Method and system for predicting service life of medium-low-temperature SCR denitration catalyst

A technology for denitration catalyst and life prediction, which is applied in the field of denitration management of air pollutants, and can solve the problems of inability to effectively analyze the service life of the catalyst online, loss of catalytic activity, and inability to effectively evaluate the deactivation of catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

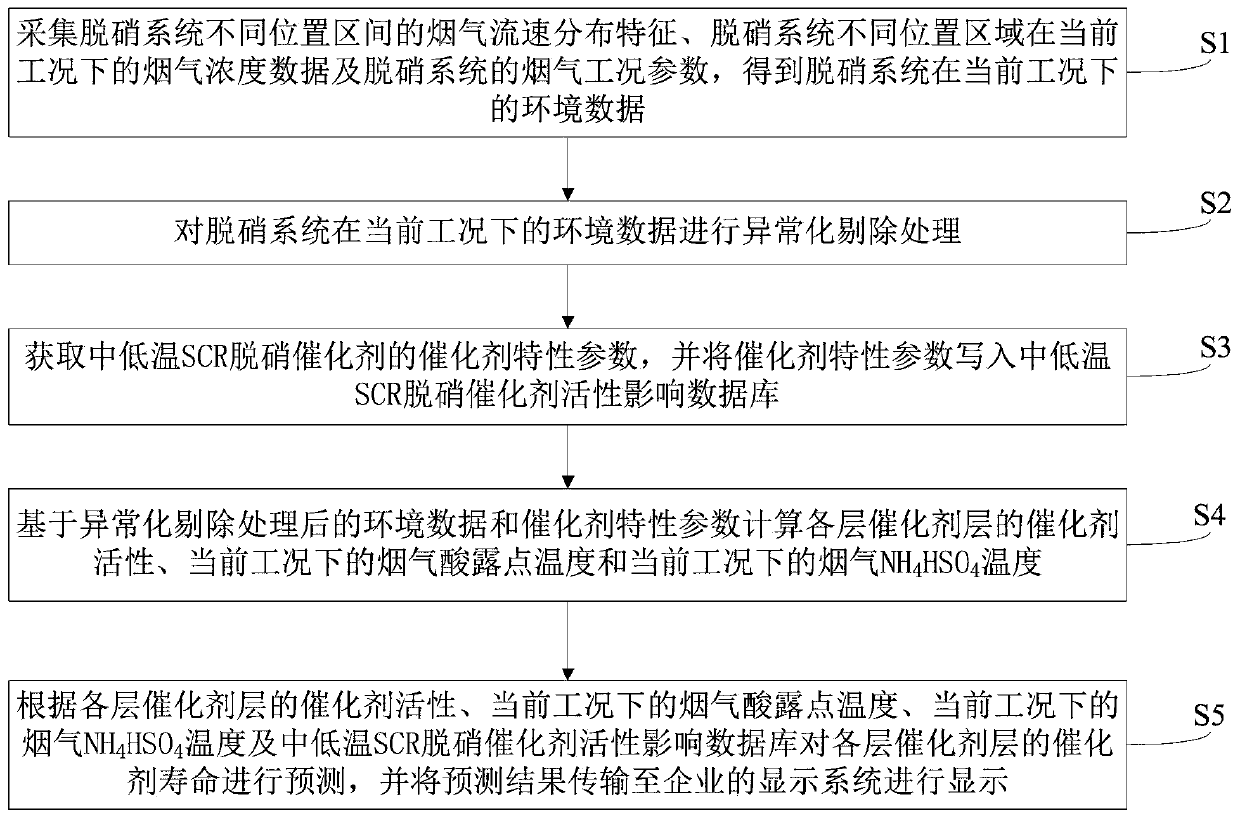

[0048] Such as figure 1 As shown, the life prediction method of the medium and low temperature SCR denitration catalyst in the present embodiment includes the following steps:

[0049] S1, collect the flue gas velocity distribution characteristics in different locations of the denitrification system, the flue gas concentration data in different locations of the denitrification system under the current working conditions, and the flue gas working parameters of the denitrification system to obtain the environment of the denitrification system under the current working conditions data.

[0050] Among them, the flue gas concentration data of different locations of the denitrification system under the current working conditions include NO x Concentration, SO 2 Raw data such as concentration, ammonia injection volume, differential pressure, ammonia slip,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com