Tool type building shaft/elevator shaft climbing formwork

A technology for elevator shafts and tools, which is applied in the direction of construction, building structure, formwork/formwork/working frame, etc., and can solve the problem of not being able to ensure uniform force on the line bearing, not having the need for section transformation of the cylinder mold, and not being able to form a tool. Features and other issues to achieve the effect of solving the problem of anti-overturning and solving the error of installation alignment

Inactive Publication Date: 2011-12-14

马永乐

View PDF11 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This new tool type described in this patented describes different technical features compared to previous tools like those mentioned earlier or older versions such as screw jackhammers. These improvements include improved safety during use, automatic control on operation processes, easy handling without external support equipment, reduced weight, easier assembly, etc., resulting in better performance efficiency than current alternatives.

Problems solved by technology

There exist technical problem addressed in this patented text relating to improving the design of tools used in constructing tall structures like houses or offsets due to environmental factors including weather conditions (rain), heavy traffic load from people driving over long distances, and frequent maintenance tasks required at sea level locations. Current solutions involve adding temporary supports to prevent tilling while maintaining structural integrity. These support systems may require changing parts or connections within the framework itself, making them difficult to install without disruptive modifications. Therefore, the objective of these improvements lies in developing a more efficient solution through autonomous clamshell type lifter bars called Self-Cliny Shuttle Molds.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

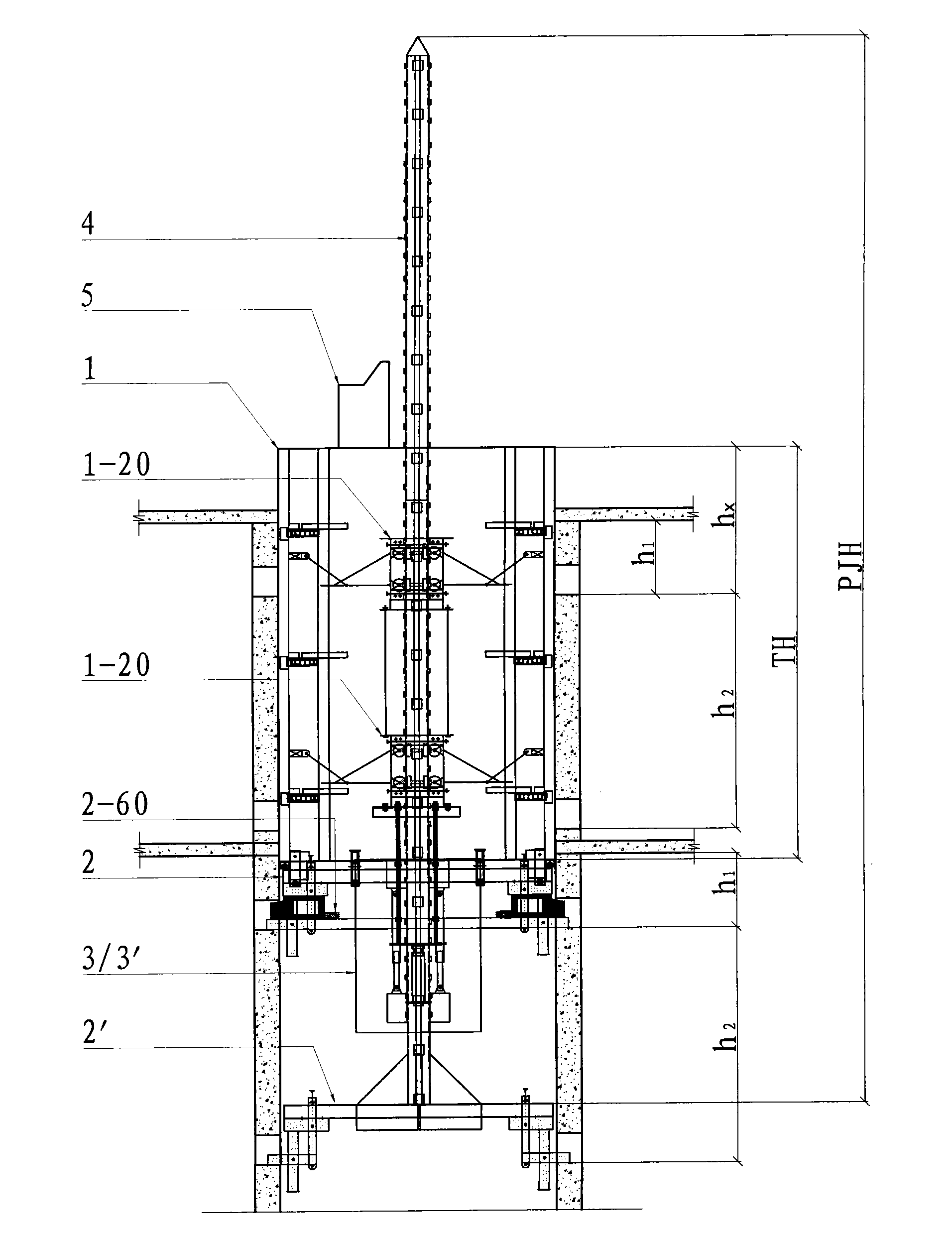

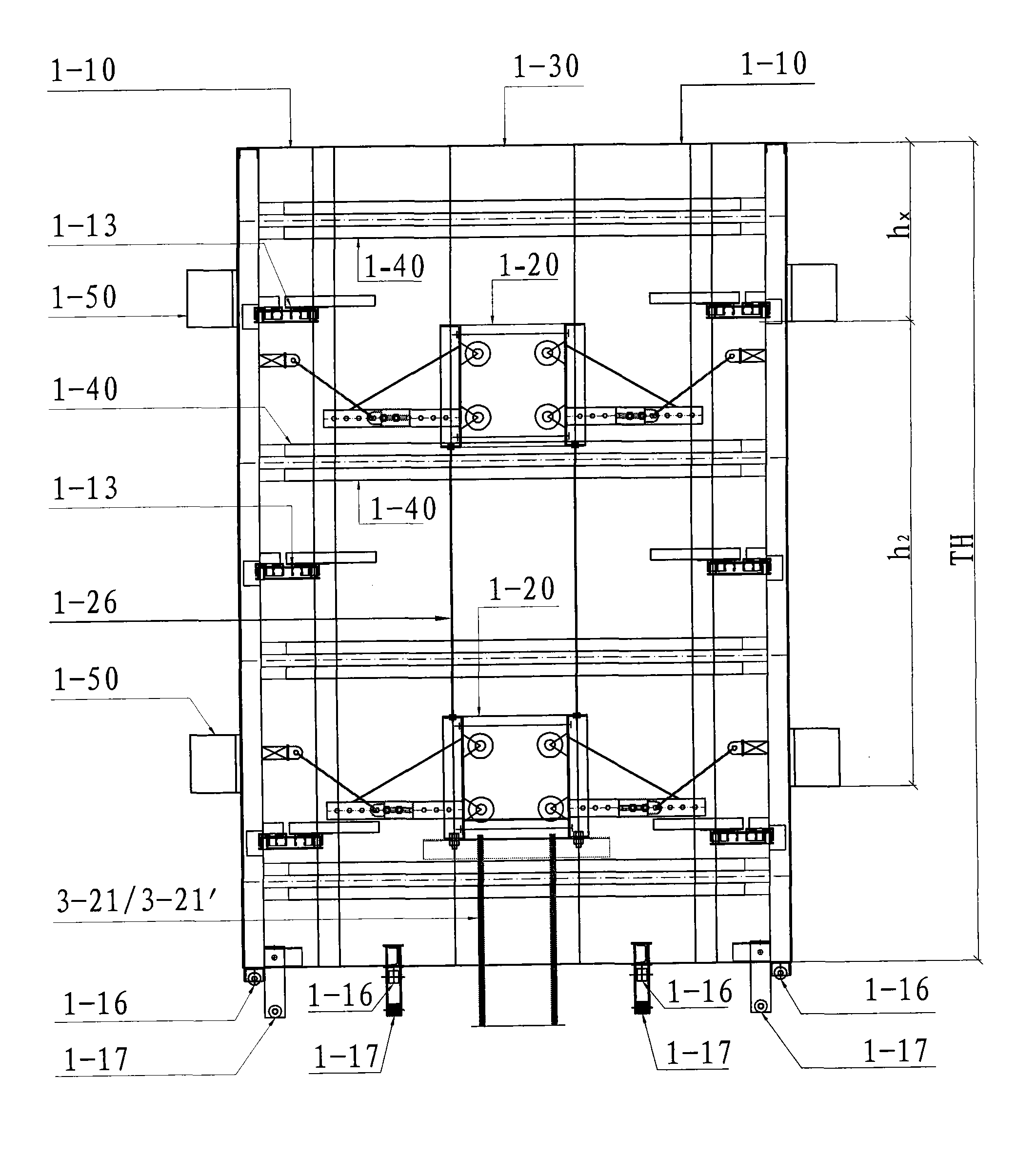

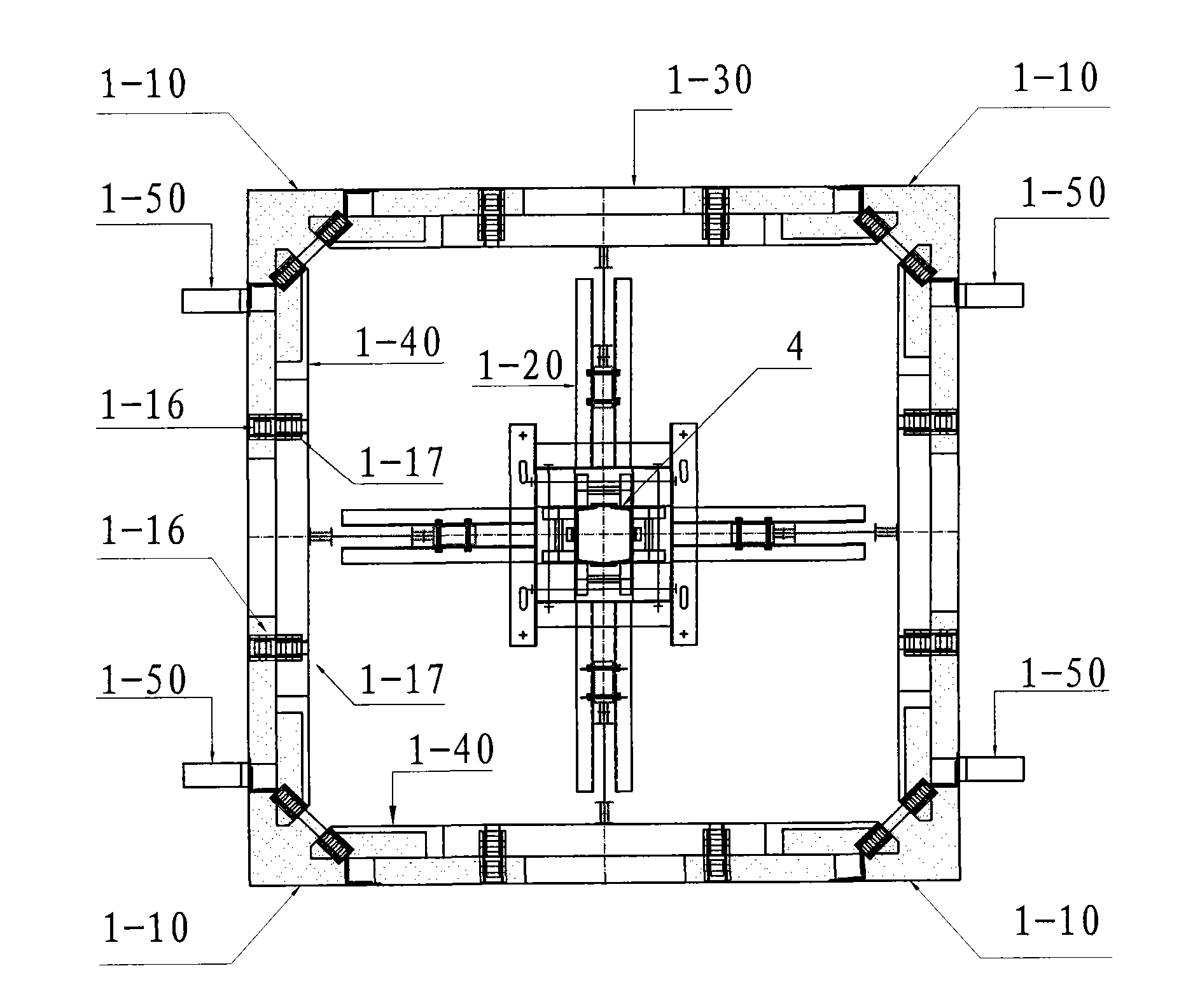

The invention discloses an instrumental climbing formwork for a building vertical shaft/elevator shaft, wherein an instrumental barrel formwork together with an upper-layer following-up platform, a power control box, a lower-layer follow-up platform, a center climbing formwork and a program circuit control cabinet constitute a combination unit. The inner cavity of the barrel formwork is provided with a girdle-type direct-pull retraction frame at a position corresponding to the center climbing frame; an anti-dumping structure is arranged at a joint between the barrel formwork and the follow-upplatform; timely locking structures are arranged between the follow-up platforms and a concrete wall; the program circuit control cabinet is used for controlling the retracting and stretching of the barrel formwork as well as the climbing of the formwork in a centralized and unified manner; and all the parts of the entire climbing formwork of the vertical shaft are fashion parts except for filling plates and back edges of the barrel formwork as well as panel structures and level replacement parts of the follow-up platforms. By means of the instrumental climbing formwork provided by the invention, the construction process for the barrel formwork of the vertical shaft represented as the elevator shaft is changed from the traditional tower crane lifting manual operation mode into a program circuit control mechanical operation mode, and the barrel formwork serving as the traditional construction amortization material becomes novel equipment of construction machines and tools.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner 马永乐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com