Steering wheel for automobile and method of fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

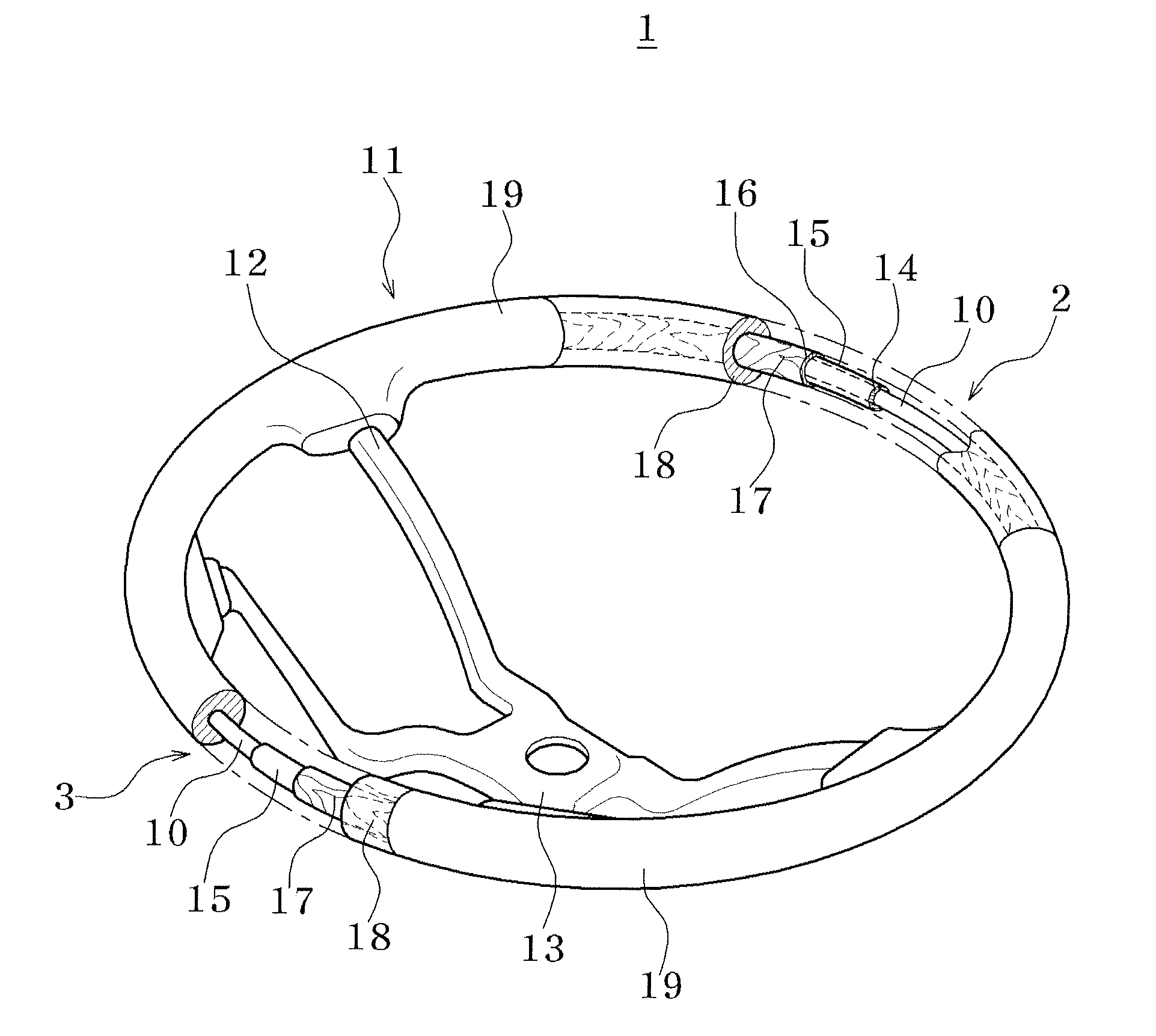

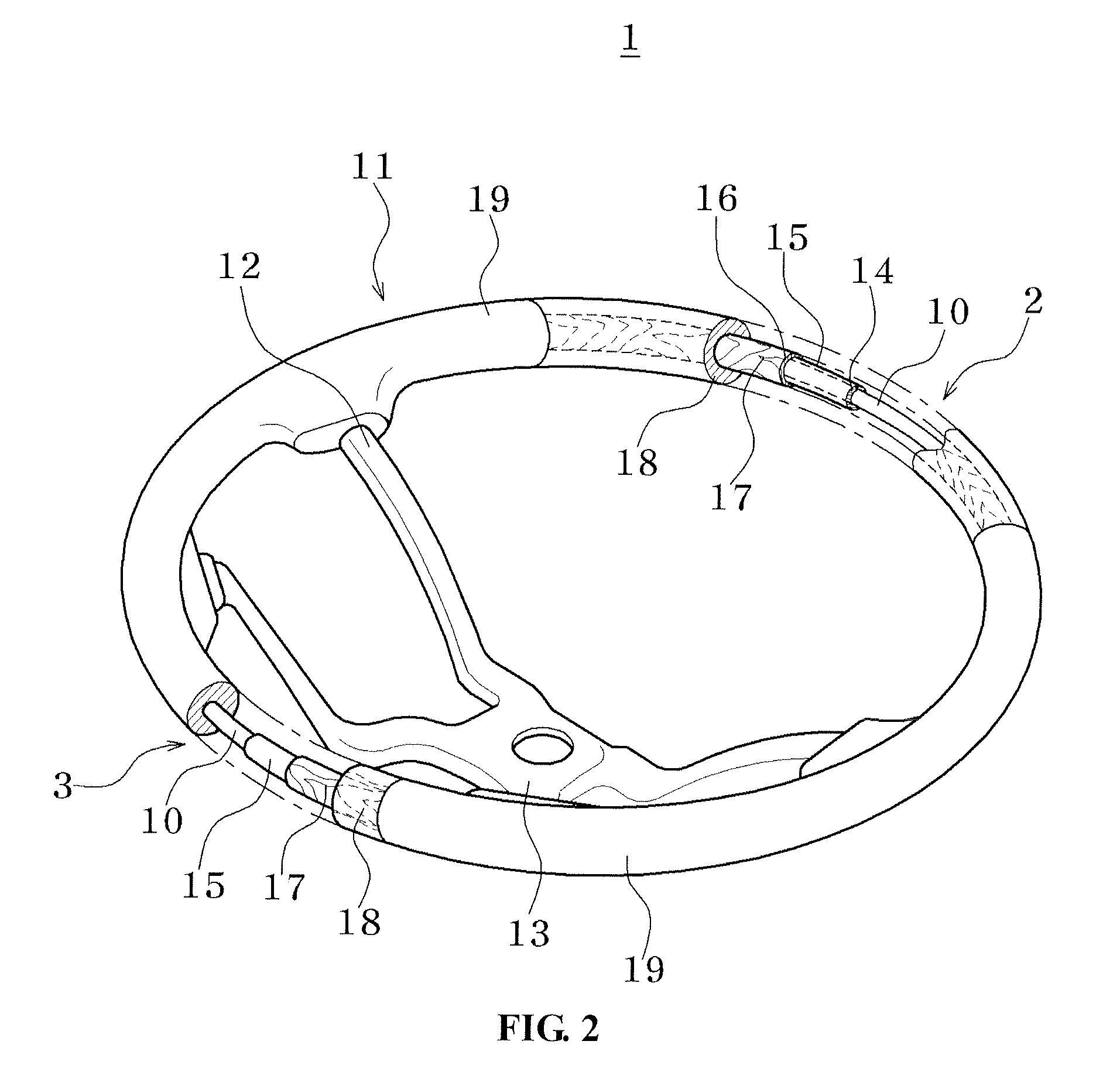

[0106]Example 1 relates to a method of fabricating a steering wheel by inserting a plurality of pattern parts through application of pad printing during multi-stage injection molding with the mold as shown in FIG. 3.

[0107]The method of Example 1 generally includes preheating, formation of a primary injection-molded part, insertion of a primary pattern part, formation of a secondary injection-molded part, insertion of a secondary pattern part, formation of a tertiary injection-molded part, formation of polyurethane foam, formation of a protective coating, and leather sewing.

[0108]The preheating is performed to preheat a hub core 13 integrally connected to a metal frame 10 in a dryer.

[0109]For this operation, the hub core 13 integrally connected to the metal frame 10 is prepared.

[0110]The hub core 13 and the metal frame 10 are subjected to various examinations to determine whether they are suitable in terms of quality and other conditions for fabrication of a steering wheel.

[0111]Afte...

example 2

[0149]Example 2 relates to a method of fabricating a steering wheel 1 by inserting a vacuum deposition part 15 and a pattern part 17 through a combination of vacuum deposition and pad printing during multi-stage injection molding with the mold as shown in FIG. 4.

[0150]The method of Example 2 includes preheating, formation of a primary injection-molded part, insertion of a vacuum deposition part, formation of a secondary injection-molded part, insertion of a pattern part, formation of a tertiary injection-molded part, formation of polyurethane foam, formation of a protective coating, and leather sewing.

[0151]The preheating is performed to preheat a hub core 13 integrally connected to a metal frame 10 in a dryer, and is the same as in Example 1. Thus, a detailed description thereof will be omitted herein.

[0152]Here, an opaque resin for the primary injection-molded part 14 may be polycarbonate (PC). However, in Example 2, polyethylene terephthalate (PET) is used as the opaque resin for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com