Adjustable jacking support under beam plate in disc buckle quick release supporting system

A support system and adjustable technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve problems such as easy runout, failure, unqualified beam structure, etc., and achieve stability Good, large bearing capacity, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

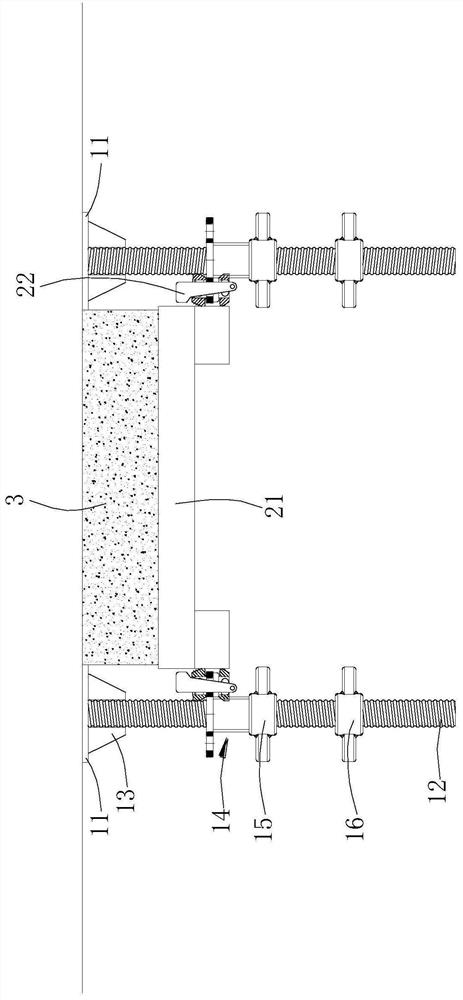

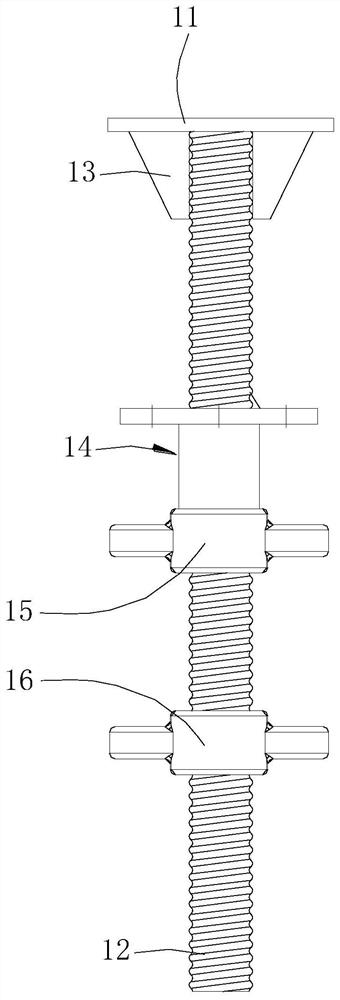

[0016] like Figures 1 to 4 shown

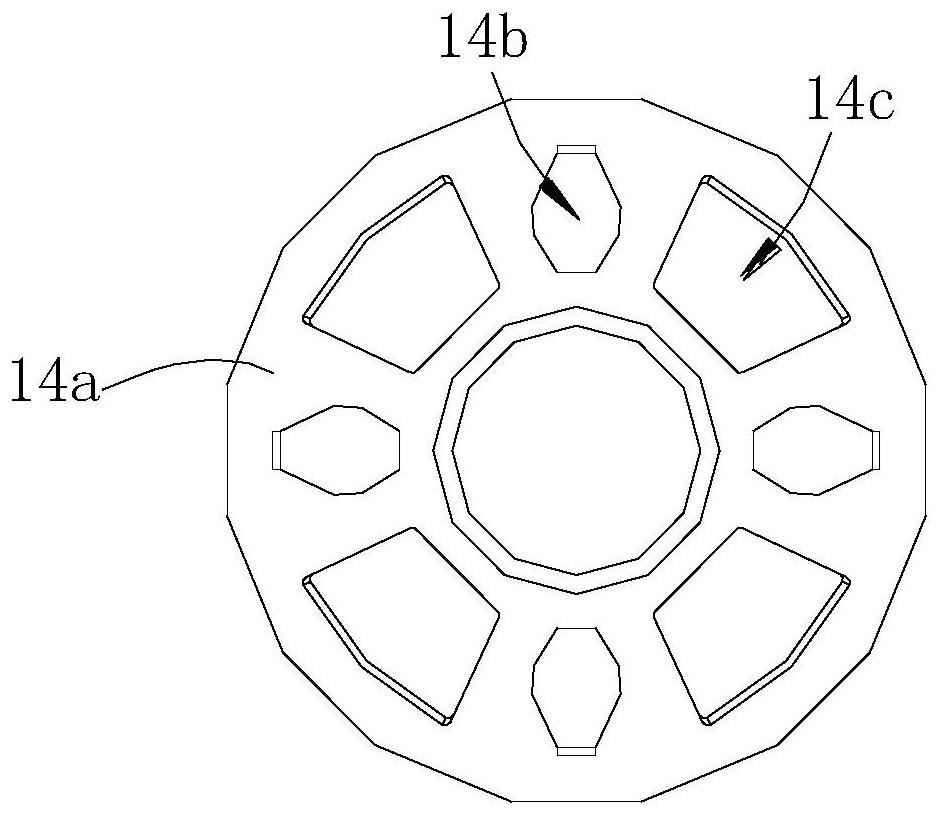

[0017] The adjustable jack under the beam includes a fixed top plate 11, a screw rod 12, a first nut 15, a second nut 16 and an adjustable support slider 14. The fixed top plate 11 is horizontally welded on the top of the screw rod 12, and the fixed top plate 11 and the screw rod 12 are welded together. There are two reinforcing ribs 13, the adjustable support slider 14 is provided with an inner hole, the adjustable support slider 14 includes an integrally formed sleeve part and a connecting disc 14a, the sleeve part of the adjustable support slider 14 is set on the outer wall of the screw rod 12 , the outer wall of the adjustment support slider 14 extends horizontally outwards with a connecting disc 14a, the connecting disc 14a has four first pin holes 14b passing through its upper and lower end faces, and the connecting disc 14a has four connecting discs 14a that are supported by diagonal rods. The matching connecting holes 14c, the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com