Rubber pad-printing production line

A technology of pad printing production line and rubber, which is applied in the direction of metal processing, etc., can solve the problems of increasing the workload of staff and low production efficiency of rubber, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

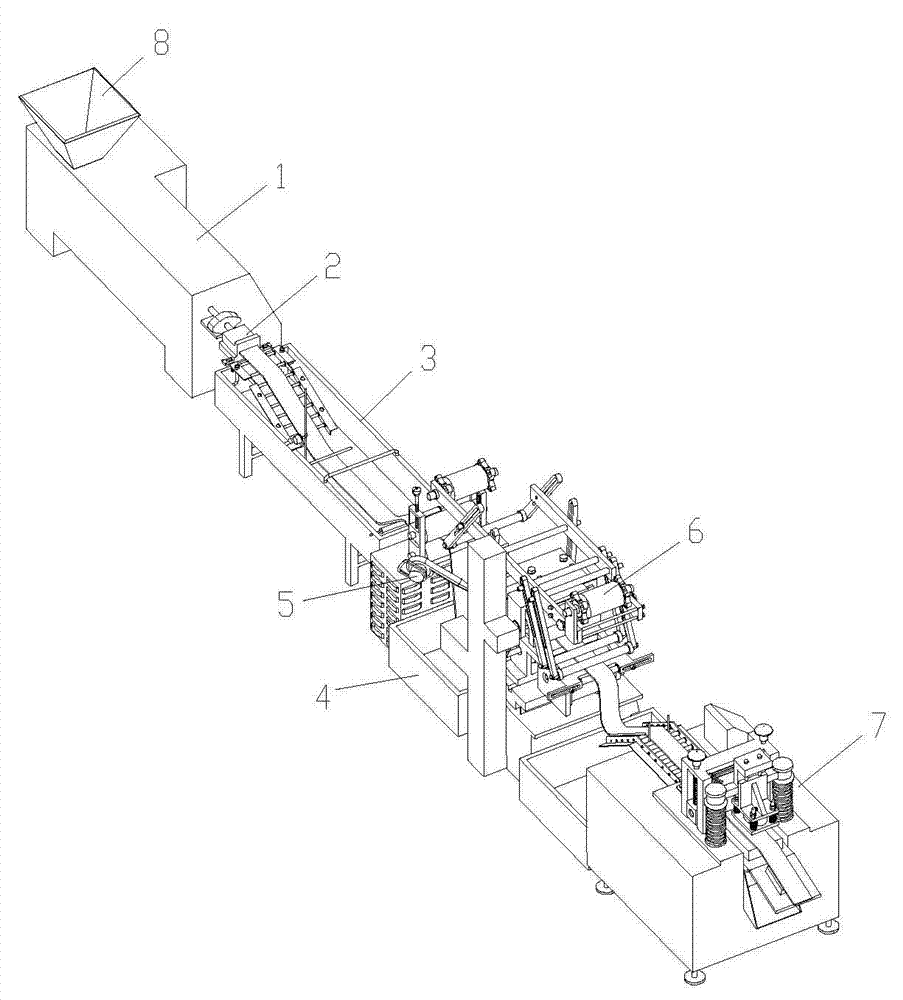

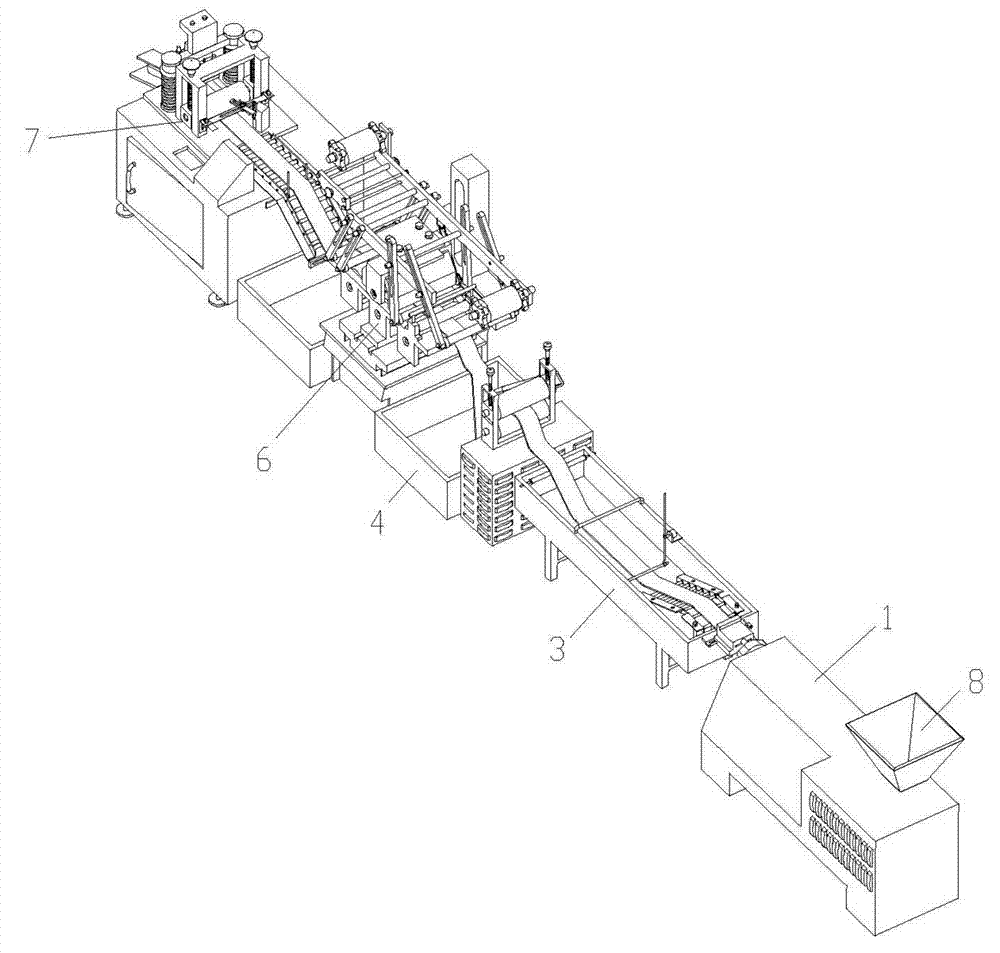

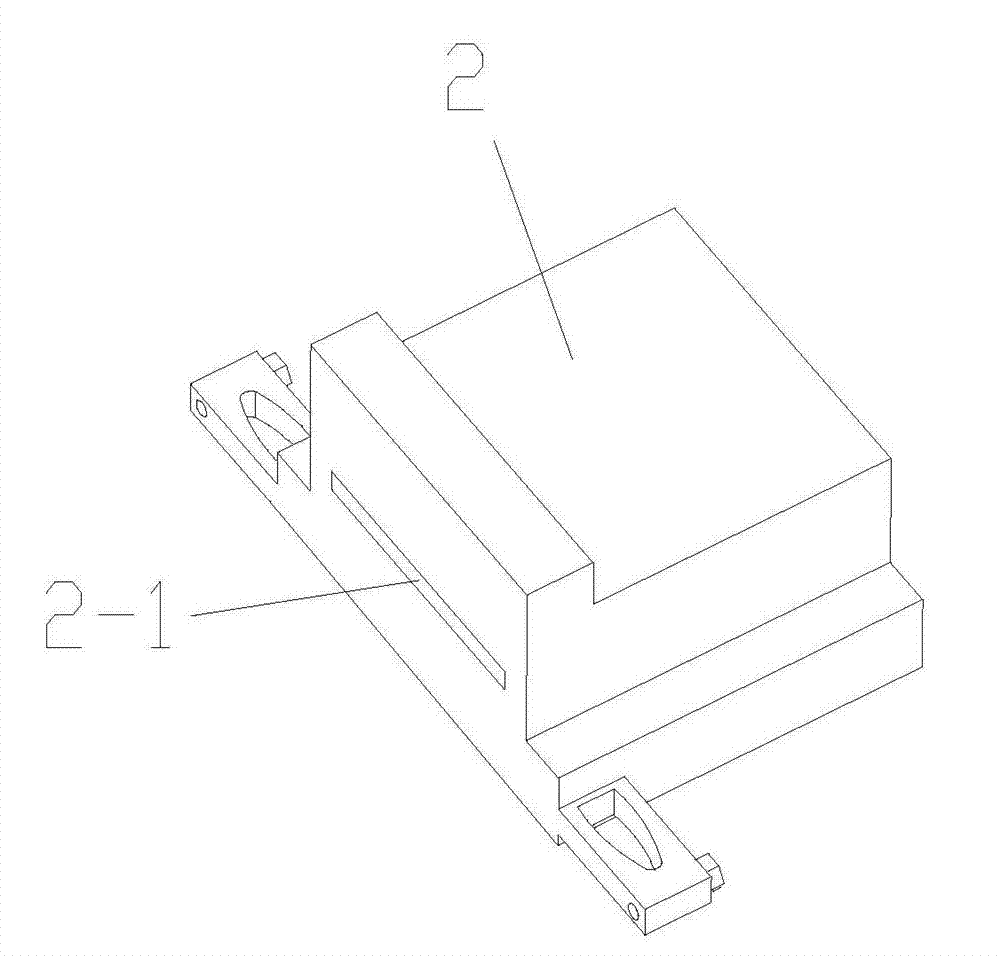

[0026] Referring to the accompanying drawings: this rubber pad printing production line includes a rubber extruder 1, the feed port of the rubber extruder 1 is equipped with a hopper 8, and the rubber extruder 1 is connected to the forming mold 2, the cooling tank 3, and the washing tank 4 in sequence , blower 5, hot-pressing pad printing mechanism 6 and cutting mechanism 7, the raw material for making rubber is poured in the hopper 8 and enters in the rubber extruder 1, and the rubber extruder passes the raw material by preheating, heating, stirring and extruding It is extruded into rubber and extruded from the molding die 2 to form a flat structure. The rubber that has just been extruded has heat, and direct printing will deform the rubber. Therefore, it is first cooled by cooling tank 3 to harden it, and then passed through clear water Wash and then dry, so that after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com