Extrusion molding device and method for manufacturing green honeycomb molded body

A technology of strengthening glass and chamfering, which is used in glass manufacturing equipment, glass cutting devices, book binding, etc., can solve problems such as increased cost and prolonged processing time, and achieve the effect of improving strength, high strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

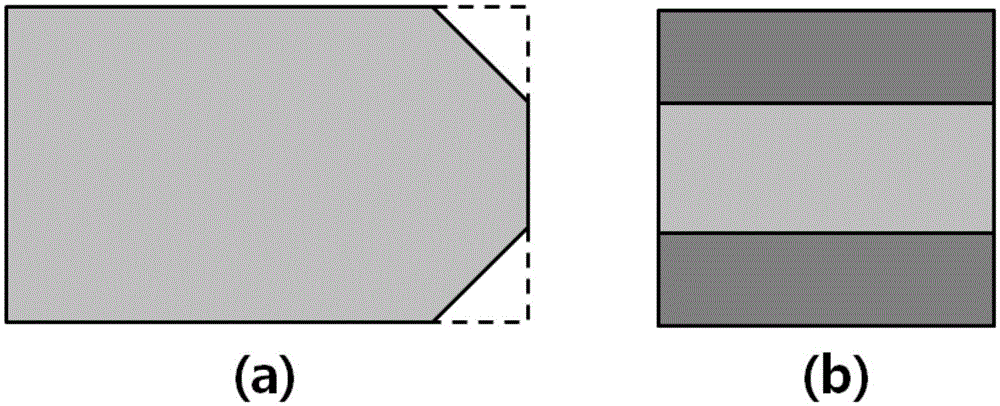

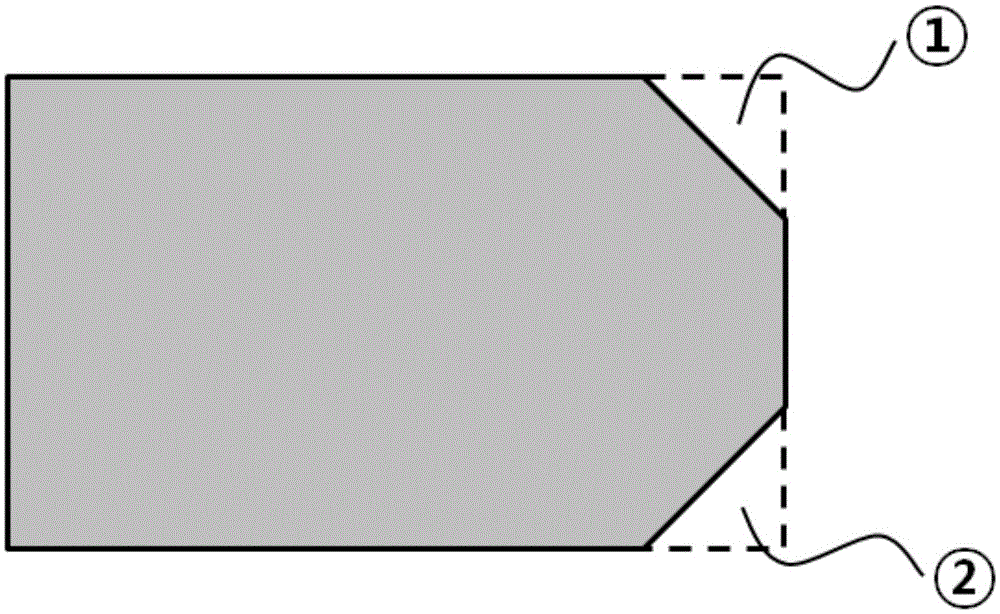

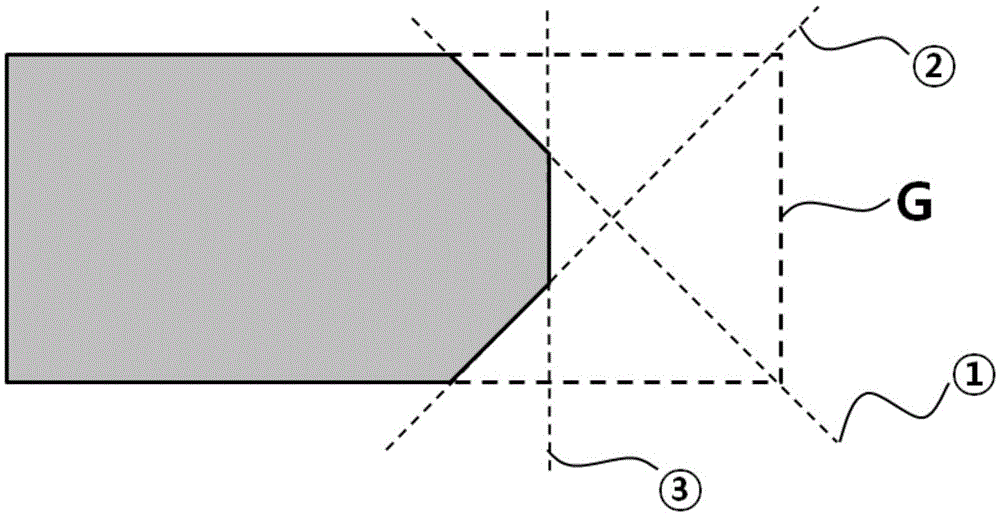

[0039] The present invention provides a method for cutting strengthened glass, the method comprising: adding water (H 2 O) spraying at a spraying pressure of 100 to 800 bar together with cutting particles having a mesh size of 120 to 600 to cut the strengthened glass at a cutting speed of 1500 mm / min or less.

[0040] The water jet method is a method that has been widely used to cut conventional glass rather than strengthened glass, and is considered to be an economical and precise method of cutting glass.

[0041] However, there is no precedent for applying the water jet method to toughened glass that is difficult to cut. In consideration of such circumstances, the present inventors discovered specific conditions of the water jet method capable of cutting strengthened glass, and completed the method of the present invention, which can economically and accurately cut strengthened glass.

[0042] The tempered glass to which the cutting method of the present invention can be ap...

Embodiment 1 to 10 and comparative example 1 to 11

[0086] In tempered glass (depth of strengthened layer: 20 to 25μm, Vickers hardness: 649kgf / mm 2 , Young's modulus: 71.5 GPa) After forming a protective resin film on the surface, the strengthened glass was cut by spraying a water jet under the conditions shown in Table 1 below. Then, it was observed whether the strengthened glass was cut, and the results are shown in Table 1 below.

[0087] [Table 1]

[0088]

[0089]

[0090] Referring to Table 1, in Examples 1 to 10 in which the injection pressure and cutting speed are within the range of the present invention, the strengthened glass can be cut, but in Comparative Examples 1 to 11 outside the preferred range of the present invention, the Strengthened glass cannot be cut or broken during cutting.

Embodiment 11 to 16 and comparative example 12 to 15

[0092] In tempered glass (depth of strengthened layer: 20 to 25μm, Vickers hardness: 649kgf / mm 2 , Young's modulus: 71.5 GPa) After forming a protective resin film on the surface, the strengthened glass was cut by spraying a water jet under the conditions shown in Table 2 below. Then, a chamfering process was performed by bringing a heat source into contact with the cut plane under the conditions shown in Table 2 below, and it was observed whether the strengthened glass was cut and elongation was measured. The observed and measured results are shown in Table 2 below. Here, the elongation is determined by an average value of 50 or more tempered glasses.

[0093] Elongation is an index capable of evaluating the strength of the strengthened glass, and is measured by arranging two separate support arches on opposite sides of the center below the window substrate of the strengthened glass, and passing through the upper center of the window substrate. While applying a load to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com