Elevator shaft operation platform and construction method thereof

A technology for operating platforms and construction methods, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., and can solve problems such as thin thickness of elevator shaft shear walls, low construction efficiency, and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

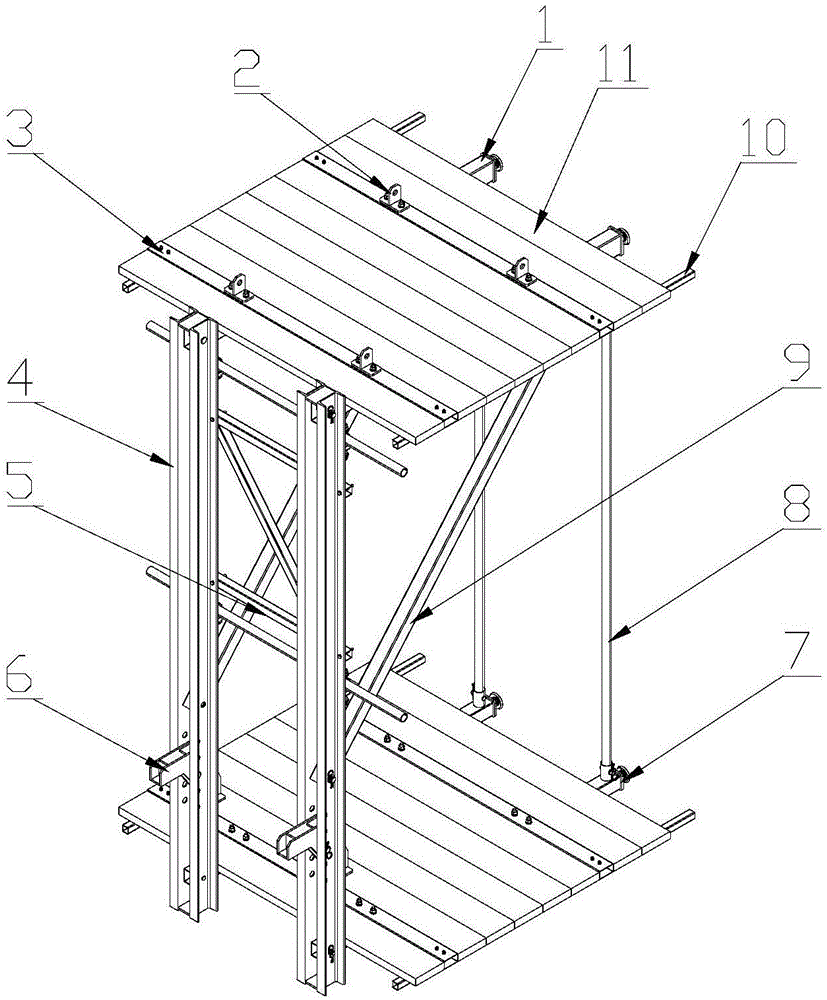

[0022] The elevator shaft operating platform of the present invention, its preferred embodiment is:

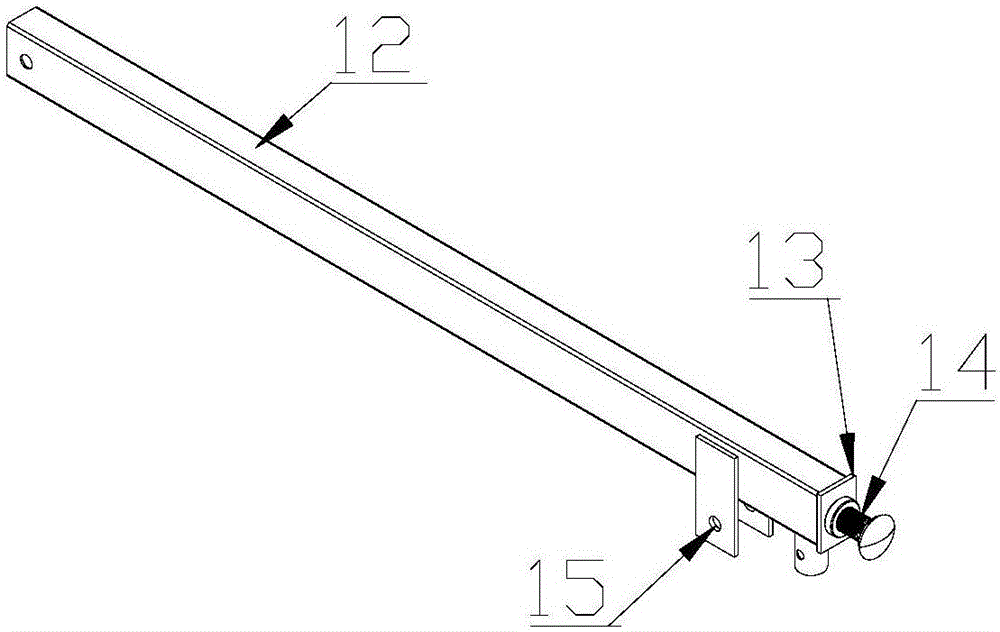

[0023] Including tripod beams, hanging plates, platform pressure beams, tripod poles, fixed trusses, platform hooks, hanging platform beams, hanging platform poles, tripod bracing, reverse hanging square steel beams, and platform plates;

[0024] The platform hook is installed on the two tripod uprights, the fixed truss is connected to the corresponding positions of the two tripod uprights, the tripod beam is connected with the tripod uprights, and the tripod The diagonal brace is connected between the tripod crossbeam and the tripod upright, the suspension platform crossbeam is connected on the tripod upright, and the suspension platform upright is connected between the tripod crossbeam and the suspension platform Between the beams, the hanging plate is installed on the platform pressure beam, the platform pressure beam is respectively installed on the tripod beam and the sus...

specific Embodiment

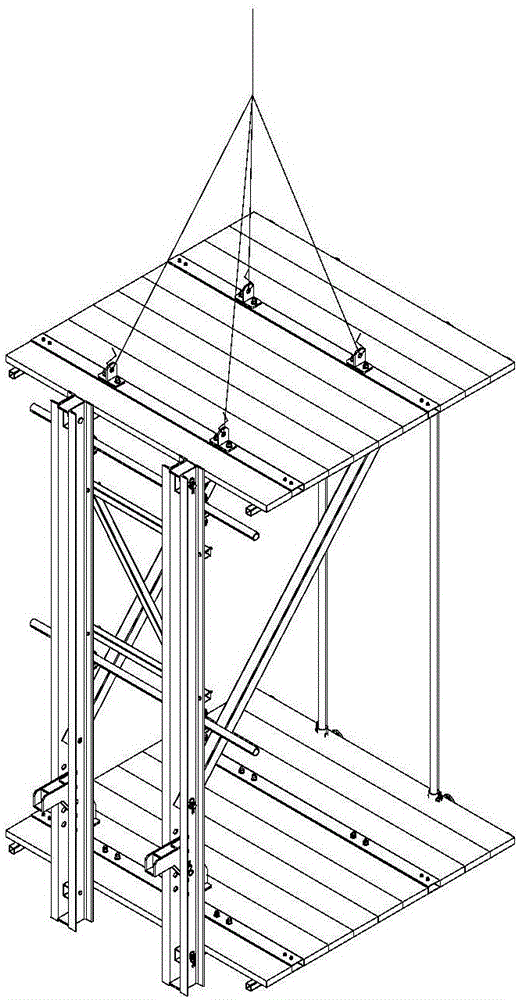

[0041] For the elevator shaft operating platform of the present invention and its construction method, those skilled in the art can select a suitable standard elevator shaft operating platform frame according to the construction object. This frame subverts the operation form of the previous construction frame. When this section is completed, there is no need to change the frame body, fill holes on the structural surface, and calculate and consider the inversion of the frame body load-bearing components after the construction of this section is completed. Use and maintenance repair.

[0042] Such as figure 1 As shown, the elevator shaft operating platform includes a tripod beam 1, a hanging plate 2, a platform pressure beam 3, a tripod pole 4, a fixed truss 5, a platform hook 6, a suspension platform beam 7, a suspension platform pole 8, and a tripod tilt Support 9, anti-hanging square steel beam 10, platform plate 11; two tripod poles 4 are placed according to the design, mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com