Method for calculating roll shaft performance index of flexible material processing device

A technology for processing equipment and flexible materials, applied in computing, computer components, instruments, etc., can solve problems such as data analysis, easy loss of data information, dimension disaster, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

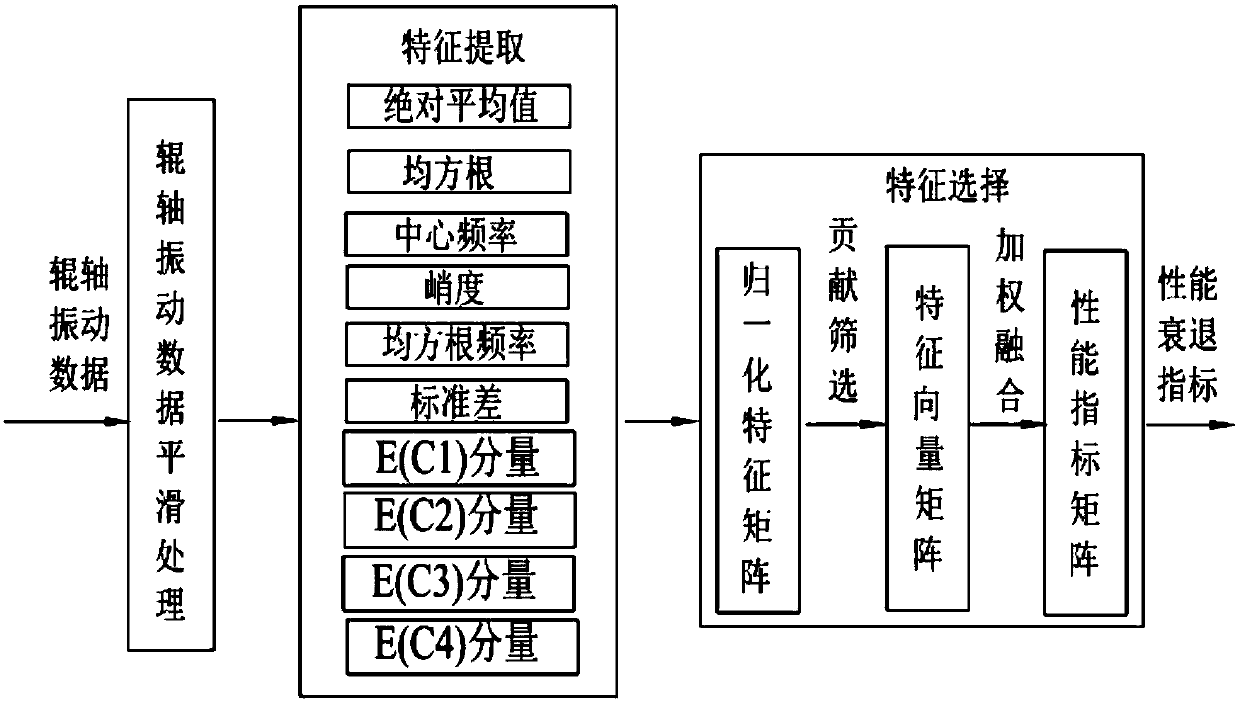

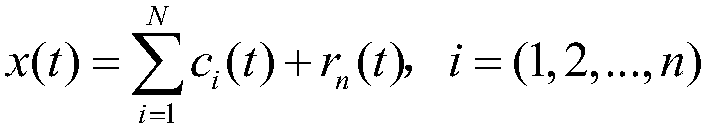

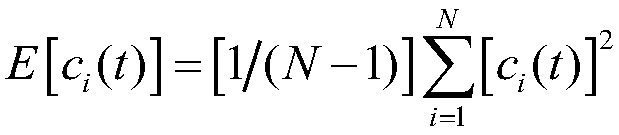

[0070] First, the vibration data of the roller shaft is collected by the three-axis acceleration sensor, and the vibration data is subjected to sliding average noise reduction to perform data feature extraction, including: time-domain characteristic parameters, frequency-domain characteristic parameters, and time-frequency domain characteristic parameters of the vibration data. Specifically, Absolute mean, root mean square, kurtosis, center frequency, root mean square frequency, standard deviation and energy values of 4 intrinsic mode function components (E(C1), E(C2), E(C3), E( C4)).

[0071] Finally, the extracted feature data is input to the principal component analysis (PCA) weighted fusion module, and the formula used for the calculation of the roll shaft performance degradation index is obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com