Construction process for aluminum sheet roof upright standing seam system

A technology of upright seaming and construction technology, which is applied to the tools used in roof engineering, roofs using flat/curved panels, and roofs, etc. It can solve the problems of temperature stress, water leakage, and inability to expand and contract, and solve temperature deformation. , The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

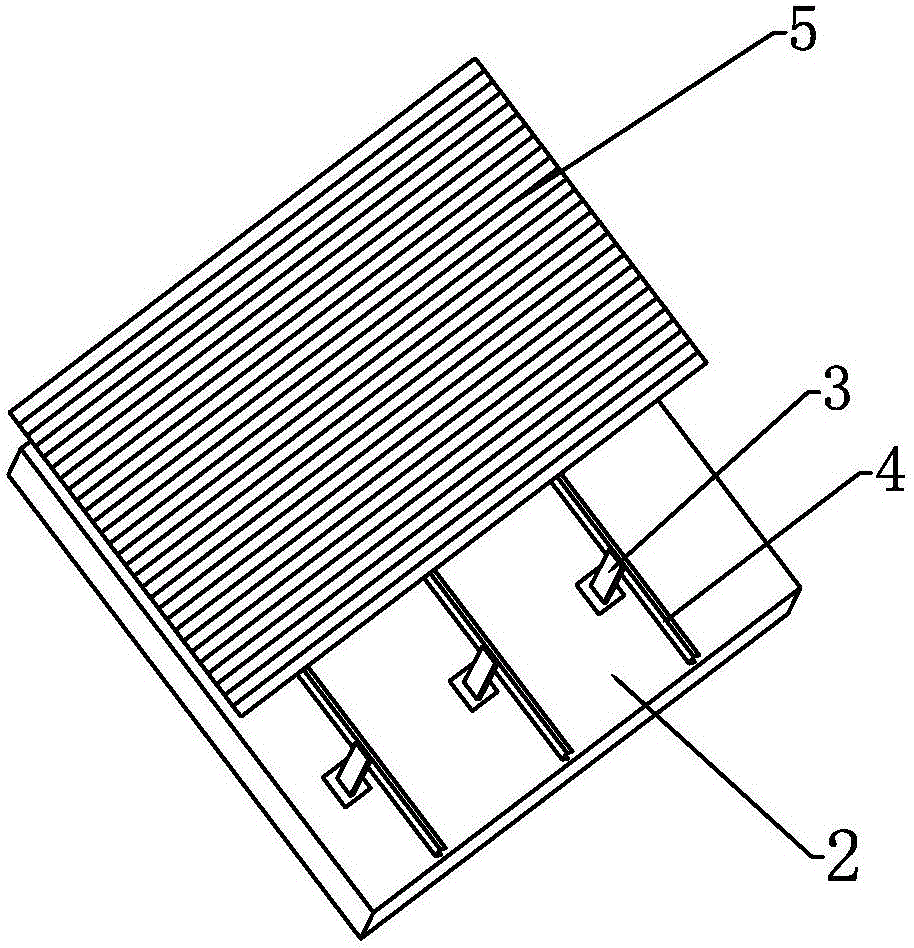

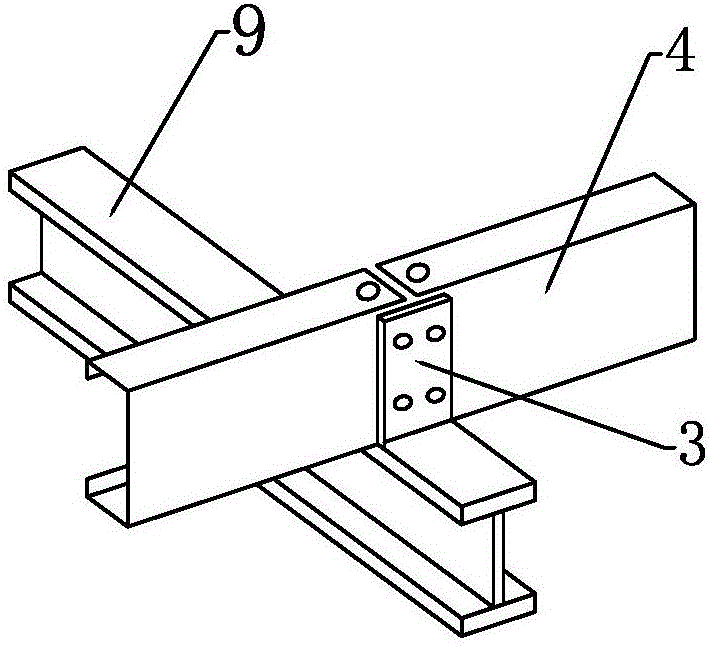

[0062] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0063] Such as Figure 1-Figure 6 Shown in, the construction technique of the aluminum sheet roof standing seam system of this embodiment comprises the following steps:

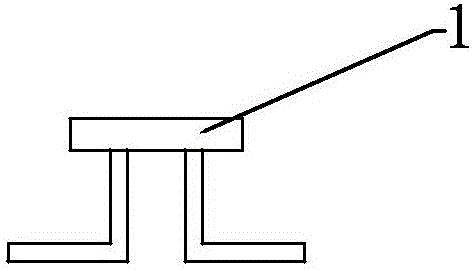

[0064] (1) Install embedded parts

[0065] The embedded part 1 of this project is made of Q235 steel, the embedded plate is 12mm thick and 150mmX150mm wide, and the 4 round steel pieces are M10 about 230mm long. After selecting qualified materials, use a shearing machine to cut the material, and then drill 4 round holes of M11 on the steel plate, insert the bent round steel into the round holes, leave about 3mm on the surface, and use plug welding on the front to weld After finishing, grind it flat, and weld 4mm fillet welding around the round steel on the back.

[0066] The embedding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com