Sheet post-processing apparatus and image forming apparatus

A post-processing device and sheet material technology, which can be used in thin material processing, equipment for electric recording technology using charge patterns, book binding, etc., can solve problems such as appearance damage, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

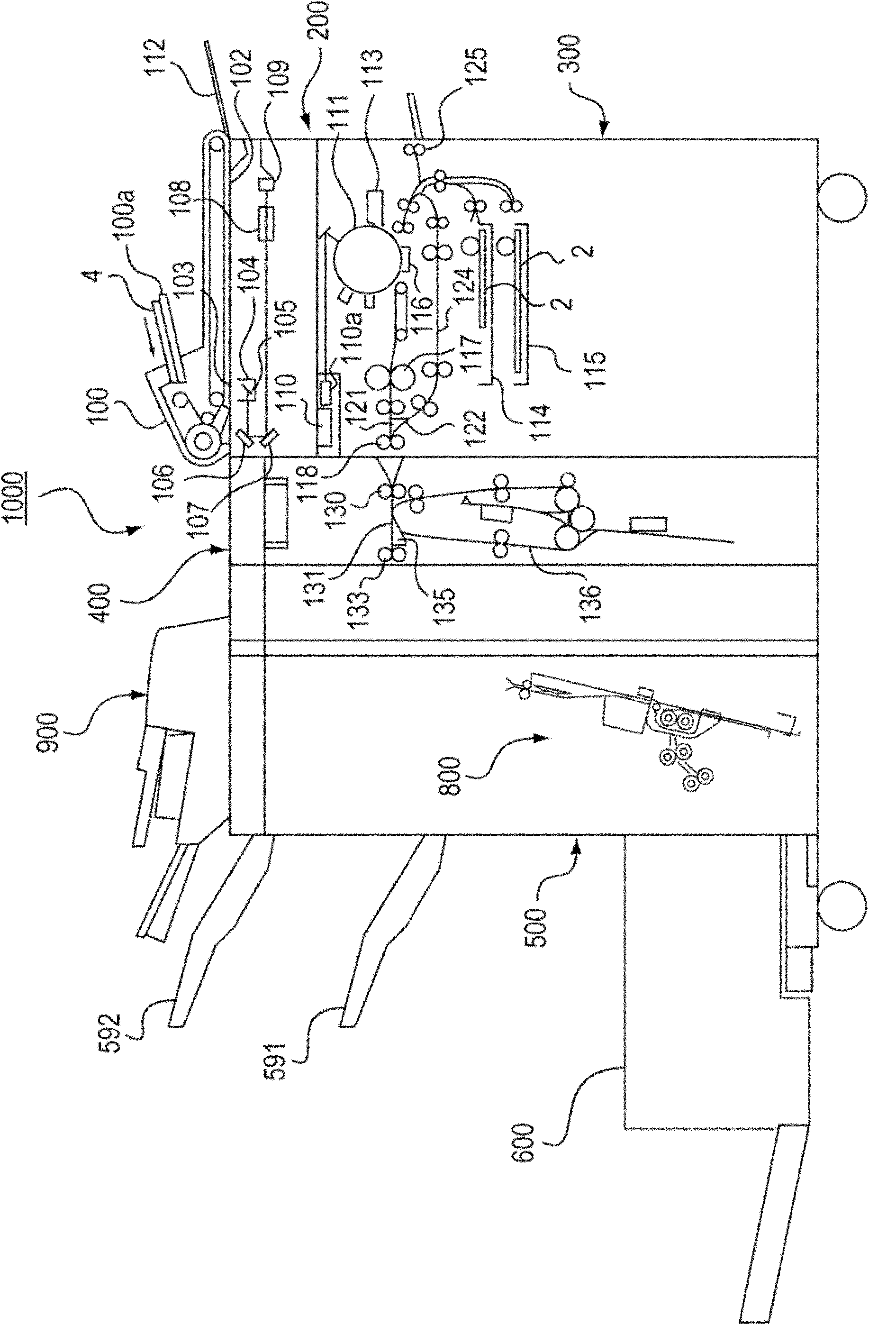

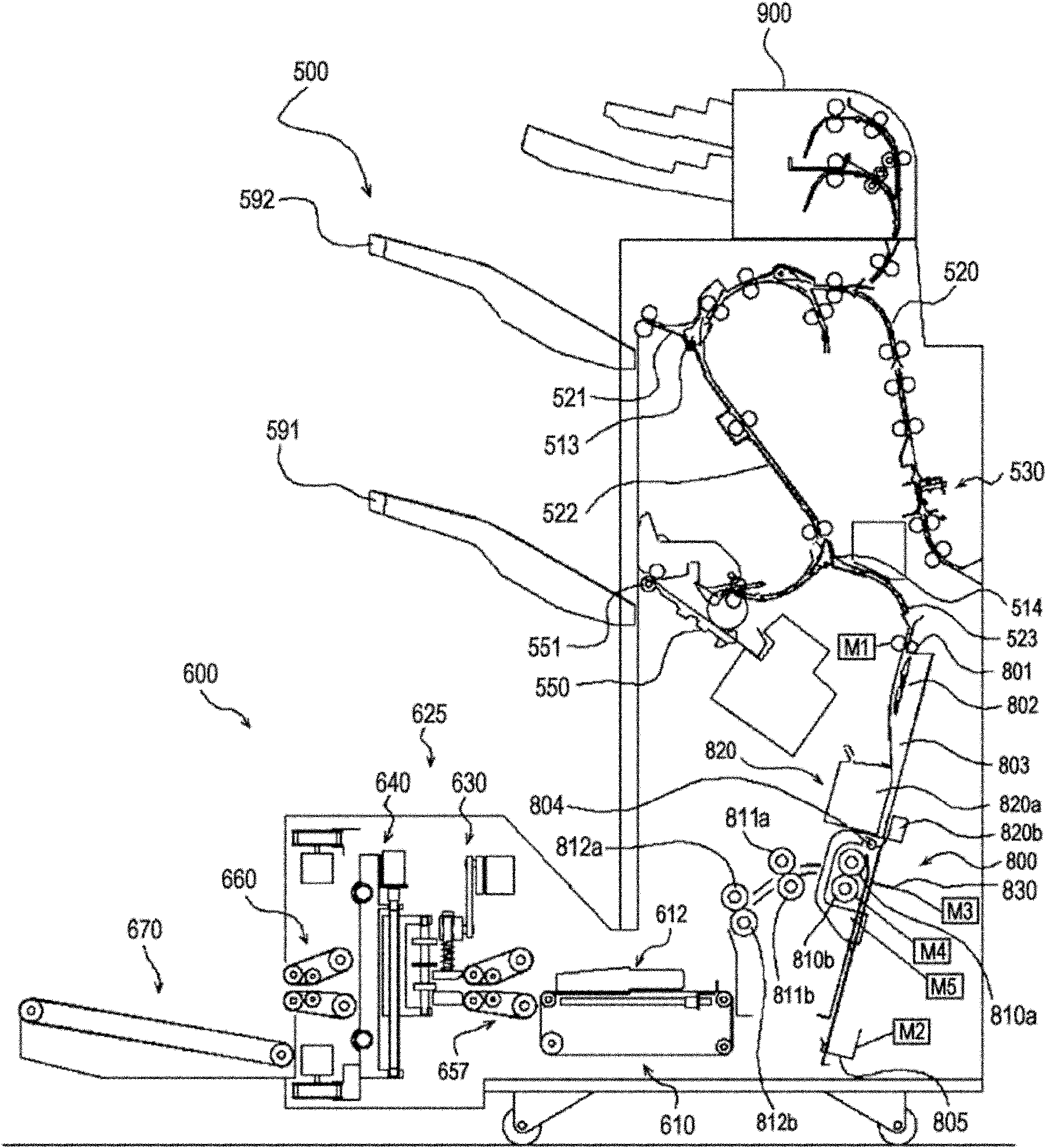

[0028] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings. figure 2 Key components of the sheet post-processing apparatus according to the present invention are shown. figure 1 is a sectional view showing the internal structure of a copying machine 1000 as an image forming apparatus capable of utilizing the sheet post-processing apparatus according to the present invention. This copier 1000 includes a document feeding section 100, an image reading section 200, a printing section 300, a folding processing section 400, a finisher 500, a saddle stitch binding section 800 ( figure 2 shown), the flat processing portion 600 and the inserter 900. The folding processing part 400, the saddle stitching part 800, the straight processing part 600, and the insertion part 900 are optional.

[0029] Such as figure 1 As shown, a document 4 is set in a document tray 100 a of a document supply section 100 . The docu...

no. 2 example

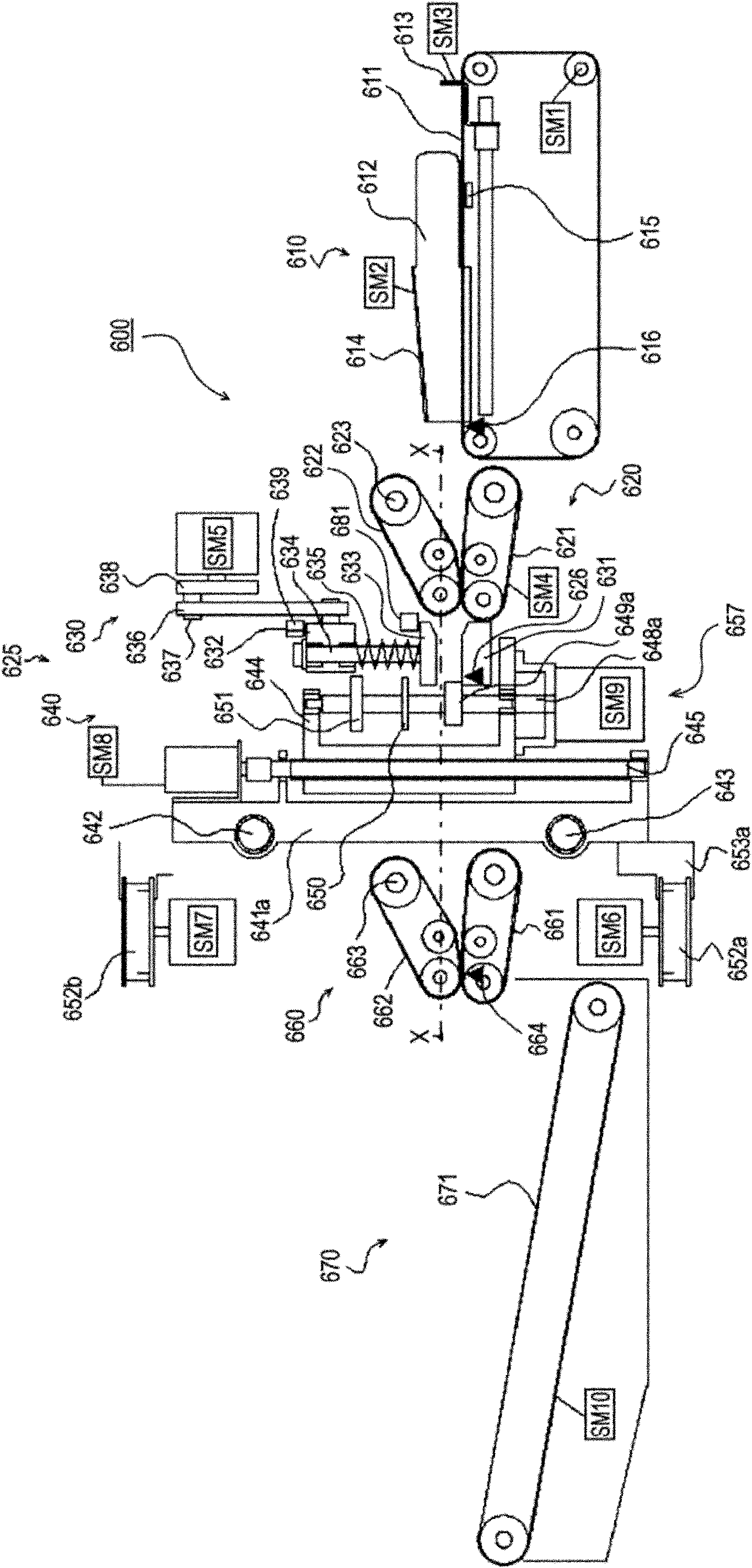

[0086] The first embodiment provides first and second pressing members 650 and 651 using rollers. Such as Figure 16 As shown, the second embodiment employs a belt 665 as a pressing member to move along the spine 2a1 of the booklet 2a while pressing the booklet 2a.

[0087] Figure 16 Belt 665 is shown extending between drive roller 666 and pulley 667 . The drive roller 666 is driven by a drive motor SM9 as a drive portion that drives the pressing member. The driving motor SM9 as a driving portion drives the belt 665 as a pressing member. The belt 665 moves at a peripheral speed V3 on the pressing surface of the spine 2a1 of the pressing booklet 2a. The flattening control section 601 functioning as a control section and a changing section adjusts the peripheral velocity V3 of the pressing surface at the position where the pressing member is pressed against the spine 2a1 of the booklet, which is set so as to be compatible with the moving unit as the moving section. The mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com