Printing system and control method therefor

A technology of printing system and control method, applied in the direction of digital output to printing unit, printing, instrument, etc., which can solve the problem of edge position offset and achieve the effect of preventing offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, embodiments according to the present invention will be described in detail with reference to the drawings.

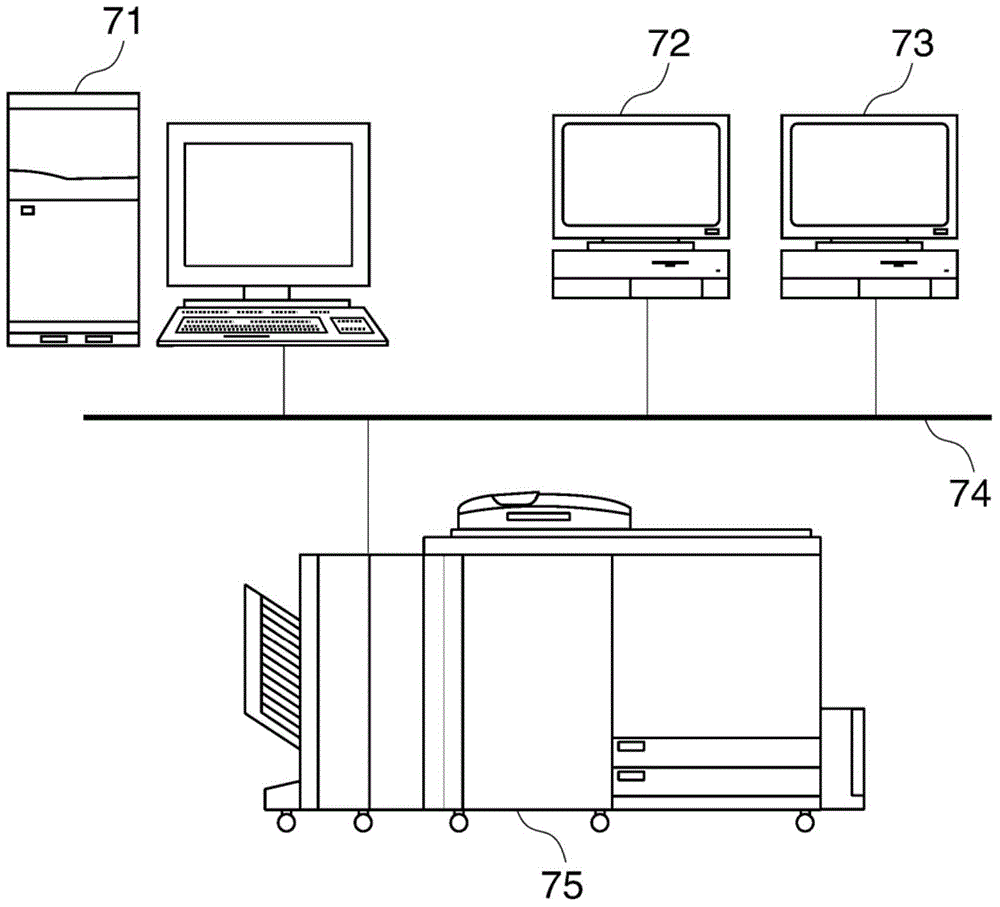

[0032] figure 1 is a diagram showing an example of a network environment including the printing system according to the first embodiment of the present invention.

[0033] Such as figure 1 As shown, a printing system 75 is connected to a print server 71 and host computers 72 and 73 via a network 74 .

[0034] The print server 71 monitors the status of print jobs executed by the printing system 75, it can temporarily stop a print job being executed and restart a stopped print job, and it can change, copy, move, and delete the settings of a print job. Host computers 72 and 73 may generate print jobs that are provided to printing system 75 .

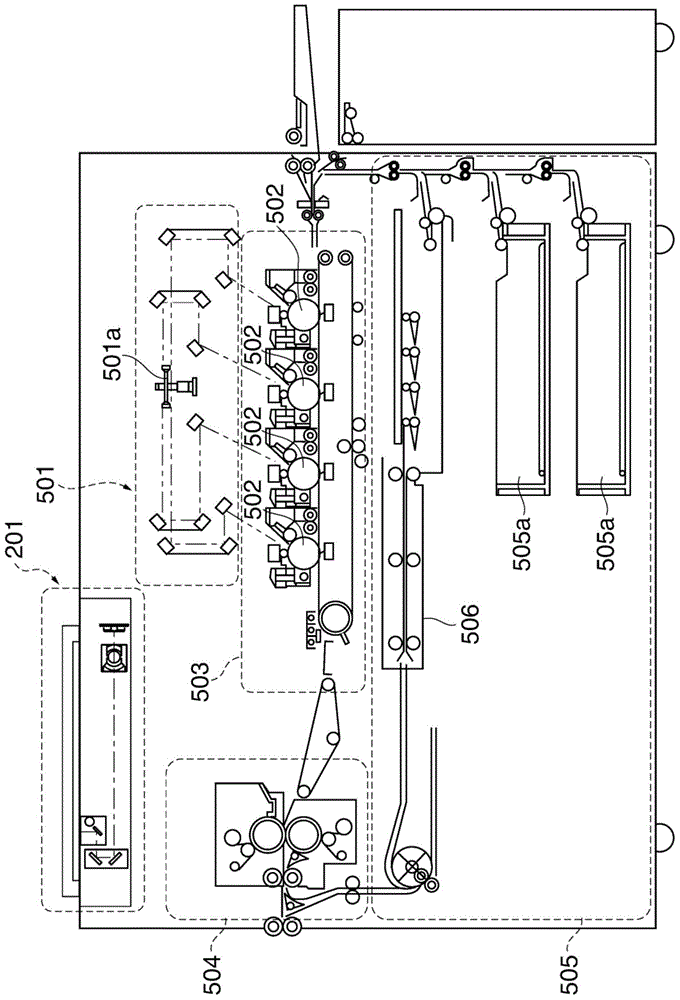

[0035] figure 2 is schematically shown figure 1 The illustrated printing system 75 is a cross-sectional view of the internal configuration of an image forming apparatus included.

[0036] The illustrated im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com