Acidic magnesia pellet and preparation method thereof

A magnesia pellet and acidic technology, which is applied in the production of acidic magnesia pellets with magnetite concentrate powder and magnesia powder and its preparation, can solve the problems of difficult mixing, many preparation procedures, and complicated processes, and achieve production The process is simple, the performance of high-temperature metallurgy is improved, and the effect of sufficient sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

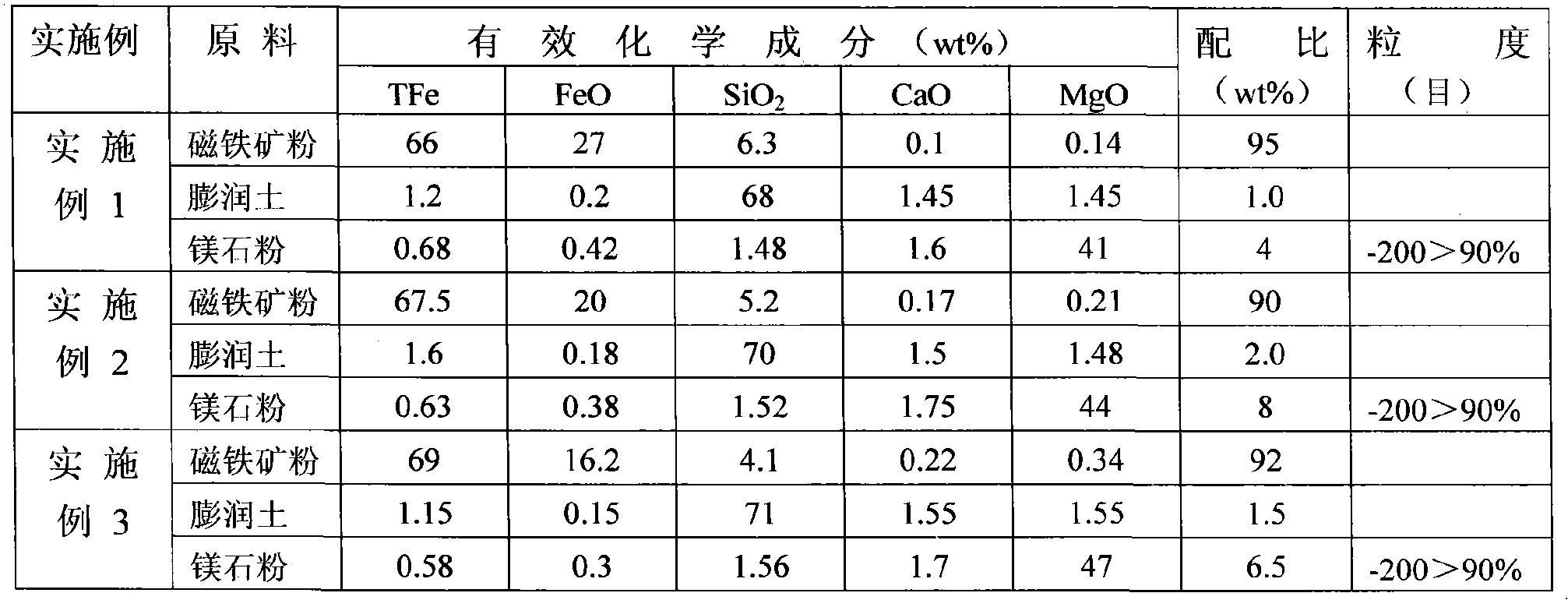

[0014] Table 1 embodiment raw material composition, effective chemical composition and proportioning list

[0015]

[0016] After preparing the raw materials listed in Examples 1, 2, and 3 in the above table, add magnesium stone powder and bentonite in the proportioning room according to their respective proportions, and perform dry mixing. Strict control of MgO / SiO in pellet raw materials 2 The ratio is between 0.4 and 0.55. The firing temperature during sintering should not be too low, and generally should be kept between 1250°C and 1300°C. For the rest, the acidic magnesium oxide pellets of the present invention can be produced by conventional techniques.

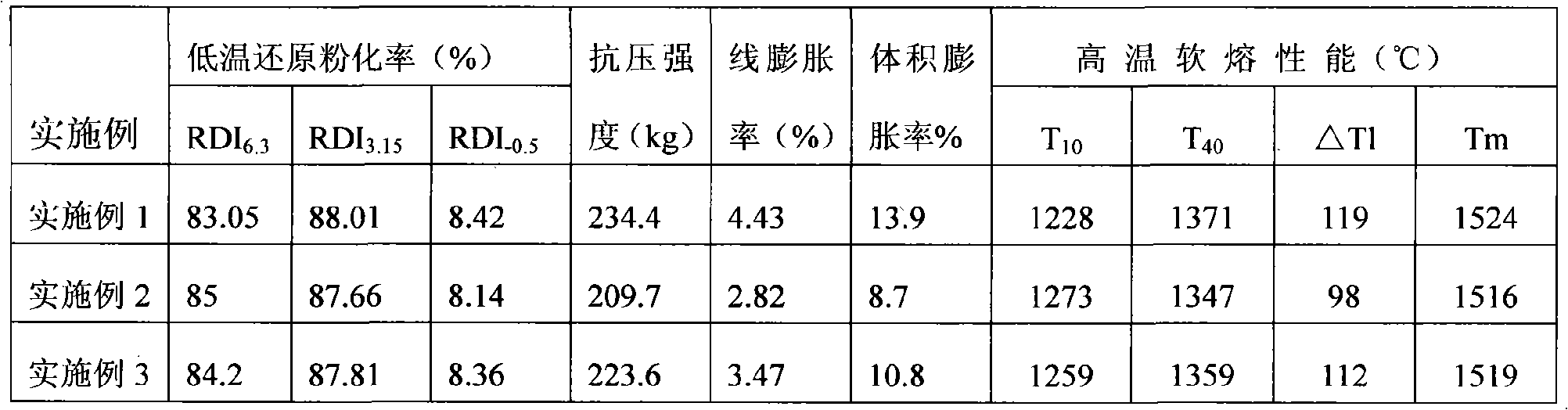

[0017] The acidic magnesium oxide pellets produced according to the above-mentioned raw material components, chemical composition, proportion and method fully meet the needs of blast furnace smelting and realize the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com