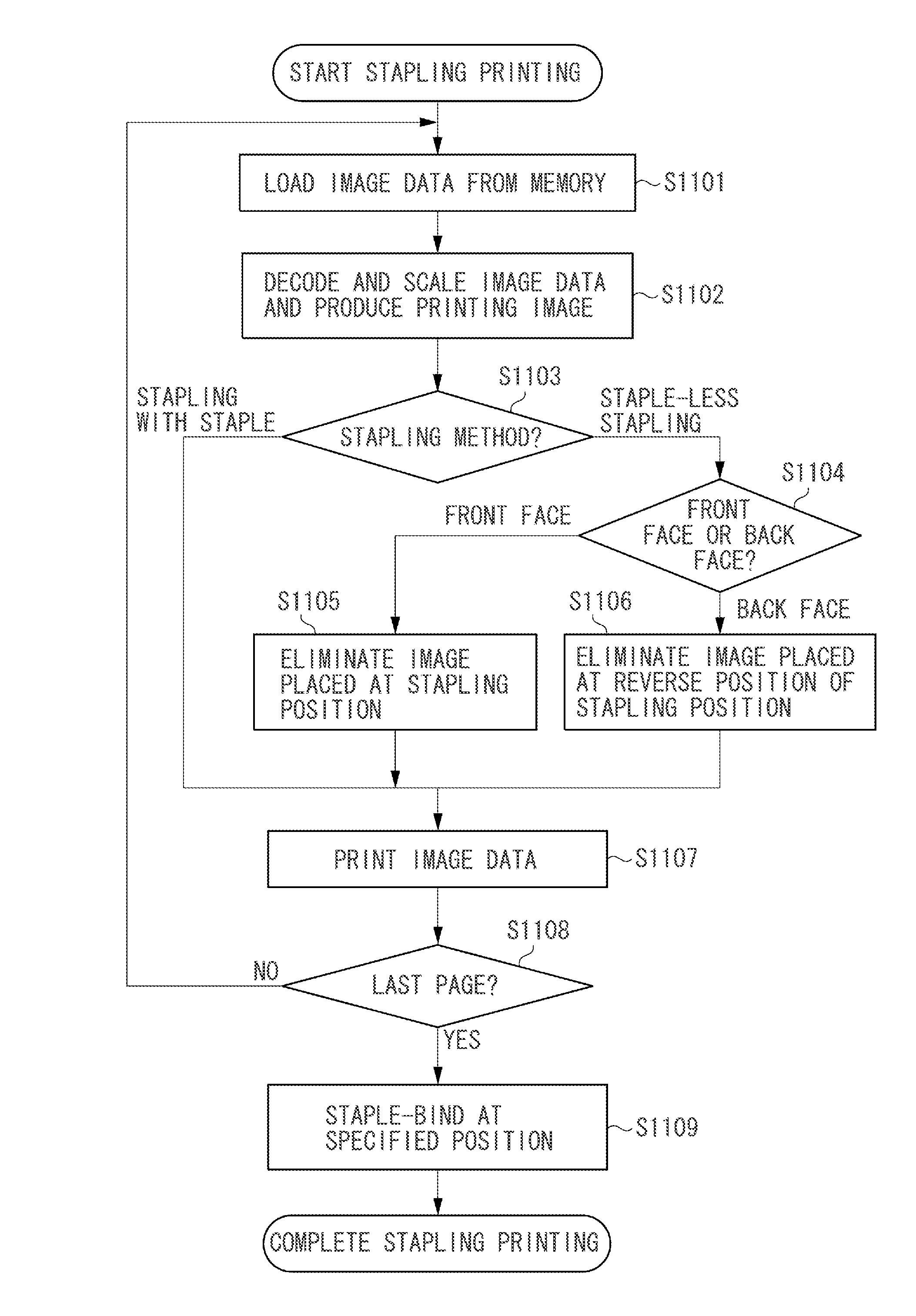

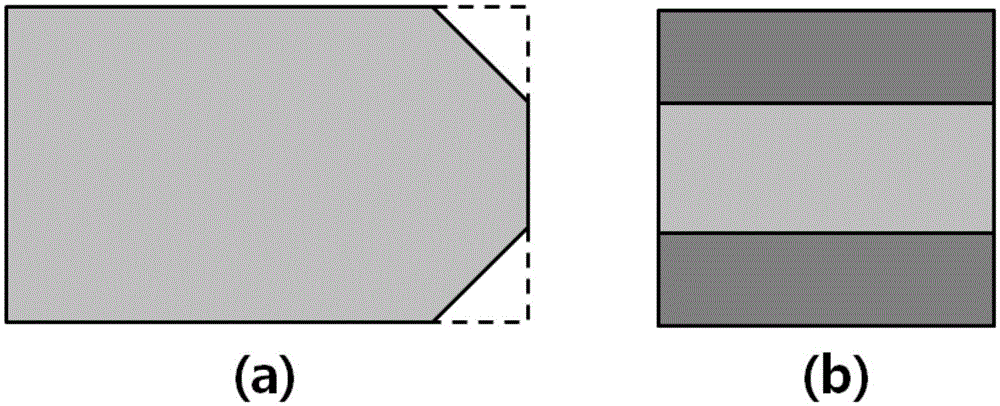

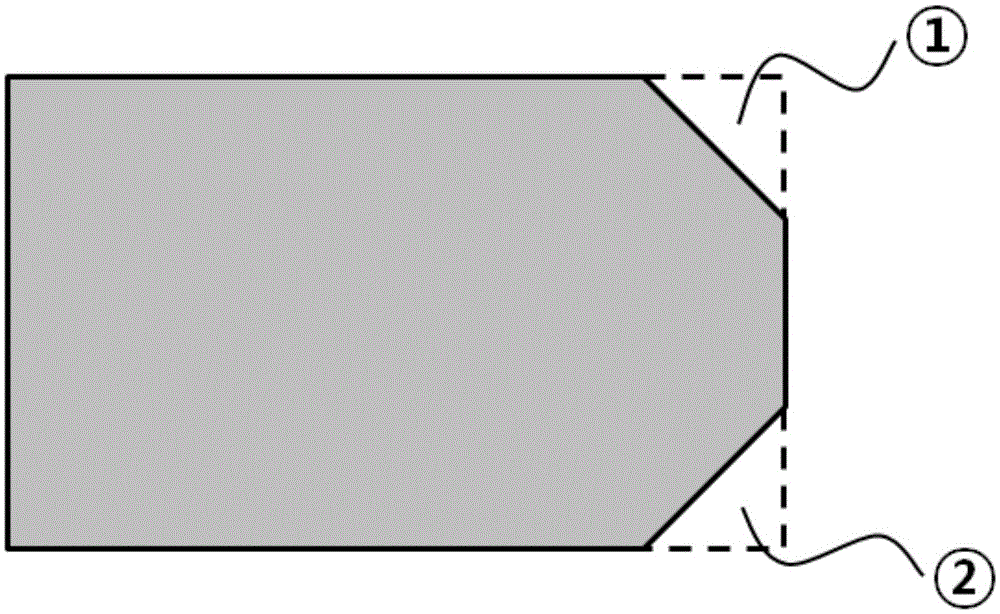

Printing apparatus that performs a binding process without using a staple

Even when a binding process for binding a plurality of sheets without using a staple is performed after performing printing on both faces of the sheets, the binding process can be performed so that the bound sheets are not easily separated. A control method for controlling a printing apparatus, comprises: performing a binding process for binding, without using a staple, a sheet on which an image is printed based on image data; specifying an area where the binding process is to be performed, the area being included in the image data; deleting image data of the specified area; and printing the image on the sheet based on the image data on which deleting is performed.

Owner:CANON KK

Extrusion molding device and method for manufacturing green honeycomb molded body

ActiveCN105579409ACuts quickly and without defectsLow costBlast gunsBook bindingHoneycombEngineering

An extrusion molding device (1) is provided with a first tube (10), a screw (2B) provided in the first tube (10), a second tube (50) connected to the outlet of the first tube (10), a flow adjustment plate (20) disposed between the first tube (10) and the second tube (50), and a die (90) connected to the outlet of the second tube (50). The second tube (50) comprises, in order from the first tube (10) side, a first portion (32) having a constant inner diameter, a second portion (34) having an inner diameter that decreases with increasing distance from the first portion (32), and a third portion (36) having a constant inner diameter. The second portion (34) is inseparably integrated with the first portion (32), and the third portion (36) is inseparably integrated with the second portion (34).

Owner:DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com