Climb formwork platform control system and its control method

A platform control and control method technology, applied in general control system, control/adjustment system, computer control, etc., can solve problems such as overload damage of lifting devices, achieve the effect of preventing overload damage and improving the safety of lifting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

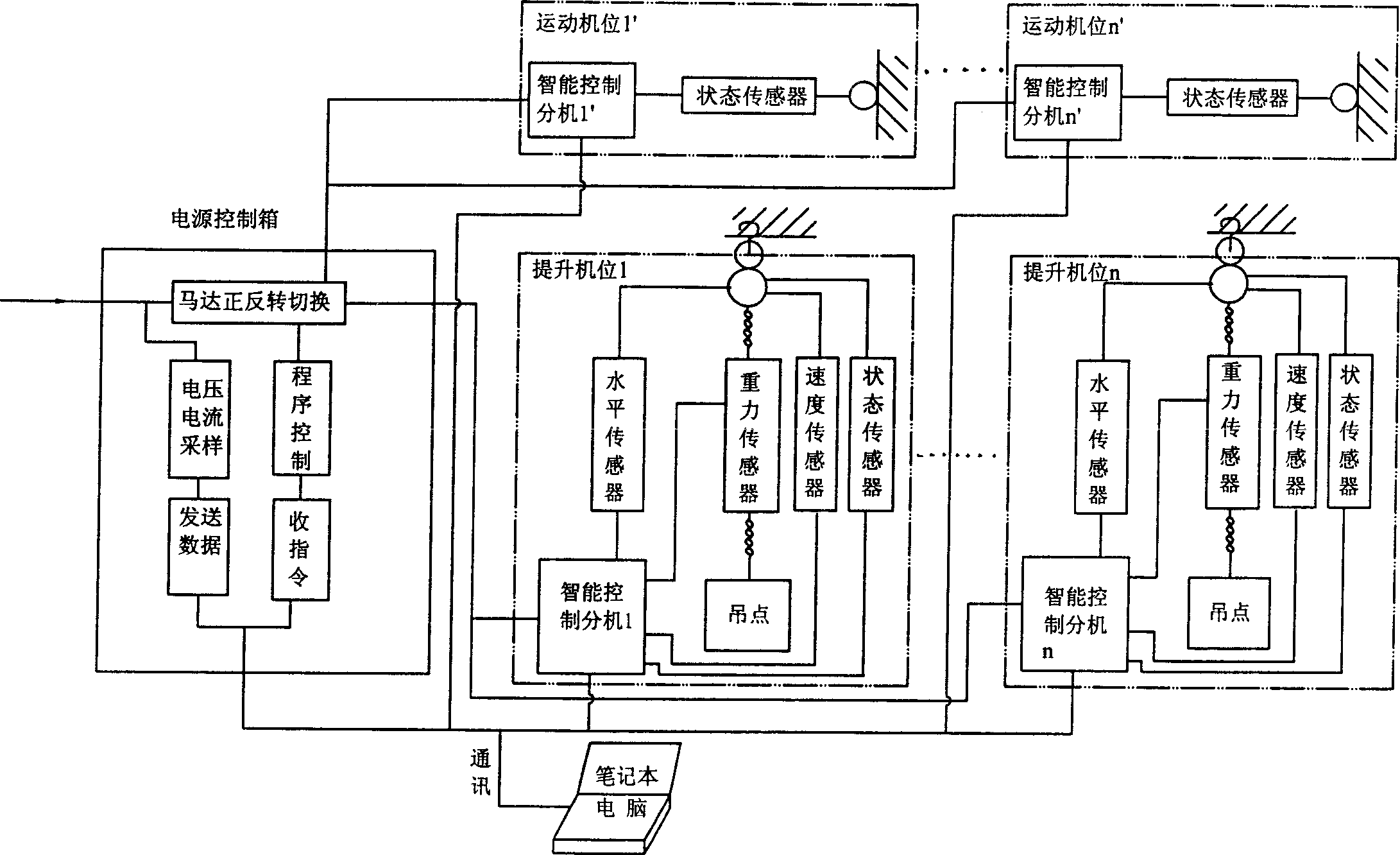

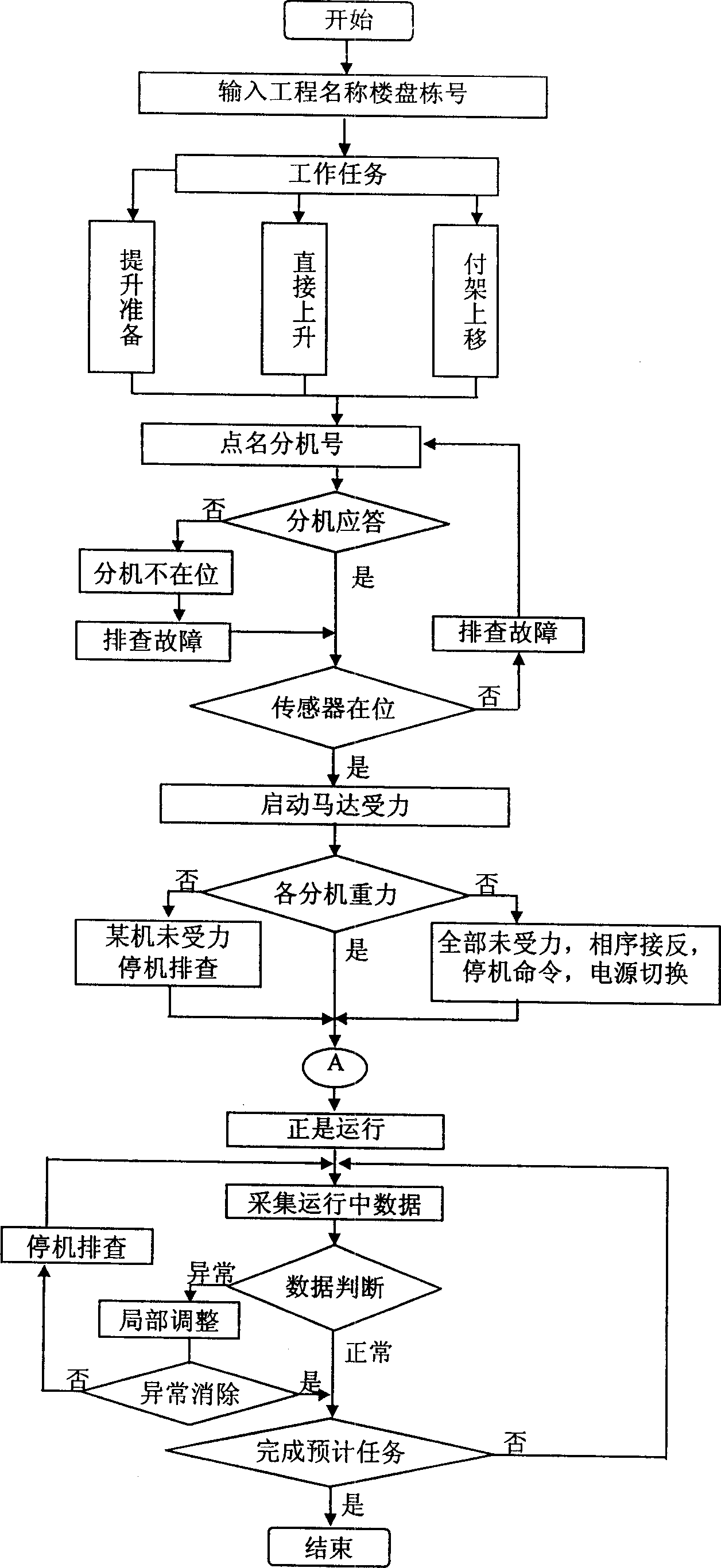

[0022] like figure 1 As shown in the figure, the control system of the climbing formwork platform includes a notebook computer as a central processing unit, an intelligent control extension and a sensor. The extension or the intelligent control extension corresponding to the motion stand is connected, and the intelligent control extension is respectively connected with the corresponding lifting device of the hoisting stand, the corresponding motion device of the motion stand and the central processing unit. The motion stand includes the stand that realizes the movement of the parts of the climbing formwork platform, such as the stand that operates the template for demoulding and installation. The motion stand is provided with an independent motion device.

[0023] In addition to notebook computers, the central processing unit can also use PCs, or specially designed single-board computers, etc. The intelligent control extension can also use notebook computers, PCs, or specially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com