Instrumental climbing formwork for building vertical shaft/elevator shaft

A technology for elevator shafts and tools, applied in the directions of architecture, building structure, formwork/template/work frame, etc., can solve the problem that the linear bearing cannot be guaranteed uniform force, does not have the need for changing the section of the cylinder mold, and the patent is not clear enough, etc. problems, to achieve the effect of solving the problem of anti-overturning and solving the installation alignment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

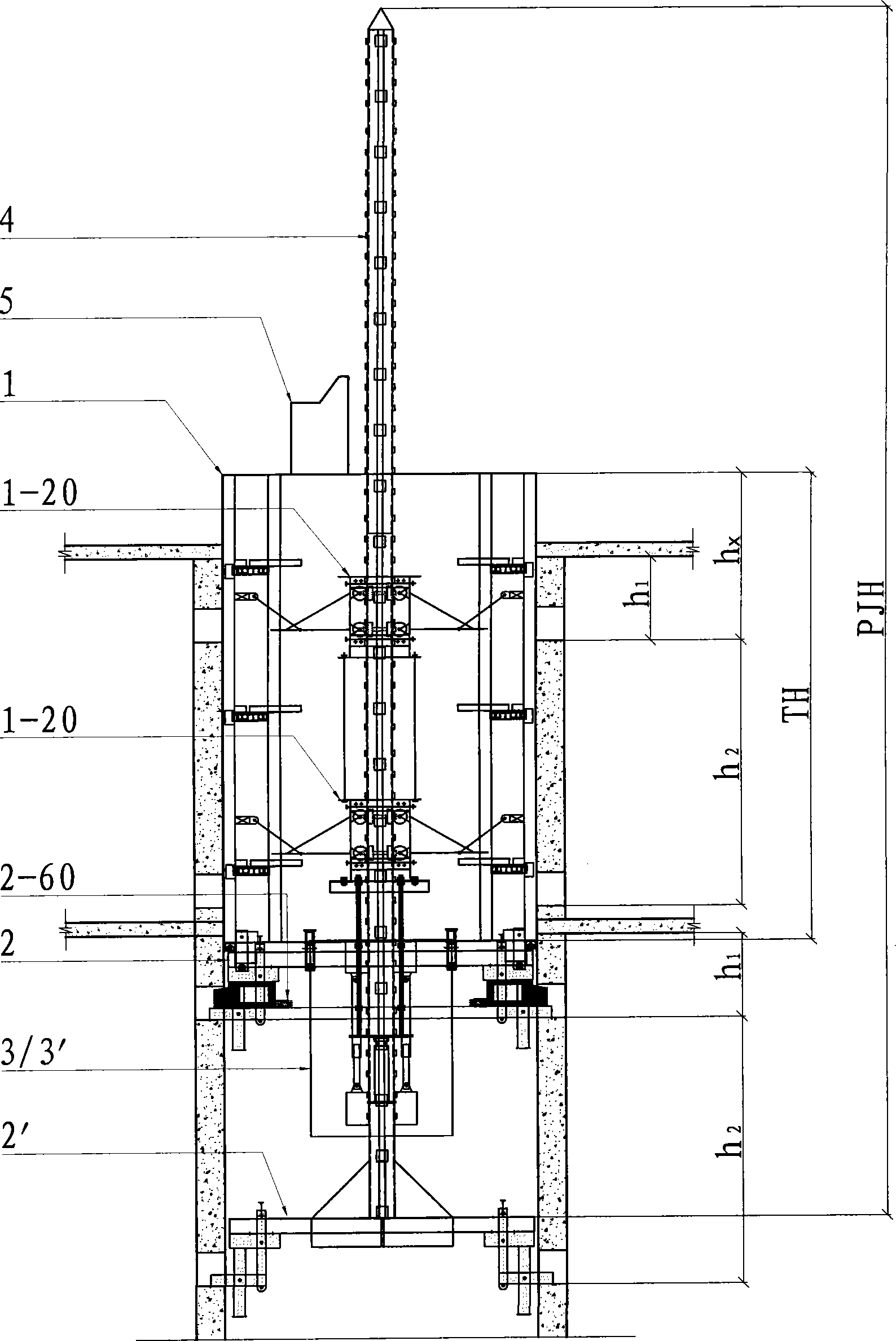

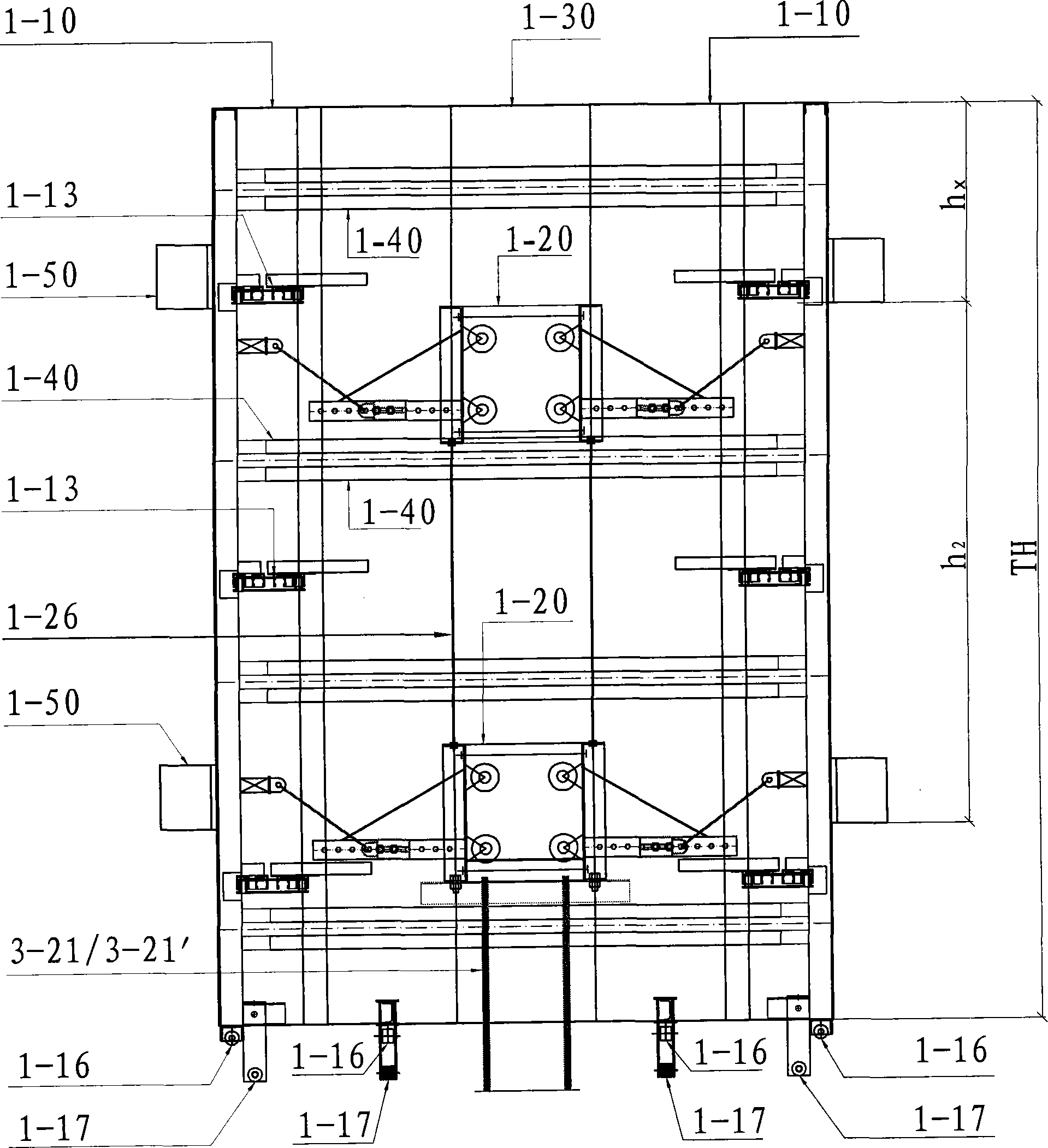

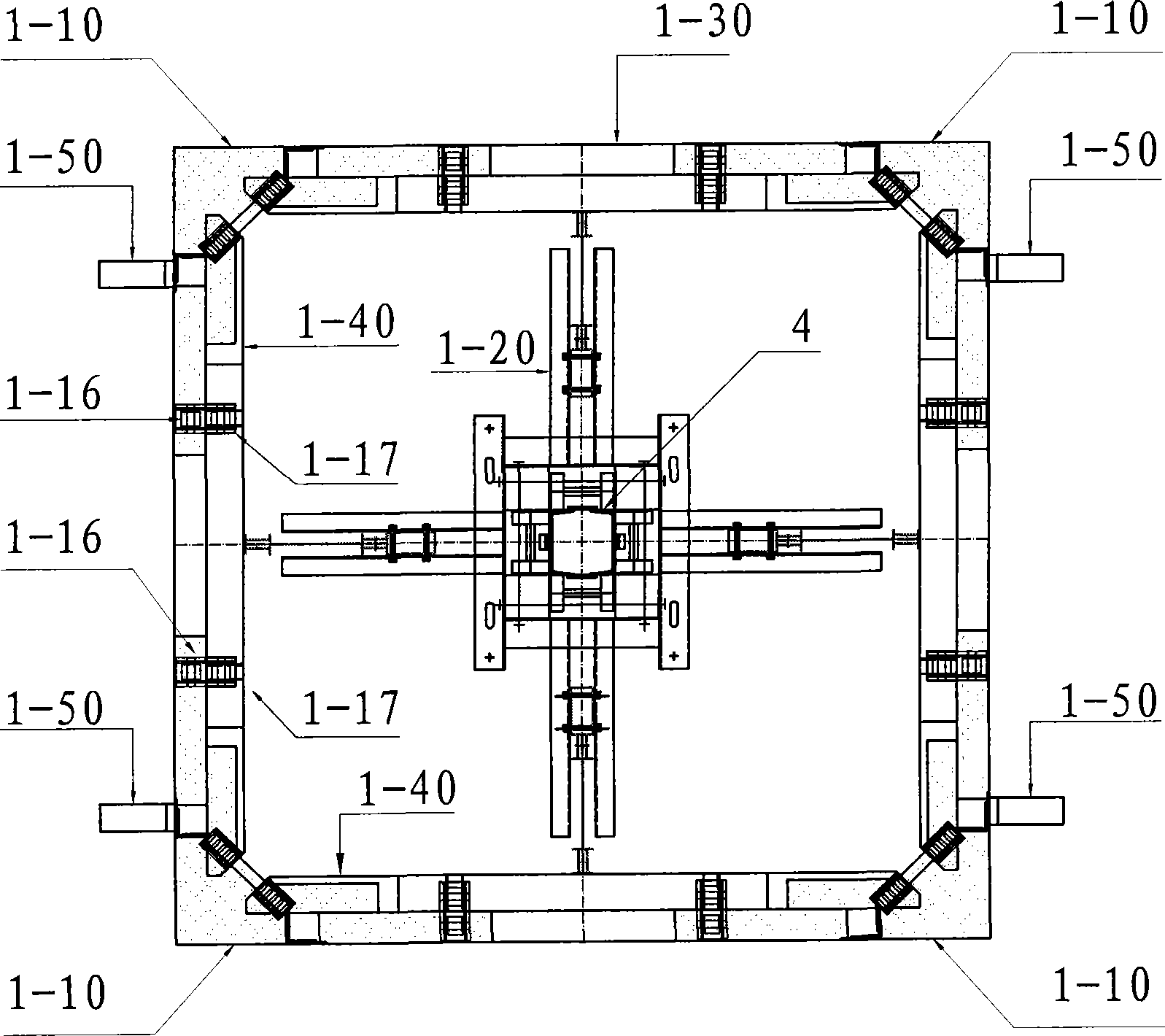

[0091] Examples see figure 1 As shown, the tool-type shaft climbing formwork is composed of a tool-type cylinder mold 1, an upper follow-up platform 2, a power box 3, a lower follow-up platform 2', a central climbing frame 4, and a program circuit control cabinet to form a combined device. The distance h between the upper and lower layers of mold boxes 2 , the distance h from the outriggers of the upper follow-up platform to the concrete pouring surface 1 . The central climbing frame 4 is installed in the panel structure 2-1' of the lower follow-up platform, and passes through the center of the upper follow-up platform 2, the power box 3 and the tool-type cylinder mold 1. The power box 3 is installed in the upper follow-up platform 2, and coincides with the center of the upper follow-up platform. The barrel mold is provided with upper and lower layers of retractable racks 1-20 surrounding the central climbing frame, and the bottom is connected with the lifting frame of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com