Apparatus for rotary working to material

A rotating axis, facing technology, applied in the field of devices for processing materials, capable of solving problems such as low tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

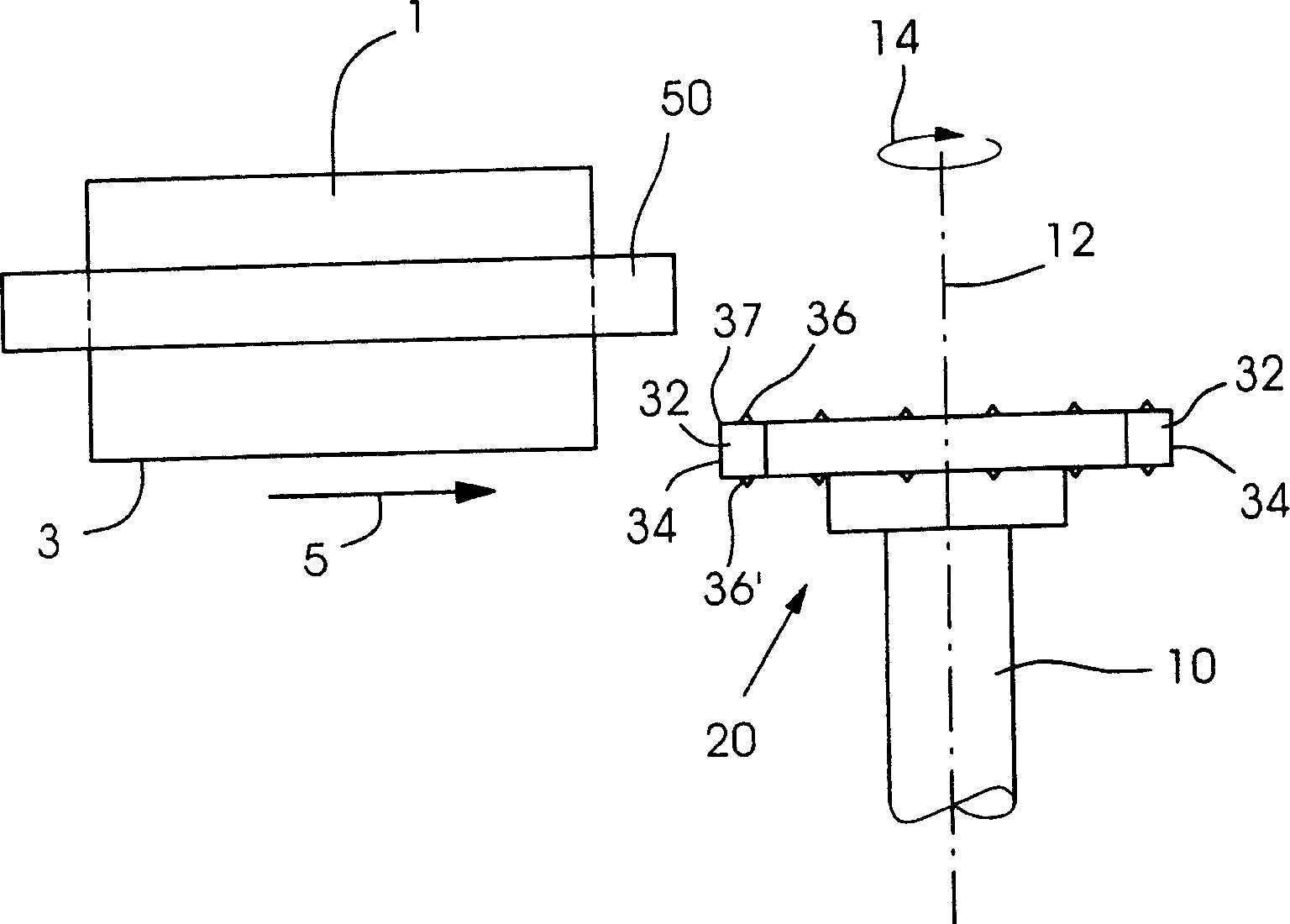

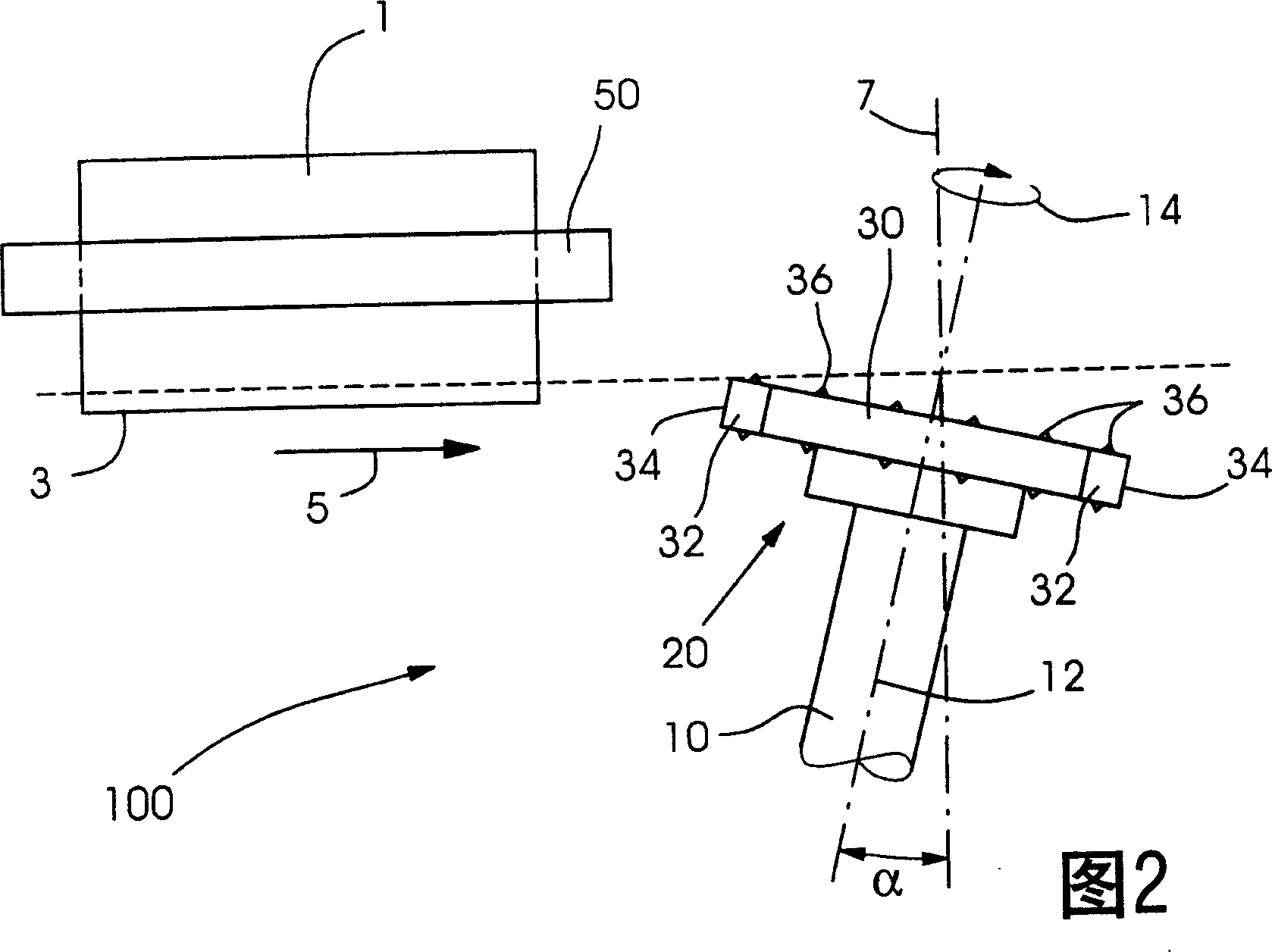

[0038] figure 1 The basic or practical principle of the device 100 of the invention during the processing of the material 1 is shown. Material 1 is a stack of sheet-like printing material in the described embodiment.

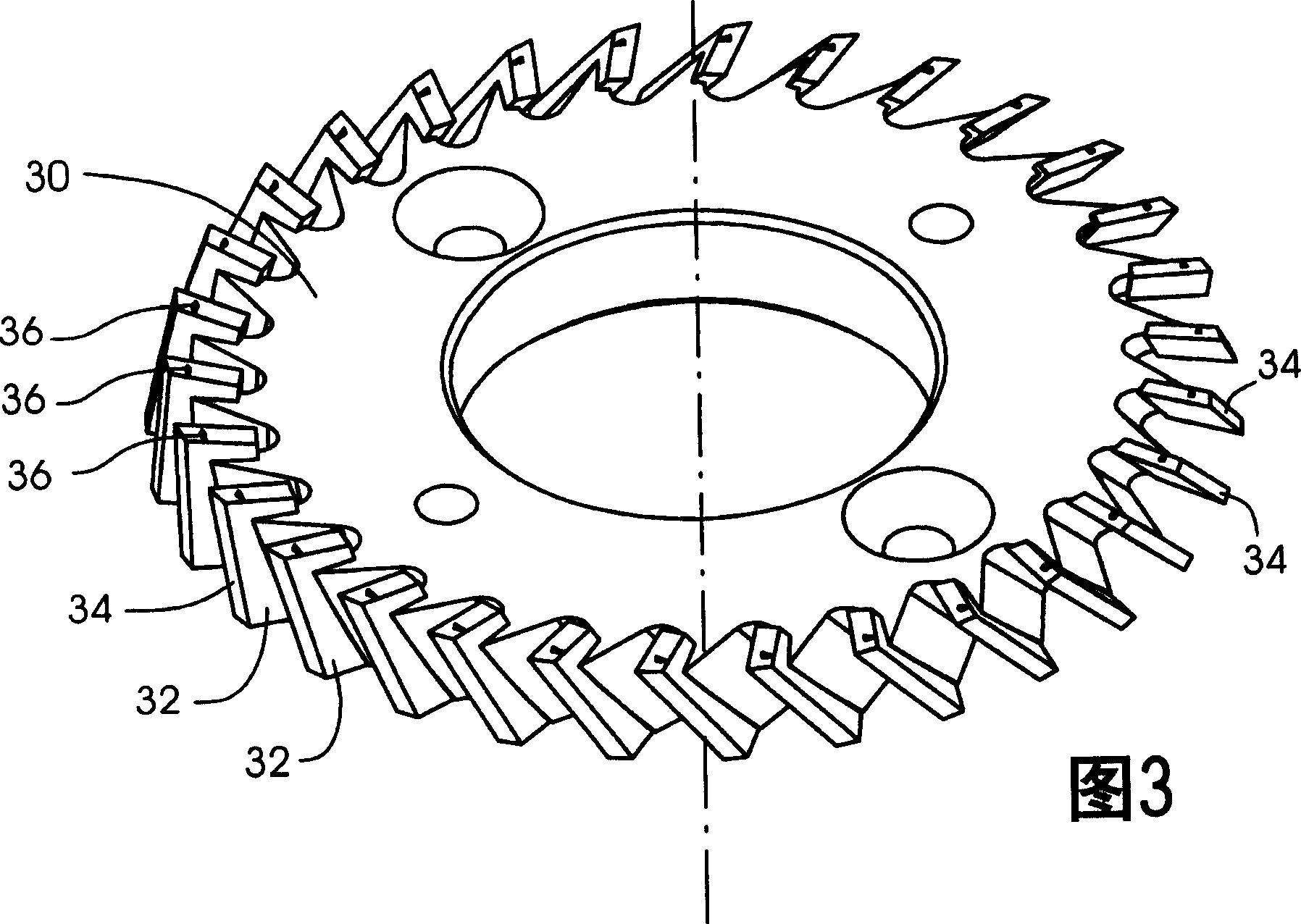

[0039] A stack of sheet-like printing material 1 with a common side 3 is conveyed towards the cutter head 20 in the direction of movement indicated by the reference symbol 5 . The stack of sheet-like printing materials is prevented from unraveling by the clamping element 50 . The clamping member 50 also helps to ensure that the sheets of printing material 1 do not slip within the stack due to the shear stresses generated. The cutter head 20 is positioned with its processing element 32 along the direction of movement of the sheet-like printing material 1 . The tool head 20 rotates about an axis of rotation 12 and the axis of rotation 12 forms an angle α with the perpendicular 7 of the cutting plane 9 , as shown in FIG. 2 . The axis of rotation 12 and the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com