Method for predicting service life of rubber shock absorber

A technology of rubber shock absorber and prediction method, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., and can solve problems such as life prediction of rubber shock absorbers

Inactive Publication Date: 2015-06-10

QINGDAO UNIV OF SCI & TECH

View PDF0 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] According to relevant information at home and abroad, there is no accurate prediction of the service life of the rubber shock absorber at present, because the rubber shock absorber will be affected by fatigue and aging factors at the same time during use.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0029] A method for predicting the service life of a rubber shock absorber, specifically comprising the following steps:

[0030] (A) Establishment of the aging life prediction model of the rubber shock absorber.

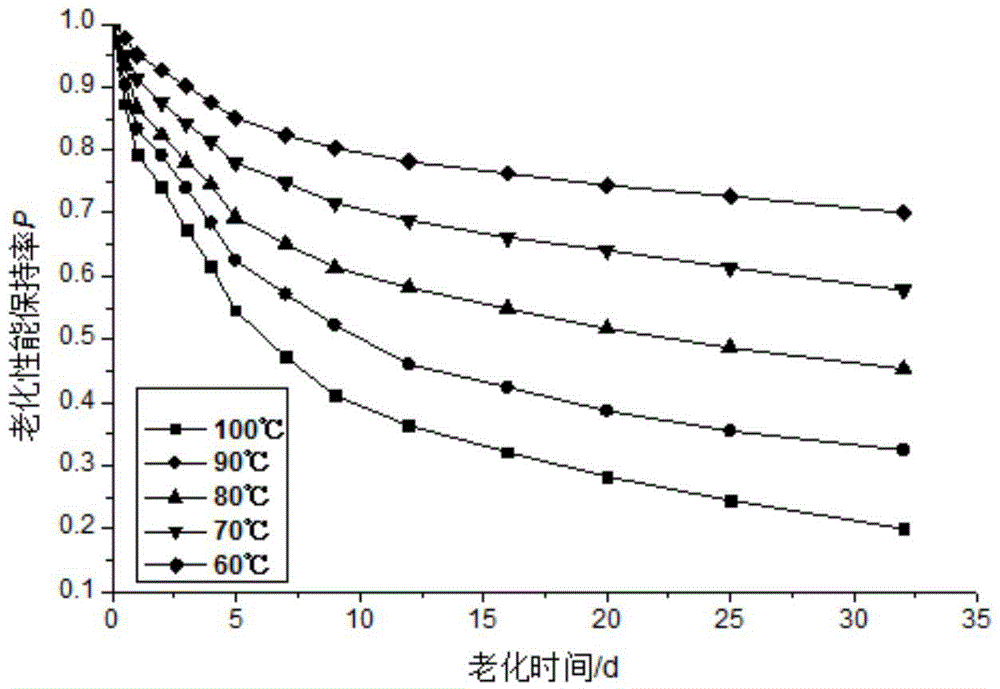

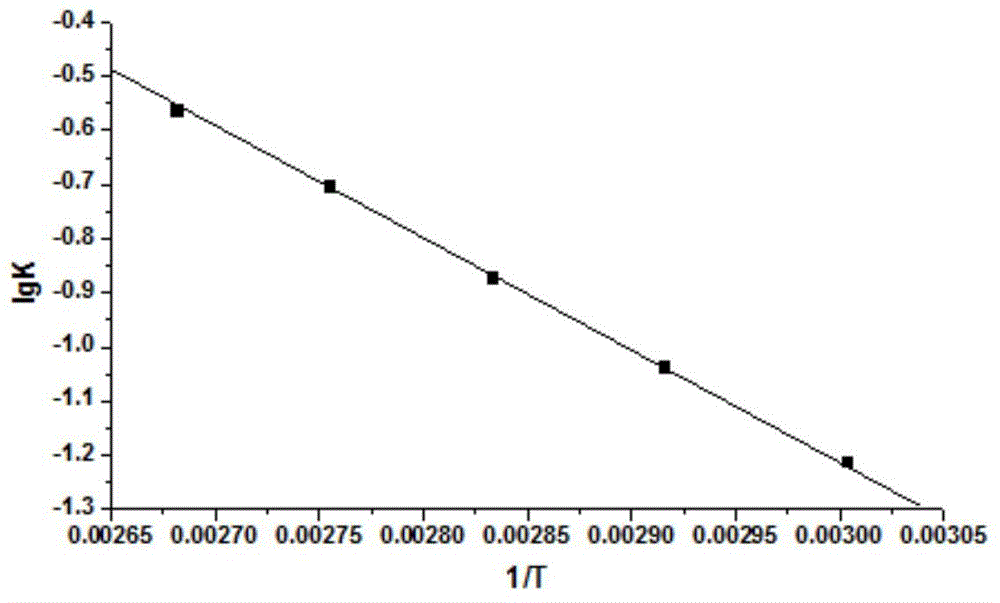

[0031] Using the hot air accelerated aging test, the aging life prediction model of the rubber shock absorber was established.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

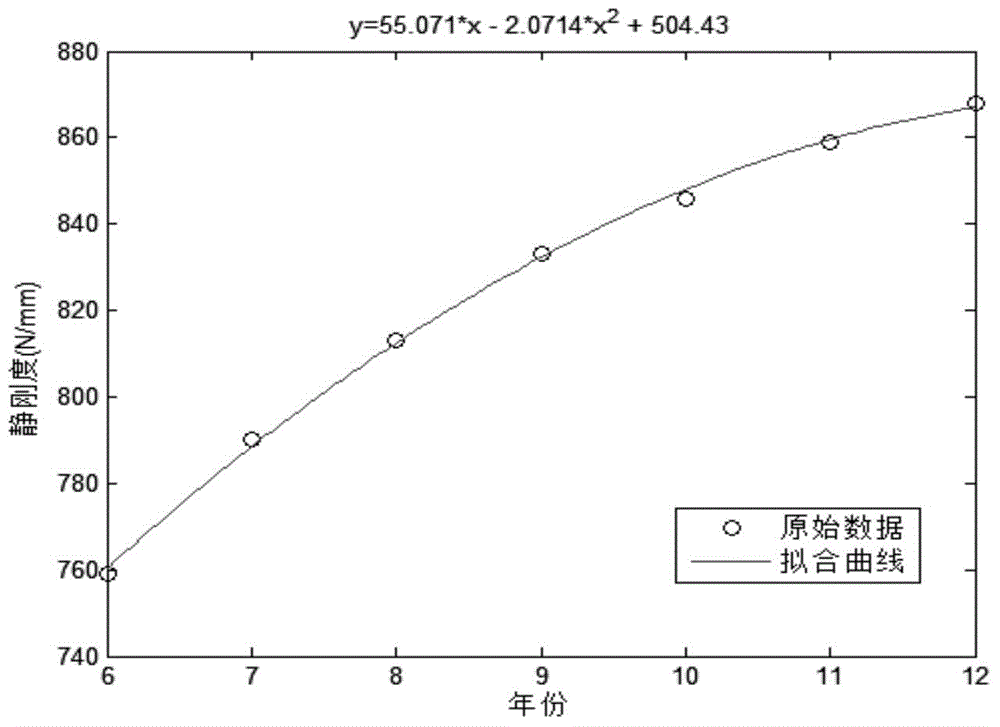

The invention discloses a method for predicting a service life of a rubber shock absorber; the method comprises the steps: combining aging factors, influencing the use of the rubber shock absorber, and fatigue factors; firstly, establishing an aging service life prediction mathematic model of the rubber shock absorber in use of a hot air accelerated aging test; secondly, establishing a model relationship between static rigidity of a new absorber and fatigue times by means of the aging service life prediction model and the existing performance parameter of an old absorber; further, establishing a relation model between the static rigidity and the time and obtaining a service life prediction model of the rubber shock absorber, thereby realizing prediction of the service life of the rubber shock absorber. The aging factors and the fatigue factors are combined well to predict the service life of the rubber shock absorber, and the prediction precision is high.

Description

technical field [0001] The invention relates to the technical field of life prediction of rubber shock absorbers, in particular to a prediction model of service life of rubber shock absorbers used for vibration reduction and noise reduction. Background technique [0002] Rubber shock absorbers have adjustable elastic parameters, can attenuate and absorb low-frequency, high-frequency vibration and noise, impact stiffness is greater than dynamic stiffness and static stiffness, and have the advantages of small size, light weight, and maintenance-free, so they are widely used in various fields. use. However, due to the fatigue damage of stress and strain and the aging of rubber materials in the actual use of rubber shock absorbers, there is a problem of service life. Once fatigue damage and aging of the rubber material occurs, the stiffness and damping parameters of the rubber shock absorber will gradually deviate from the design value, and its vibration isolation and impact re...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N17/00G01N3/00

Inventor 曾宪奎韩广文孙延奎焦淑莉褚福海

Owner QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com