High-altitude long-span overhung cornice formwork supporting system and constructing method thereof

A technology of large-span cantilever and formwork support, applied in formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve the problems of complex construction, low construction safety, and high engineering cost. , to achieve the effect of convenient three-dimensional cross operation, easy to master the construction process, and small construction site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

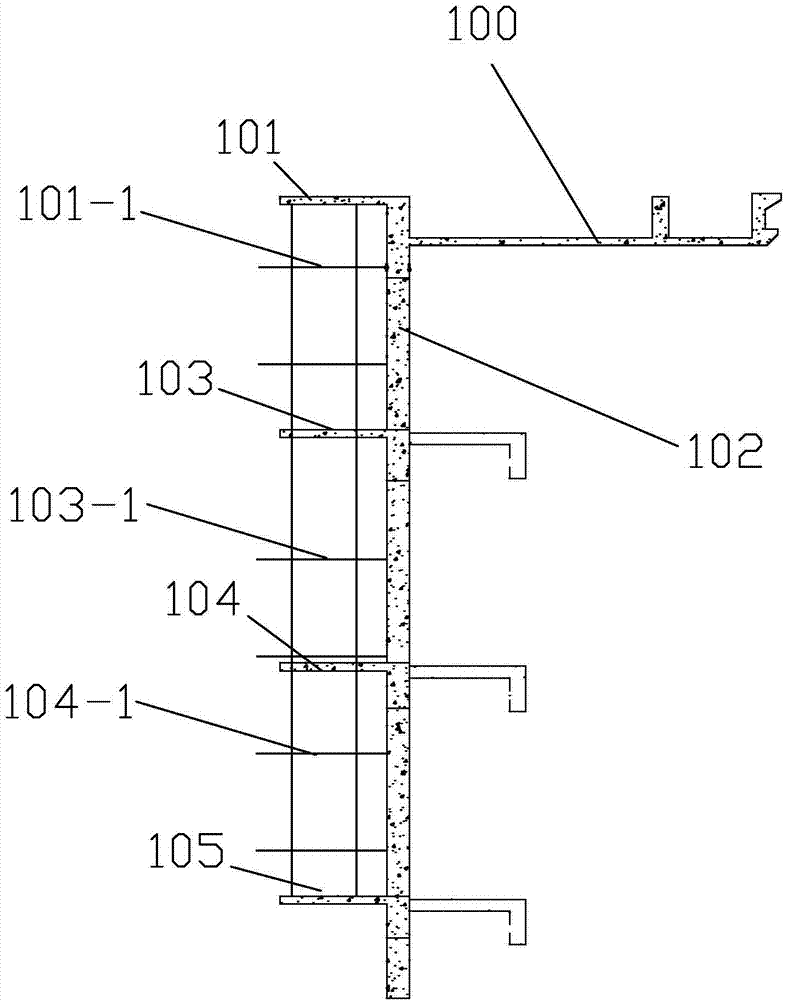

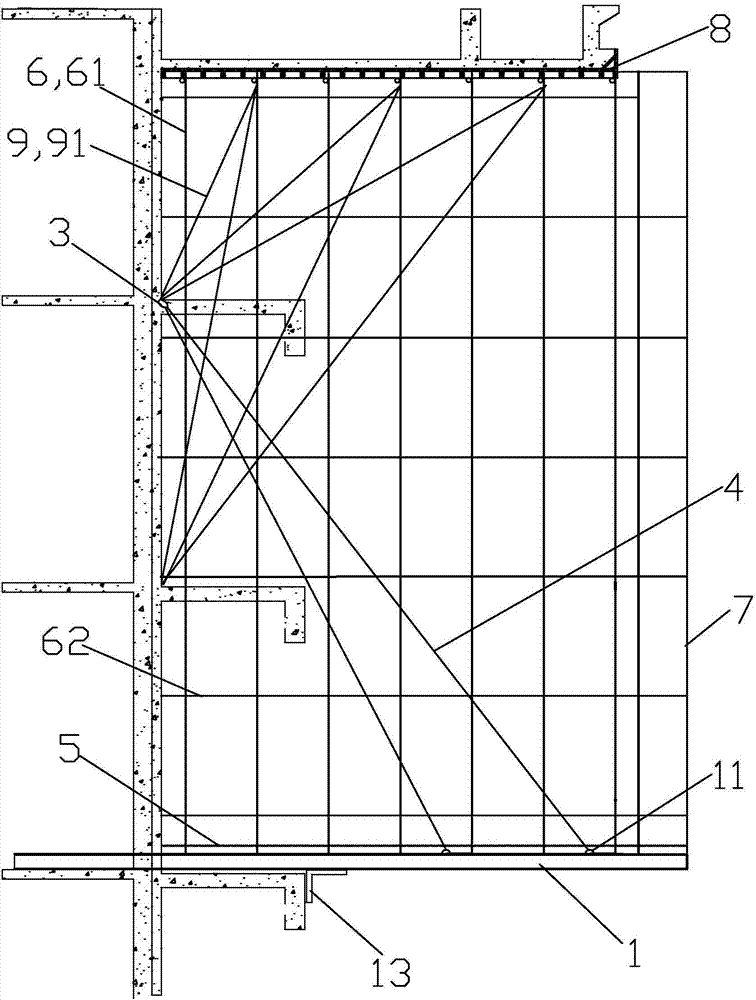

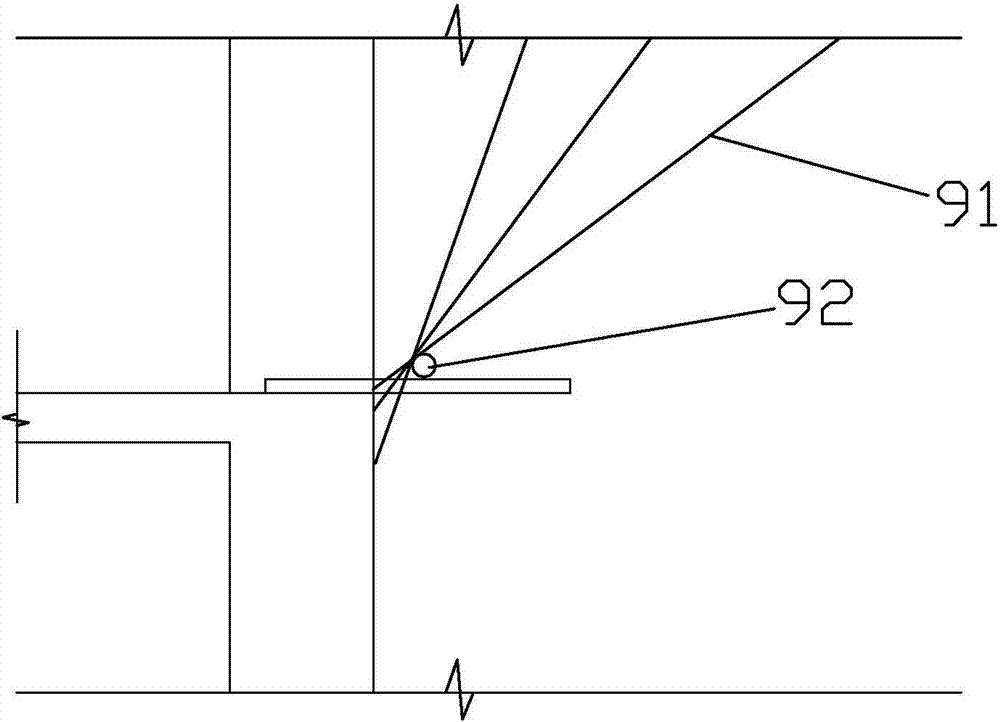

[0051] See Figure 2 to Figure 6 , the high-altitude large-span cantilevered cornice formwork support system of this embodiment mainly consists of cantilevered steel beams 1, cantilevered steel beams fixing clamps 2, steel wire rope rings 3, steel wire ropes 4, operating platforms 5, and cantilevered structure load-bearing frames 6. Outer protective scaffolding 7 and eave support formwork 8 are formed.

[0052] The cantilevered steel beam 1 preferably adopts 16# national standard Q235 I-beam in this embodiment, and the cantilevered steel beam 1 is provided with a pull ring 11 , a vertical pole insertion positioning piece 12 and an angle steel 13 . The material of the pull ring 11 is φ20 round steel, the pull ring 11 is arranged on the right part of the cantilevered steel beam 1, and there are two left and right, and the pull ring 11 is welded with the cantilevered steel beam 1. The vertical rod insertion positioning part 12 is a φ20 round steel head positioning part with a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com