Performance degradation evaluation method based on FCM-HMM rolling bearing

A rolling bearing and performance technology, which is applied in the field of mechanical product quality reliability assessment and fault diagnosis, can solve the problems of poor consistency between the degradation curve and fault, consume a lot of time, and cannot accurately determine the failure state of the bearing, so as to prevent major emergencies Fault detection, data dimensionality reduction, and condition-based maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

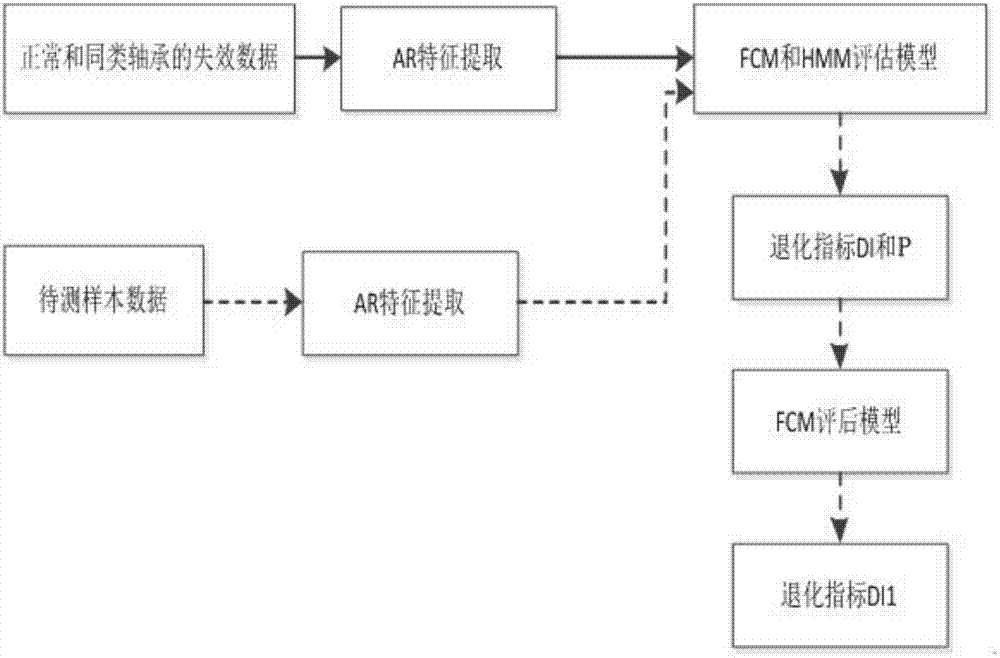

[0050] like figure 1 It is an evaluation flow chart of the present invention, based on the FCM-HMM rolling bearing performance degradation evaluation method, the specific steps are:

[0051] (1) Feature extraction: For the first 100 groups of non-fault data samples and the last 10 groups of failure data samples of similar bearings, the AR model is used to extract the autoregressive coefficients and residuals, and the order of the AR model is determined to be 14 by the AIC criterion. These 15 parameters including model residuals are used as input feature vectors.

[0052] (2) Model establishment: set the fuzzy weighted index q=2 in the FCM model, and the iteration threshold ε 1 =10 -4 , the number of clusters c=2, and set the iteration counter l=1, use the 110 groups of samples to form vector features with a size of 110×15 to build the FCM model and obtain the normal and invalid cluster centers c 1 ,c 2 ; The state number N of the Markov chain in the hidden Markov model is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com