A Jet Tube Electro-hydraulic Servo Valve with High Linearity and Force Feedback

An electro-hydraulic servo valve, linearity technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve problems such as unfavorable actuator control, poor output signal linearity, affecting the movement of the jet tube, etc. The effect of weight reduction, improved linearity, and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

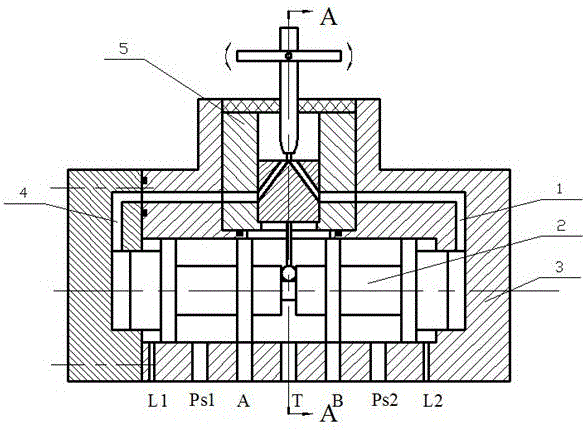

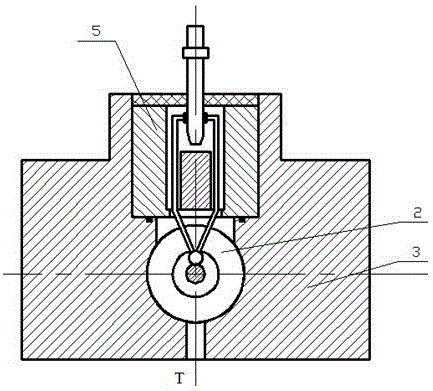

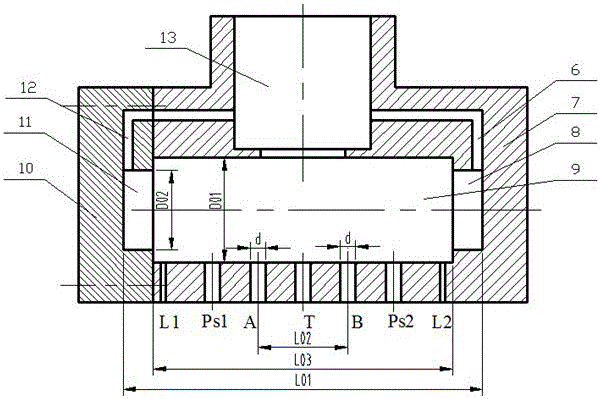

[0046] A jet tube type electro-hydraulic servo valve with high linearity and force feedback. Such as figure 1 and figure 2 As shown, the electro-hydraulic servo valve is composed of a valve body 3 , a valve core 2 and a feedback fluidic device 5 . The horizontal cavity of the valve body 3 is equipped with a valve core 2 , and the vertical cavity of the valve body 3 is equipped with a feedback jet device 5 , the lower end of the feedback jet device 5 is embedded in the middle of the valve core 2 . The electro-hydraulic servo valve is symmetrically provided with a left oil passage 4 and a right oil passage 1, one oil port of the left oil passage 4 communicates with the left end of the horizontal cavity of the valve body 3, and the other of the left oil passage 4 The oil port communicates with the upper cavity of the feedback jet device 5, one oil port of the right oil passage 1 communicates with the horizontal cavity near the right end of the valve body 3, and the other oil p...

Embodiment 2

[0070] A jet tube electro-hydraulic servo valve with high frequency and high linearity. Except following technical parameter, all the other are with embodiment 1.

[0071] L11+(2.2~2.4)d=L01 (Ⅱ)

[0072] The depth of the annular groove 19 is (0.8-1) times the diameter of the steel ball 28 .

[0073] The distance between the top corners of the two isosceles triangles is 0.01-0.03mm, and the angle between the two receiver oil passages 30 is 45-60°.

[0074] The pressure oil of the present invention is ejected from the jet pipe 23 of the feedback jet device 5, the pressure oil enters the right control oil chamber 8 and the left control oil chamber 11 through the right oil passage 1 and the left oil passage 4, and the pressure oil acts on the right controlled piston 14 and the end face of the left controlled piston 16.

[0075] When the armature assembly 22 does not generate torque, the jet tube 23 is in the middle position of the two receiver oil passages 30, that is, the zero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com