A stage caving mining method with overhanging eaves and bottomless pillars with artificial false roof of steel-concrete structure

A technology of artificial false roof and stage caving, which is applied in ground mining, underground mining, special mining, etc. It can solve the problems of complex construction, high material consumption, and lack of research on the control of waste rock funnels, so as to achieve a small laying range and reduce ore poverty. The effect of reducing and solving the problem of loss impoverishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

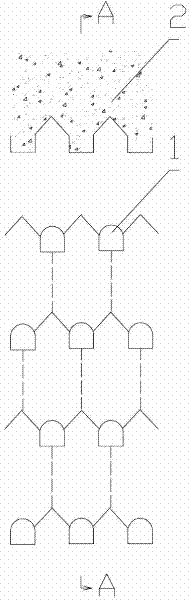

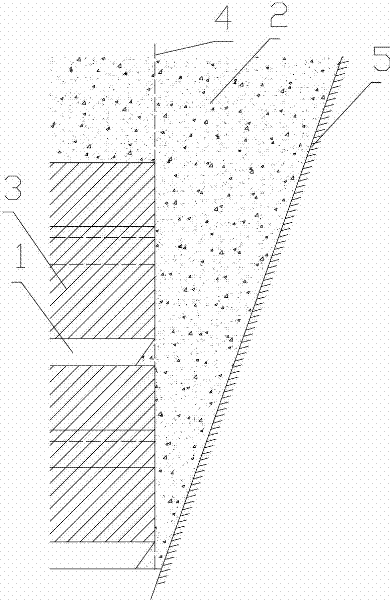

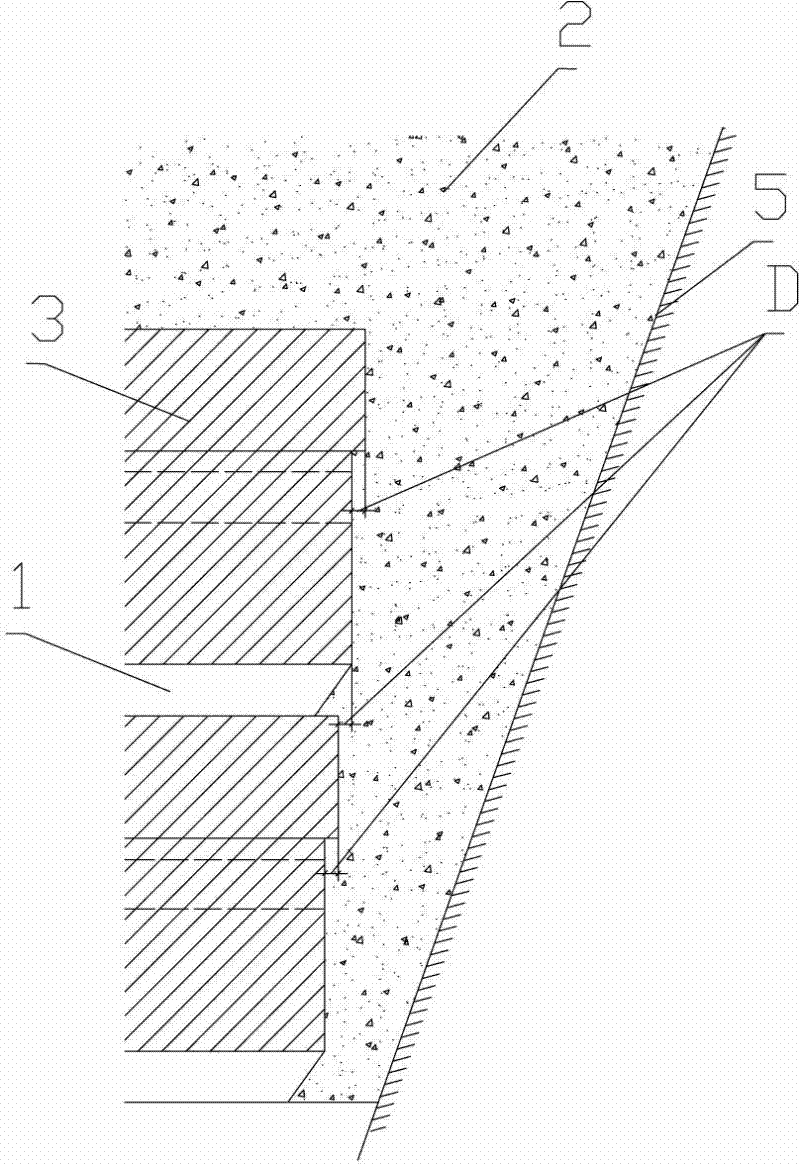

[0047] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown in Fig. 1, a stage caving mining method with steel-concrete structure and artificial false roof, which includes dividing the ore body into stages, and then dividing the stages into sections. Arrangement, in the mining roadway 1, adopt the pre-concentrated rock drilling method to arrange the upward fan-shaped medium-deep holes 7, and carry out retreating mining under the overburden rock layer 2. Start from one end, cut first, and then continue mining. At the same time, the upper covering rock formation 2 is filled with new gobs. When the end of each segment in the stage reaches the same vertical position, the end walls of each segment in the stage are in a vertical state as a whole 4, as figure 2 As shown, then, the topmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com