Honeycomb core welding frame

A technology for welding frame and honeycomb core, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency of honeycomb core welding frame, improve adaptability and versatility, improve welding efficiency, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

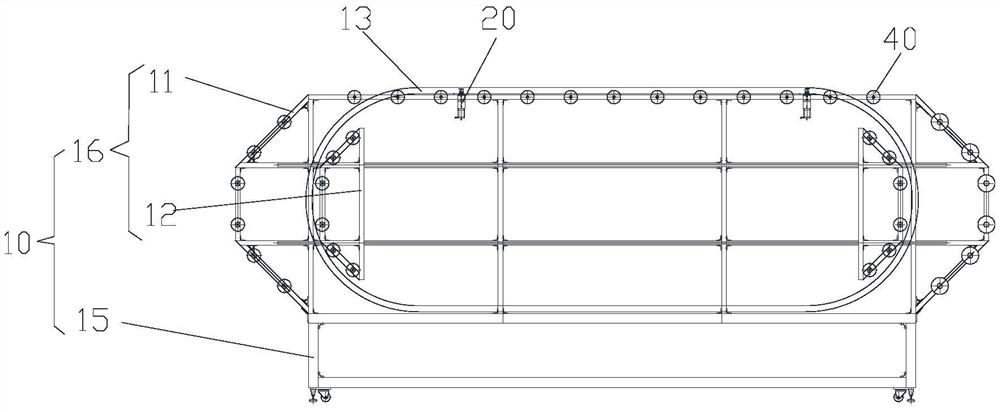

[0035] like figure 1 A honeycomb core welding frame shown includes a frame 10 and a clamping mechanism 20, the frame 10 has a fixed part 11 and a movable part 12, the fixed part 11 and the movable part 12 are movably connected, and the frame 10 has an annular ring supporting the honeycomb core The support area 13, and at least a part of the annular support area 13 is formed by the movable part 12, so that the size of the annular support area 13 changes with the movement of the movable part 12; the clamping mechanism 20 is movably connected with the frame 10 and the honeycomb core, and drives The honeycomb core moves along the annular support zone 13 .

[0036] In this embodiment, the honeycomb core is supported by the annular support area 13 of the frame 10, and the size of the annular support area 13 can be changed following the movement of the movable part 12, so that the annular support area 13 can be adapted to the size of the honeycomb core, improving It improves the ada...

Embodiment 2

[0054] The difference from the first embodiment is that the fixed part 11 is slidably connected to the movable part 12, and the movable part 12 slides along the vertical direction.

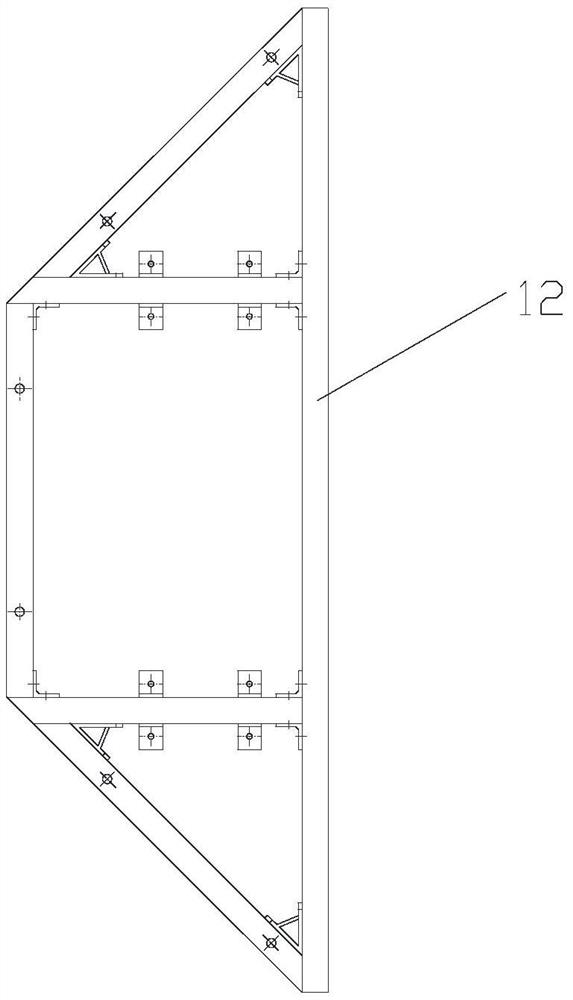

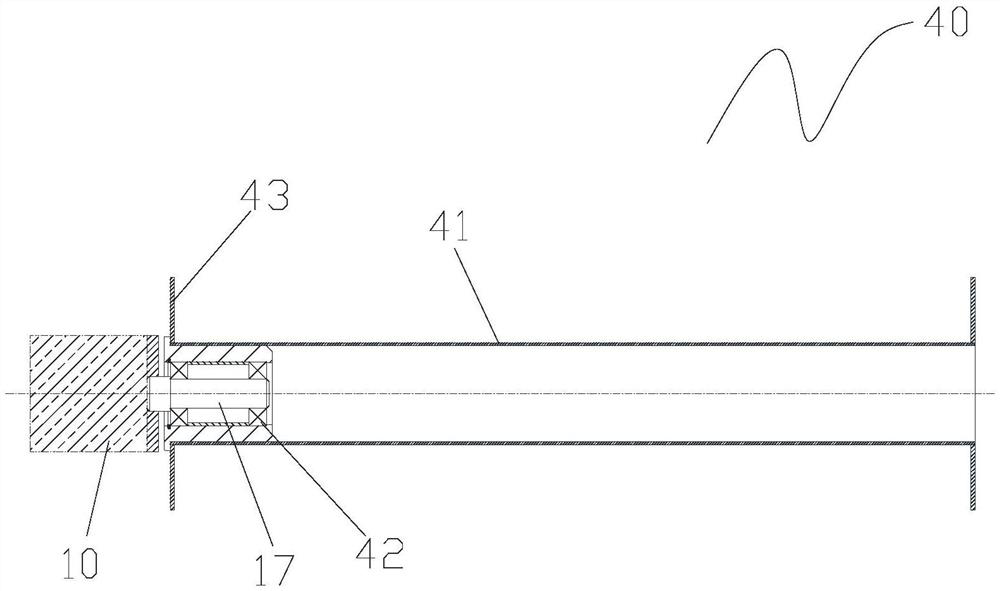

[0055] Such as Figure 4 As shown, the fixed part 11 is a column, and the movable part 12 forms an annular support area 13. Specifically, the movable part 12 has a plate-shaped piece arranged horizontally, and a plurality of extending arms 14 are arranged on the plate-shaped piece. The end of 14 and the plate-like member are provided with idler mechanisms 40, and at least some of the idler mechanisms 40 have different heights, the honeycomb core is supported on the idler mechanisms 40, and at least part of the extended arms 14 form an annular support area 13, The clamping mechanism 20 is connected with the plate to lock and unlock the honeycomb core and the plate, and can also drive the honeycomb core to move.

[0056] In this embodiment, the honeycomb core welding frame further includes a liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com