Device used for producing relay

A relay and equipment technology, applied in relays, circuits, electrical components, etc., can solve the problems that the production process order cannot be completed in time, affect the product delivery time, and product management difficulty, so as to save material turnover time, simple and reasonable structure, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

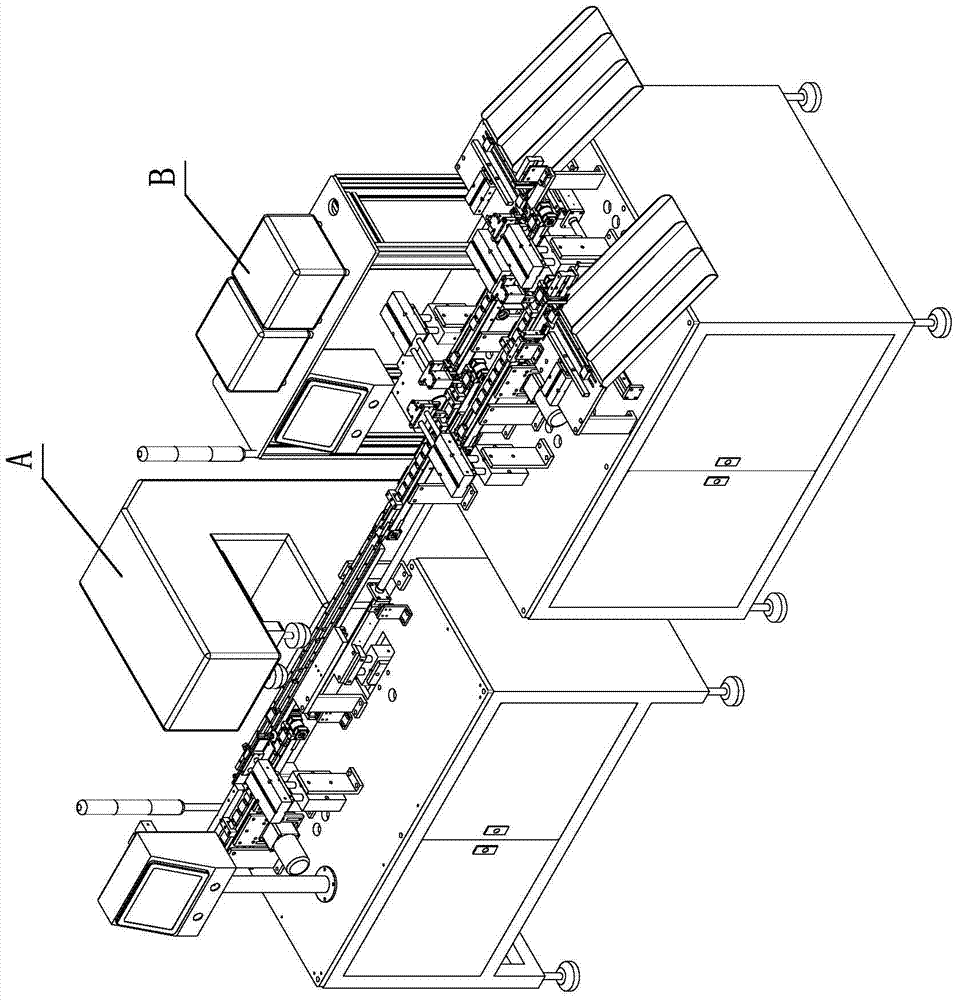

[0032] see figure 1 , the equipment used to produce relays, including the main body of the equipment, is characterized in that: the main body of the equipment is integrated with a screen printing system A for relay printing and a comprehensive testing system B for testing the performance of relays; wherein, the screen printing system A includes The silk screen feeding mechanism and the pad printing machine, the comprehensive testing system B includes the testing feeding mechanism and the computer comprehensive testing instrument; the silk printing feeding mechanism is connected end to end with the testing feeding mechanism.

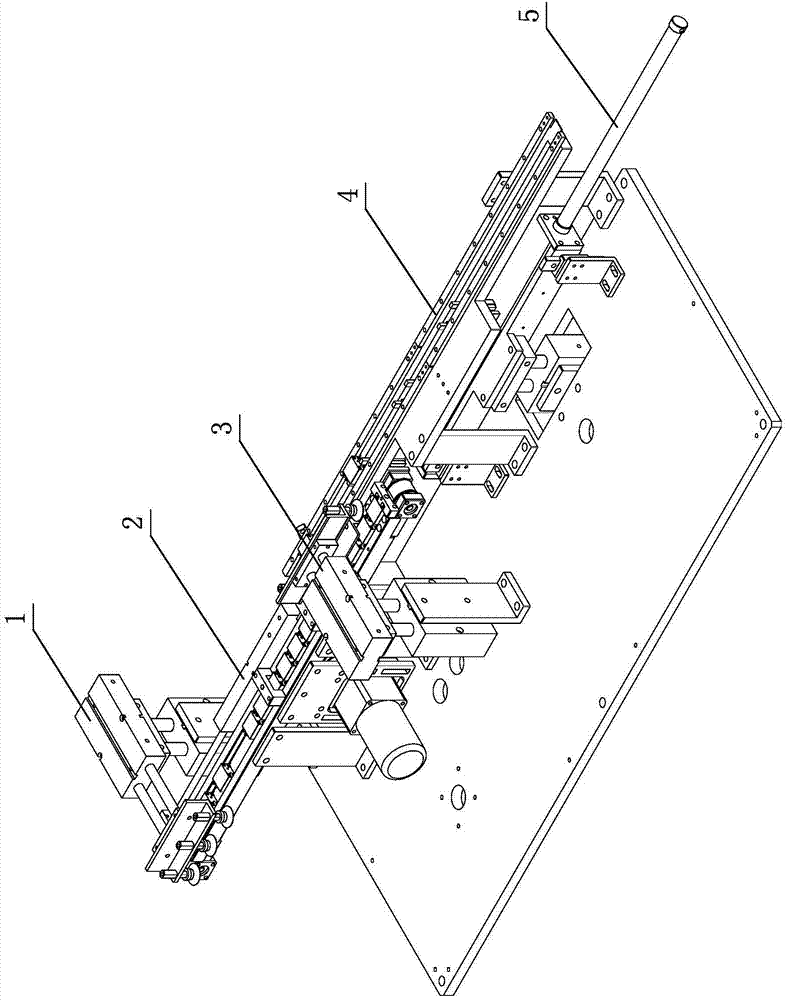

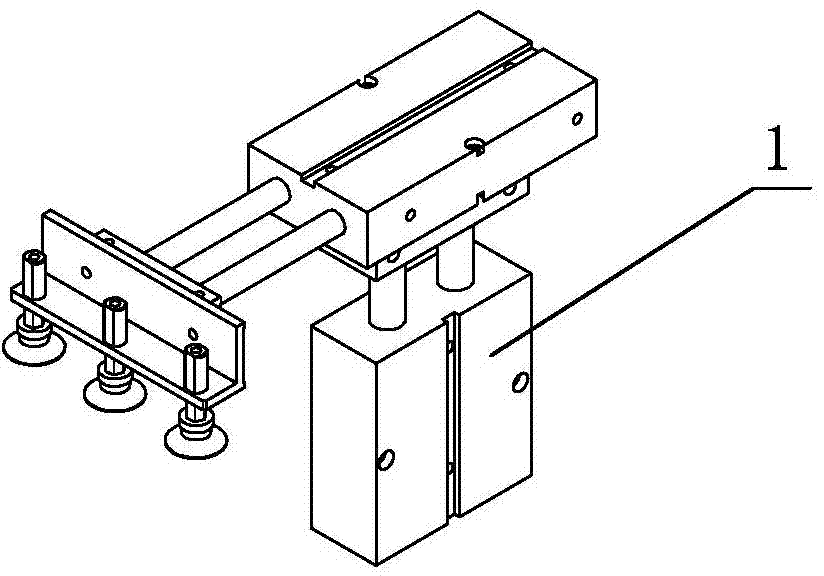

[0033] see Figure 2-Figure 7 The silk screen feeding mechanism includes the first suction cup feeding assembly 1, the silk printing feeding belt line 2, the second suction cup feeding assembly 3, the silk printing feeding conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com