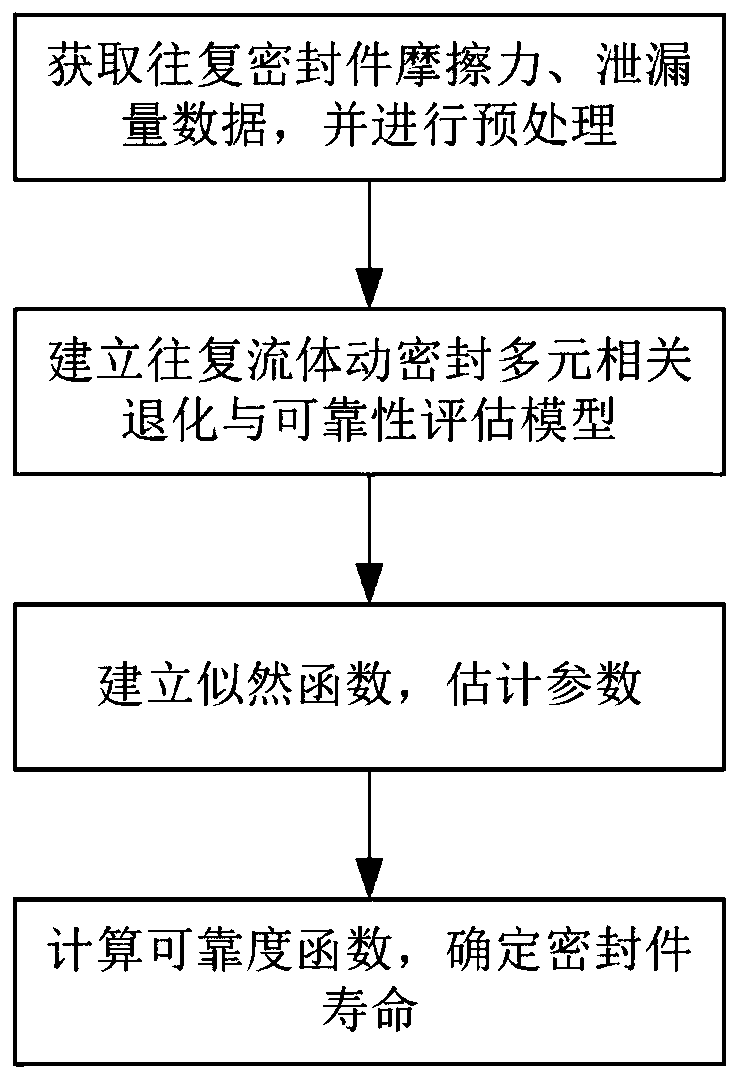

A reciprocating fluid dynamic seal life prediction method based on multivariate correlation degradation modeling

A life prediction and dynamic sealing technology, applied in prediction, special data processing applications, instruments, etc., can solve the problems of reliability evaluation and life prediction of reciprocating seals, etc., and achieve the effect of strong flexibility and simple calculation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

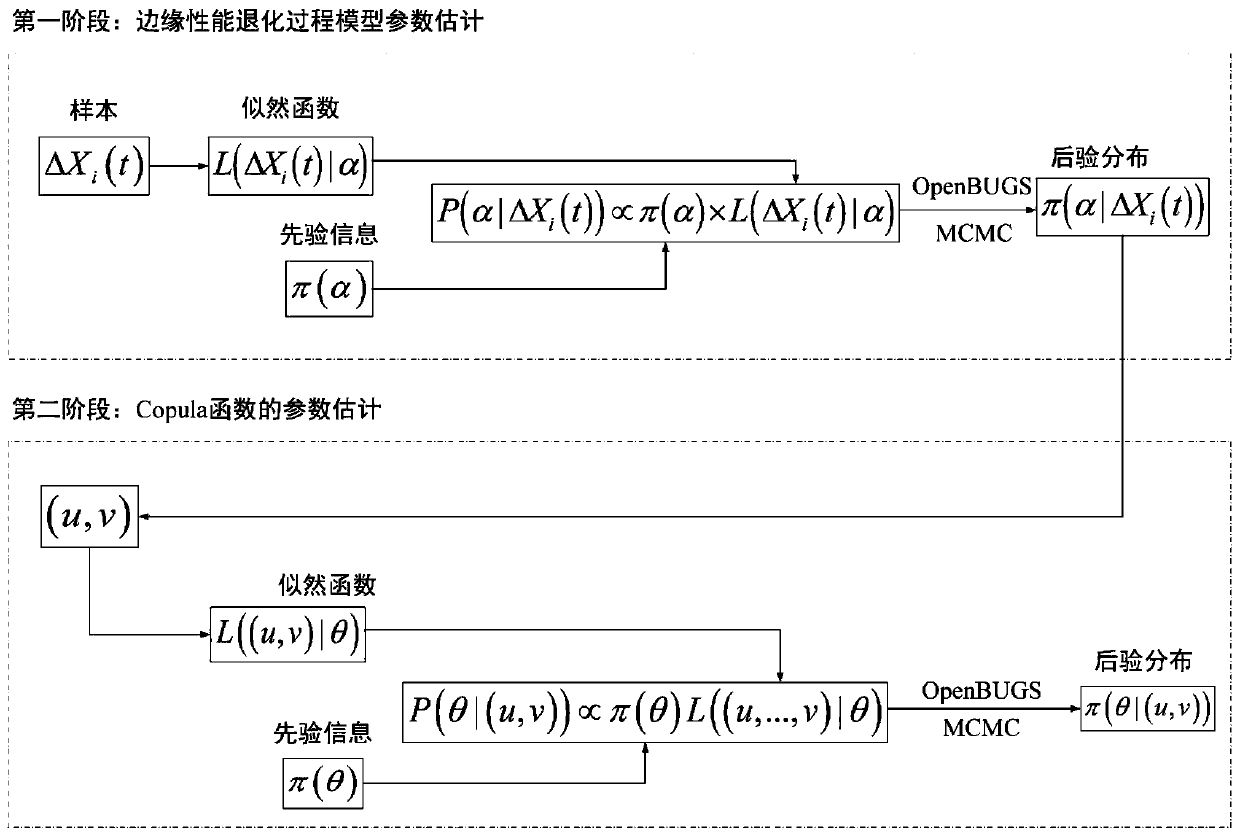

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the drawings and embodiments.

[0038] The multivariate correlation degradation modeling and life prediction method of the reciprocating fluid dynamic seal provided by the present invention is based on the research and statistics of the test data of the piston rod reciprocating seal of the hydraulic actuator, and the following conditions can be set first:

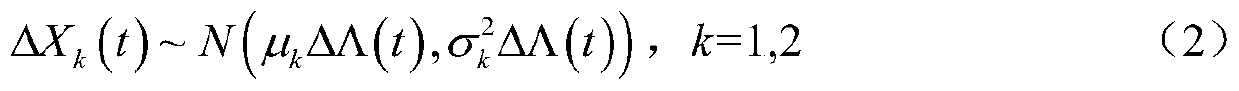

[0039] (1) For the hydraulic actuator piston rod reciprocating seal, the friction and leakage of the two performance degradations obey the Wiener process. Let {X k (t), t≥0} represents the degradation of the kth (k=1, 2) performance degradation of the reciprocating seal at time t, then:

[0040] X k (t)=μ k Λ(t)+σ k W(Λ(t)) (1)

[0041] Among them, μ k Indicates the drift parameter, σ k Represents the diffusion parameter, Λ(t) represents the time scale parameter, generally, Where q k It is a positive real number, W(t) represents the standard B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com