Display panel and preparing method thereof

A technology for display panels and display areas, which is used in semiconductor/solid-state device manufacturing, organic light-emitting device manufacturing/processing, and semiconductor/solid-state device testing/measurement, etc. Monitoring and other issues to achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

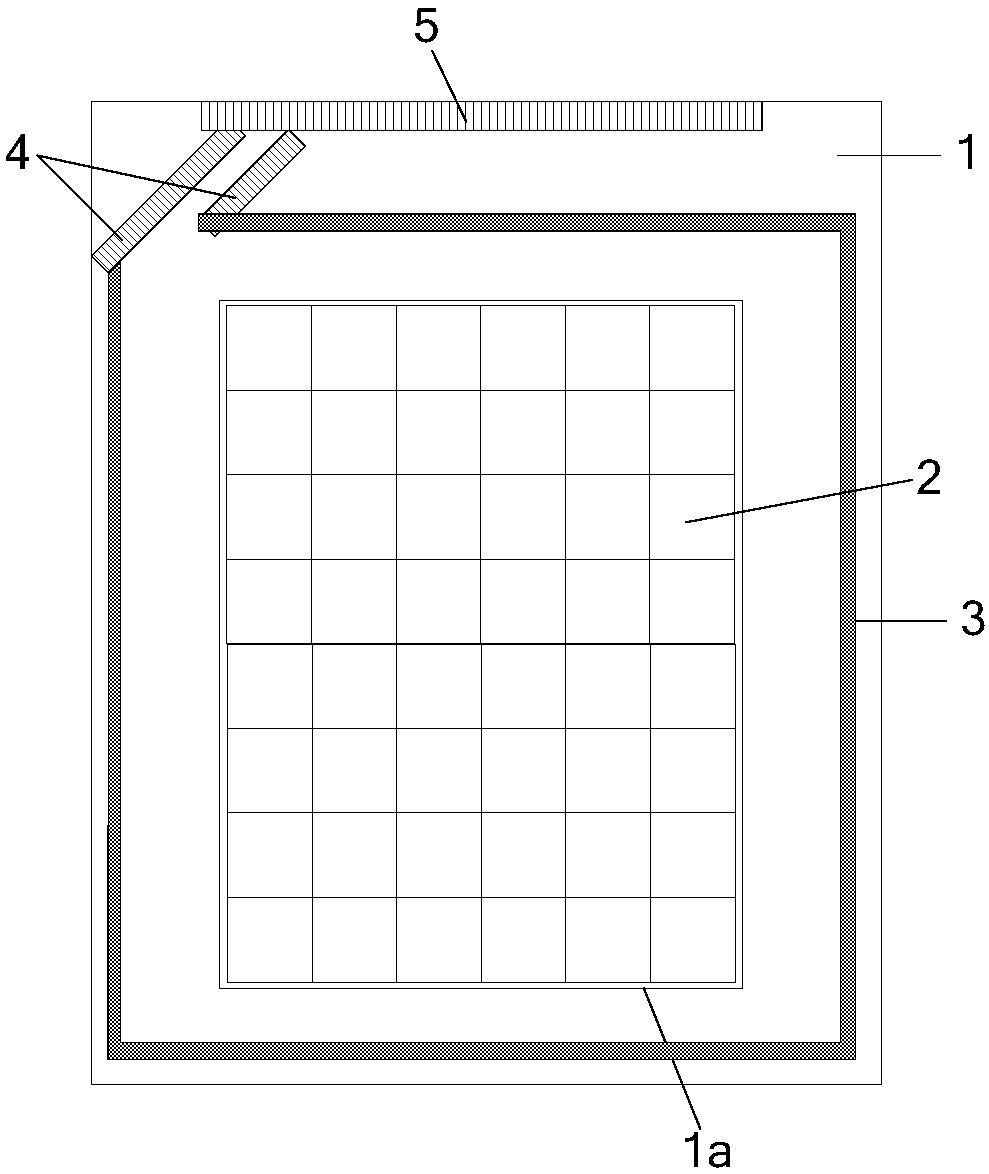

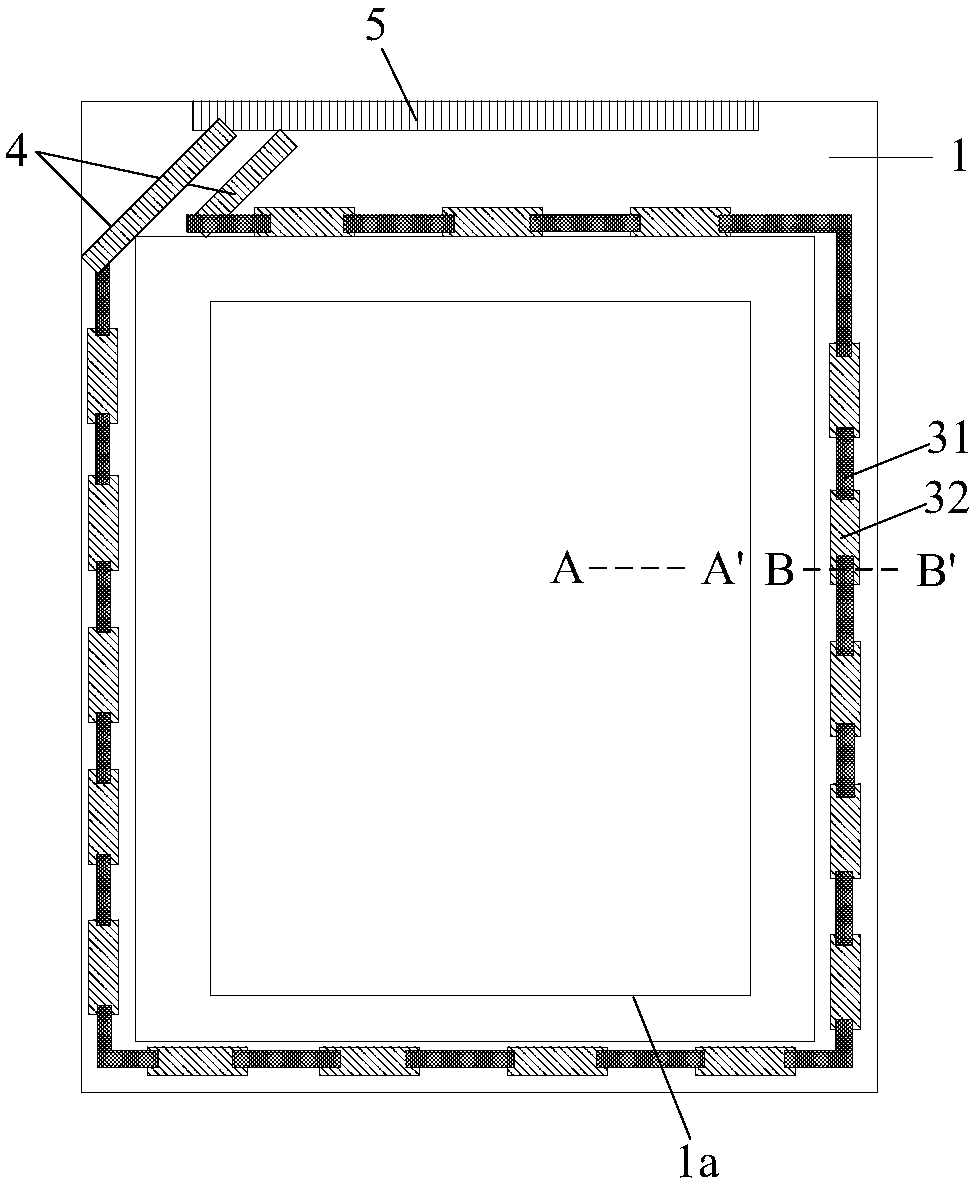

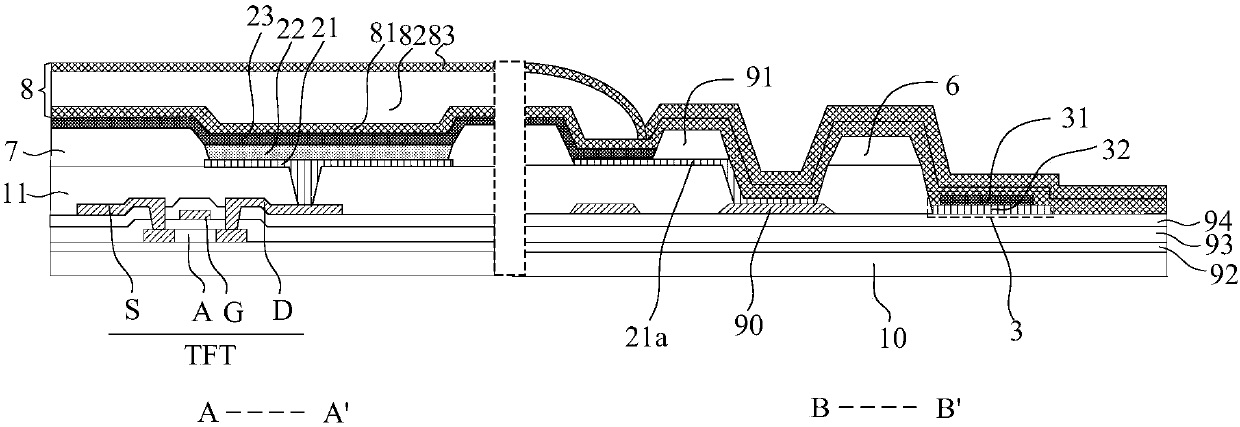

[0034] Such as figure 1 As shown, Embodiment 1 of the present invention provides a display panel, including a substrate 1, and the substrate 1 is divided into a display area 1a; the above-mentioned display panel further includes: a plurality of OLED units 2 arranged in the display area 1a; and setting On the above-mentioned substrate 1 and the monitoring electrode 3 located outside the display area 1a, the resistance value of the monitoring electrode 3 changes after reacting with water and / or oxygen; at least the film encapsulation layer covering the display area 1a and on the monitoring electrode 3 (not shown in the figure).

[0035] It should be noted that, firstly, the aforementioned substrate is specifically an array substrate (Array, or called a backplane) on which an array layer of thin film transistors is formed.

[0036] Second, the pattern of the above-mentioned monitoring electrode 3 is not limited to figure 1 A ring with an opening shown in , as long as it is plac...

Embodiment 2

[0083] An embodiment of the present invention also provides a method for preparing the above-mentioned display panel. The preparation method includes: the steps of forming a plurality of OLED units in the display area of the substrate and forming monitoring electrodes outside the display area; Or the resistance value changes after the oxygen reacts; the step of forming a thin film encapsulation layer covering at least the display area and the monitoring electrodes.

[0084] Further, in order to improve the monitoring efficiency, the formed monitoring electrode is specifically a monitoring ring surrounding the display area; the monitoring ring is provided with openings; the above preparation method also includes: the step of forming test leads respectively connected to the two ends of the opening on the substrate .

[0085] Further, the step of forming the monitoring ring includes: forming a plurality of spaced connection electrodes around the display area of the substrate;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com