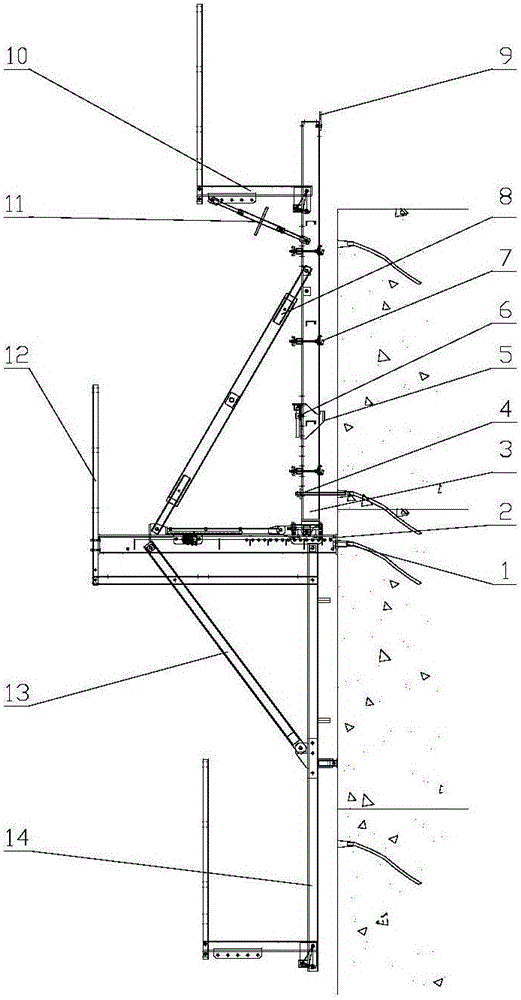

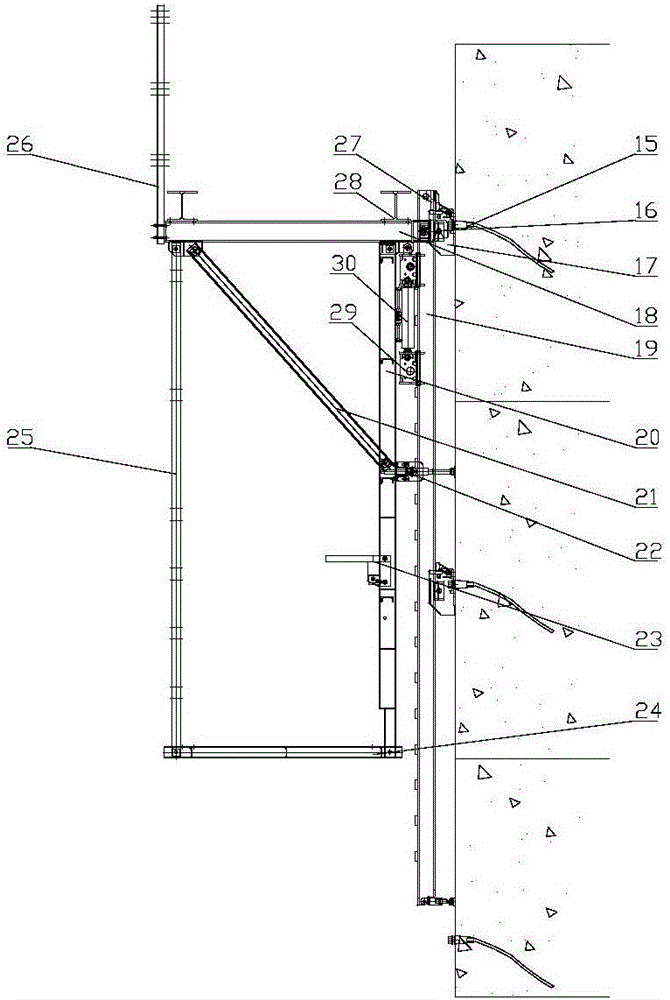

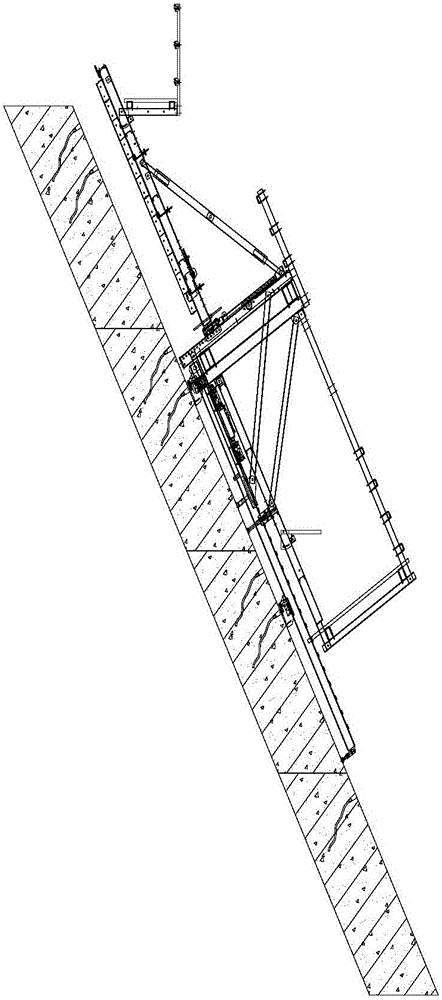

Single-side self-climbing cantilever formwork and construction method thereof

A self-climbing, cantilever technology, applied in formwork/formwork/work frame, infrastructure engineering, erection/assembly of bridges, etc., can solve the problems of low construction efficiency, low flexibility, inability to save time and effort, and improve construction. Efficiency, convenient operation and high efficiency, the effect of saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention will be further described in detail below.

[0032] The self-climbing formwork frame and one-sided cantilever formwork used in the present invention are all prior art, and those skilled in the art can select a suitable self-climbing formwork frame such as hydraulic climbing formwork frame and electric climbing formwork frame according to the construction object , and the single-sided cantilever formwork, the single-sided cantilever formwork is installed on the frame body of the self-climbing formwork, the specific installation and connection methods of the single-side cantilever formwork and the self-climbing formwork frame body have various forms, and those skilled in the art can use it according to their own needs. The different structures of the selected self-climbing formwork frame and the one-sided cantilever formwork adopt different installation and connection methods, and the automatic climbing of the one-side cantilever fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com